Method for manufacturing flexible-substrate metal microneedle array

A flexible substrate and microneedle array technology, applied in the directions of microneedles, metal material coating process, needle heads, etc., can solve the problems of limiting the development and promotion of metal microneedles, synchronizing the expensive production cycle of X-rays, and the process being complicated and difficult to control. Achieve significant economic and social benefits, easy operation, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

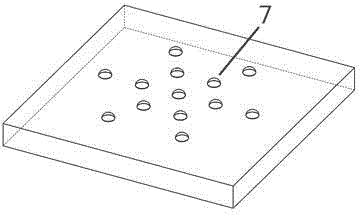

[0032] A method for manufacturing a metal microneedle array on a flexible base, the metal microneedle array on a flexible base comprises a flexible base 1 and a microneedle array 2, wherein the microneedle array 2 is fixed on the flexible base 1;

[0033] The fabrication method of the flexible base metal microneedle array comprises the following steps:

[0034] a. Production of "solidifiable ferromagnetic fluid": the solidifiable ferromagnetic fluid includes magnetic nano or micro particles, polymer materials and curing agents, which are mixed in an appropriate proportion according to performance requirements. The present embodiment selects magnetic nanoparticle, and selects epoxy resin as polymer material, selects epoxy resin curing agent as curing agent, and its ratio is: magnetic nanoparticle: epoxy resin: epoxy resin curing agent=5:3: 2;

[0035] b. According to the predetermined design, the soft solid material is made into a sheet-like flexible substrate 1, which i...

Embodiment 2

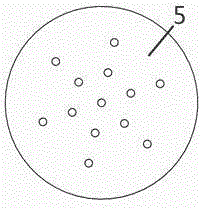

[0040]This embodiment is similar to Embodiment 1, except that the method of "arranging the droplets of solidifiable ferromagnetic fluid in an array on the flexible substrate 1" in this embodiment is: The fluid is loaded into the cavity formed by the hole mold 5, the piston and the barrel wall, and the pressure is applied through the piston to make the solidifiable ferromagnetic fluid flow out from the small hole of the hole mold 5 and adhere to the flexible substrate 1 to form a droplet array.

Embodiment 3

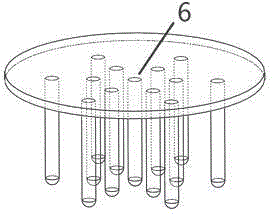

[0042] This embodiment is similar to Embodiment 1, except that the method of "arranging the solidifiable ferrofluid droplets on the flexible substrate 1 in an array" in this embodiment is: using a hollow needle mold 6 , to form a droplet array in a manner of pouring into the flexible substrate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com