An Inertial Impact Linear Piezoelectric Motor Based on Cantilever Beam Structure

An inertial impact, piezoelectric motor technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. High, difficult to assemble, etc., to achieve the effect of stable and accurate step distance, improved displacement resolution, and suitable load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

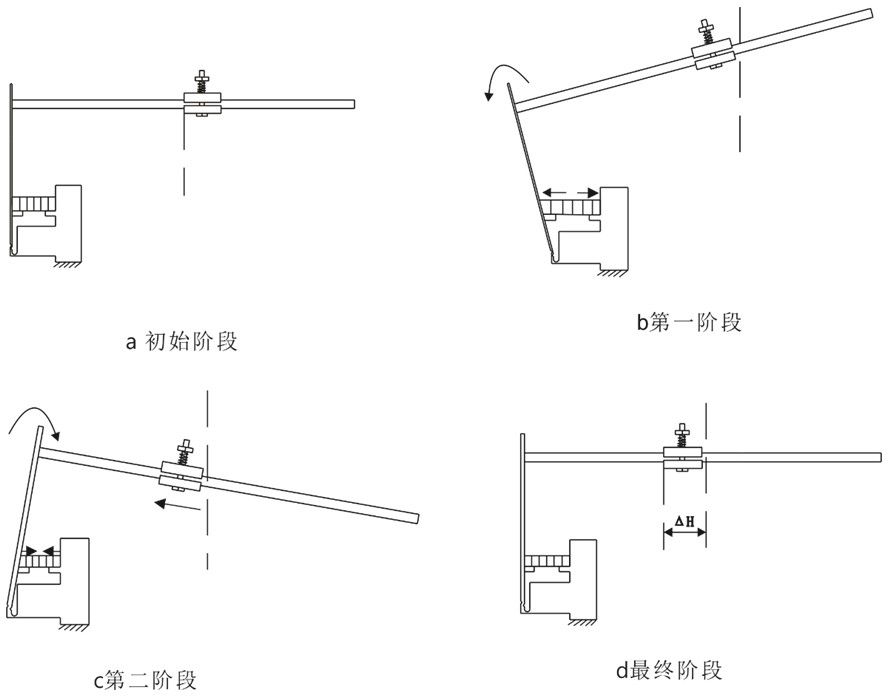

[0024] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

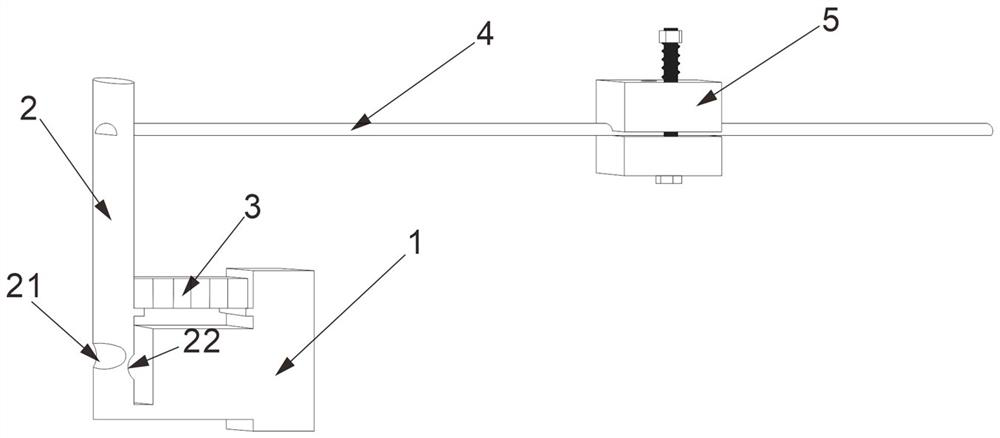

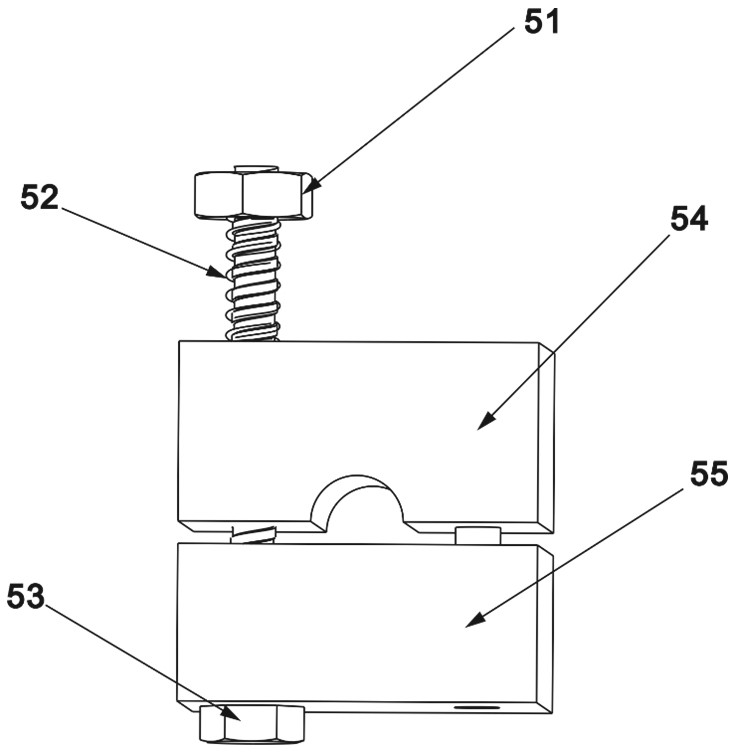

[0025] see figure 1 , an inertial impact linear piezoelectric motor based on a cantilever beam structure includes a base 1 , a pole 2 , a piezoelectric stack 3 , a guide rail 4 and a moving slider 5 .

[0026] Depend on figure 1 It can be seen that the base 1 is in the shape of an angle steel block, and the lower part of the outer end of the horizontal block of the base 1 is fixedly connected with the lower end of the vertical rod 2 .

[0027] The vertical rod 2 is a cylindrical rod that is elliptical in cross section; a flexible hinge is provided at the near lower end of the vertical rod 2, and the flexible hinge is composed of an outer groove 21 and an inner groove 22 that are cross-sectionally arc-shaped, and the outer groove 21 and the inner groove 22 are arc grooves with the same radius, and the distance between the outer groove 21 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com