Drilling fluid filtrate separator

A drilling fluid and separator technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve problems such as filter screen clogging, and achieve the effect of solving clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

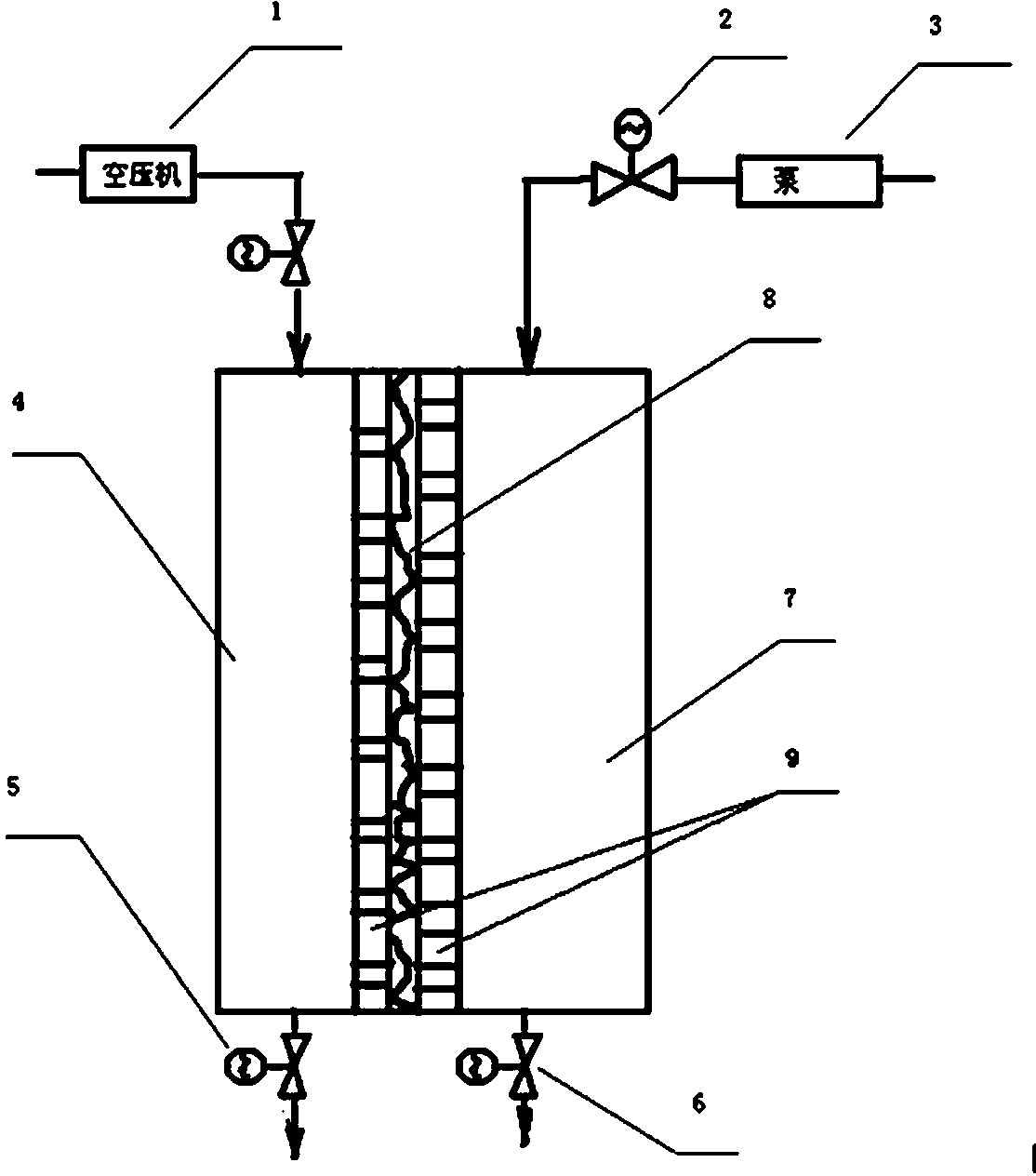

[0017] refer to figure 1 , drilling fluid filtrate separator, including pump 3, filter container 4, filter cloth or filter screen 8, filter cloth or filter screen support 9. filter container 4 is a closed container, filter cloth or filter screen 8 is vertically arranged on In the middle part of the filter container 4, the drilling fluid inlet 2 and the drilling fluid outlet 6 are respectively set on the top and bottom of the filter container 4 on the right side of the filter cloth or filter screen support, and the top and bottom of the filter container 4 on the other side are respectively set Compressed air inlet and filtrate outlet 5.

[0018] Control valves are respectively arranged on the connecting pipelines of the drilling fluid inlet and the drilling fluid outlet, the compressed air inlet and the filtrate outlet. Compressed air is output by air compressor 1.

[0019] The filter screen is made of stainless steel wire, nylon, glass fiber or carbon fiber filter screen.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com