Powder sorting unit

A sorting device and powder technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of the overall quality of powder and the effect of use, unable to separate and remove powder, unable to classify or classify powder, etc., to prevent oxidation , reduce pollution, improve the effect of sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

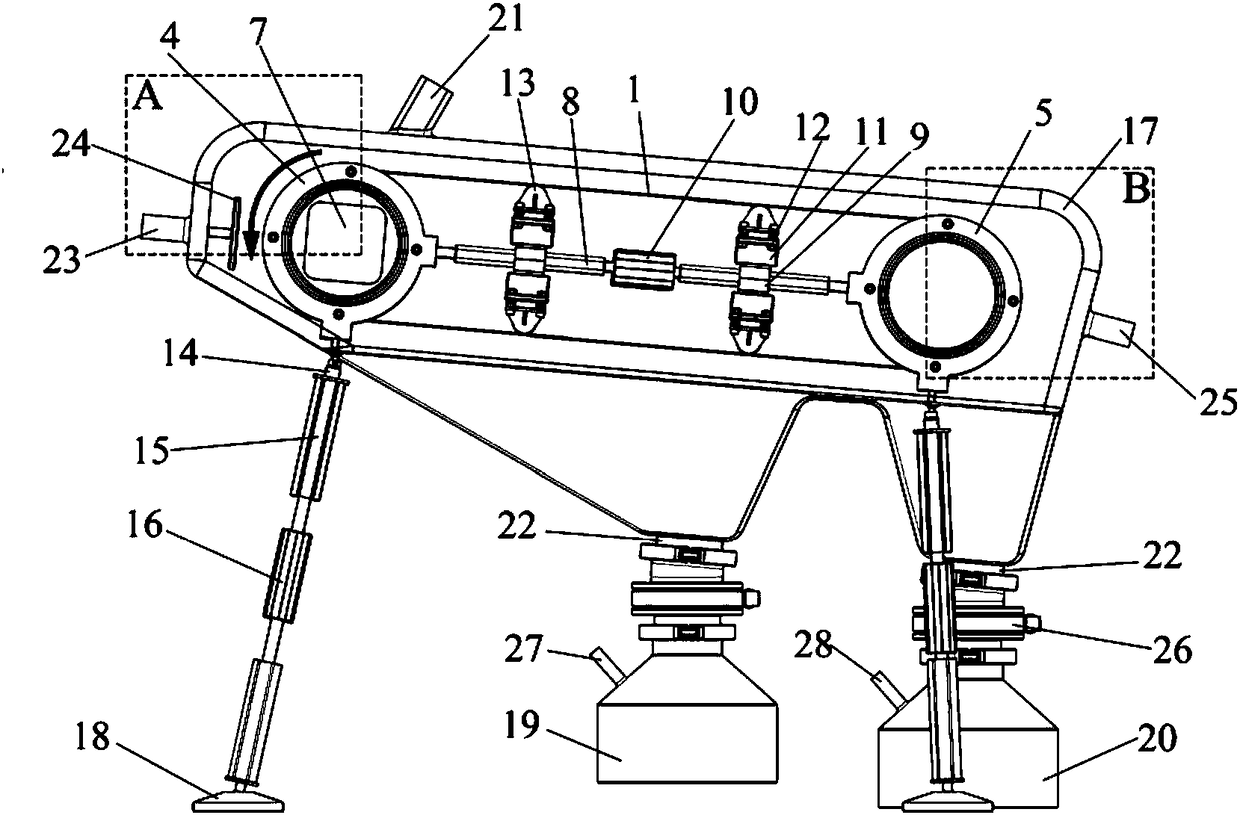

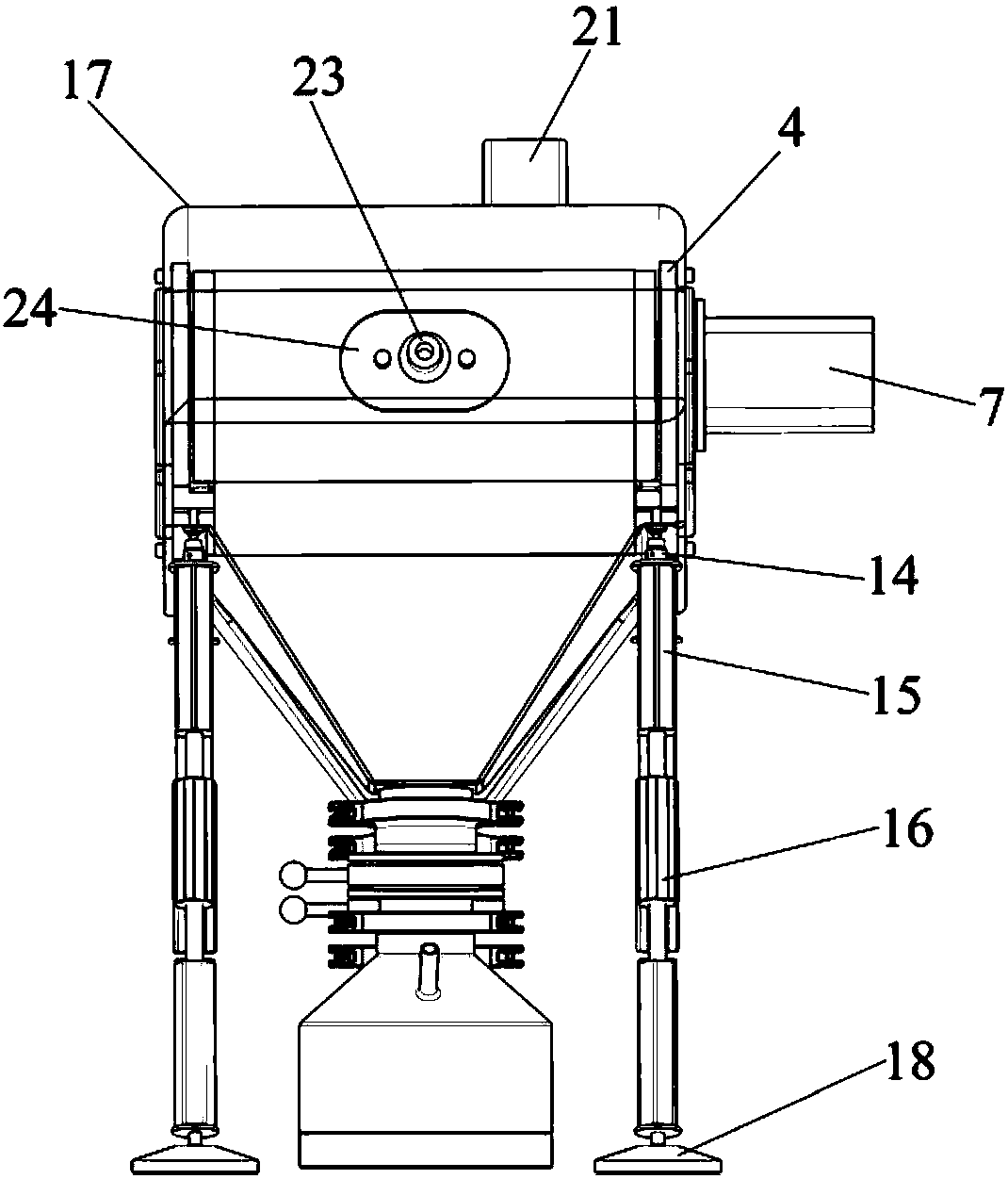

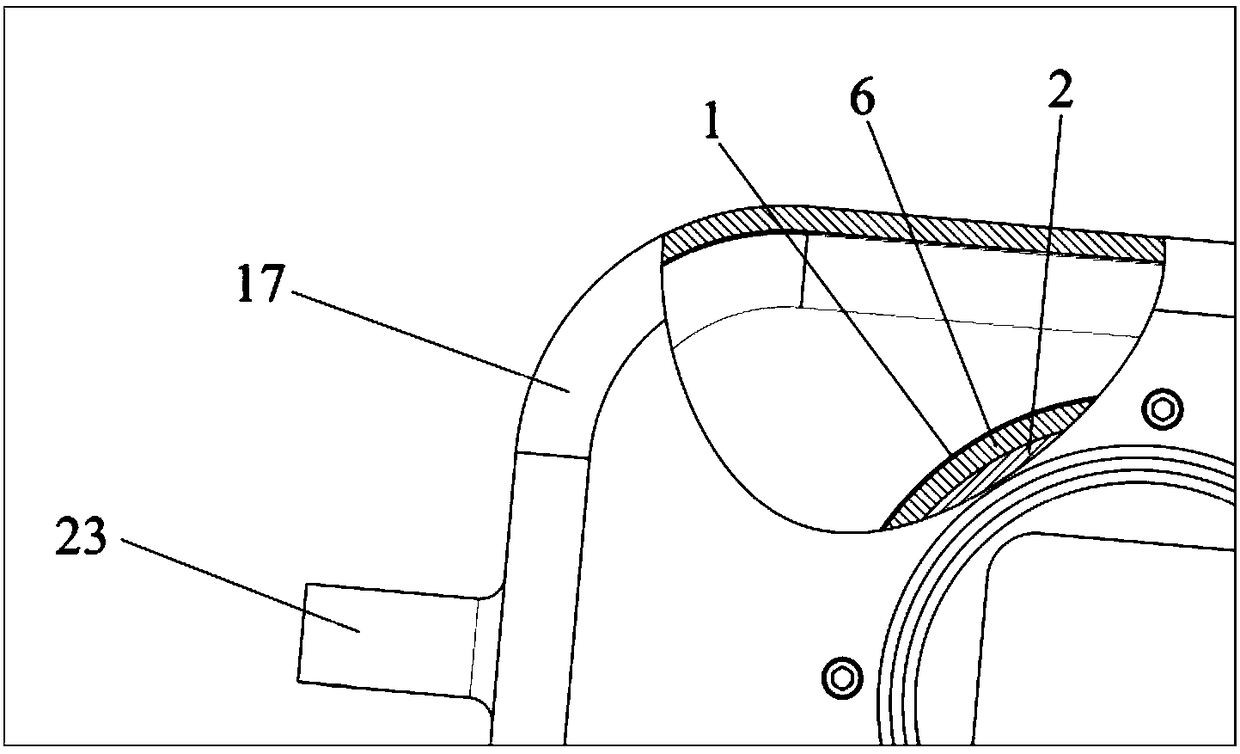

[0034] A powder sorting device, such as Figure 1-Figure 4 As shown, the device comprises a sorting plane 1, a driving wheel shaft 2, a driven wheel shaft 3, a motor 7, a vibration source 13, a dust cover 17, a powder recovery tank 19 and a powder collecting tank 20, and the sorting plane 1 is made of a thin metal strip It is connected end to end. The sorting plane 1 is supported by the driving wheel shaft 2 and the driven wheel shaft 3. The driving wheel shaft 2 is connected with the motor 7. The driving wheel shaft 2, the driven wheel shaft 3 and the sorting plane 1 form a conveyor-type movement mechanism. The driving wheel shaft 2 Rotation occurs under the drive of the motor 7, which drives the sorting plane 1 to move, and the inside of the upper and lower planes of the sorting plane 1 contacts the vibration source 13, and a dust cover 17 is arranged outside the movement mechanism, and the powder recovery tank 19 and the powder collection tank 20 are all connected with dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com