Patents

Literature

45results about How to "Eliminate thermal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

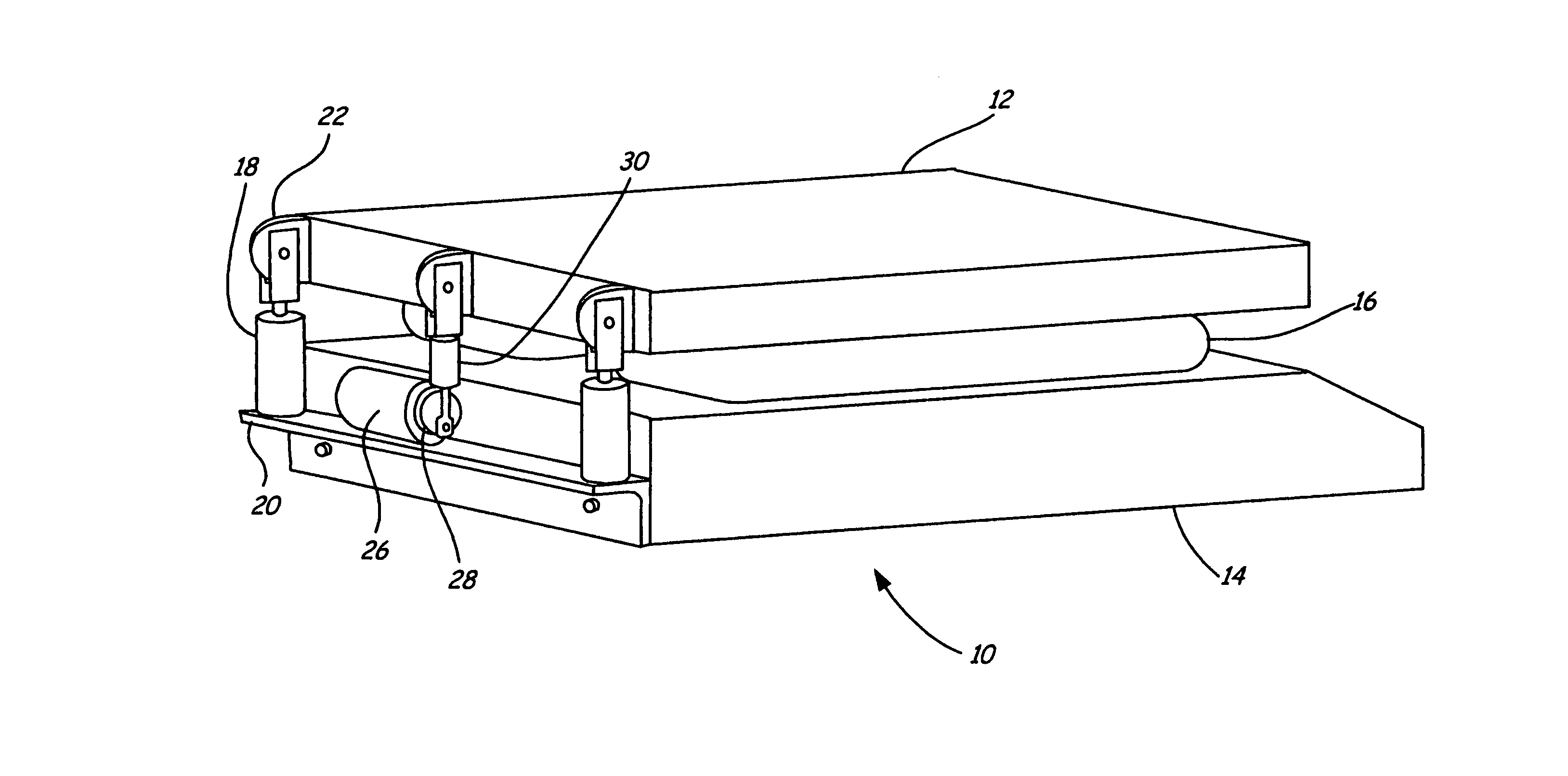

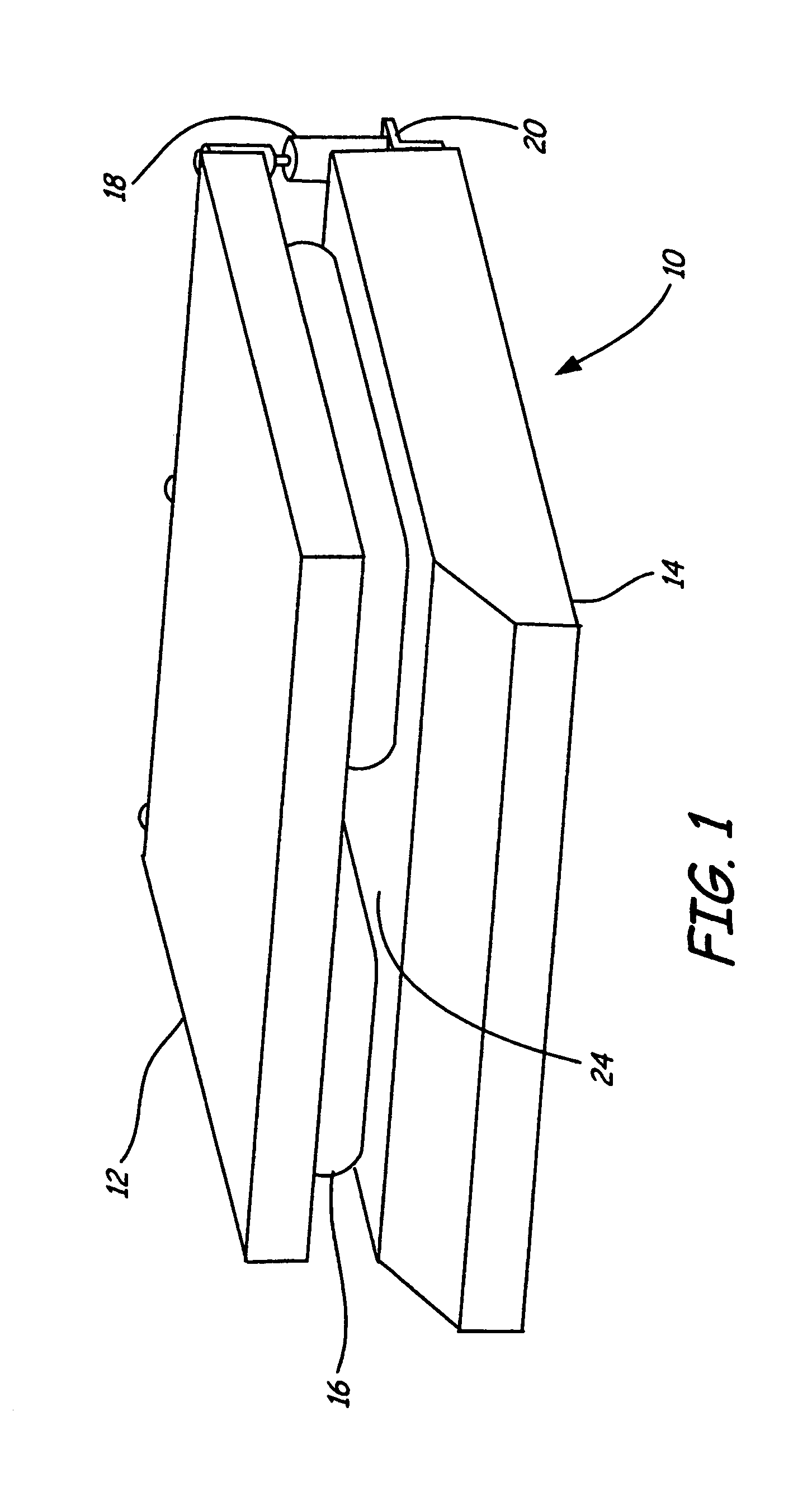

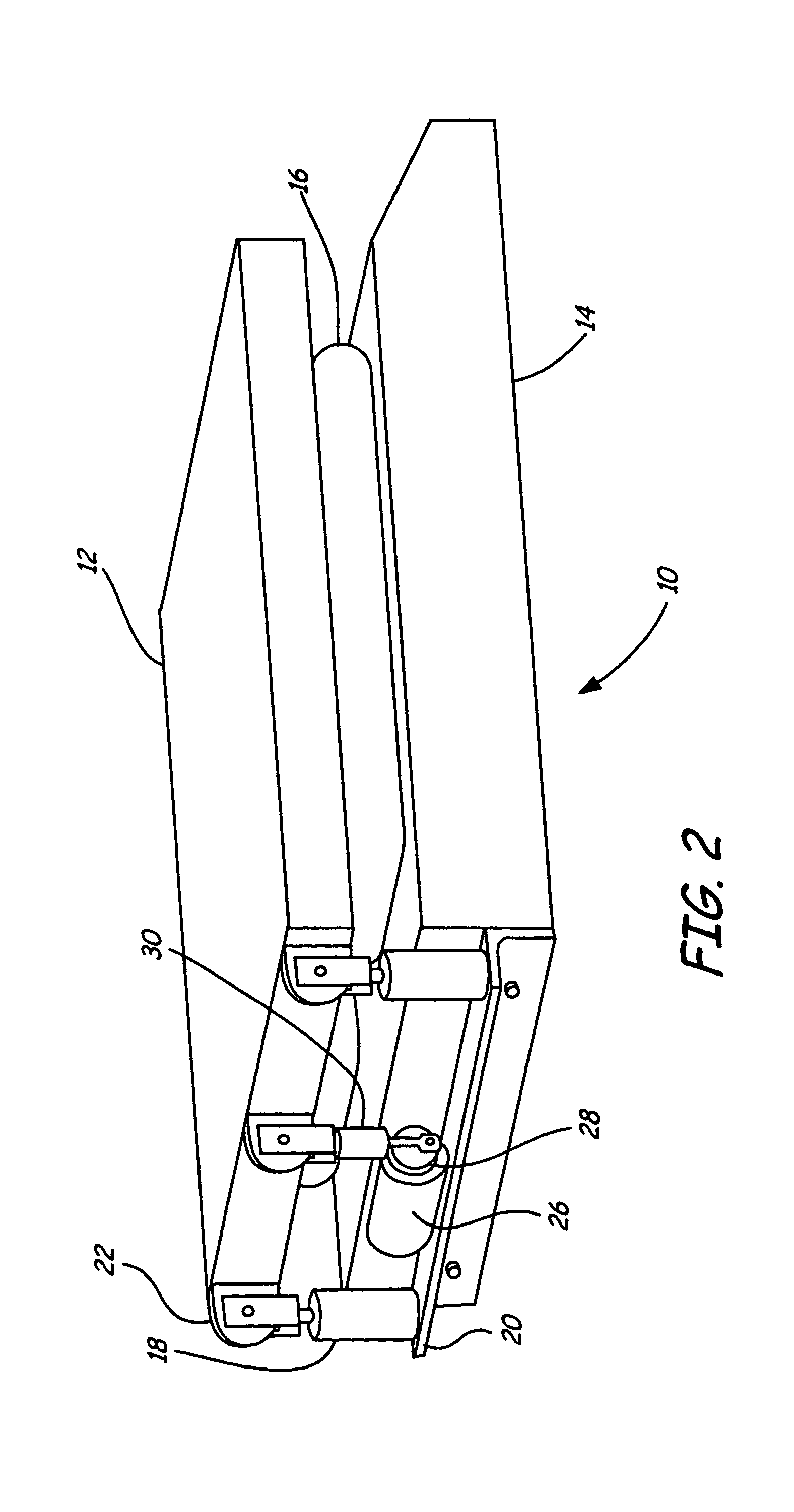

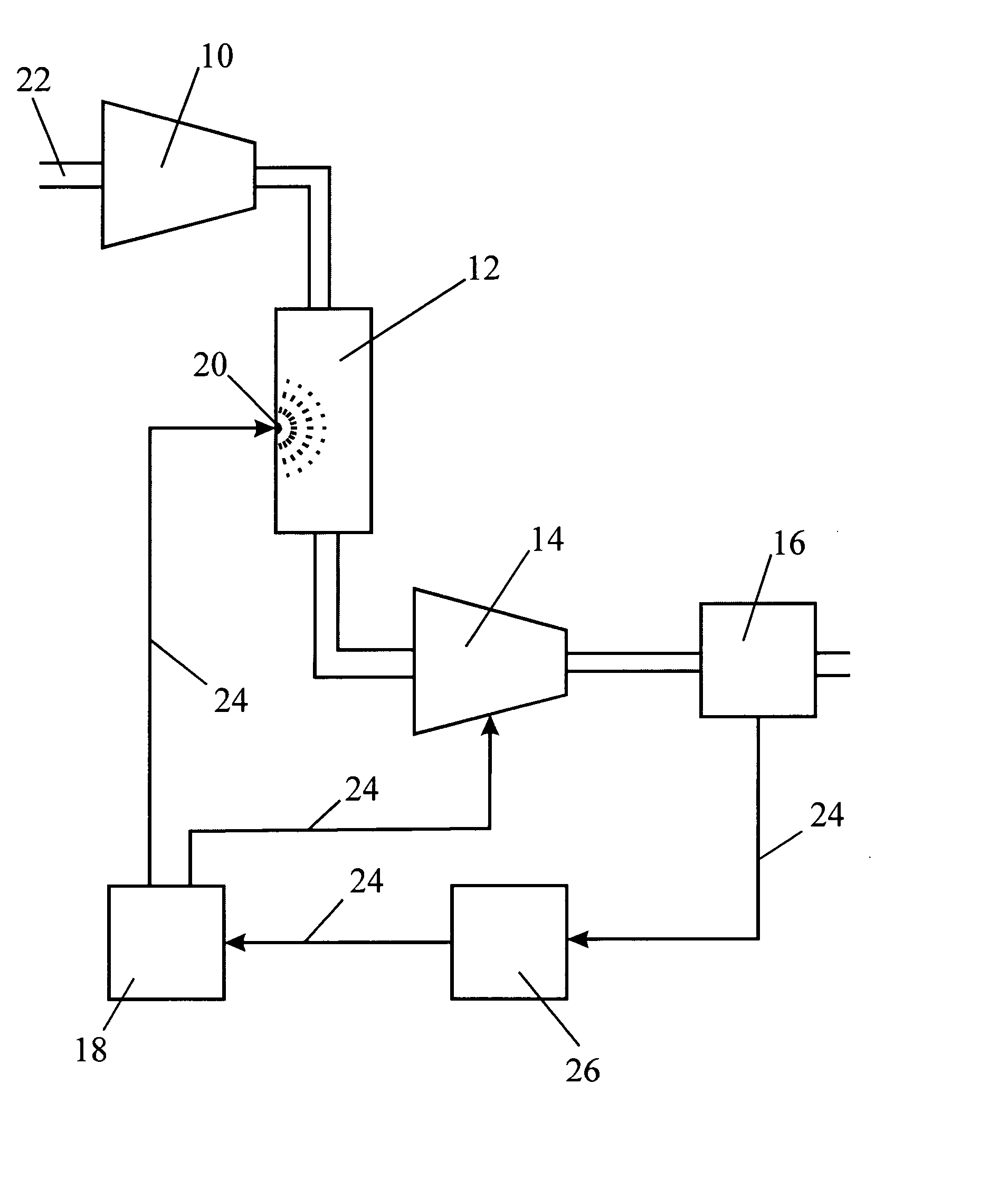

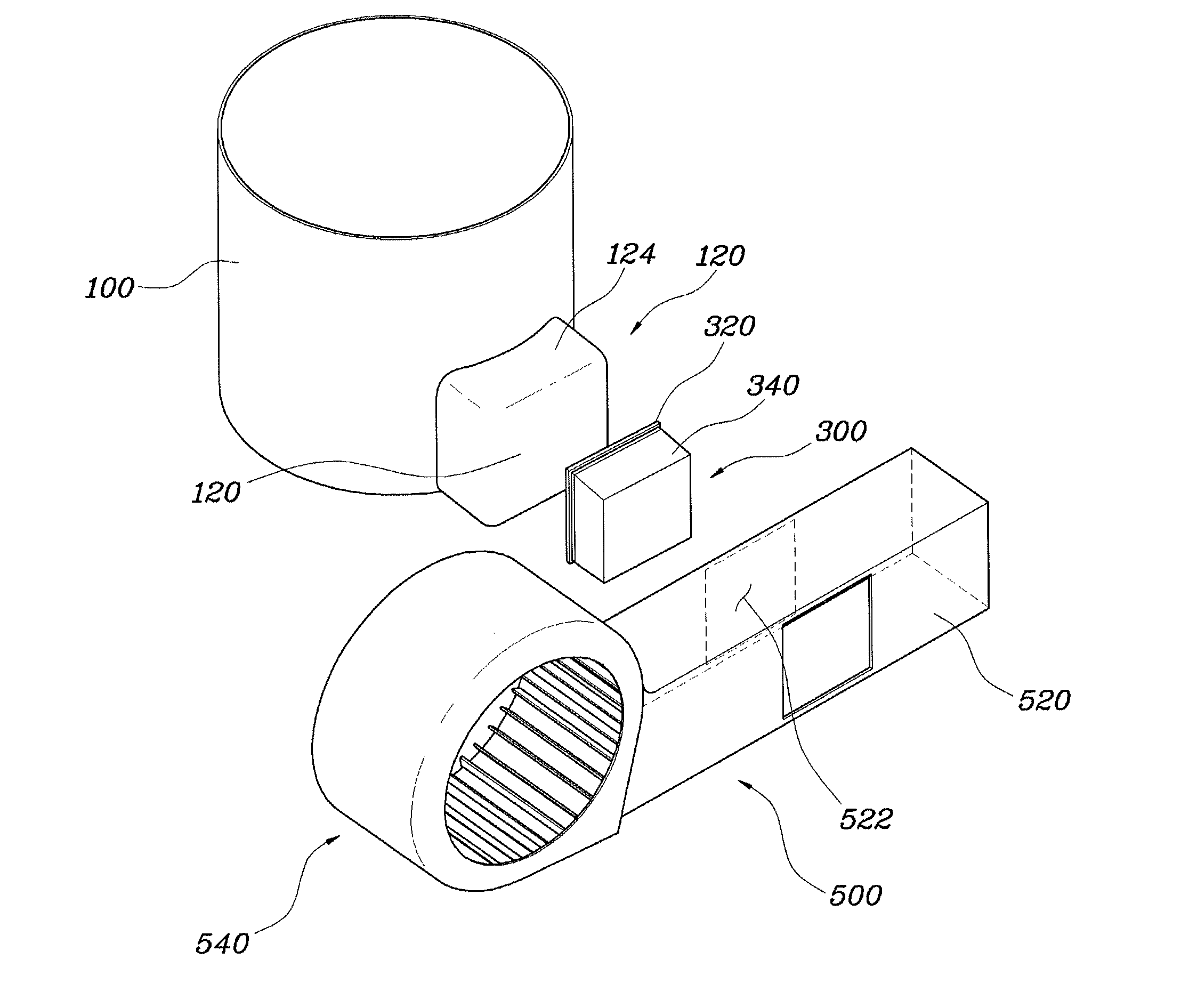

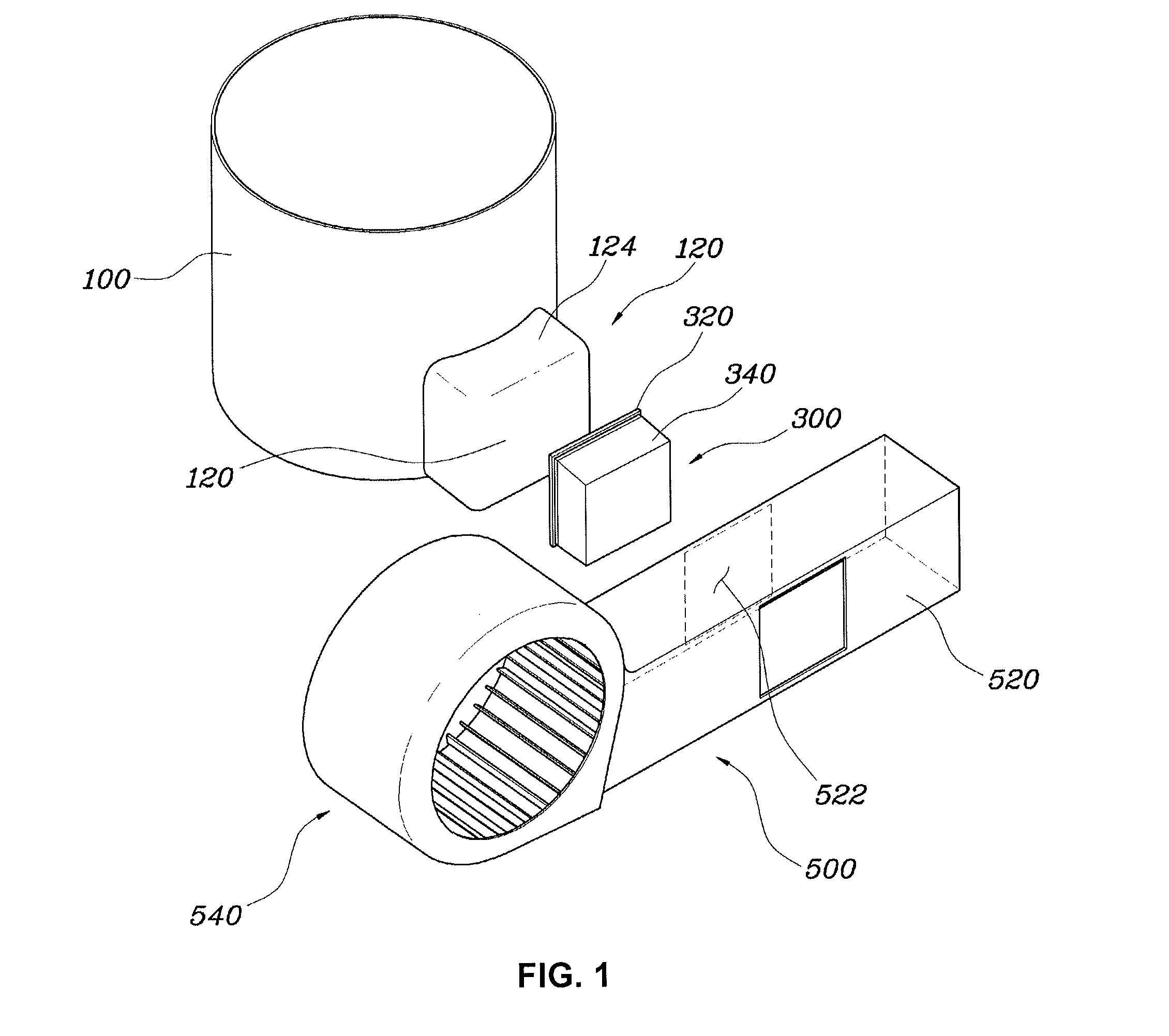

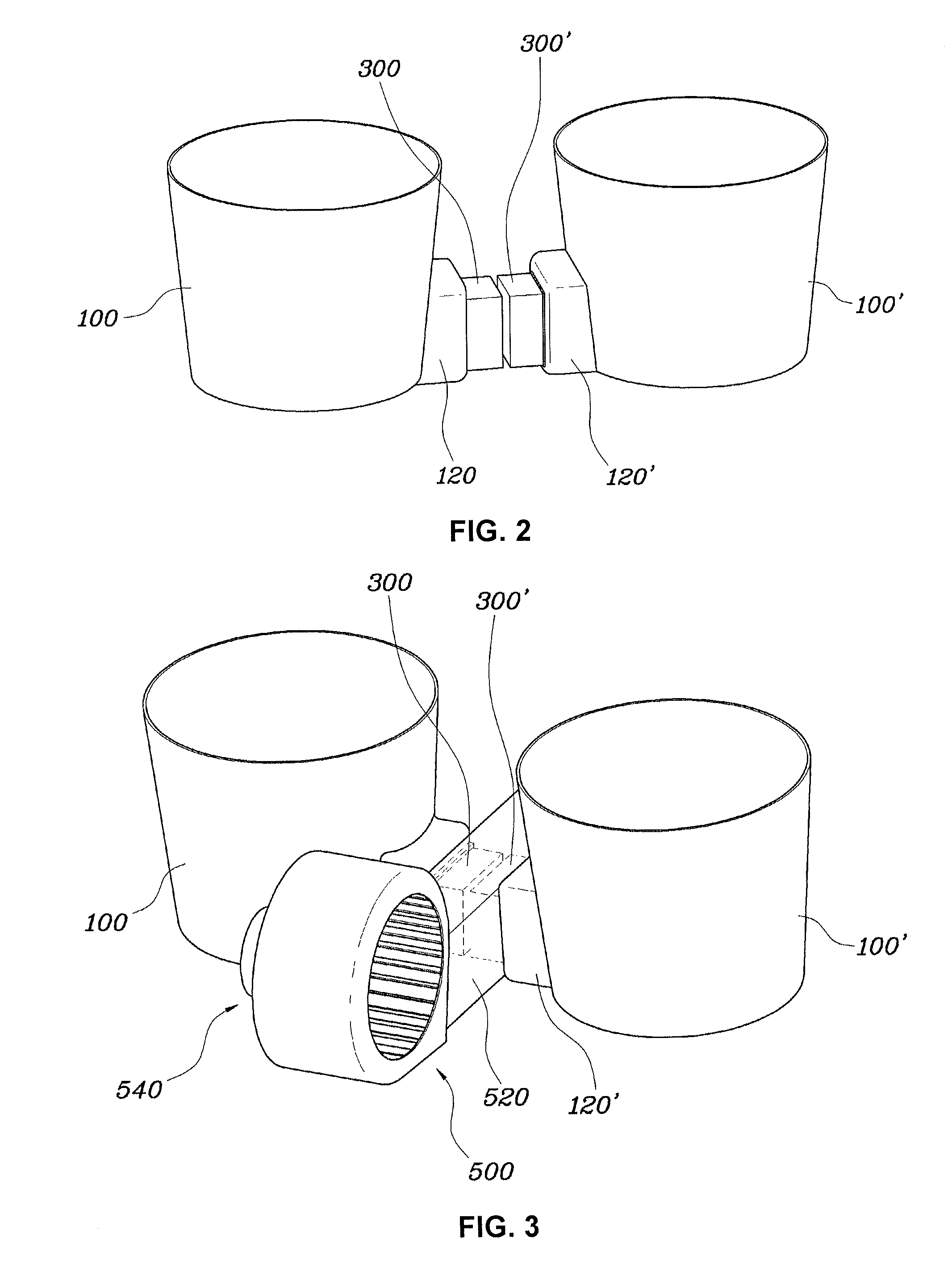

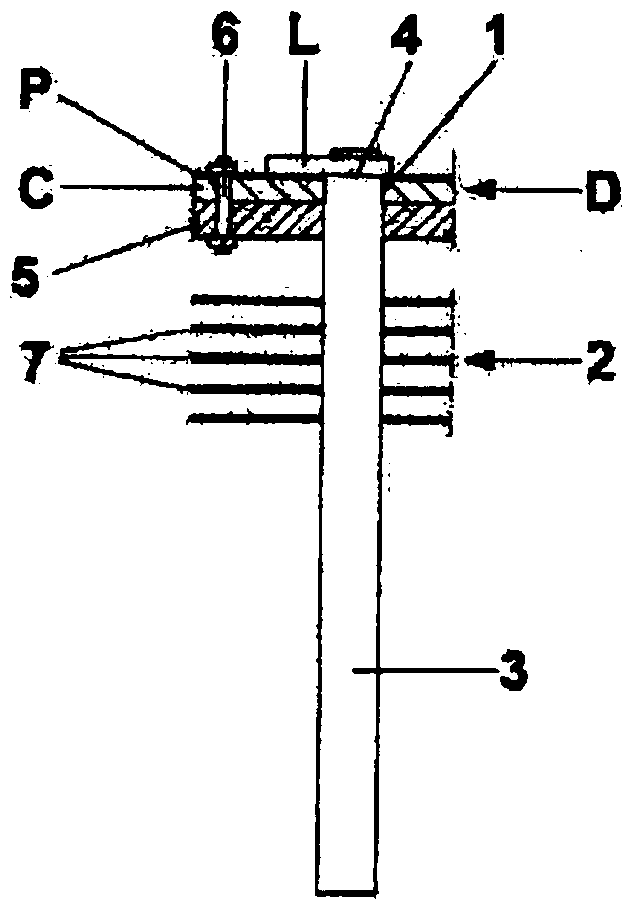

Apparatus for thawing frozen biological fluids utilizing heating plates and oscillatory motion to enhance heat transfer by mixing

ActiveUS7011797B2Less timeEliminate thermal resistanceSurgeryMaterial analysis by optical meansWater bathsElectricity

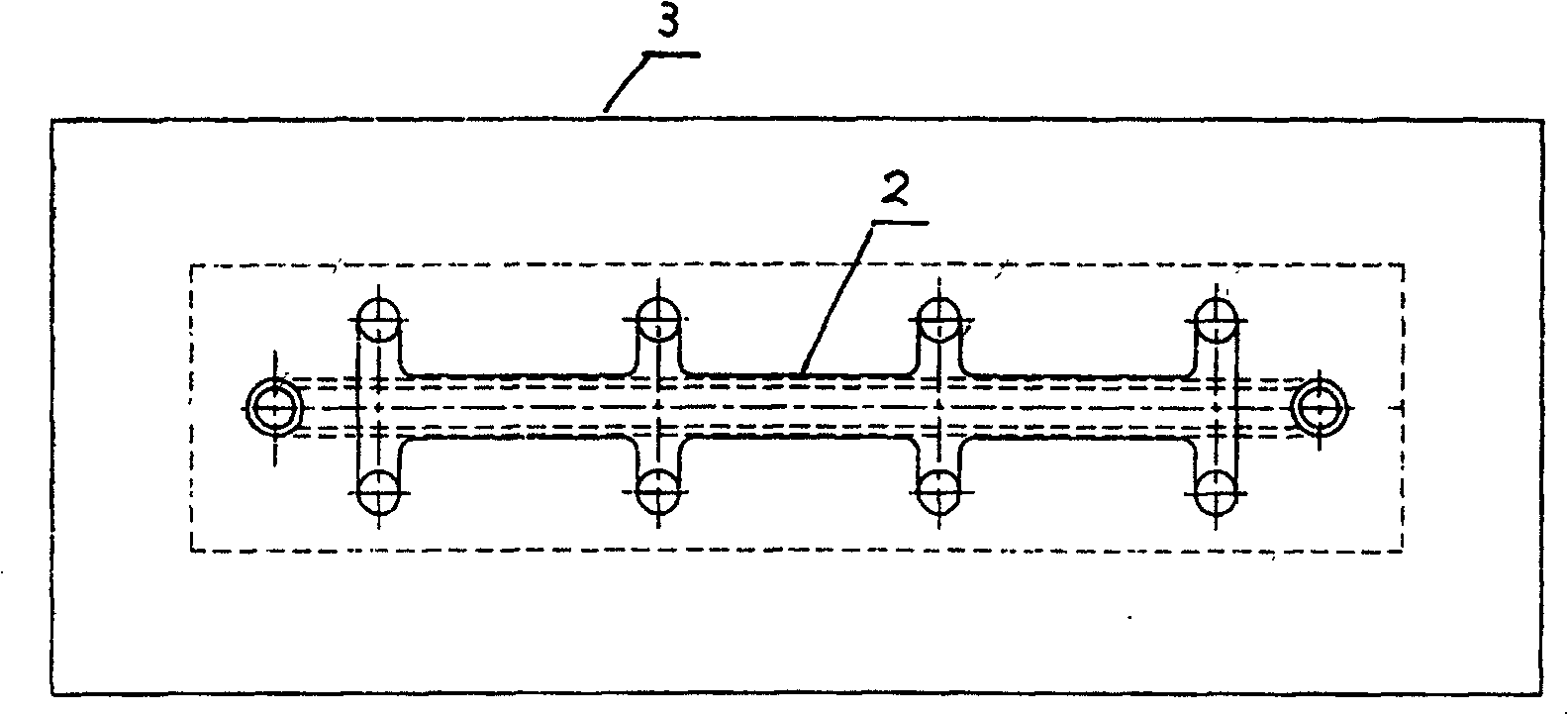

An improved dry heat method and apparatus for thawing frozen biological fluids utilizing electrically heated plates and oscillatory motion to enhance heat transfer by mixing as the fluid thaws. Bags of frozen fluid to be thawed are lightly squeezed between two heating plates, one of which is gently oscillated to facilitate mixing of the thawing fluid, increasing heat transfer and reducing time required for thawing. Direct contact of the heating plates against the bag surfaces increases heat transfer by eliminating insulative effects of another bag wall and a water boundary layer, compared to water bath units. Flat (or curved to conform to bag) heat pipes are preferred as heating plates compared to plain aluminum sheet. Flat heat pipes have the property of an isothermal heating surface, thus maximizing heat transfer to the coldest areas, preventing hot spots, and simplifying heating plate temperature control.

Owner:BAKKE ALLAN P

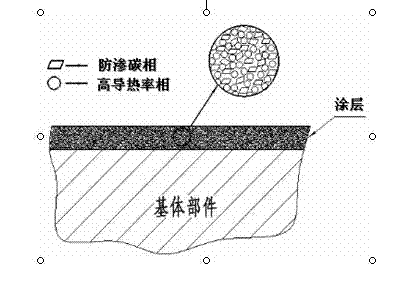

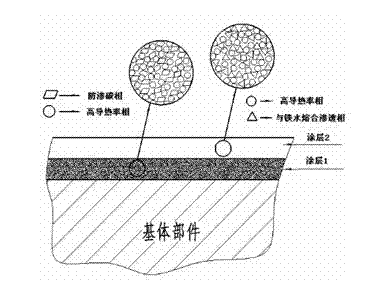

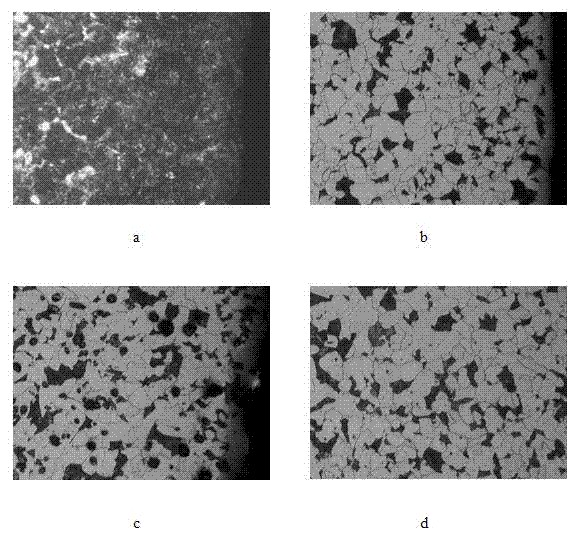

High-temperature nano-grade anti-carburizing material and coating, and application thereof

