LED light source with heat dissipation device and processing method thereof

A technology of LED light source and heat dissipation device, which is applied in the parts of lighting device, light source, cooling/heating device of lighting device, etc. The effect of poor contact, simplified process flow, and guaranteed life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Now, a 3W white LED light source is specifically manufactured by using the method of integrating the LED chip 3 and the heat dissipation device in the present invention,

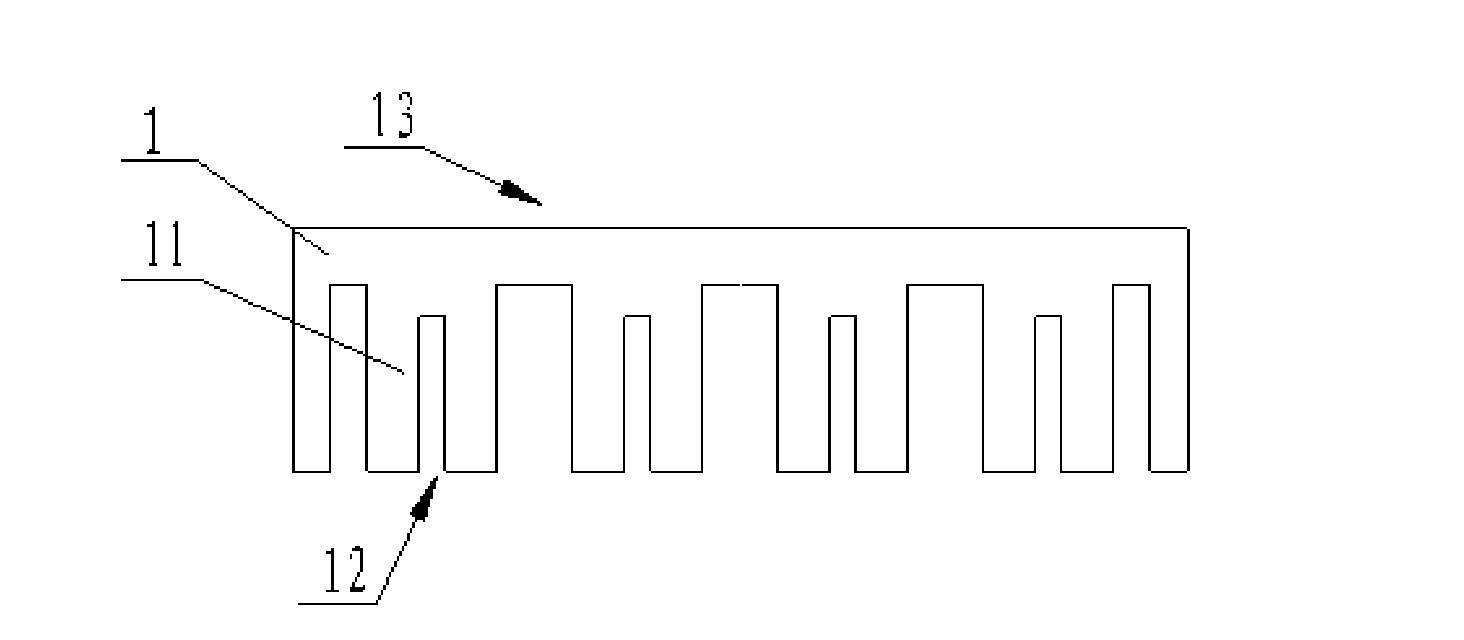

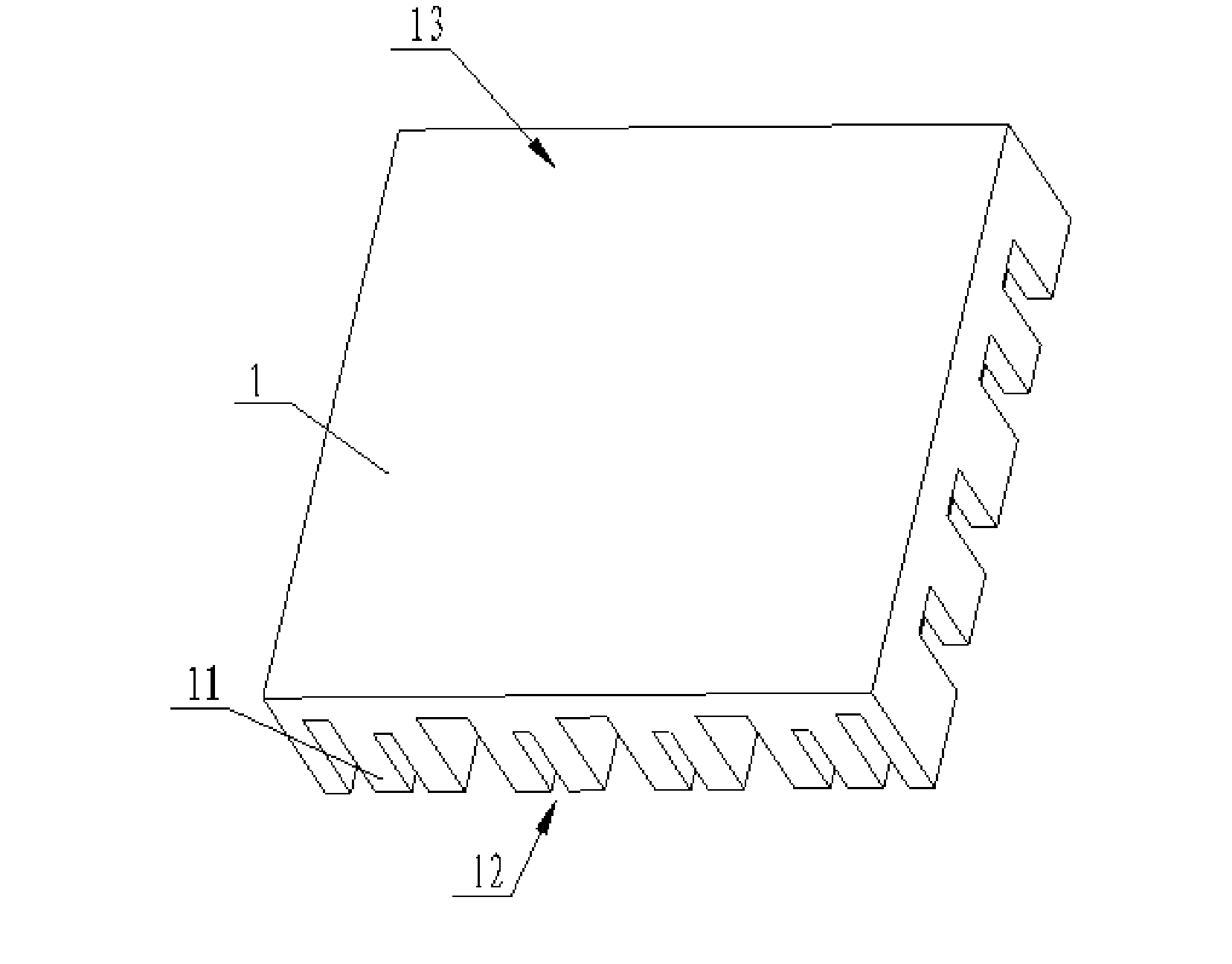

[0057] The manufacture of the LED base 1 applies the method described in the patent "radiation device", we adopt such as Figure 7 The LED base 1 of the structure shown. The front is a diameter? 2, with 6 ribs 11 on the back and 4 ribs 11 in the middle, each rib 11 has a 0.6mm cooling groove 12 in the middle, which is used to insert a carbon nano heat sink 2 with a thickness of 0.5mm or other Heat sink 2 of high thermal conductivity material. The height of the heat sink 2 is determined according to the requirements of heat dissipation and the conditions allowed by the lamp body. In this example, the height is 4mm, and after the heat sink 2 is inserted, press it and the rib 11 mechanically.

[0058] On the front of the base 1, the pattern for installing the LED chip 3 is made in the same way as mak...

Embodiment 2

[0061] Adopt the method of the present invention, make a 7W blue light LED.

