Waste plastic recovery device

A recycling device and waste plastic technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of low space utilization, difficult stacking, etc., and achieve the effects of improving utilization, easier stacking, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

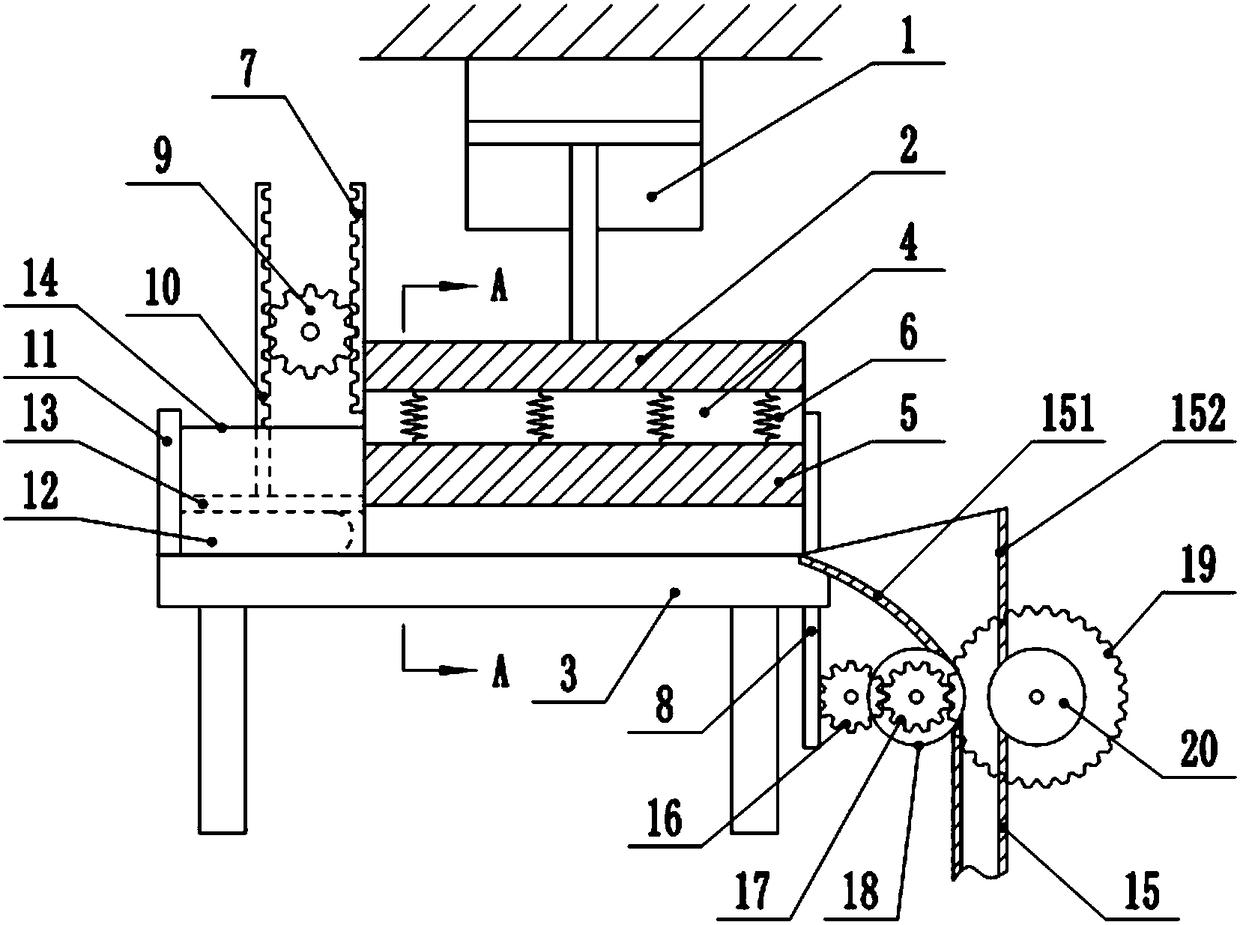

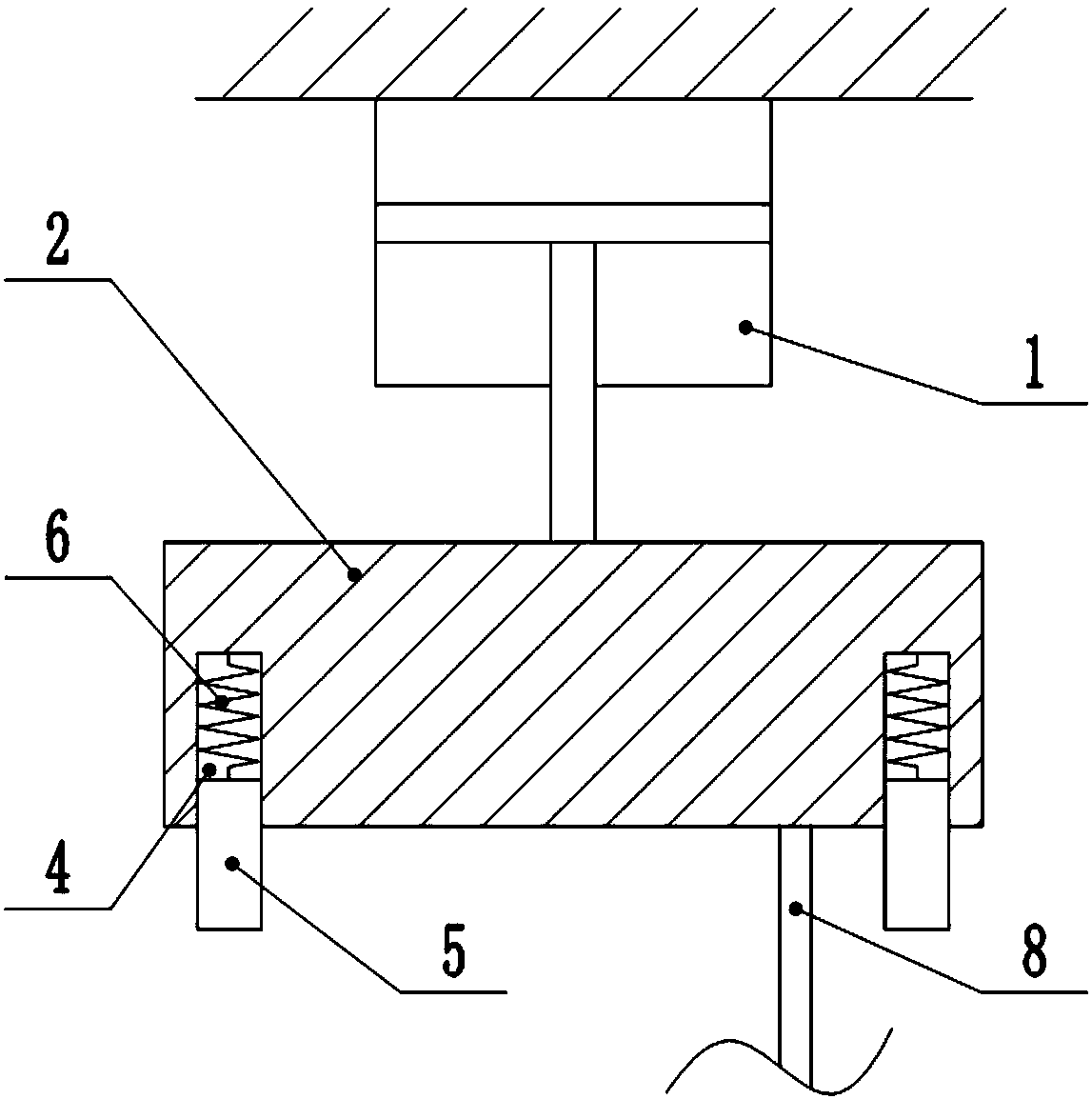

[0022] The reference signs in the drawings of the description include: telescopic cylinder 1, first pressure plate 2, pressure platform 3, chute 4, slide plate 5, spring 6, first rack 7, third rack 8, first gear 9 , the second rack 10, the first baffle 11, the air bag 12, the second pressure plate 13, the second baffle 14, the special-shaped tube 15, the smooth part 151, the limit part 152, the second gear 16, the third gear 17, The first rotating roller 18 , the fourth gear 19 , and the second driving roller 20 .

[0023] This embodiment is basically as figure 1 As shown, the waste plastic recycling device includes a frame, the frame is fixedly installed with a telescopic cylinder 1, the output end of the telescopic cylinder 1 is fixedly connected with a first pressure plate 2, and a pressure platform 3 is fixedly installed under the first pressure plate 2, combined with figure 2 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com