ActiveCN102352142AReliable effectHigh thermal conductivityLiquid surface applicatorsLayered productsCarbon steelThermal conductivity

The invention discloses a high-temperature nano-grade anti-carburizing material, a coating formed with the material, and an application thereof. The material is formulated slurry. The slurry is sprayed and / or painted on a work-piece, such that a coating is formed. The coating is characterized in high-temperature carburization resisting, high thermal conductivity, and good bonding strength with substrate parts. When the coating is imbibed with molten iron, air gaps can be removed. When the coating is applied on the surface of a low-carbon steel part such as a cooling pipe of a cast iron cooling stave in a steel plant, carburization of the low-carbon steel part in a high-temperature carbon atmosphere is avoided. A main application scope of the material coating is that: slurry with the high-temperature nano-grade anti-carburizing material formulation can be sprayed and / or painted on surfaces of equipments / cooling pipes of cast iron cooling staves, and compact high-efficiency long-life anti-carburizing coatings are formed after curing; the slurry can be sprayed and / or painted on surfaces of large steel parts / forging dies, and decarbonization resisting coatings are formed after curing.

Owner:SHILIN LUOHE METALLURGY EQUIP +1

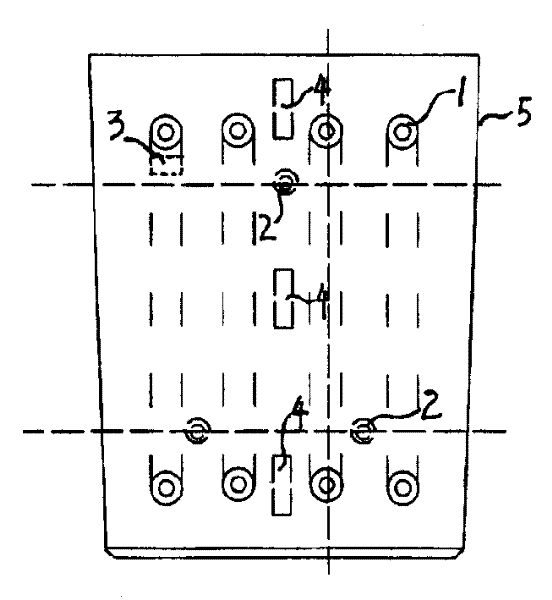

Casting method of metal substrate cooling wall

InactiveCN1513622AEnhanced feedingImprove feeding capacityFoundry mouldsCooling devicesIron powderChemical reaction

A technology for casting the steel-based cooling wall features that the cooling medium which is the mixture of corundum powder, iron powder and electrode powder is filled in its cooling pipeline. Said cooling medium features strong cooling action, low thermal expansibility, not adhering to pipe wall, and easy removing it.

