Automatic food bagging machine and working method thereof

A bagging machine, automatic technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of single track, difficult packaging bag, suction, etc., to improve work efficiency, maintainability, long-term retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

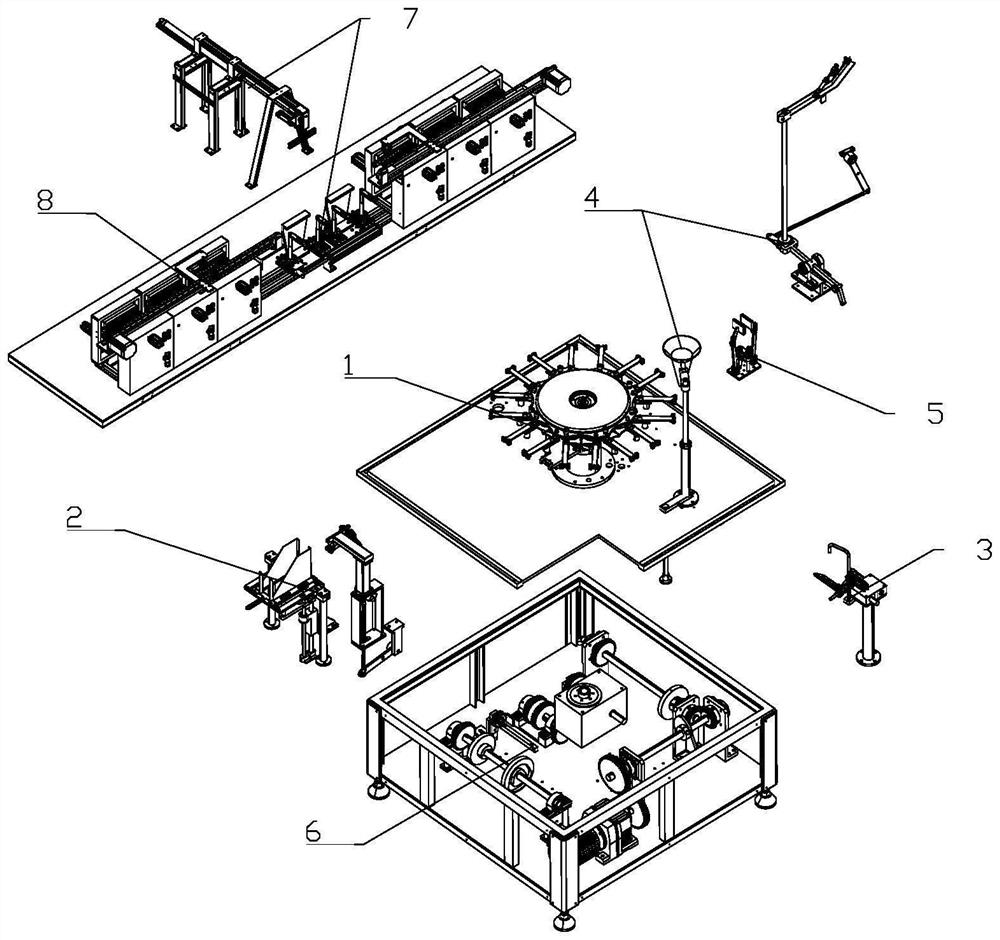

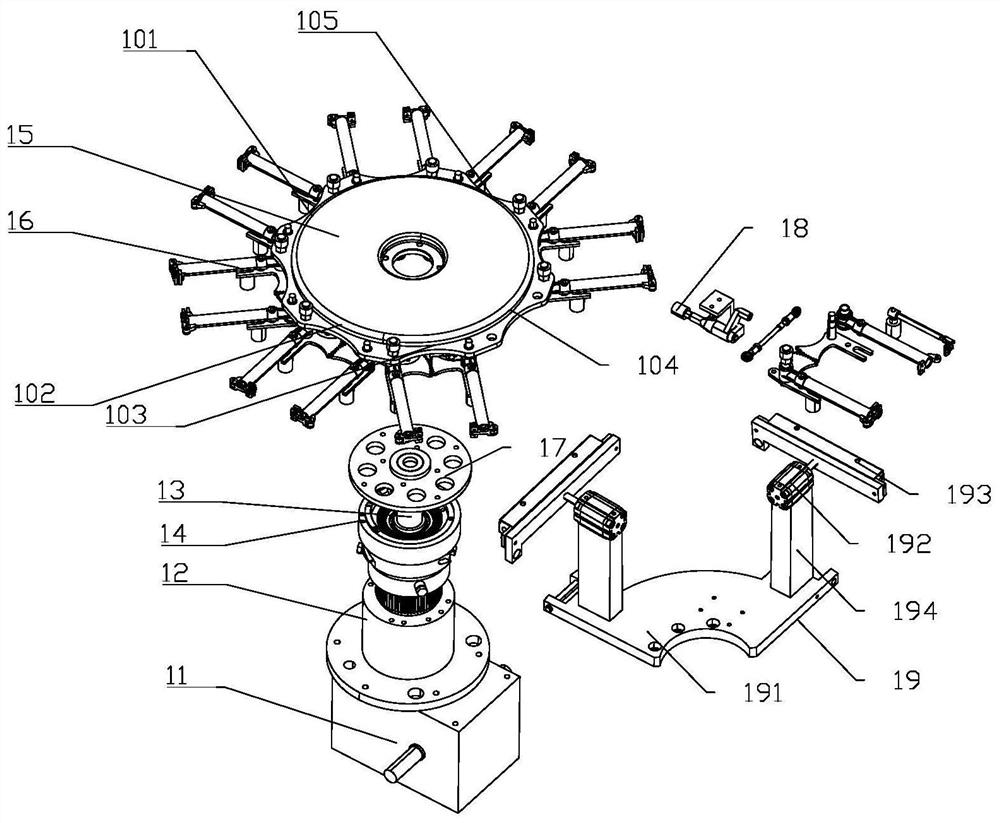

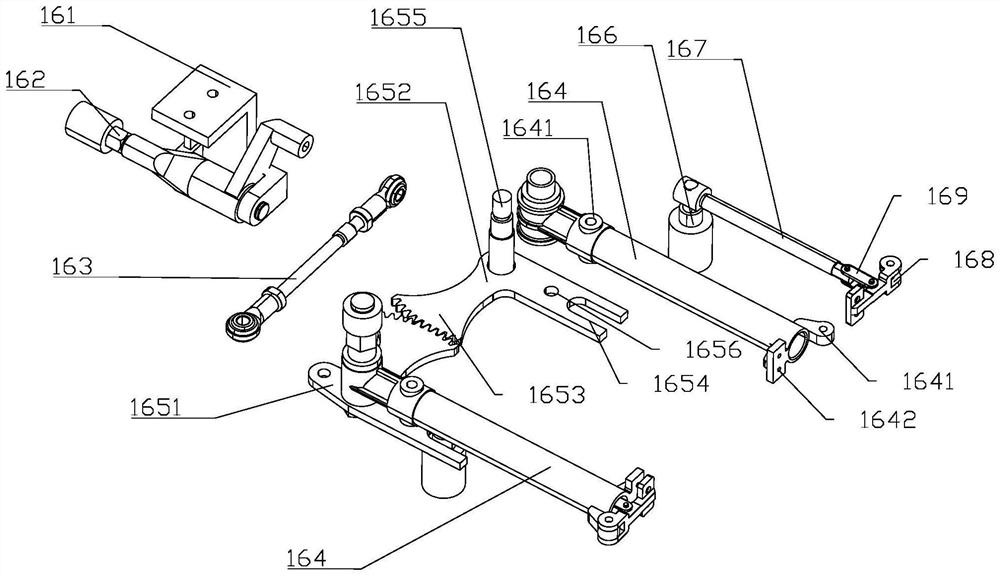

[0040] Such as figure 1 As shown, a food automatic bagging machine includes a frame and a rotating bag clamping device 1 installed on the frame, a bag loading device 2, a bag opening device 3, a blanking device 4, a bag clamping device 5, a power unit 6, Removing device 7 and heat-sealing device 8; Rotating bag clamping device 1 is installed in the center of the frame, along the direction of processing, described upper bag device 2, bag opening device 3, blanking device 4, bag clamping device 5 and The removal device 7 is connected successively around the rotary bag clamping device 1; the power device 6 is arranged under the frame, and the removal device 7 is connected to the rotary bag clamping device 1 and the heat sealing device 8. The sealing device 8 is arranged on both sides of the removal device 7 .

[0041] The rotating bag clamping device 1 is used to clamp the packaging bag and realize rotation, the described bag loading device 2 is used to realize the loading of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com