One-part propelling and retreating mechanism and endoscopic cutting stapler comprising same

A technology of cutting teeth and transmission gears, applied in anatomical instruments, medical science, surgery, etc., can solve the problems of complex structure, poor reliability, and many mechanisms, and achieve the effect of simplifying the cutting mechanism, high reliability, and simplifying the operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

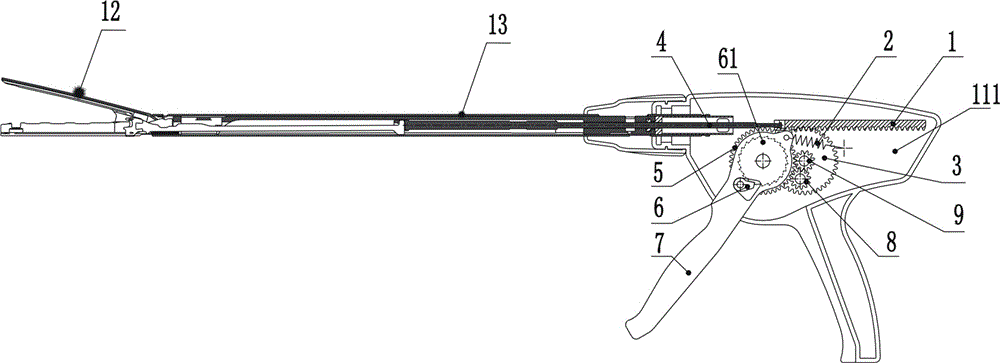

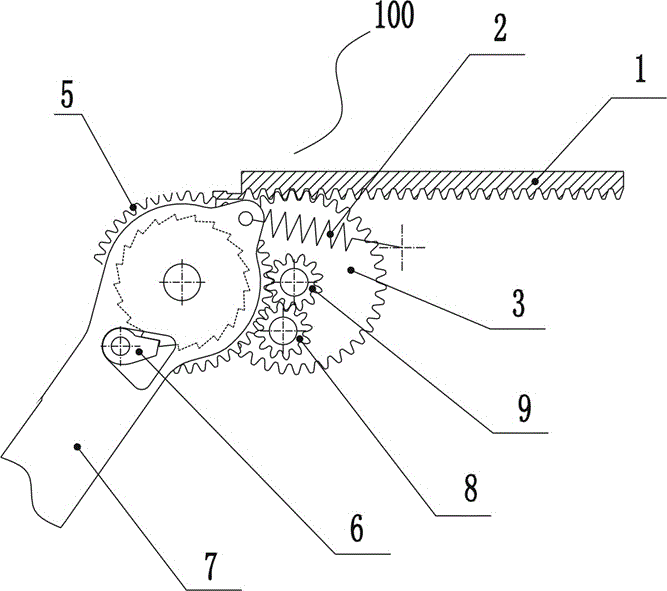

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings (1, 2).

[0027] The one-stage advancing and retreating mechanism 100 involved in the present invention includes a rotating rod 7, a pawl 6, a driving gear 5, a transmission gear 9, a reversing gear 8, a cutting gear 3, and a cutting rack 1. The rotating rod 7 By overcoming the pulling force of the spring 2 to rotate, the pawl 6 is fixedly connected with the rotating rod 7, and the rotating rod 7 is also fixedly connected with a ratchet 61 matched with the pawl 6, and the ratchet 6 is connected with the rotating rod 7. Ratchet 61 transmission connection, described driving gear 5 and described ratchet 61 are coaxially fixedly installed, and described driving gear 5 can be connected with described transmission gear 9, described reversing gear 8 respectively, and described cutting gear 3 and The transmission gear 9 is coaxial and fixedly installed, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com