Owner:MAANSHAN IRON & STEEL CO LTD

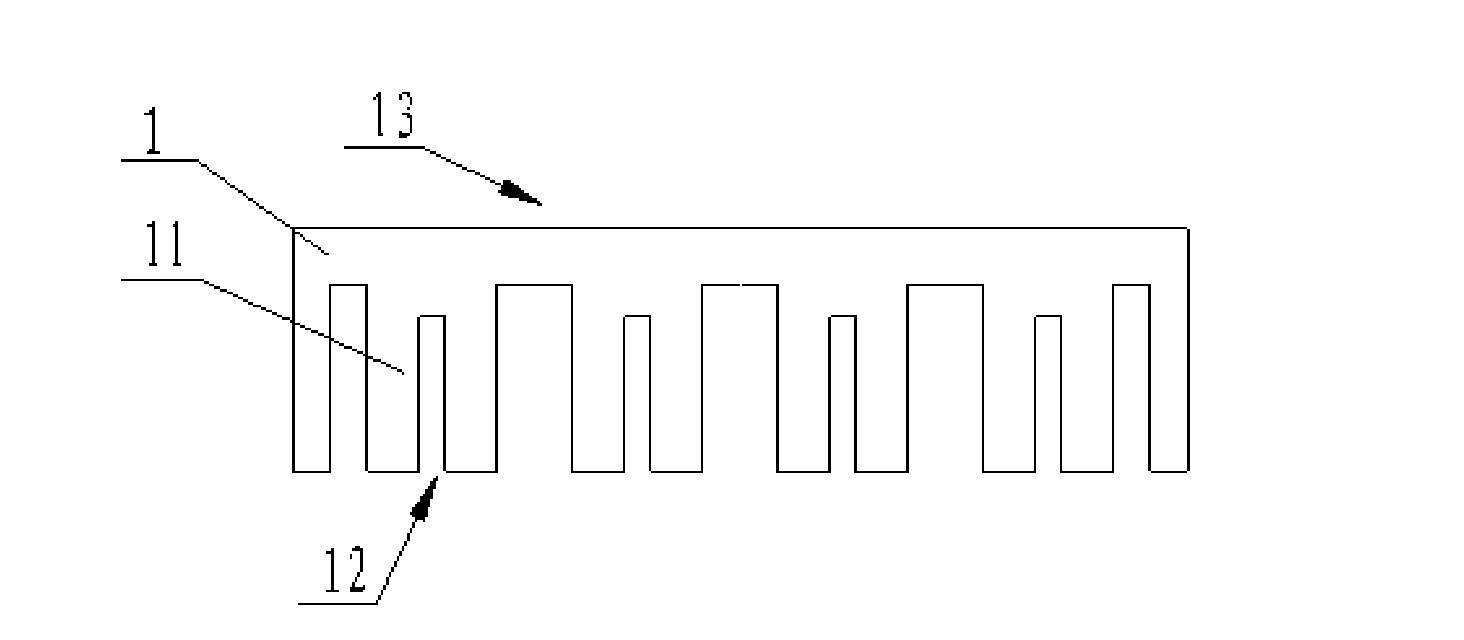

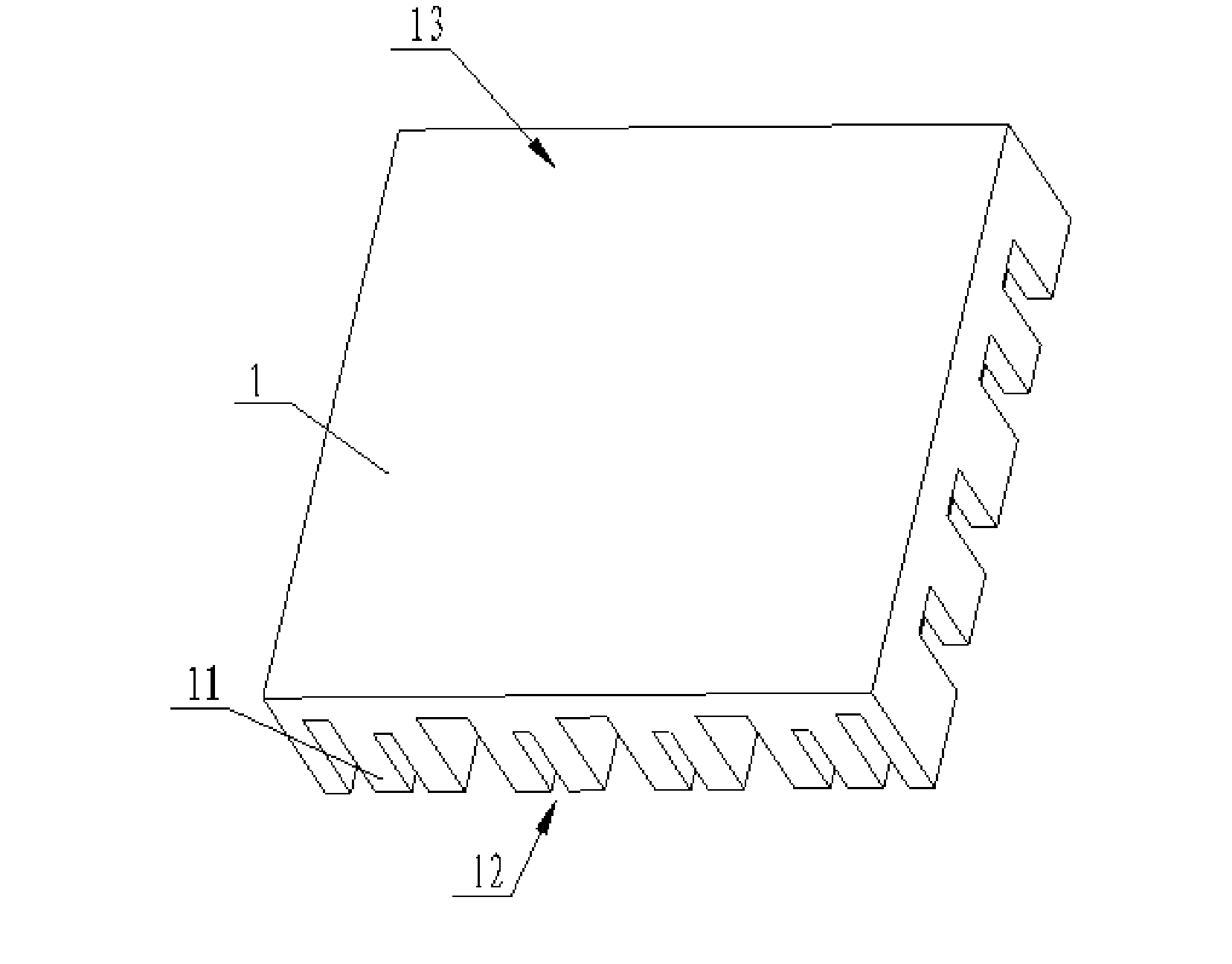

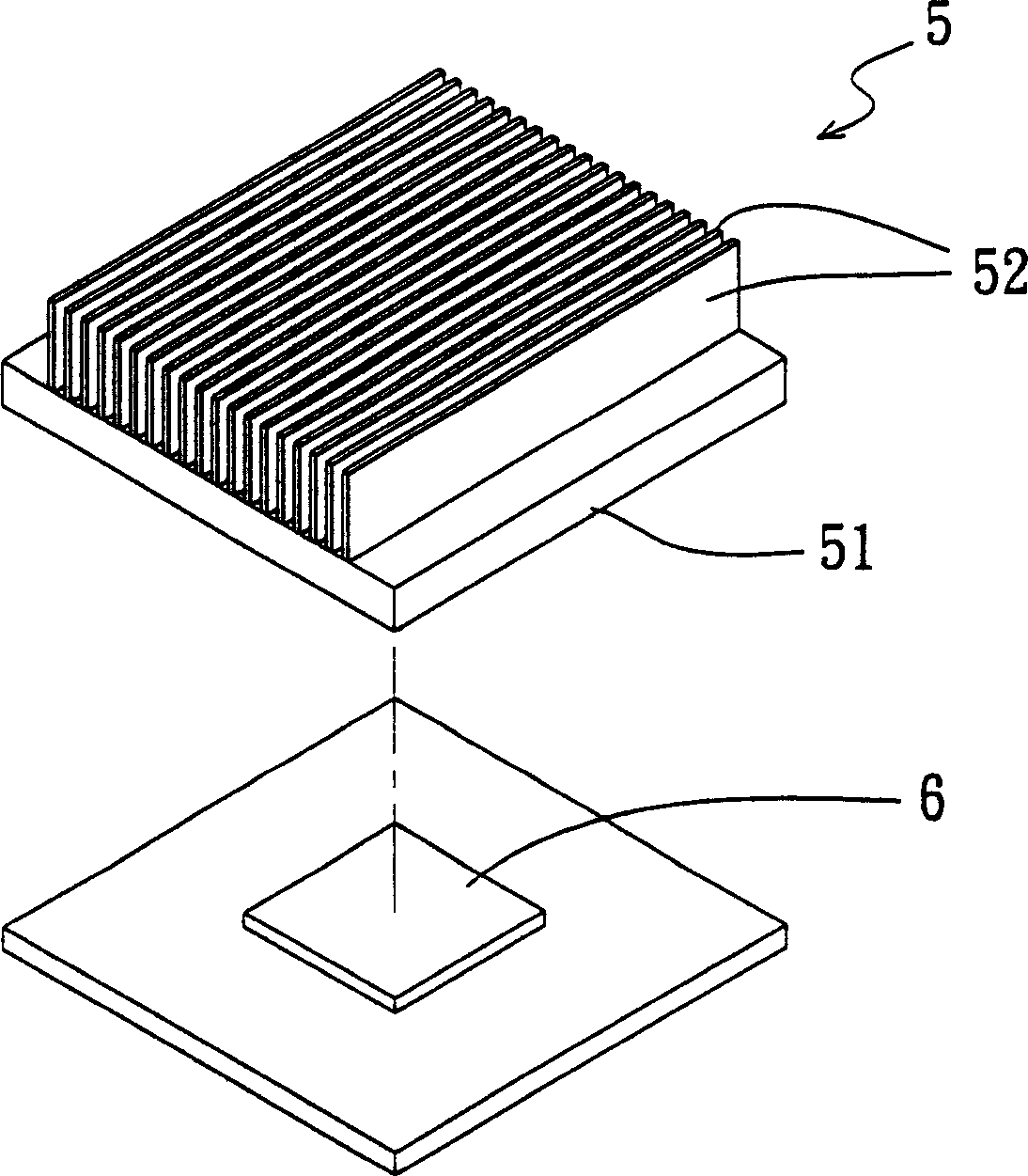

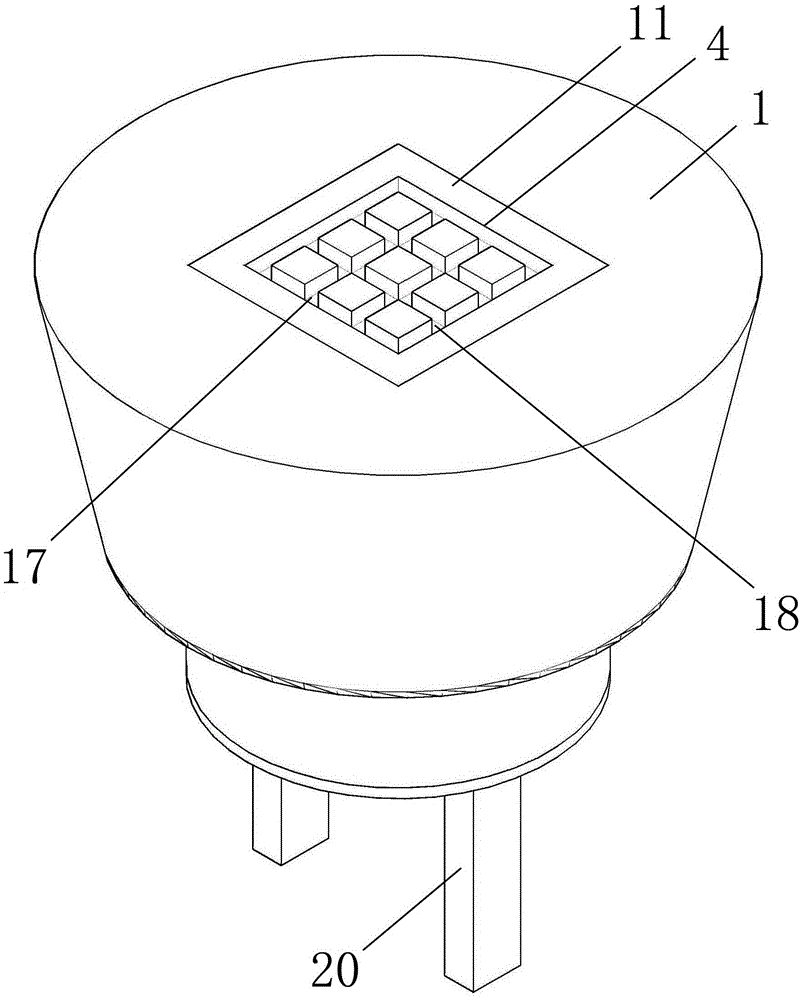

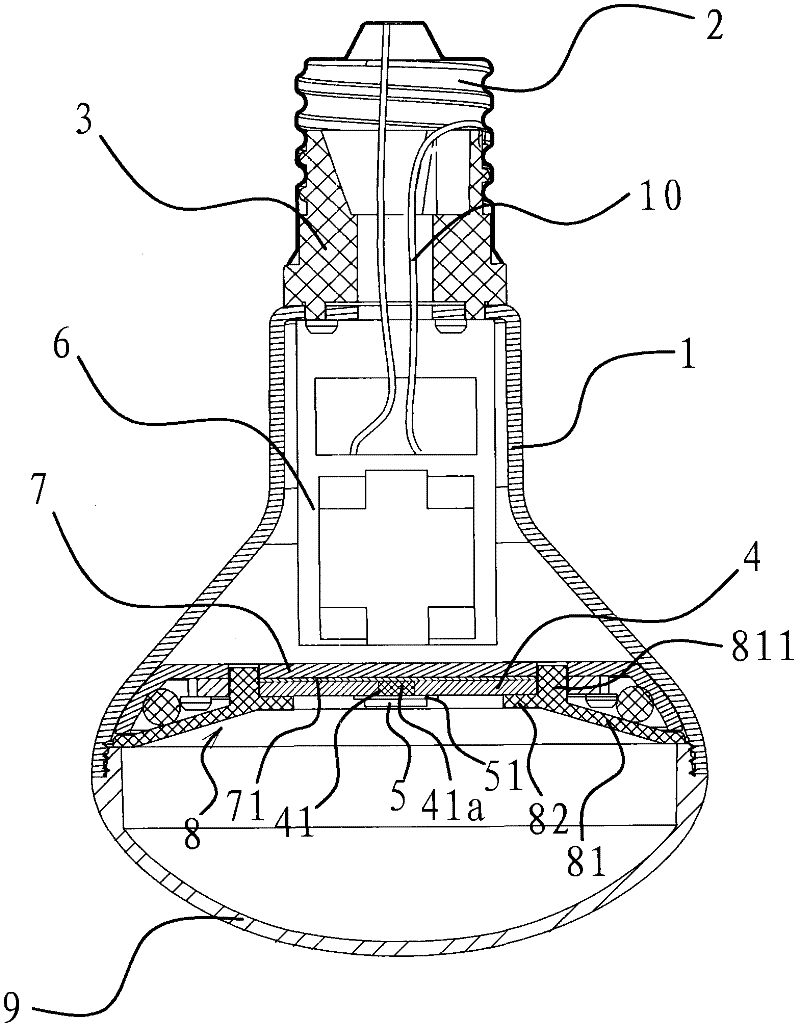

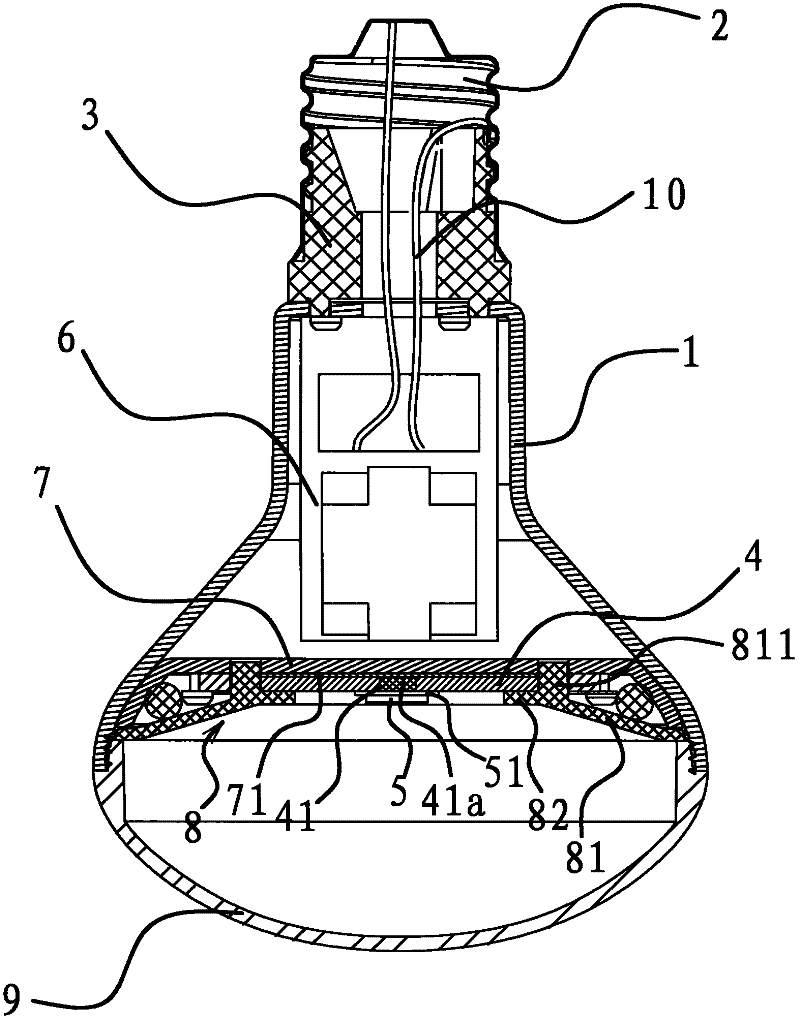

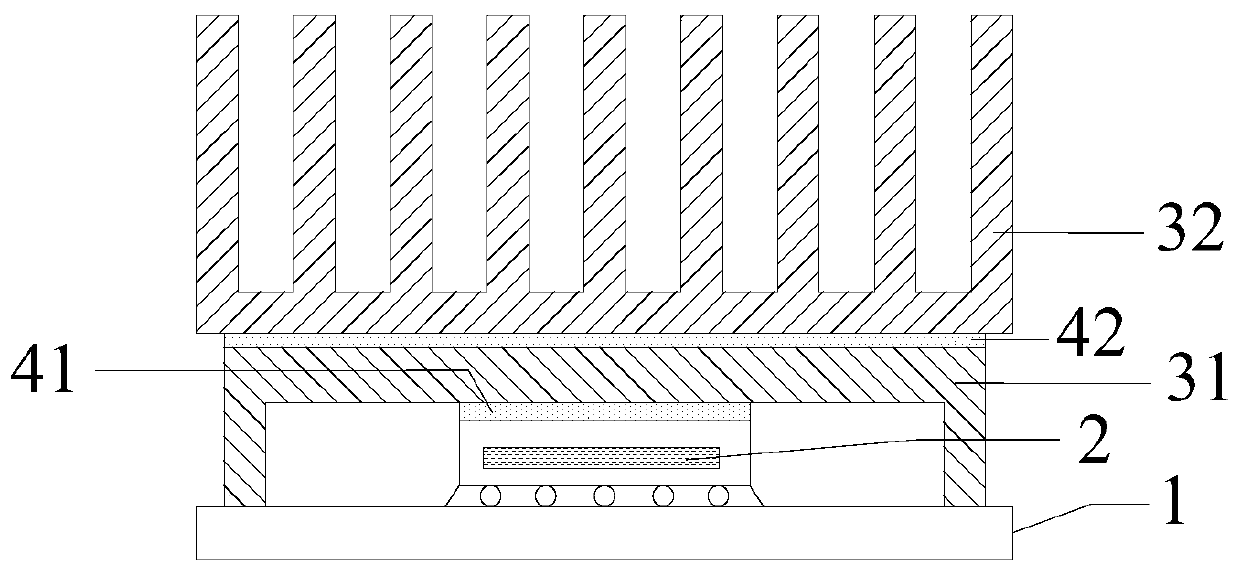

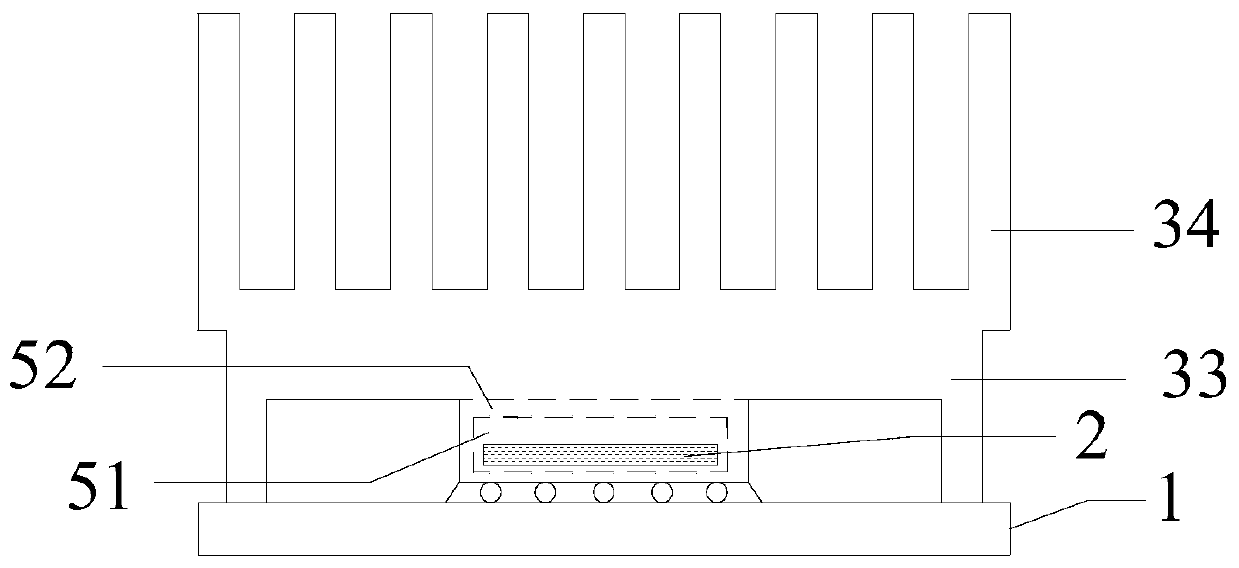

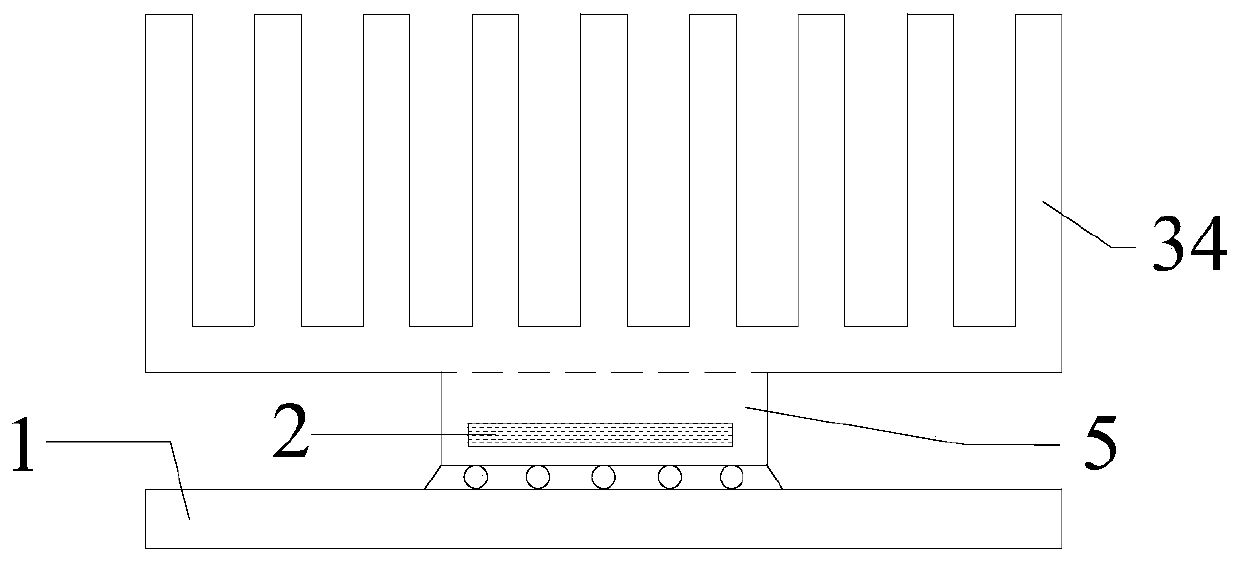

LED light source with heat dissipation device and processing method thereof

InactiveCN101839414AGuaranteed lifeSimple processPoint-like light sourceElectric circuit arrangementsHeat resistanceEngineering

The invention discloses an LED light source with a heat dissipation device and a processing method thereof, relating to an LED light source. The conventional LED light source has low heat dissipation efficiency, large size, heavy weight and more production procedures. The LED light source comprises a base, a plurality of LED chips arranged on the upper surface of the base and an electrode lead-out region which is convenient to connect a driving power supply. The LED light source is characterized in that a convex rib is arranged at the lower part of the base in an extension way, a heat radiation tank is arranged in the middle of the convex rib, an LED chip supporting body is arranged at the upper part of the base, and the heat dissipation device is arranged at the lower part of the base. Differing from an LED light source and heat dissipation device split structure in the prior art, the invention prevents the thermal resistance between the LED light source and the heat dissipation device from generating, greatly improves the heat dissipation efficiency because heat generated during the working process of the LED chips is directly transferred to heat dissipation fins through the base and heat resistance layers, such as an adhesion layer, and the like is not arranged between the LED light source and the heat dissipation device, improves the heat dissipation and the quality of an LED lamp, reduces the size of a lamp body for accommodating LEDs, and can ensure that the product is standardized and serialized, and has less working procedures and high processing efficiency.

