Combined multi-blade saw device and sawing method

A multi-blade saw and wood technology, applied in the direction of feeding devices, circular saws, sawing components, etc., can solve the problems of not being able to dissipate heat in time, the saw blade bears a large load, and has a lot of heat, and achieves a convenient, fast and reliable installation method. Improve work efficiency and cooperate scientifically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

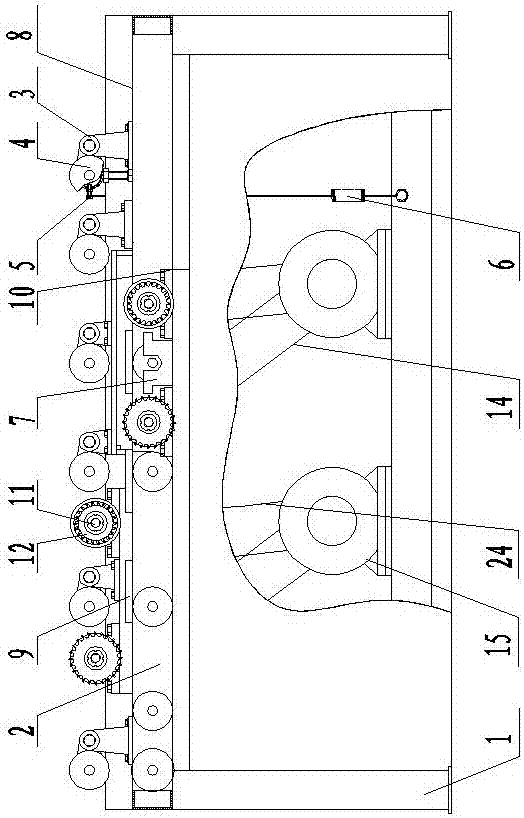

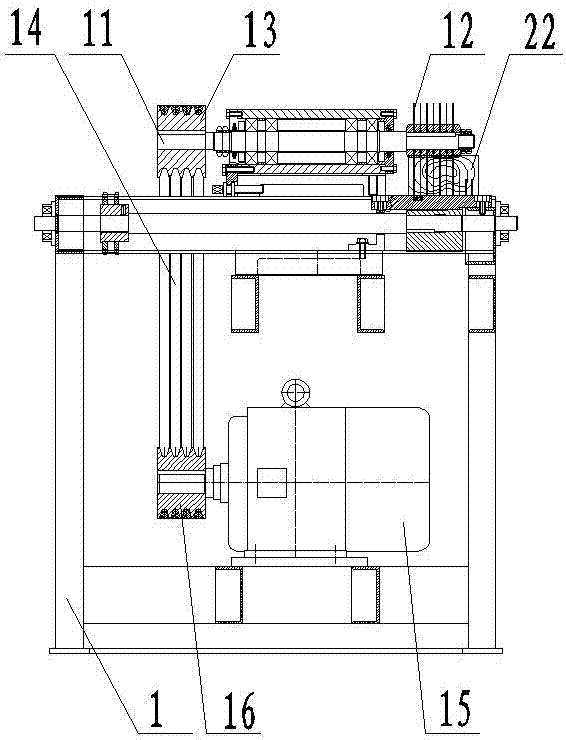

[0024] A combined multi-blade saw device, which consists of: a base 1, a workbench 2 is installed above the base, and a set of auxiliary wheels 3 and a set of feeding parts 4 are installed on the upper part of the workbench. The feeding part is connected to one end of the spring 6 through the connecting bolt 5, and the other end of the spring is connected to the lower part of the machine base. A group of brackets 7 are installed on the lower part of the workbench, and the feeding part is mounted on the bracket. , the described workbench is provided with a feeding platform 8, a group of guide plates 9 are installed on the described feeding platform, a group of bearing blocks 10 are installed on the described workbench, a saw shaft 11 is housed in the described bearing block, the described One group of saw blades 12 is equipped with one end of the saw shaft, and the shaft pulley 13 is equipped with the other end, and described shaft pulley is connected with the power output wheel...

Embodiment 2

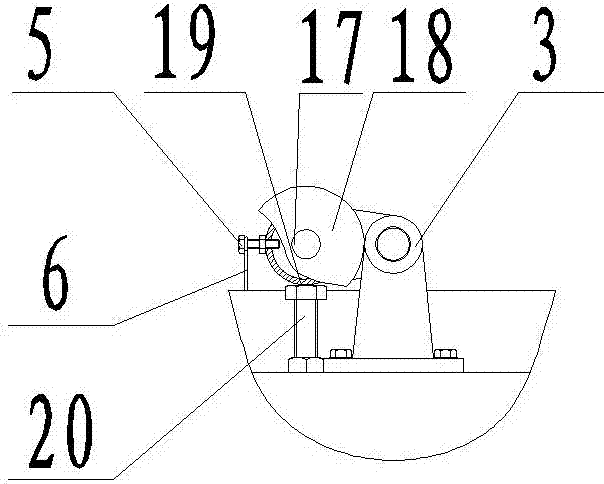

[0026] According to the combined multi-blade saw device described in Embodiment 1, the feeding part includes a feeding shaft 17, a feeding roller 18 is installed at the end of the feeding shaft, and a shaft seat 19 is installed outside the feeding shaft. The connecting spring is installed on the shaft seat, and the workbench is equipped with adjusting bolts 20 at corresponding positions below the shaft seat, and the bottom surface of the shaft seat is in contact with the adjusting bolts.

Embodiment 3

[0028] According to the combined multi-blade saw device described in Embodiment 1, the guide plate is fixed on the feeding platform through the extrusion of the mounting block 21, and the position of the guide plate corresponds to the saw edge 23 of the wood 22; The feeding shaft and the auxiliary wheel are connected with the power take-off wheel through a chain 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com