High-performance antifouling paint

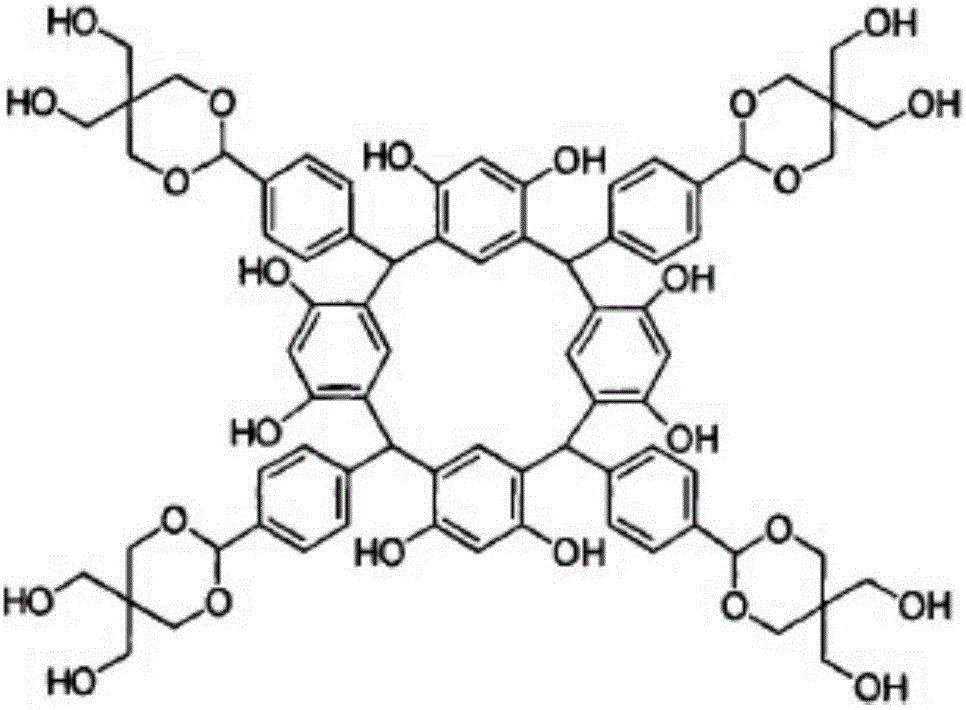

An antifouling coating, high-performance technology, applied in antifouling/underwater coatings, epoxy resin coatings, coatings, etc., can solve the problems of graphene being difficult to disperse stably, affecting the performance of graphene, and limited functional groups, etc., to achieve high Antifouling performance, low cost, effect of promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

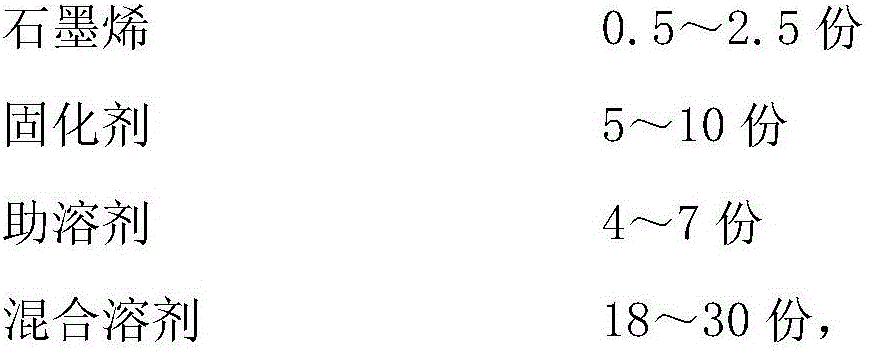

[0033] A high-performance antifouling paint, calculated in parts by weight, the antifouling paint comprises the following components:

[0034]

[0035] First dissolve the co-solvent in the mixed solvent, then add epoxy resin E-44 and graphene to it, and mix well to obtain component A; polyamide curing agent 651 is packaged as component B separately.

[0036] When in use, fully mix component A and component B, and then solidify to form a film, and the coating properties are tested as shown in Table 1.

Embodiment 2

[0038] A high-performance antifouling paint, calculated in parts by weight, the antifouling paint comprises the following components:

[0039]

[0040] First dissolve the co-solvent in the mixed solvent, then add epoxy resin E-42 and graphene to it, and mix well to obtain component A; polyamide curing agent 651 is packaged as component B separately.

[0041] The film-forming process was the same as in Example 1, and the coating performance was tested as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com