Owner:ZHEJIANG MANELUX LIGHTING

Multi-stage no-oil gas compressor

InactiveUS20050193763A1Potential compactnessHigh trafficSolidificationLiquefactionIntercoolerEngineering

Owner:CORAC GROUP

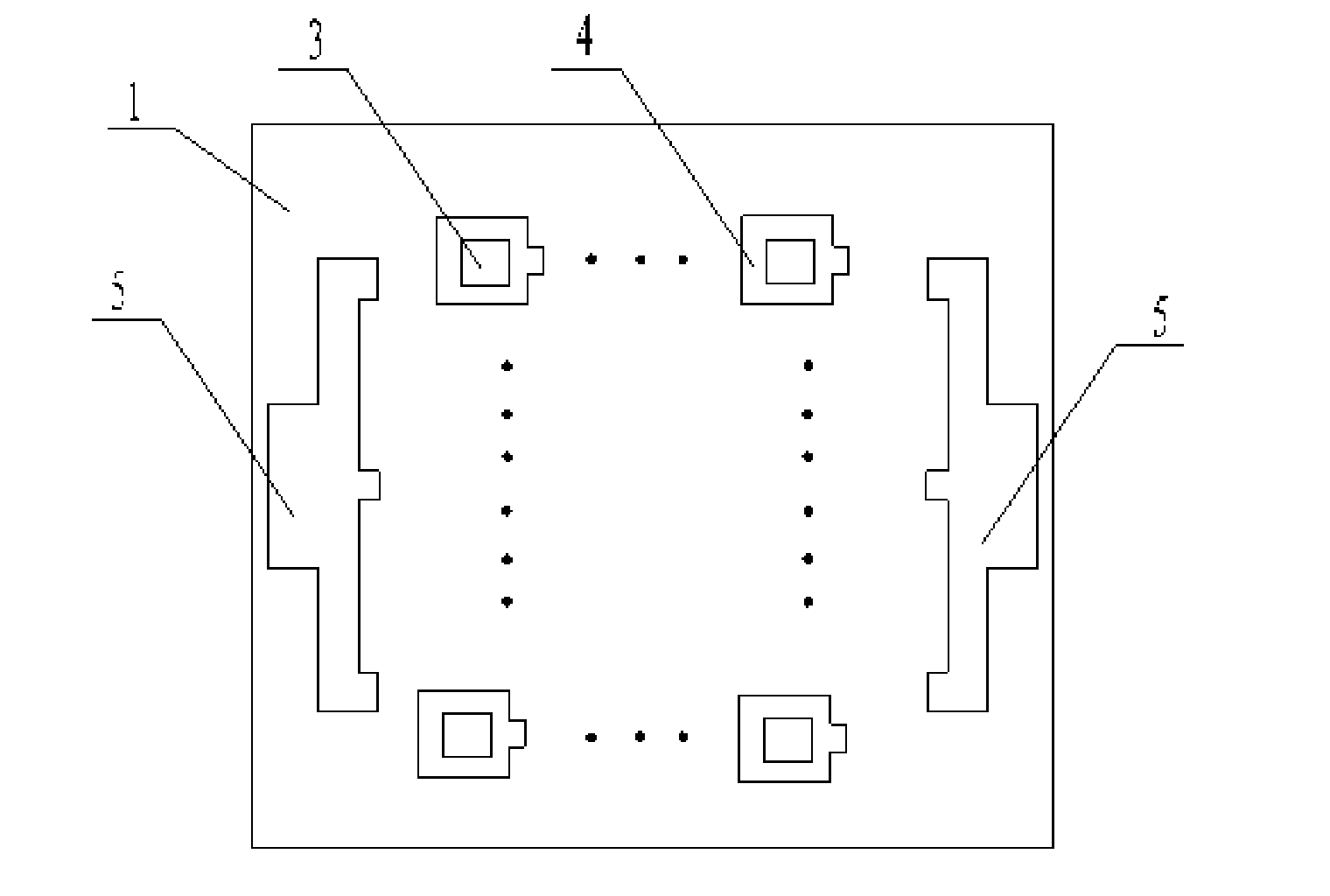

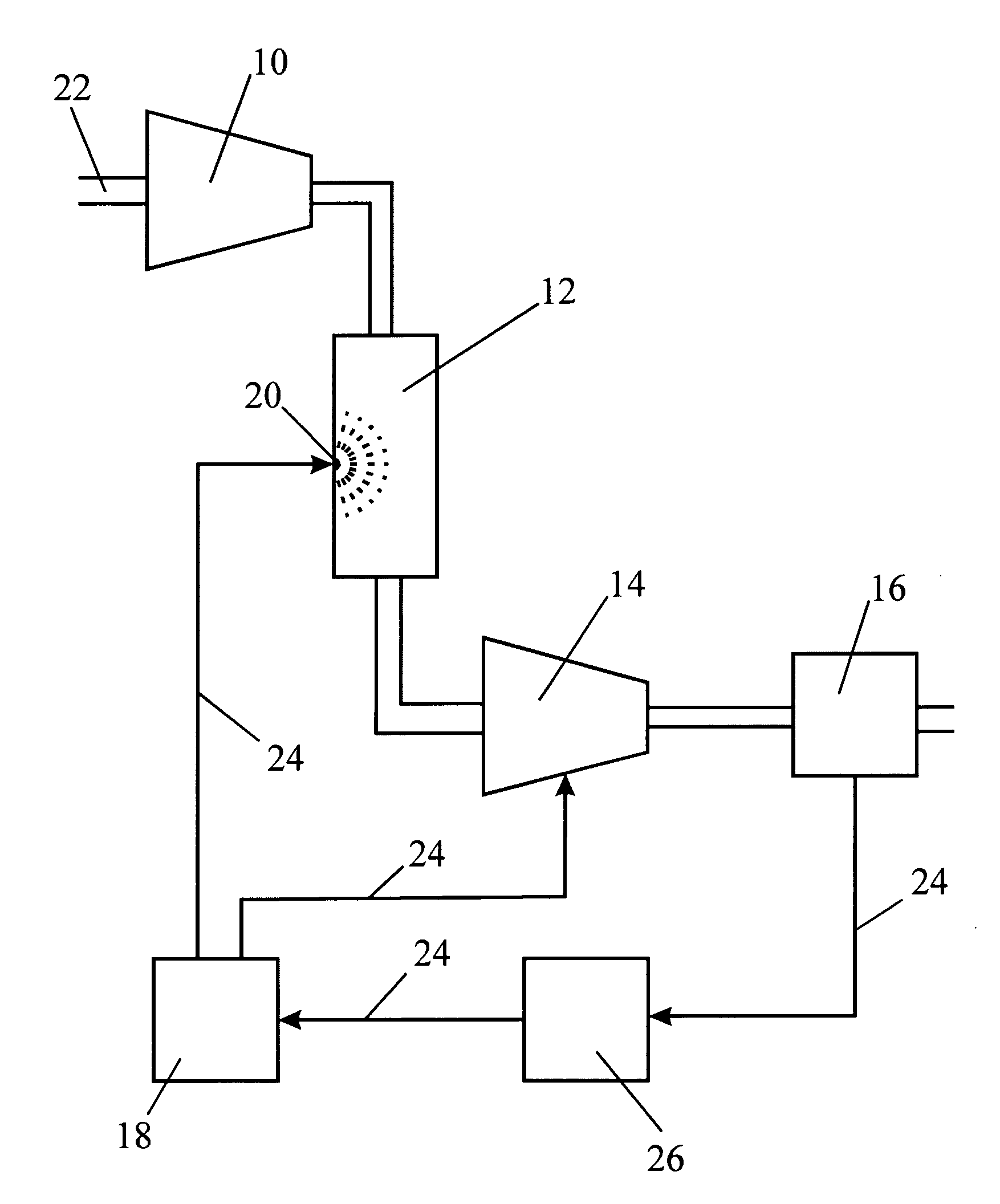

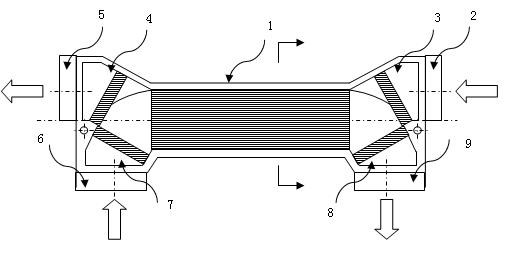

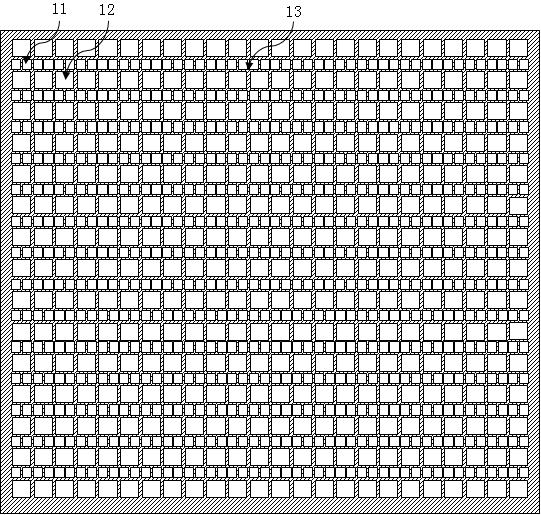

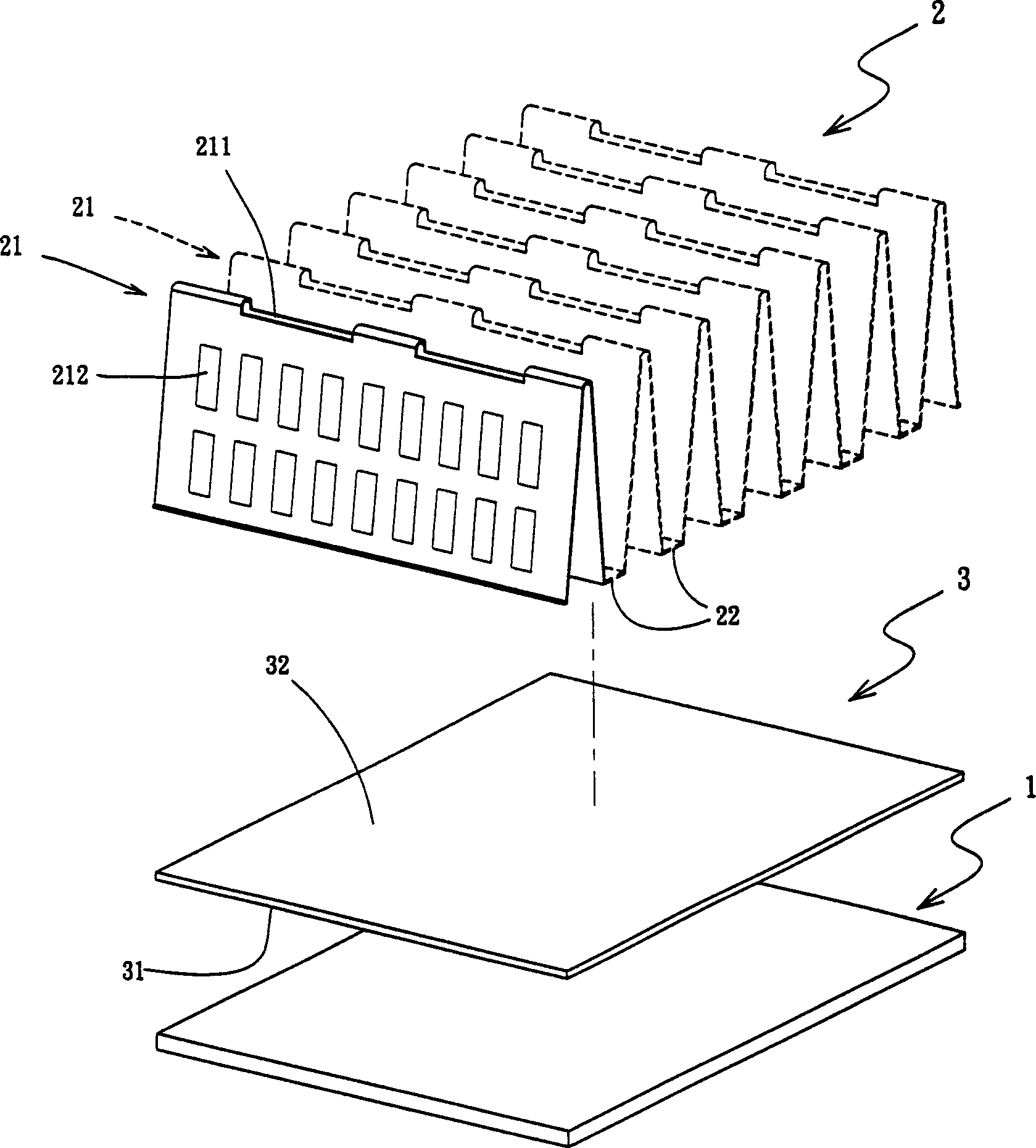

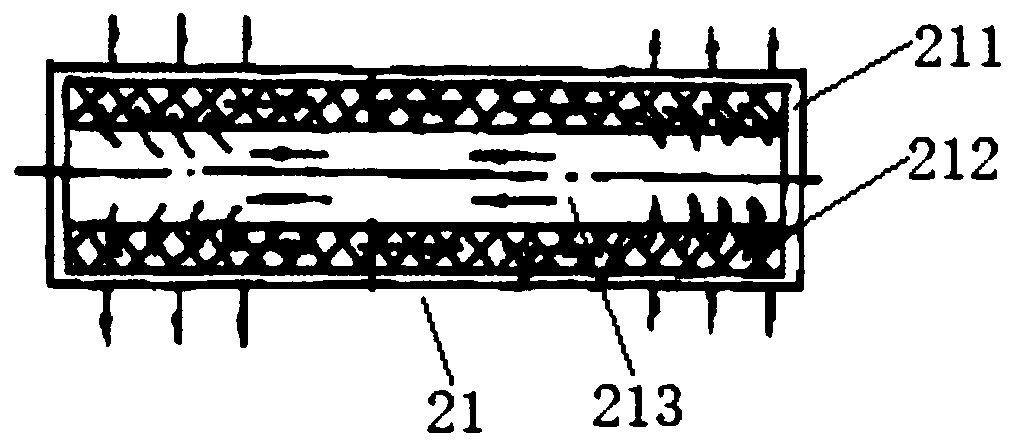

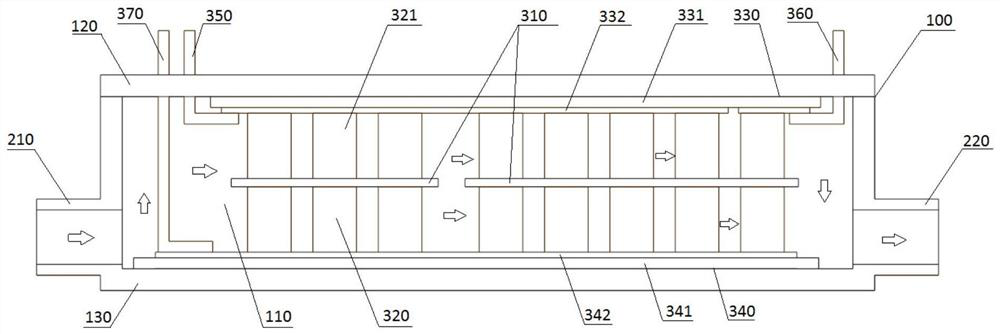

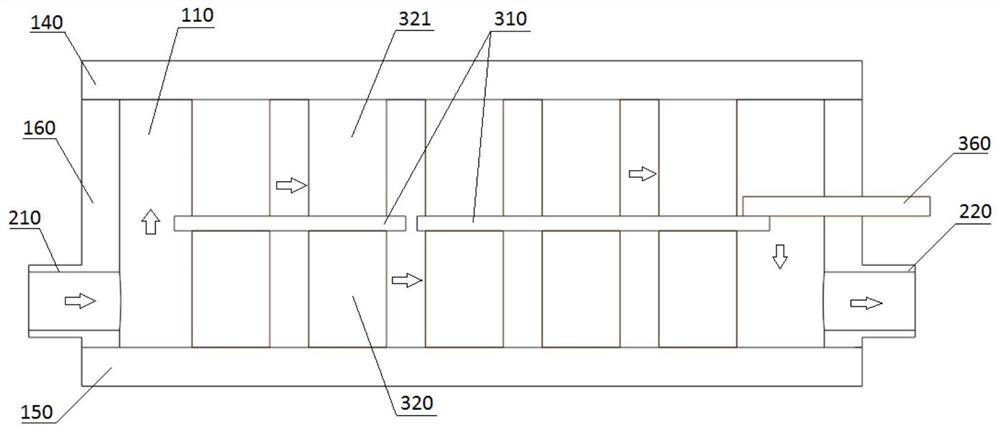

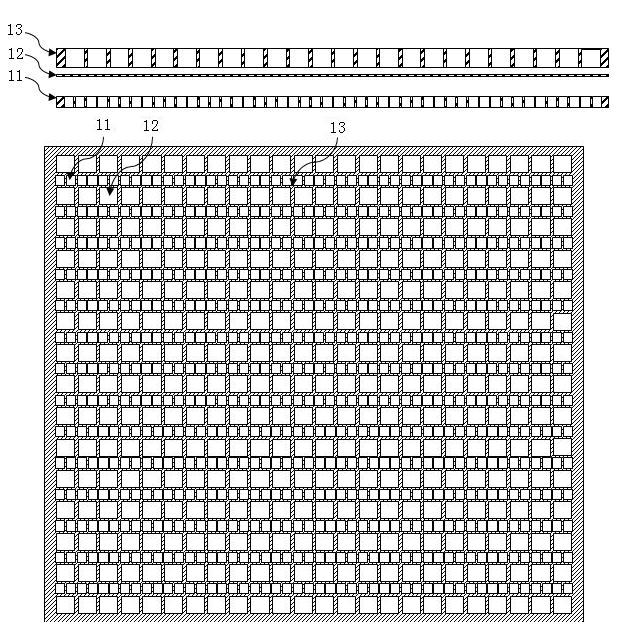

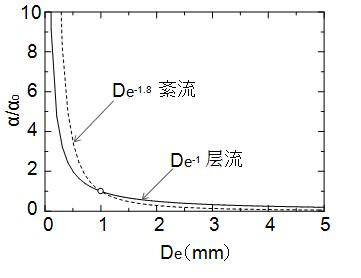

Microchannel heat exchanger

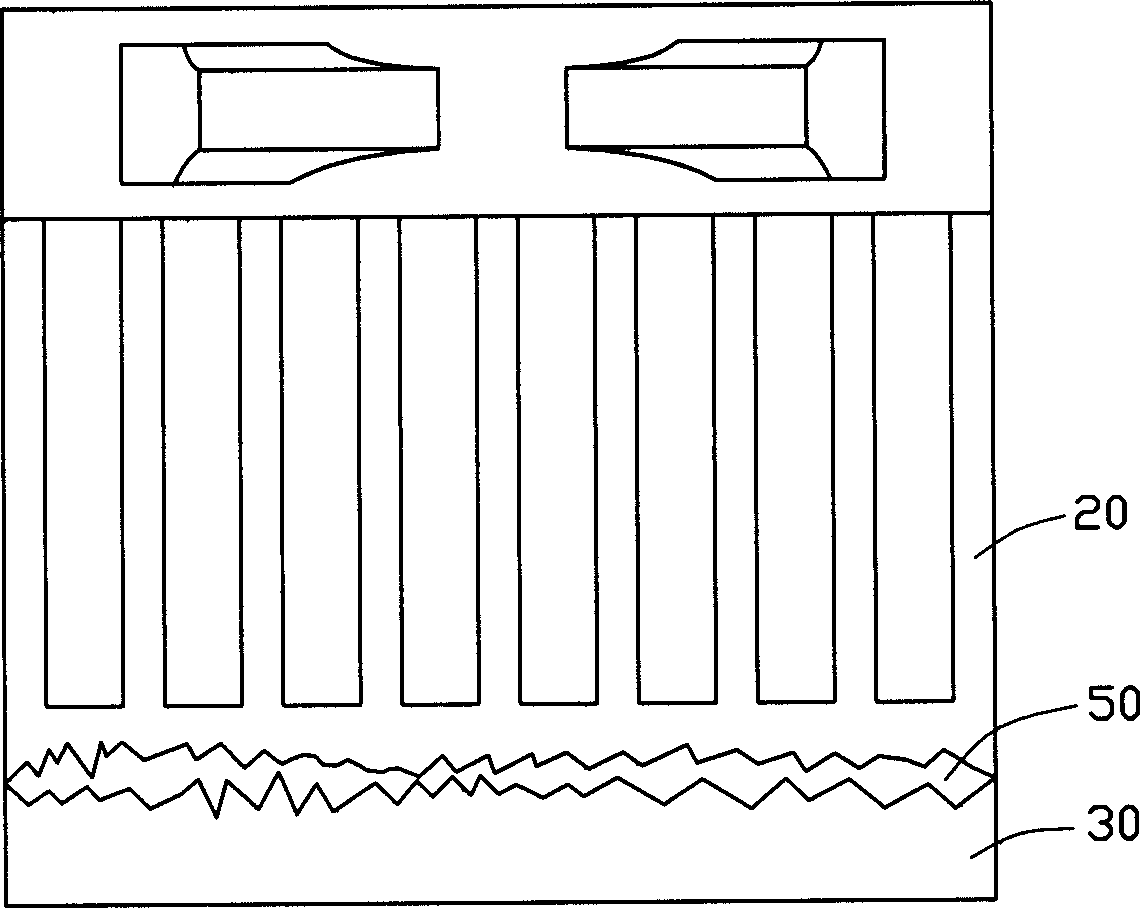

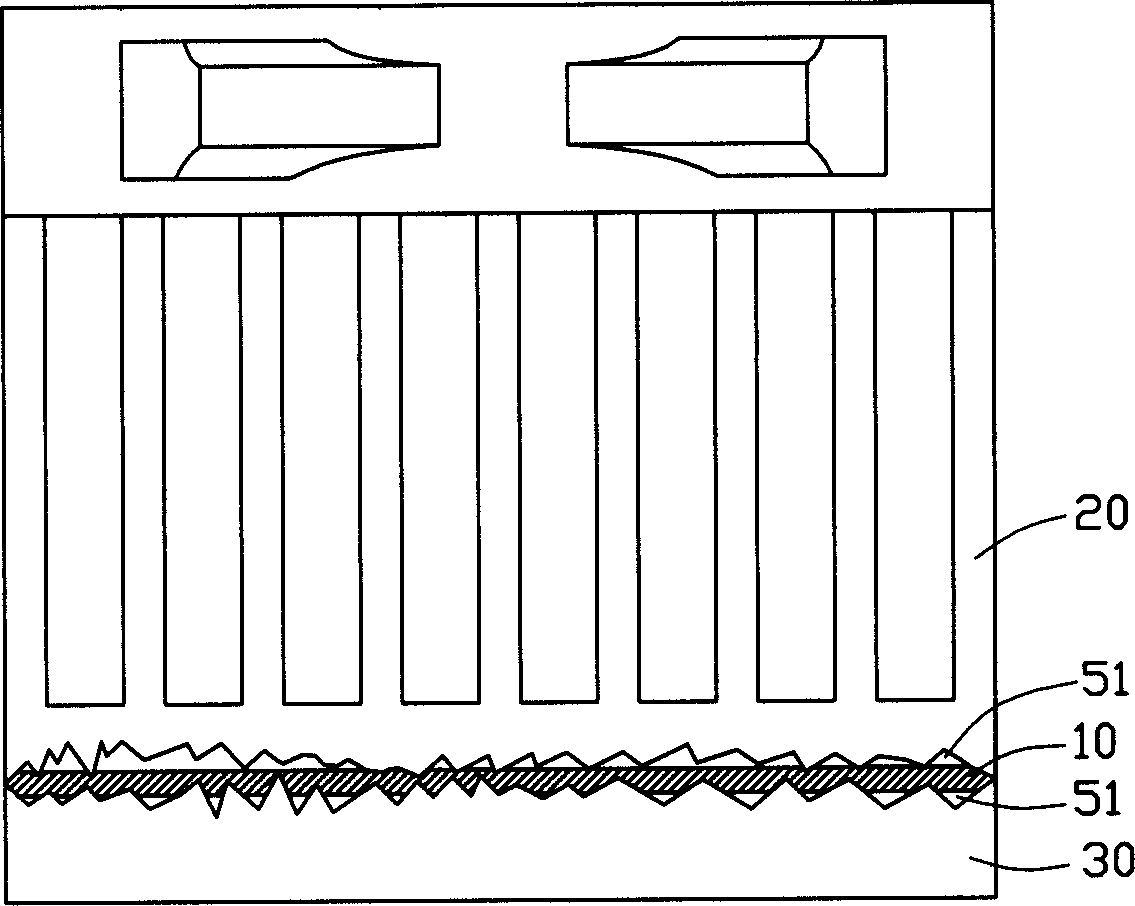

InactiveCN102116545ATaking into account rationalityIncreased forced convection heat transfer coefficientEvaporators/condensersWorking fluidHeat transfer efficiency

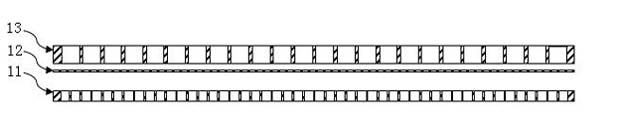

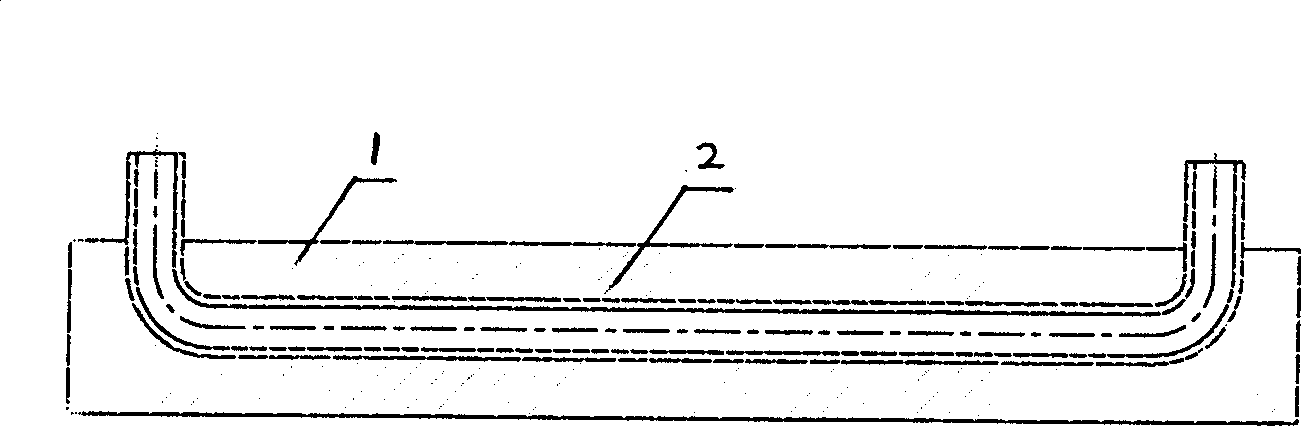

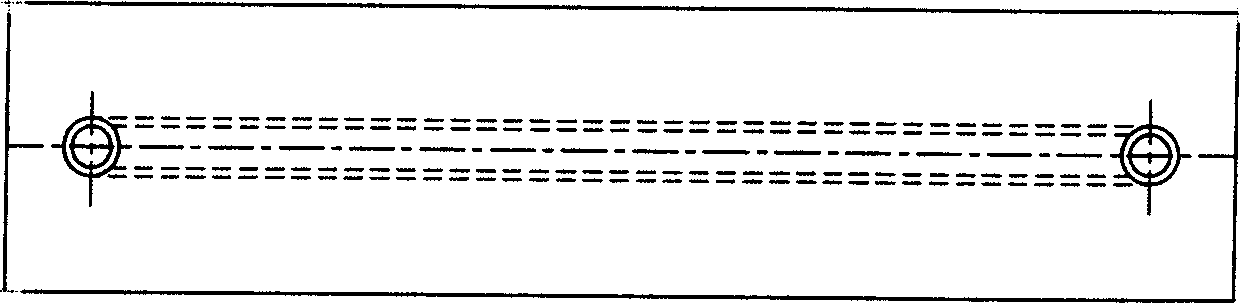

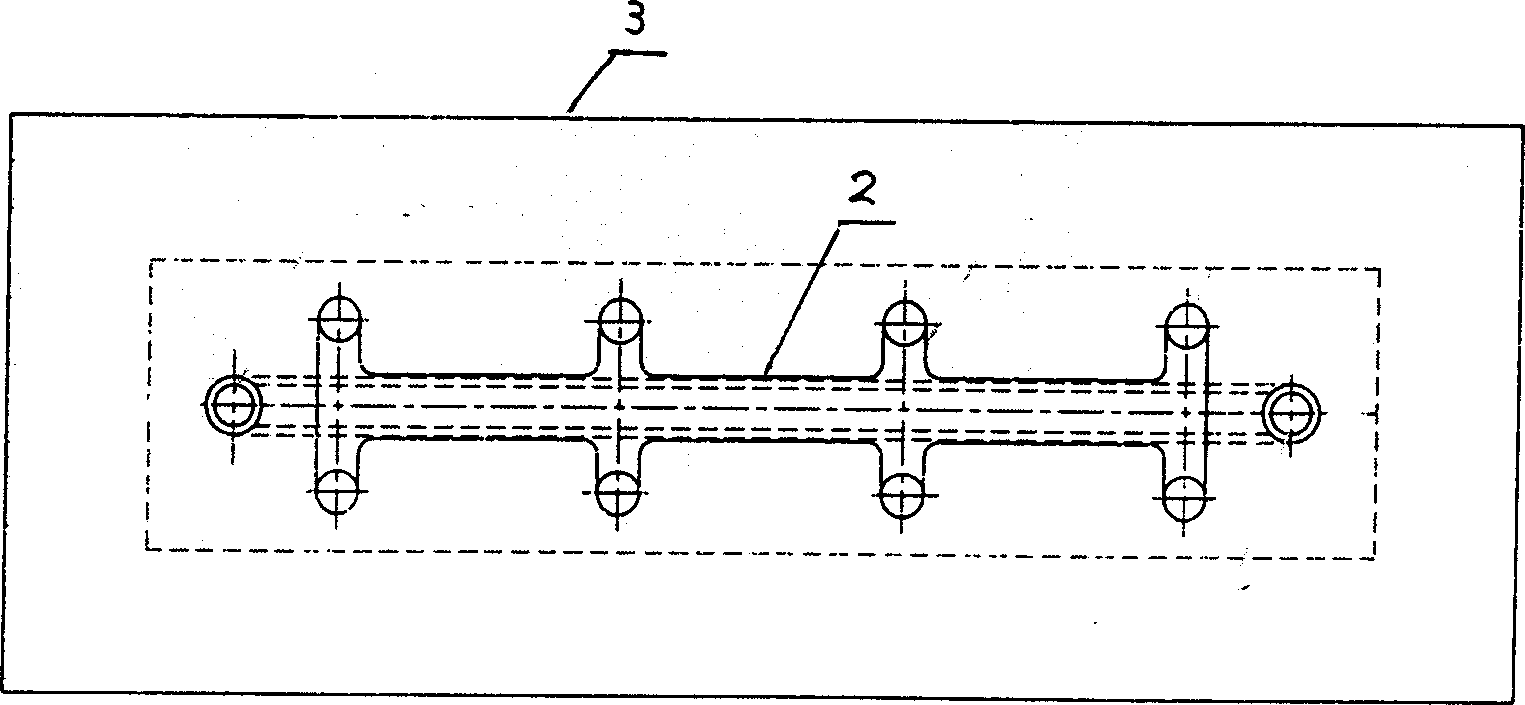

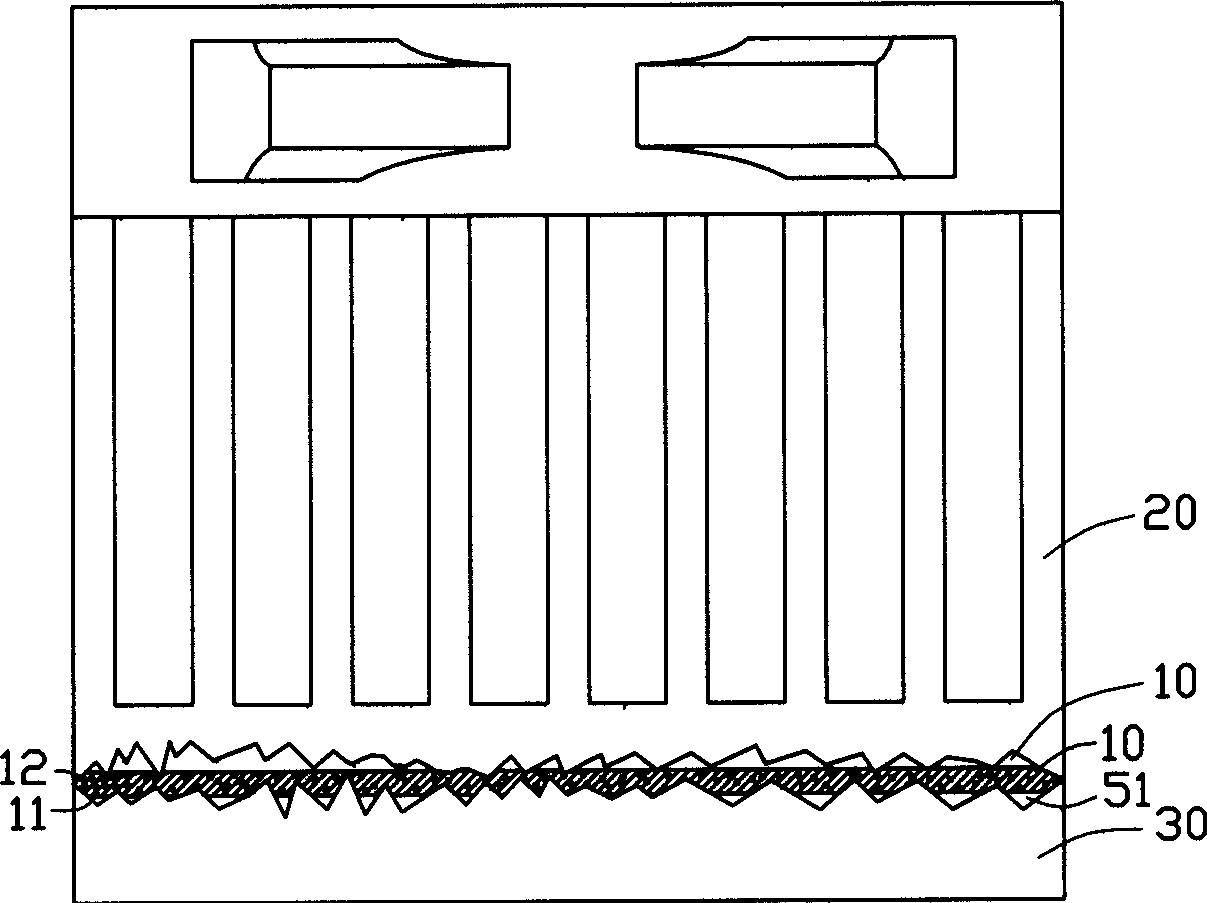

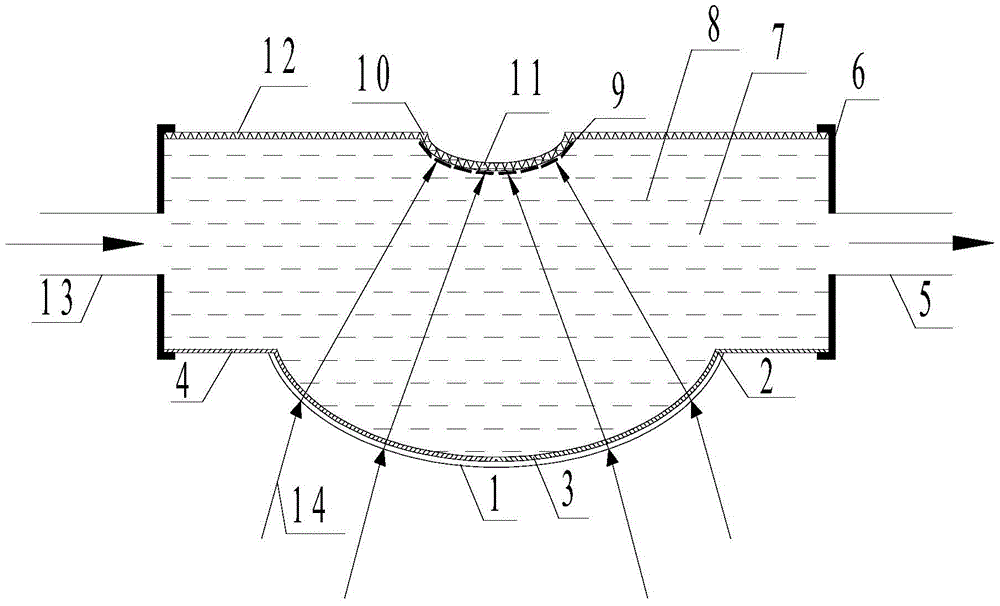

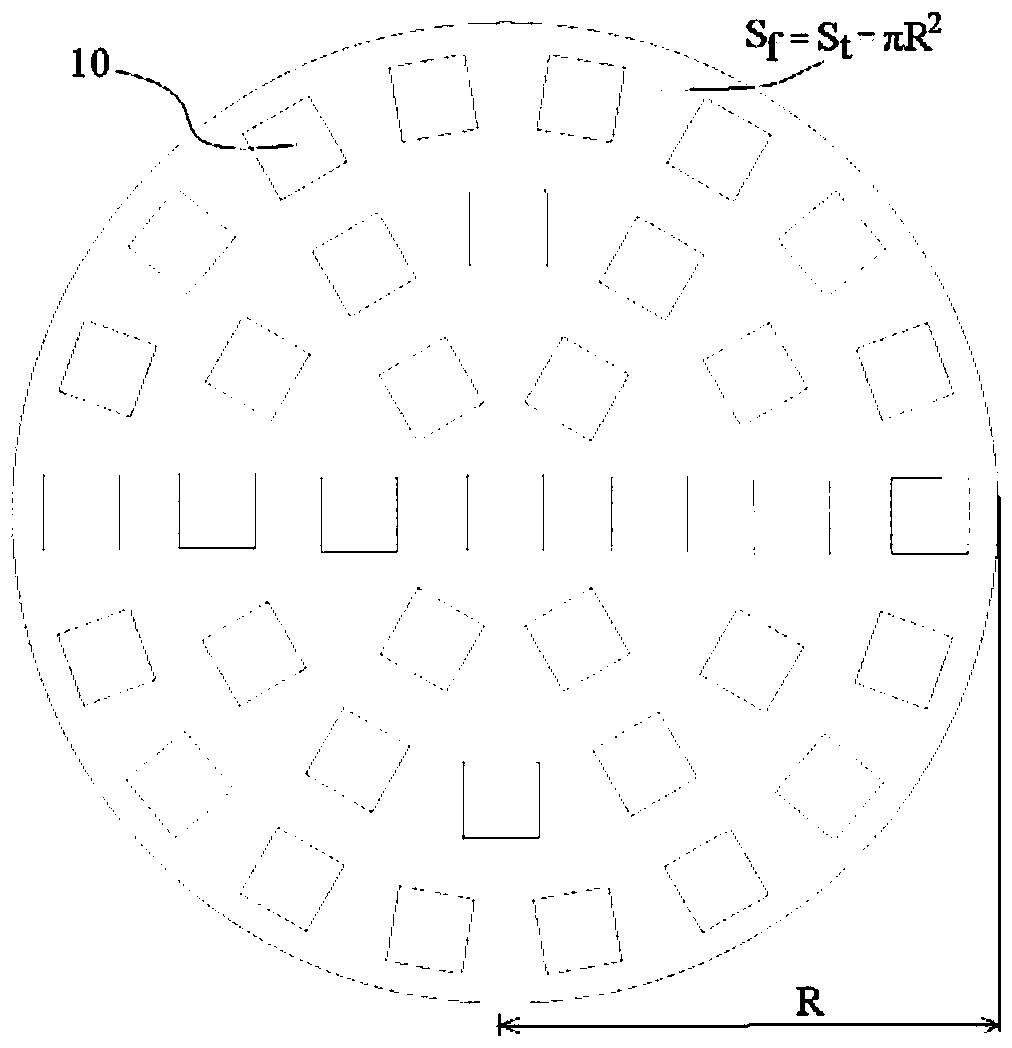

The invention discloses a microchannel heat exchanger belonging to the technical field of heat transfer and heat exchange. The microchannel heat exchanger comprises a fluid channel, wherein a working fluid inlet (2) and a refrigerating medium outlet (9) are molded at one end of the fluid channel, and a working fluid outlet (5) and a refrigerating medium inlet (6) are molded at the other end. A heat exchange segment (1) is arranged in the fluid channel and is formed by alternately superposing a refrigerating medium layer (11) and a working fluid layer (13), the refrigerating medium layer (11) and the working fluid layer (13) are isolated through a baffle plate layer (12), and the refrigerating medium layer (11), the baffle plate layer (12) and the working fluid layer (13) are homogenously bonded. A plurality of parallel microchannels are respectively arranged on the refrigerating medium layer (11) and the working fluid layer (13), the heat exchange units are in homogenous structures, and the ratio of the hydraulic diameter of the microchannels of the refrigerating medium layer (11) to the hydraulic diameter of the microchannels of the working fluid layer (13) is 1:(0.25-15). In the invention, according to the use conditions of the heat pump system, a group of optimized hydraulic diameter values of the refrigerating medium microchannels and the working fluid microchannels are obtained through the heat transfer theory and fluid mechanics calculation and analysis. The heat transfer efficiency of microchannel heat exchanger is higher than that of the traditional heat exchange product.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