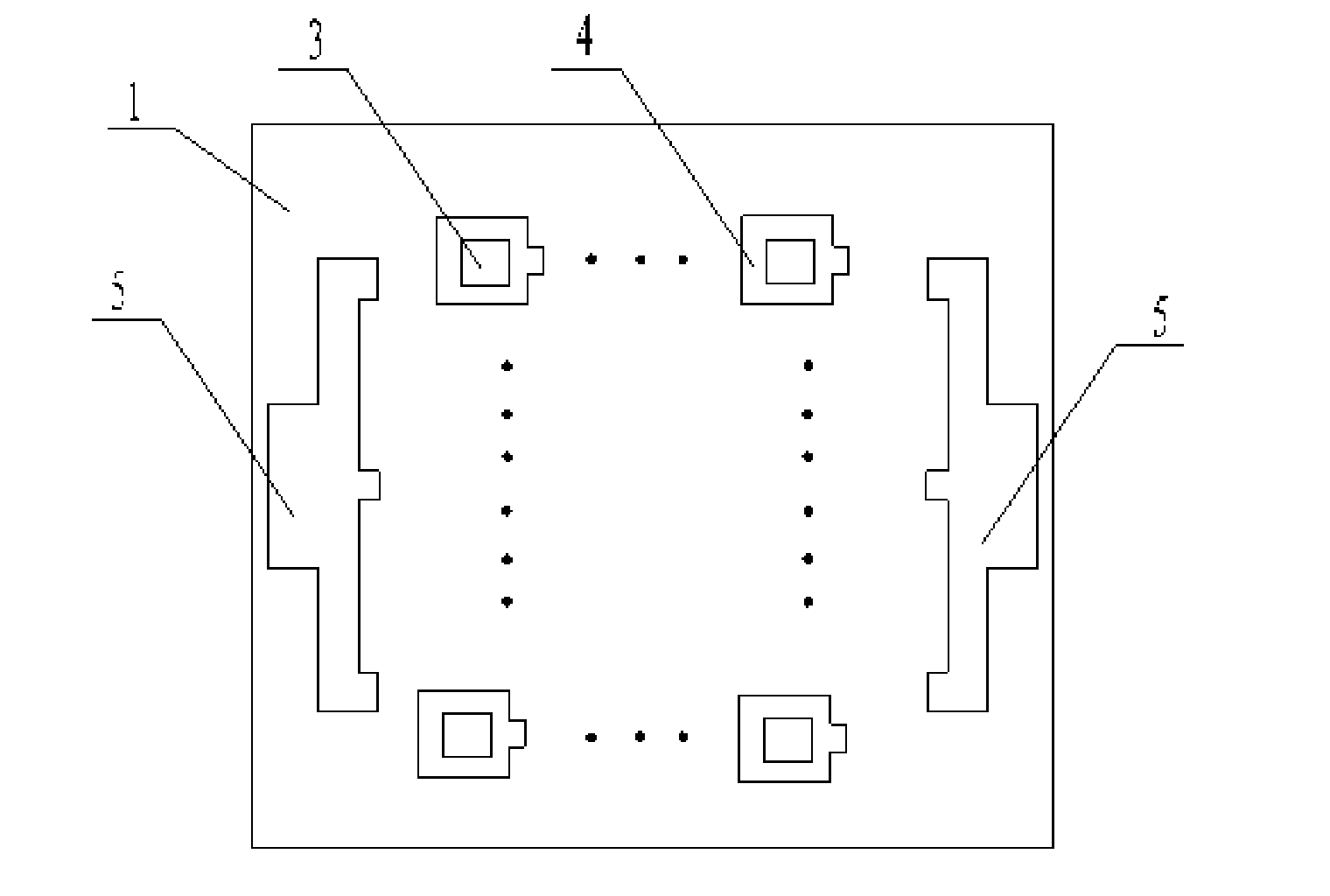

[0062] Because the power of the LED is much higher than that in Embodiment 1, the entire LED base 1 adopts the square base 1 shown in FIG. 1 . The size of the plane part of the square base 1 is 24mm×24mm, there are 6 ribs 11 on the back, the height is 2-10mm, and there are 4 ribs 11 in the middle, and there is a cooling groove 12 of 0.5-0.6mm in the middle of each rib 11. Same as in Example 1.

[0063] The front is also similar to Embodiment 1, and the chip 3 placement area is made. In this example, 38 14mil×14mil Blu-ray chips are arranged in a 9×9 matrix, all connected in series. As shown in Figure 2, corresponding to the square base 1, the surrounding frame 7 outside the mounting area of the chip 3 is also made into a square shape and fixed on the base 1. The steps for making the LED light source are the same as in Embodiment 1 thereafter, except that The process of coating phosphor can be ch...

Embodiment 3

[0065] A variable color LED light source is produced by applying the method of the invention.

[0066] Currently on the market, color-changing LEDs are composed of three chips 3 of red, green and blue. In this embodiment, four chips 3 with emission wavelengths of 455nm, 525nm, 585nm and 630nm are used to form an LED light source capable of changing the emission color.

[0067] In this embodiment, the structure of the LED base 1 is exactly the same as that in Embodiment 2. In the distribution of the chip 3, we use 18 chips 3 with a luminous wavelength of 455nm, 27 chips 3 with a luminous wavelength of 525nm, 18 chips 3 with a luminous wavelength of 585nm, and 18 chips 3 with a luminous wavelength of 630nm, and each chip 3 electrodes are respectively drawn. Four current-adjustable power supplies are used to respectively drive the LED chips 3 of four light colors to emit light. A variety of colors can be obtained by matching different currents in each group.

[0068]The above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com