Two-way reciprocating rectilinear movement dual-drive device

A reciprocating linear motion, dual-drive technology, used in textiles and papermaking, continuous winding spinning machines, spinning machines, etc., can solve problems that affect user convenience and product quality, and cannot achieve doffing position, etc. Achieve the effect of improving product quality, improving motion accuracy, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

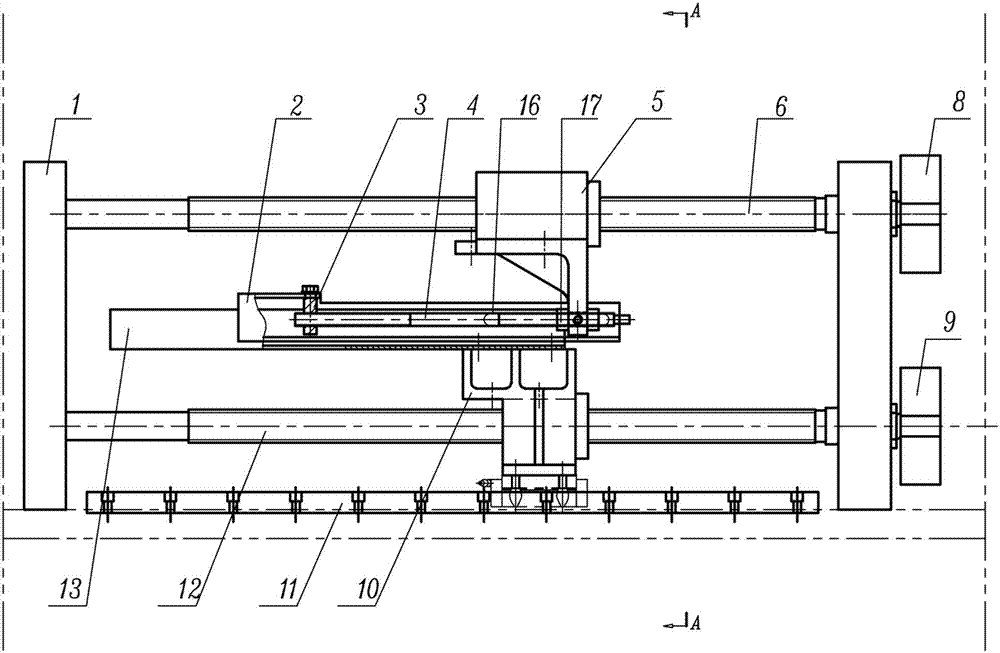

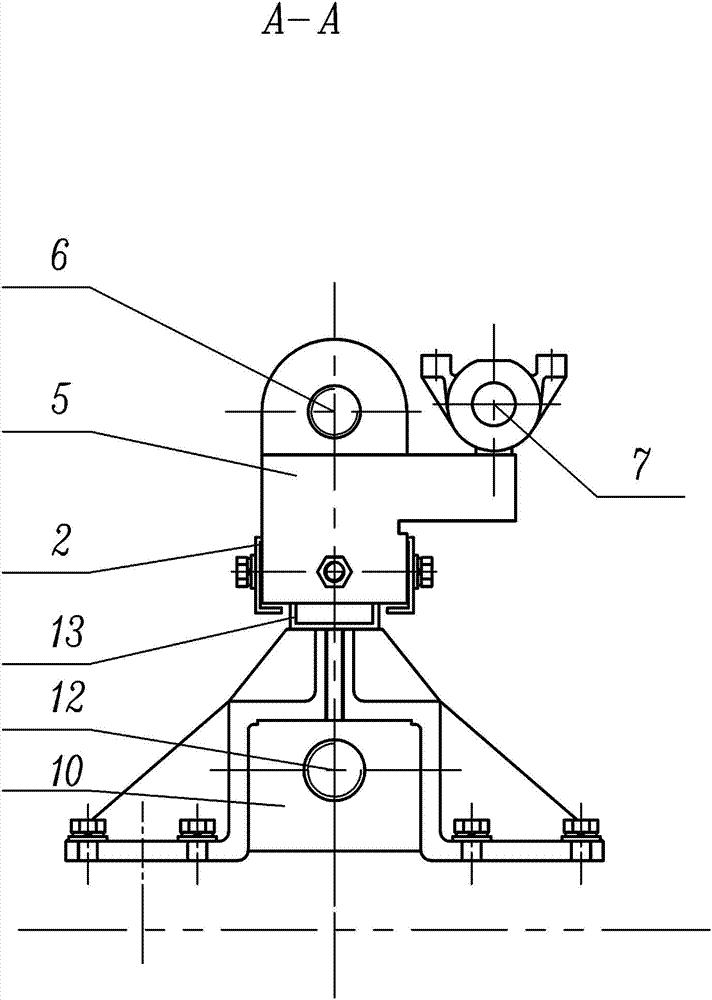

[0018] Such as figure 1 Among them, a two-way reciprocating linear motion double driving device includes a frame 1, and a fender screw nut mechanism 6 and a ring plate screw nut mechanism 12 are installed in parallel on the frame 1.

[0019] Such as figure 1 , figure 2 Among them, the ring plate sliding seat 10 is installed on the ring plate screw nut mechanism 12 and is slidably matched with the ring plate guide rail mechanism 11, and the ring plate pull rod 13 is fixedly connected with the ring plate sliding seat 10.

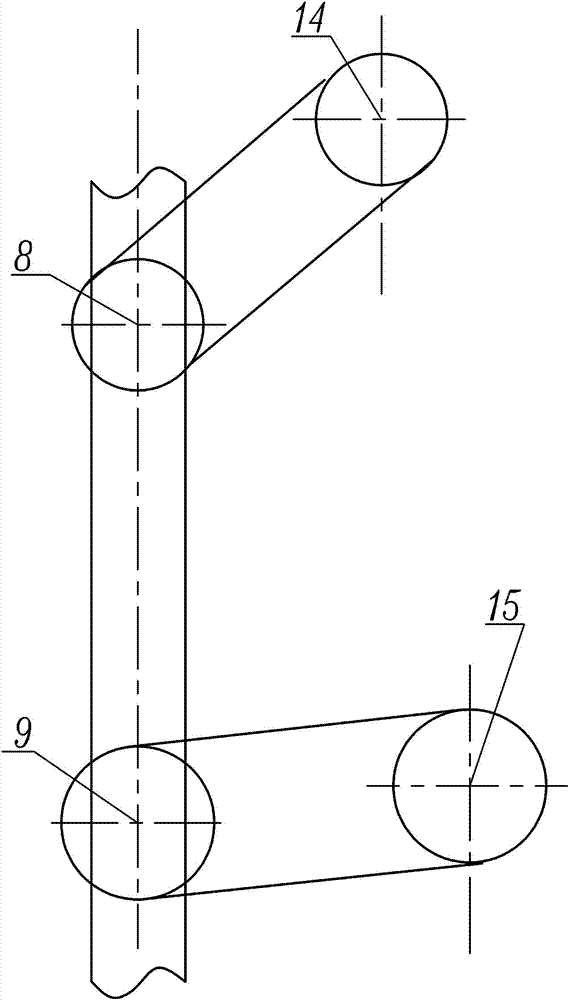

[0020] Such as figure 1 , figure 2 Among them, the fender sliding seat 5 is installed on the fender screw nut mechanism 6, that is, the fender sliding seat 5 is fixedly connected with the nut in the fender screw nut mechanism 6, and the fender sliding seat 5 also slides with the fender guide rail 7 Cooperate, the fender pull rod 2 is connected with the fender sliding seat 5 in a manner that the length can be adjusted along the axial direction of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com