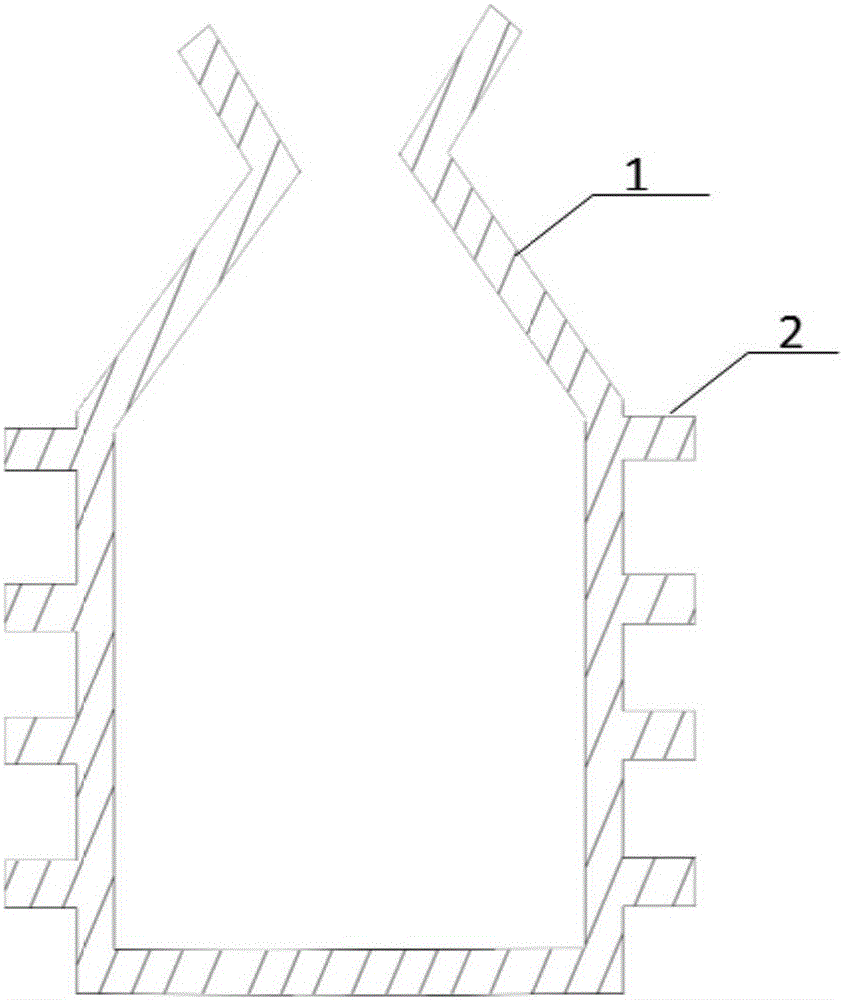

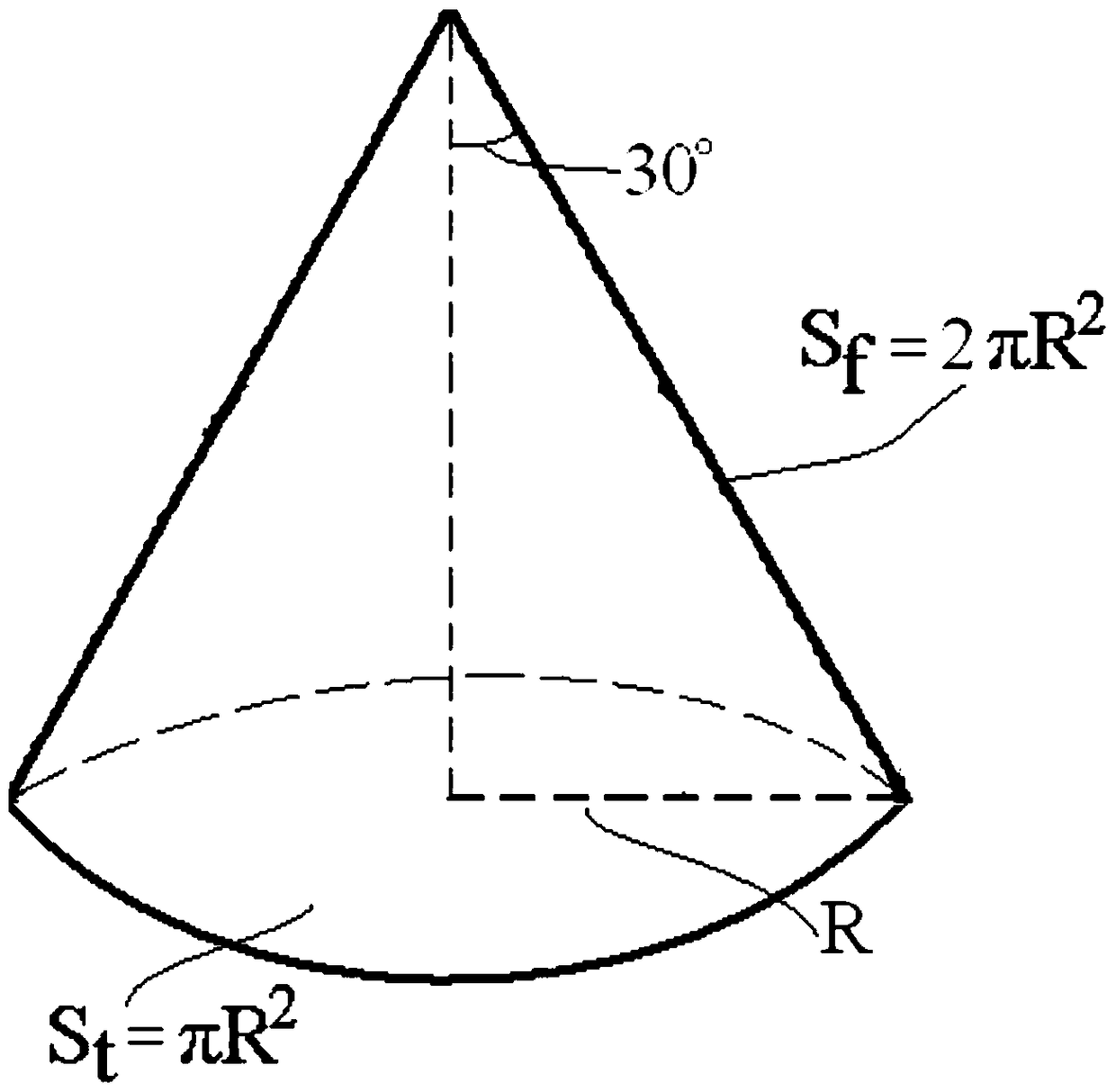

Low thermal resistance cast-iron cooling wall and manufacturing method thereof

InactiveCN1869568AImprove heat transfer efficiencyImprove thermal conductivityFurnace cooling arrangementsCarbon coatingDuctile iron

The invention relates to a new type low thermal resistance cast iron cooling wall. The feature is that the identity material of cooling wall is nodular cast iron or gray cast iron and the cooling water channel in cooling wall is made up from pure copper. The clearance between the cooling wall identity and the outer wall of pure copper pipeline is below 0.1mm. The manufacture method includes the following steps: fixing the molded pure copper pipeline into the sand box; casting by molten iron of nodular cast iron or gray cast iron, and taking inertia vapor cooling to copper pipeline to molding. The invention eliminates the thermal resistance caused by anti seepage carbon coating layer to make the heat exchange efficiency sharply increase and prolong the useful life of cooling wall.

Owner:NANJING NANGANG IND DEV CO LTD

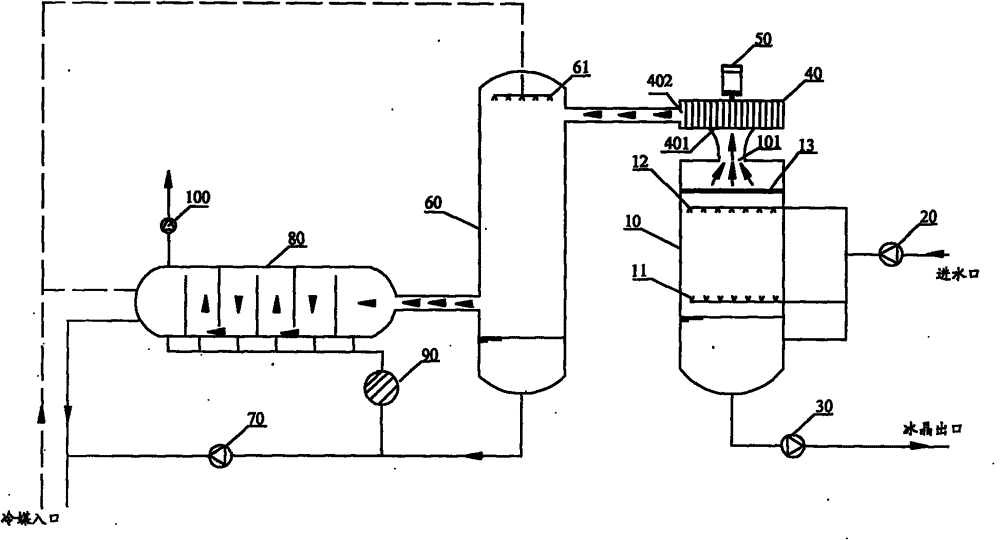

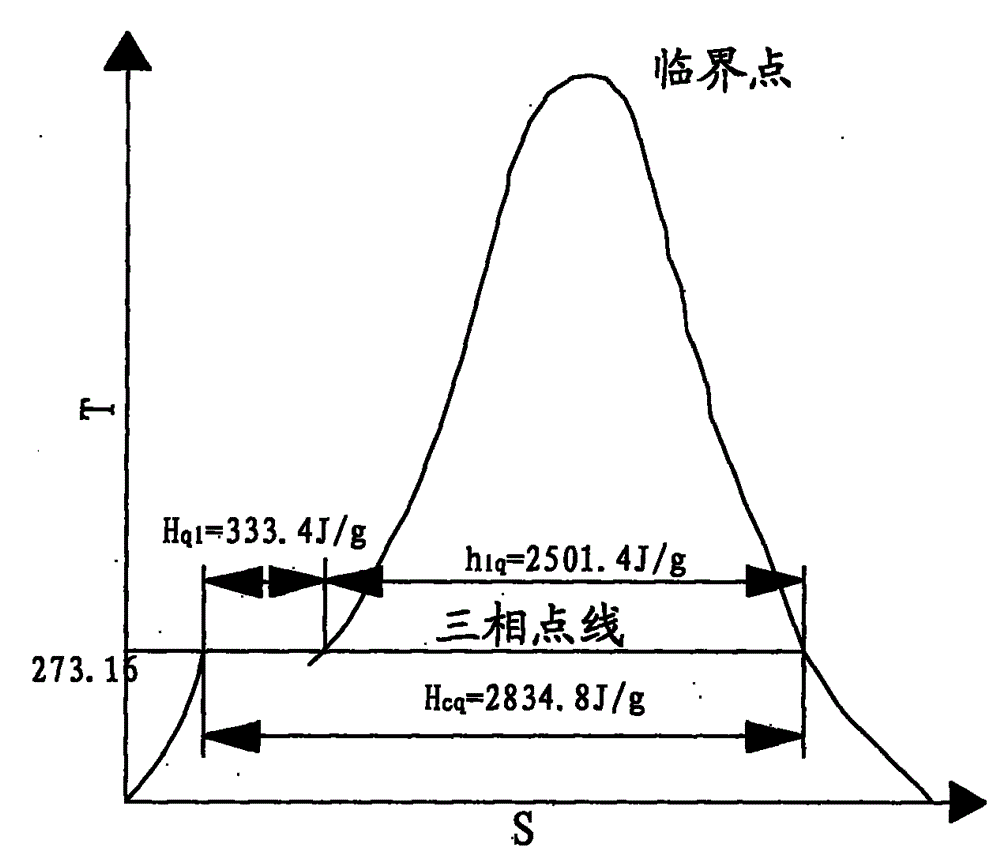

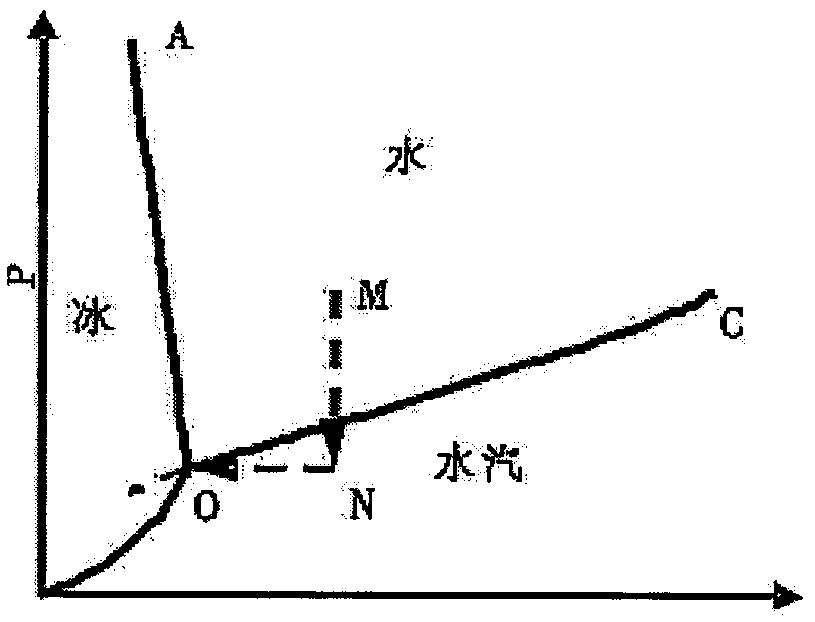

Hydroenergy vaporization ice-making device and control method thereof

InactiveCN103822420AInhibition formationIncrease productivityDomestic cooling apparatusLighting and heating apparatusIce waterWater vapor

The invention discloses a hydroenergy vaporization ice-making device which comprises an ice crystal generator, an ice water pump and an ice crystal pump, wherein an ice water nozzles, vaporization nozzles and a water baffle grid are arranged inside the ice crystal generator; the ice water nozzles are arranged at the lower part of the ice crystal generator; the vaporization nozzles are arranged at the upper part of the ice crystal generator; an exhaust opening is further formed in the ice crystal generator and is used for exhausting vapor generated after the water inside the ice crystal generator is vaporized; the absolute pressure inside the vaporization is 611 Pa; the ice water pump is respectively connected with the lower part of the ice crystal generator, the ice water nozzles and the vaporization nozzles, and is used for pumping ice water into the ice crystal generator; the ice crystal pump is connected with the ice crystal generator and is used for sucking out a mixture of ice crystals and water generated in the ice crystal generator. The invention further provides a control method of the hydroenergy vaporization ice-making device. By the adoption of the device, not only is the ice blocking phenomenon avoided, but also the phenomenon of thermal resistance of ice layers is eliminated.

Owner:SHENZHEN CHILLING POOL AIR CONDITIONING

Heat conductor and its complex machining process

InactiveCN1469219AEliminate thermal resistanceImprove heat transfer efficiencyDigital data processing detailsSemiconductor/solid-state device detailsHeat resistanceHeat conducting

The complex machining process of heat conductor includes making the first heat conducting element and at least one second heat conducting element, pressing the second heat conducting element for jointing to the first heat conducting element, and heating the contact surface between the two heat conducting elements while hot forging to form the complex heat conductor. The heat conductor may be used in heat transmitting, heat conducting and heat dissipating assembly in 3C product, and can eliminate heat resistance and raise heat conducting efficiency.

Owner:简鹏

Sapphire printed circuit board LED lamp and manufacture method thereof

ActiveCN104613379AAchieve preparationImprove cooling effectNon-electric lightingPoint-like light sourceLight guideComputer module

The invention relates to a lamp, in particular to an LED lamp with an efficient heat dissipation function. The LED lamp comprises a shell, a light guide module and a light-emitting module; the light guide module and the light-emitting module are fixedly arranged in the shell and are both with heat dissipation structures; the light guide module comprises a first sapphire substrate and a reflecting layer, and the light-emitting module comprises a second sapphire substrate, a light filtering layer, a metal conducting layer, a light-emitting module group and a transmission enhanced layer. The sapphire printed circuit board LED lamp and the manufacture method thereof have the advantages that a sapphire printed circuit board LED lamp with the efficient heat dissipation function, die bond, wire bonding and dispensing are conducted on the sapphire printed circuit board directly through arranging the heat dissipation structures on the sapphire printed circuit board, and the manufacture of the LED light-emitting module is achieved, so that thermal resistance generated from cemedin which is used in traditional printed circuit boards is eliminated, and heat dissipation efficiency is improved; light filtering layer is arranged on the printed circuit board, so that luminous flux of the light-emitting module group is guaranteed, light leak is prevented, and the light is kept in a highlighting mode; the structure is simple, and the cost is low.

Owner:DONGGUAN BRIGHT LED ELLECTRONICS LTD

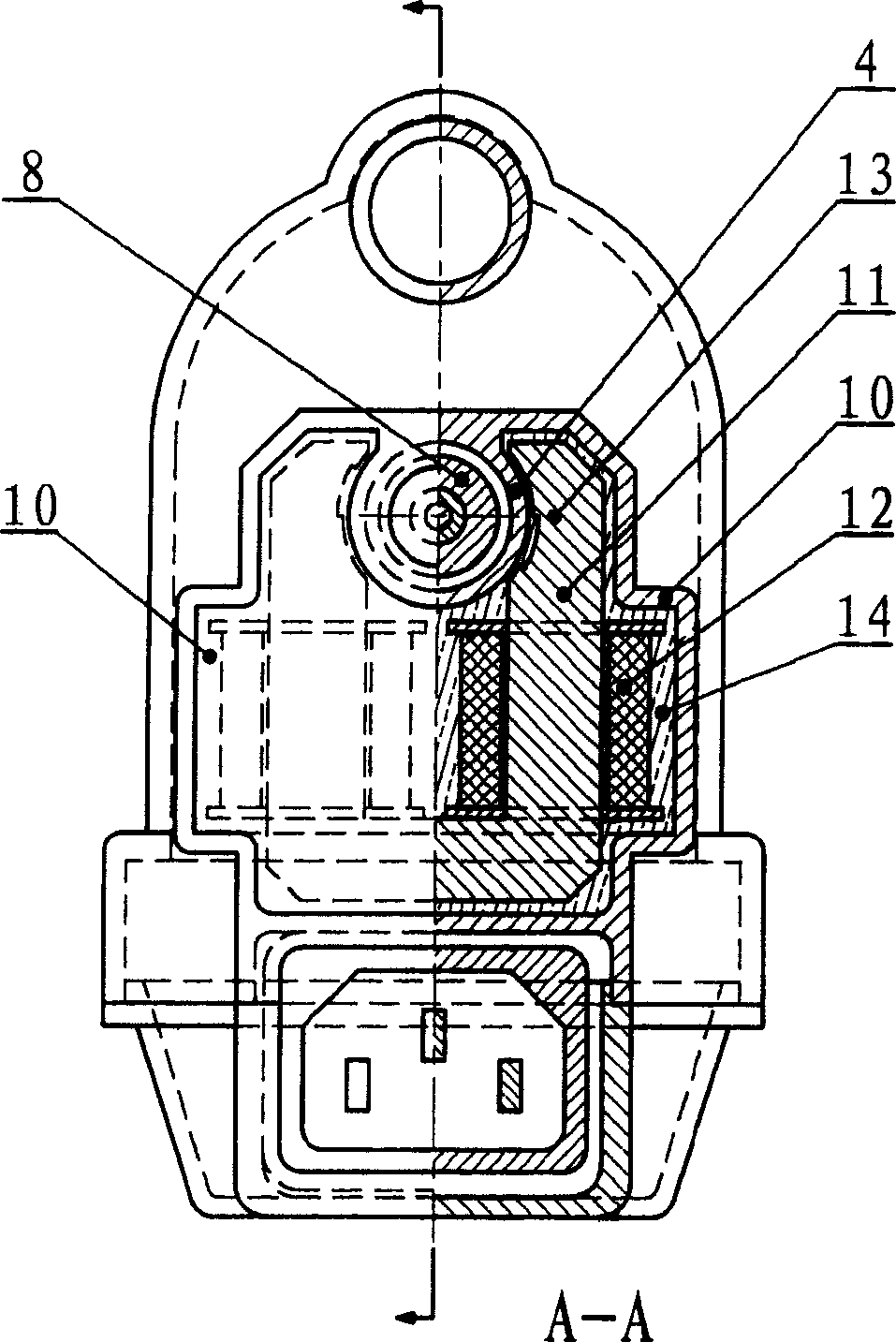

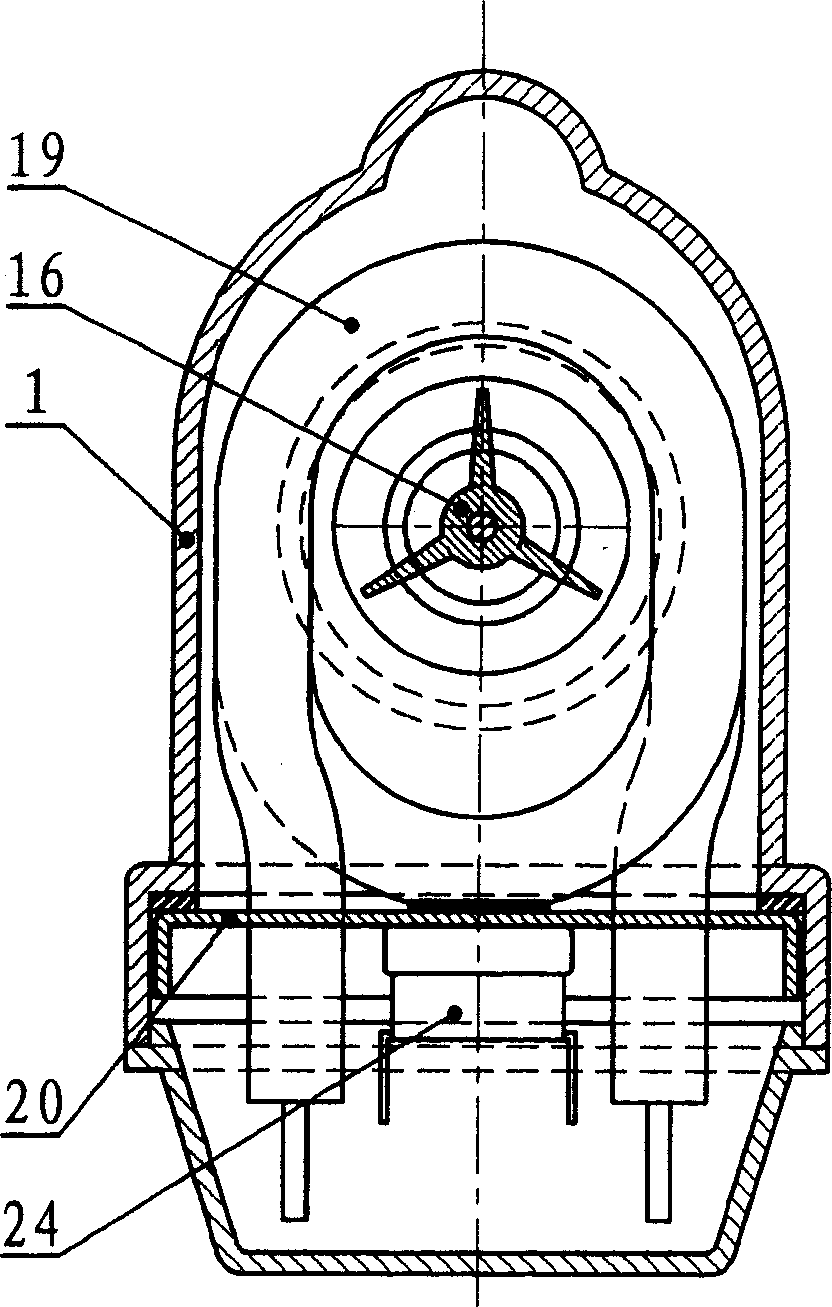

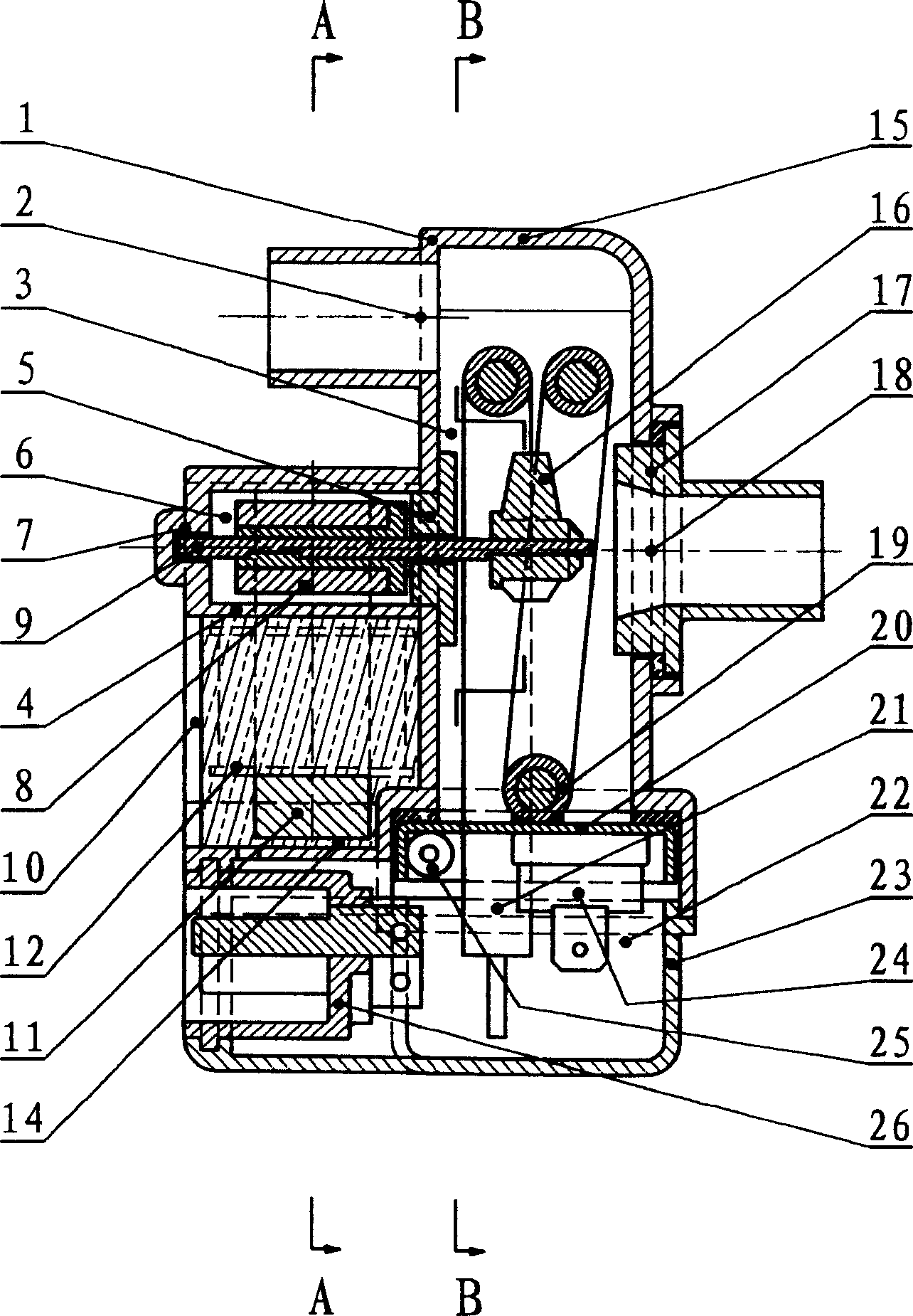

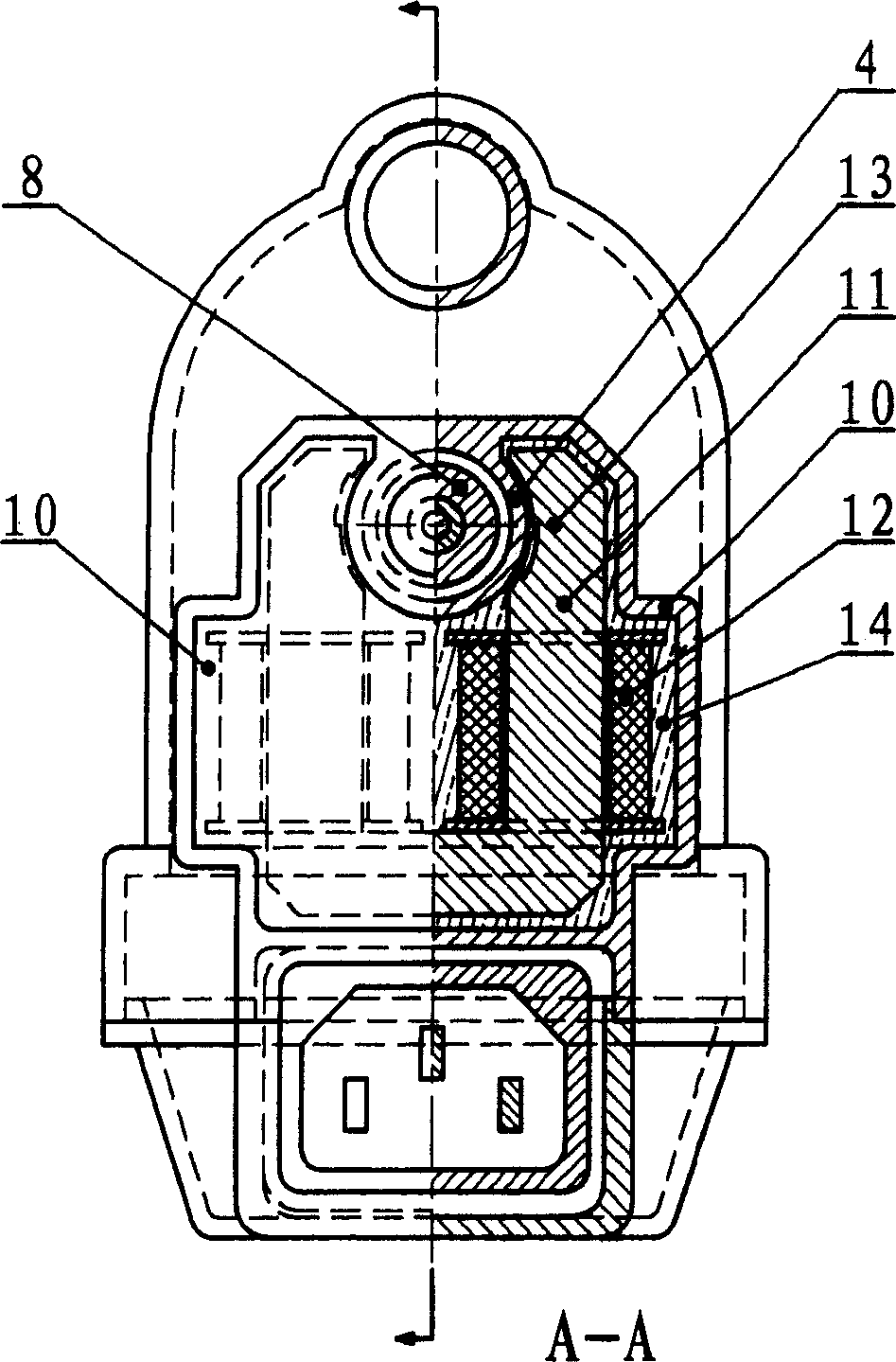

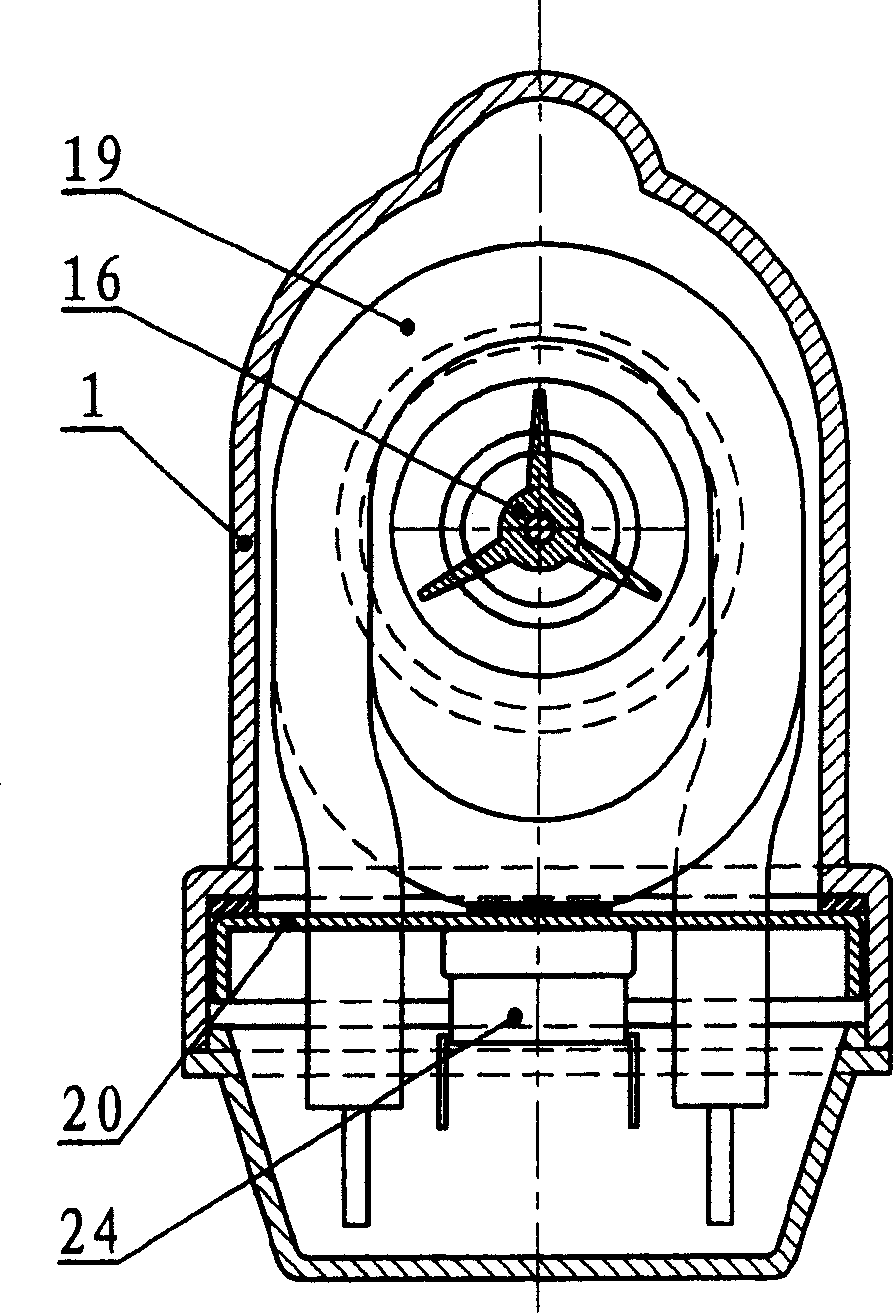

Circular preheater of permanent magnet rotary pump in single cavity, and assembly method

ActiveCN1760535ASmall footprintSmall sizeMachines/enginesEngine startersPermanent magnet rotorImpeller

A circulating preheater with single cavity permanent magnet rotor ( PMR ) pump is featured as preparing cavity body rotor and cavity shell by plastic injection molding for setting then in one body or one body connected structure ; setting outlet , front head opening , electro thermal tube ( ET ) opening at bottom and separated stator slot on cavity body ; installing PMR , front hearing and impeller in rotor or heating cavity from front head opening ; installing ET spiral portion in heating cavity from its own opening ; filling and sealing stator in stator slot ; setting temperature sensing component on external side surface of ET fixture disc and setting junction box below ET fixture disc and stator slot . The ET should be installed first when assembling operation is carried out.

Owner:青岛快乐电气有限公司

Cooling and heating cup holder

InactiveUS20140069114A1Eliminate thermal resistanceReduce heat lossVehicle arrangementsMachines using electric/magnetic effectsEngineeringConductive materials

Owner:HYUNDAI MOTOR CO LTD

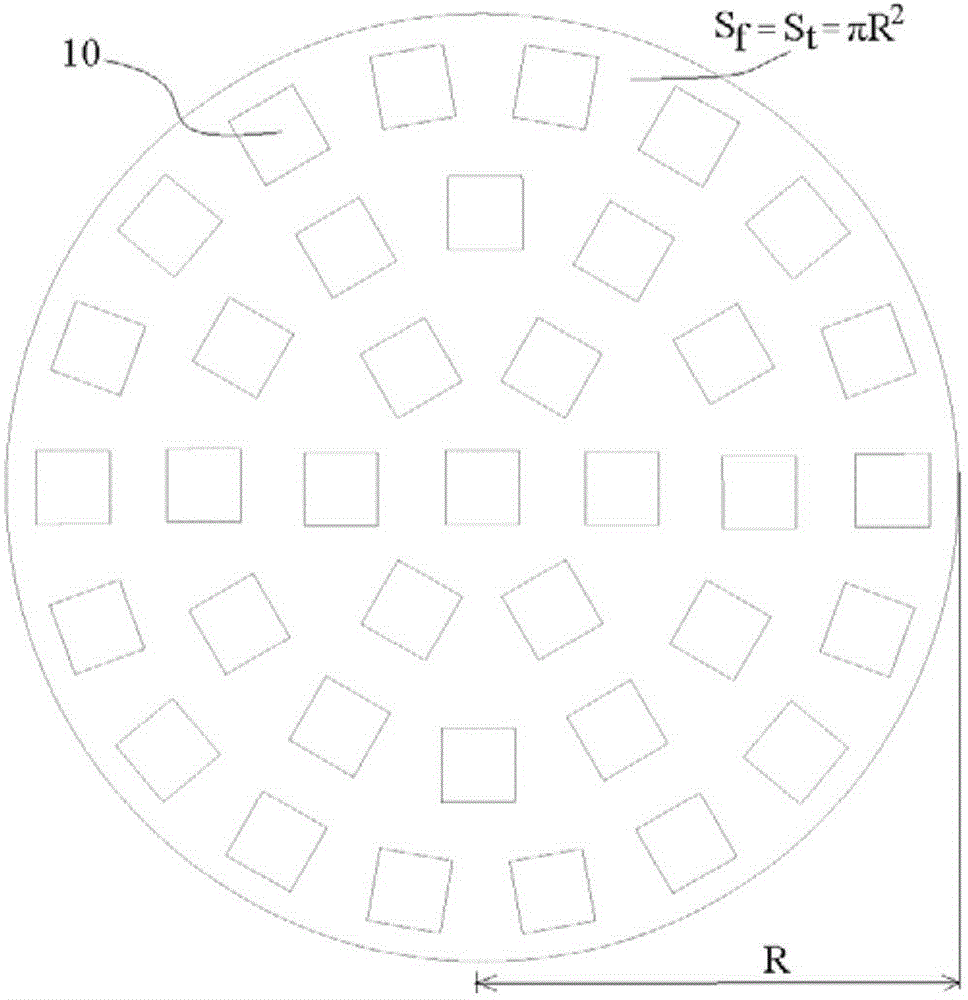

Fired mold precision casting method for improving solidification heat dissipation conditions of directional solidification casting

ActiveCN105033180ASpeed up coolingImprove performanceFoundry mouldsFoundry coresCrystal structureSingle crystal

The invention belongs to the technical field of precision casting of directional solidification column crystal or single crystal test bars, and relates to a fired mold precision casting method for improving solidification heat dissipation conditions of a directional solidification casting. In the directional column crystal or single crystal test bar manufacturing process, selected mold shell materials are the same as universal mold shell materials. The shape of a mold shell is changed, the equal-distance variable cross section is increased, and a plurality of equal-distance rectangular grooves are formed. When the directional solidification test bars and the mold shell move to the position below a heat insulation plate together, mechanical expansion rings arranged in a directional solidification furnace are inlaid in the equal-distance rectangular grooves of the mold shell; the mechanical expansion rings expand downwards to remove the part, below the grooves, of the mold shell; the lower end of the directional solidification casting is in direct contact with cooling media, so that the heat exchange conditions of the directional solidification test bars and the cooling media are improved; and therefore, the cooling speed of the directional solidification casting and the temperature gradient of a solid-liquid interface are greatly improved, the dendritic crystal structure of the directional solidification casting is refined, dendritic segregation is reduced, and the mechanical property of the casting is remarkably improved.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Thermal interface material

InactiveCN1715361AImprove thermal conductivityFast heat conductionSemiconductor/solid-state device detailsSolid-state devicesHeat conductingHeat resistance

The thermal interface material includes gap filling fluid and metal particle dispersed in the fluid and capable of reacting with air. The particle capable of reacting with air is nanometer level particle. Inside the thermal interface material, the metal particle reacts with air in the interval of the heat source and heat dissipating assembly to reduce or even eliminate interval to lower heat resistance and raise heat conducting performance. The reaction product with high heat conducting performance may further improve the heat conducting performance of the thermal interface material.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

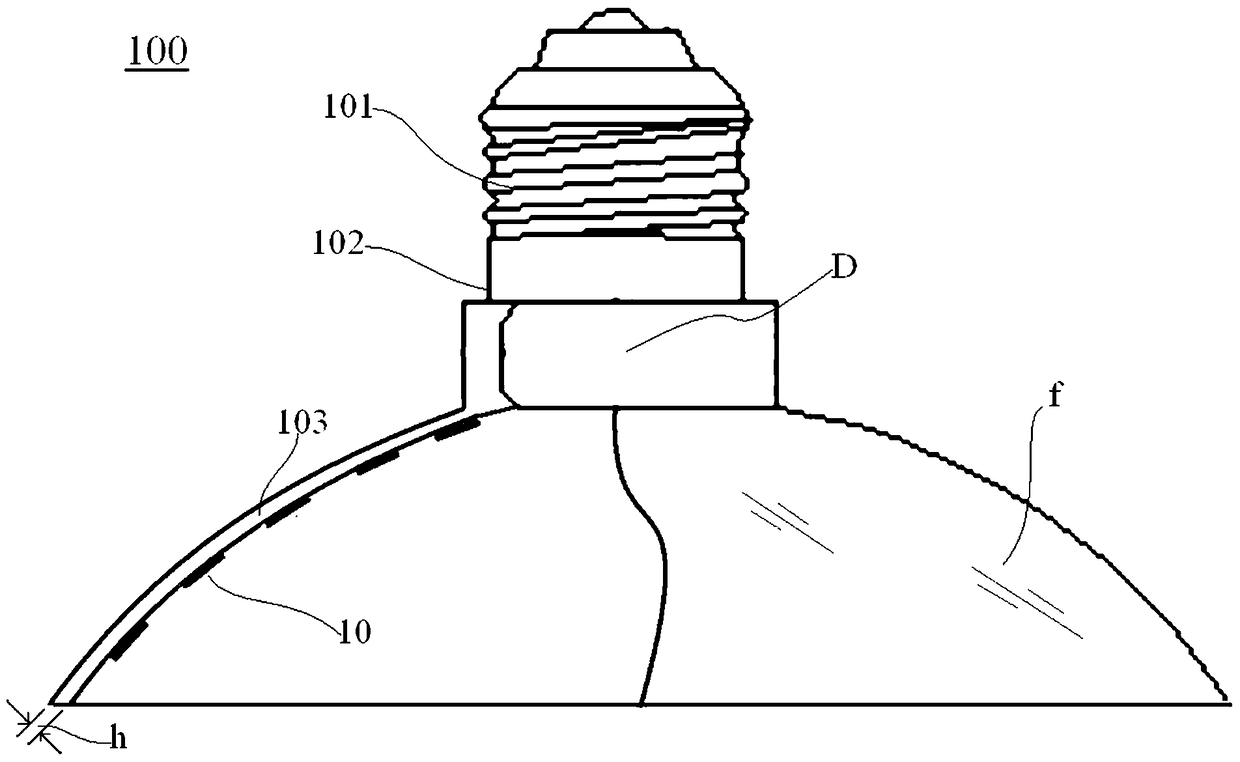

LED (light emitting diode) lamp with high heat dissipation performance

InactiveCN102384385AReduce interfaceEliminate thermal resistancePoint-like light sourceLighting heating/cooling arrangementsCopper coatingEngineering

The invention provides an LED (light emitting diode) lamp with a high heat dissipation performance, belongs to the technical field of LED lamps, and is used to solve the problem of poor heat dissipation effect of the existing LED lamp. The LED lamp with the high heat dissipation performance comprises a main body lamp shell and a lamp cap; a connection seat is arranged between the main body lamp shell and the lamp cap; the main body lamp shell is internally provided with an LED lamp, a printed circuit board, a heat dissipation plate and an LED driving circuit board group; one surface of the printed circuit board is provided with the LED lamp, and the other surface of the printed circuit board is installed on the heat dissipation plate; the rear surface of the heat dissipation plate is provided with the LED driving circuit board group; the board at one side of the printed circuit board which is provided with the LED lamp is provided with a return light cover; a connection line is arranged between the lamp cap and the LED driving circuit board group; a copper coating layer is sprayed and coated on one side of the printed circuit board facing to the heat dissipation plate; the printedcircuit board and the heat dissipation plate are pasted tightly, and a heat conduction through hole is formed at the heat dissipation bottom plate of the LED lamp; and the heat conduction through hole is provided with a heat conduction material. The LED lamp has the advantage of good heat dissipation effect.

Owner:NINGBO KOMAES ELECTRICAL IND

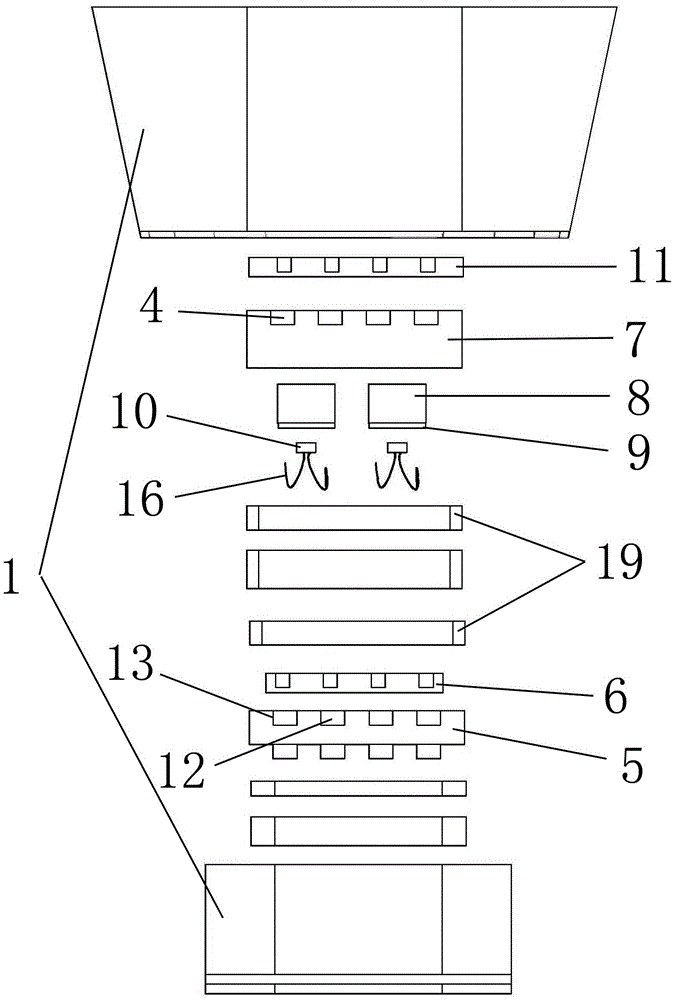

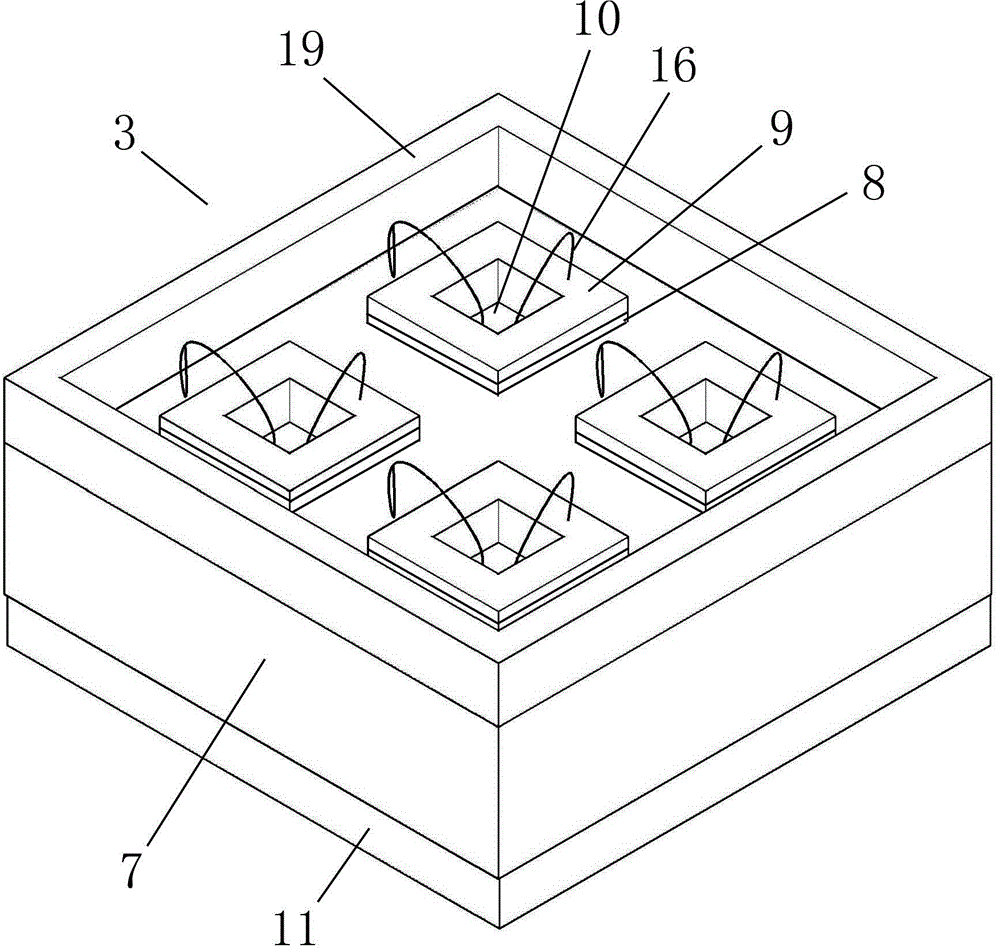

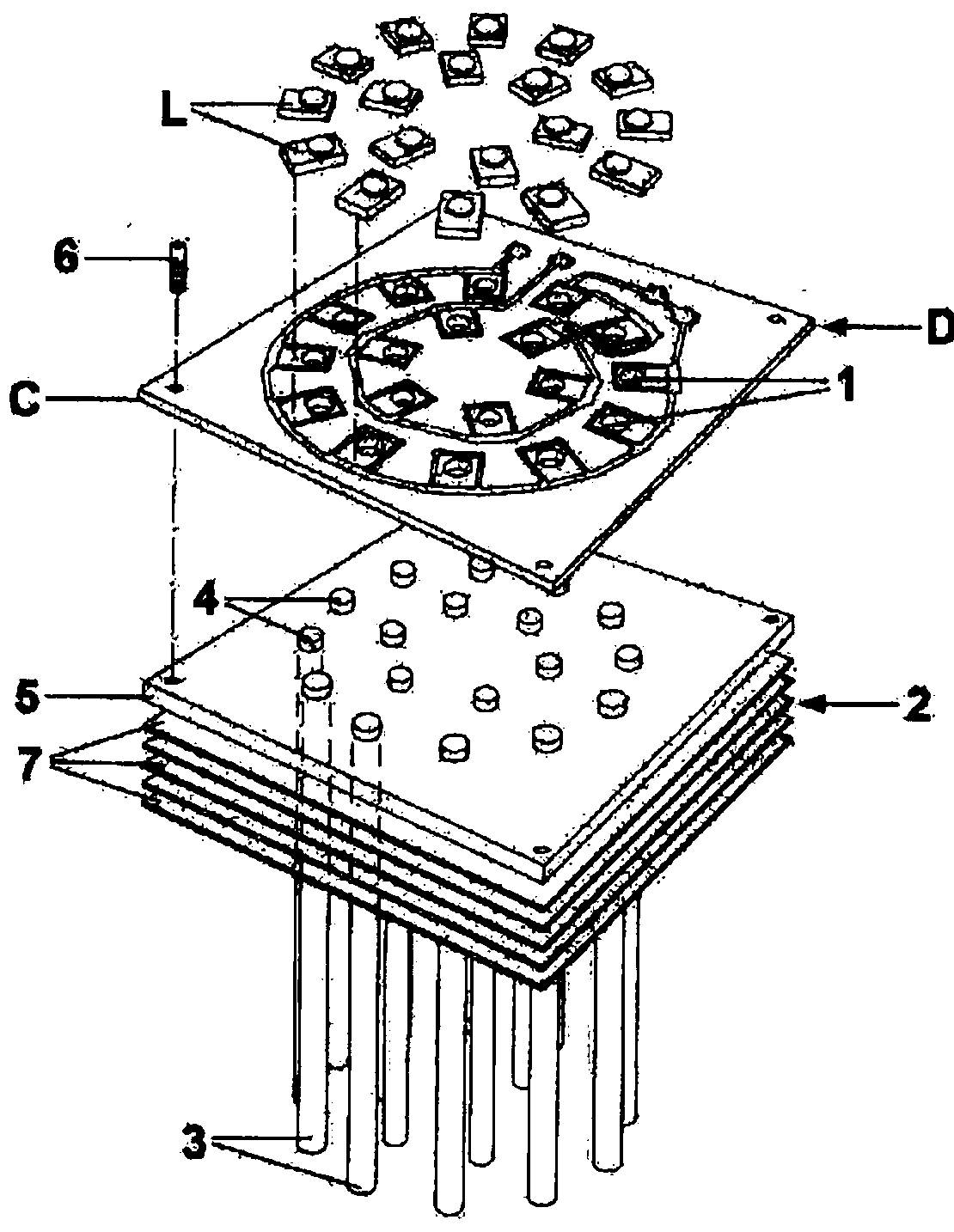

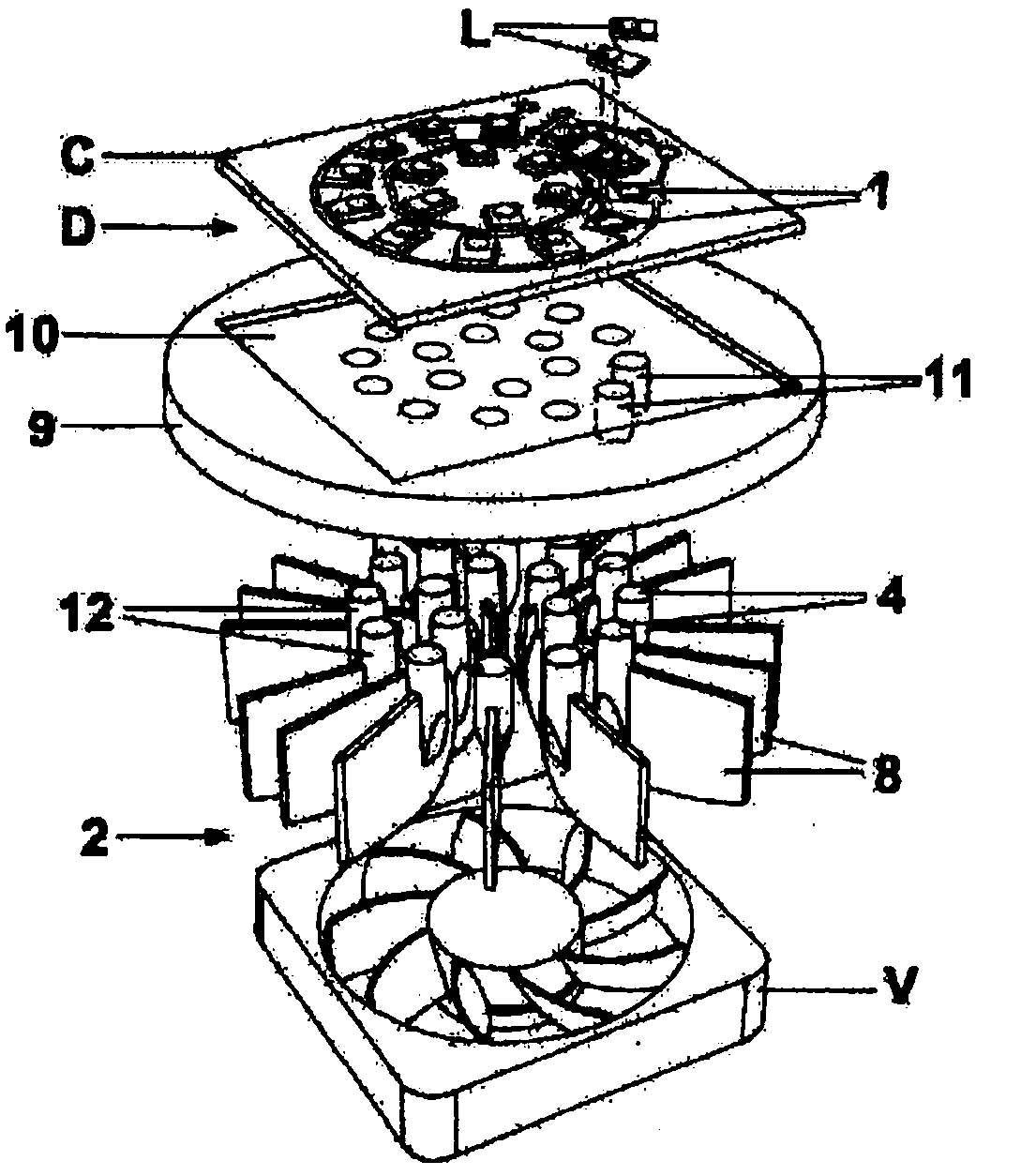

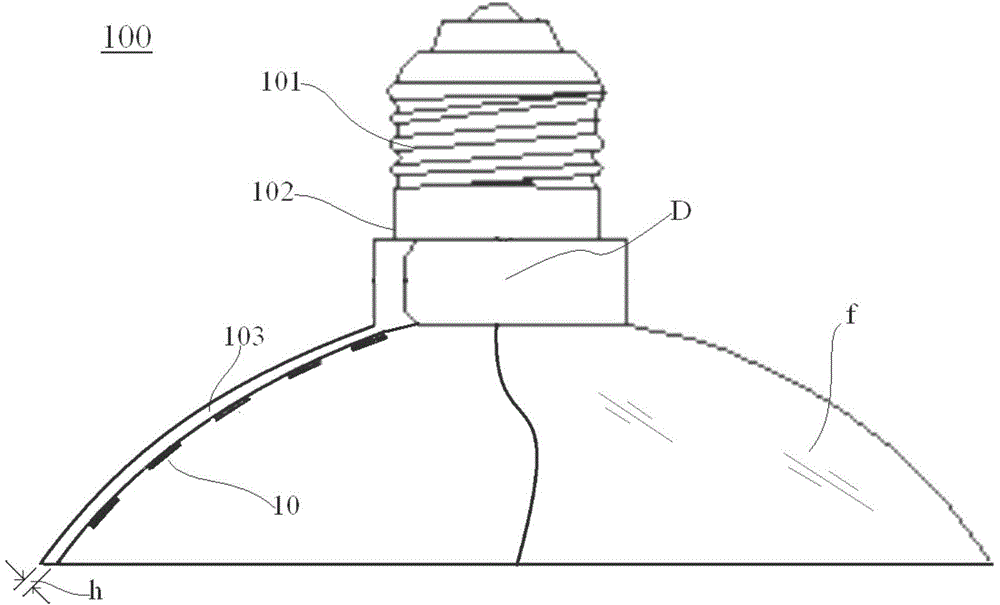

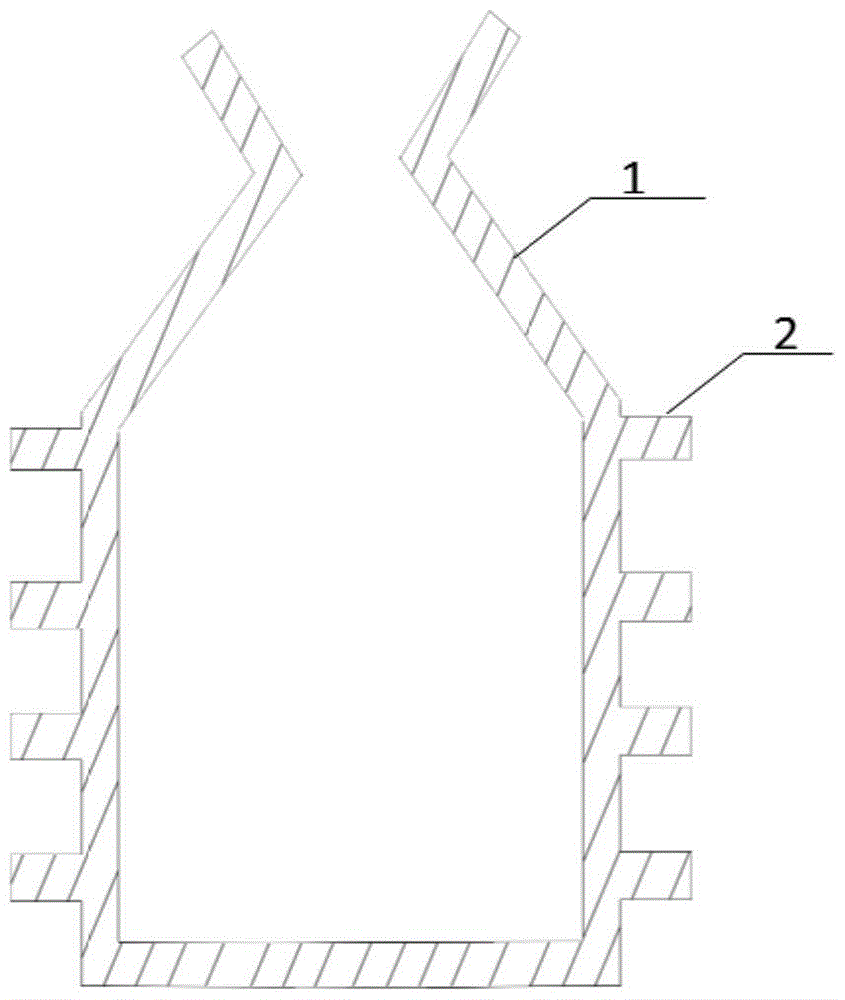

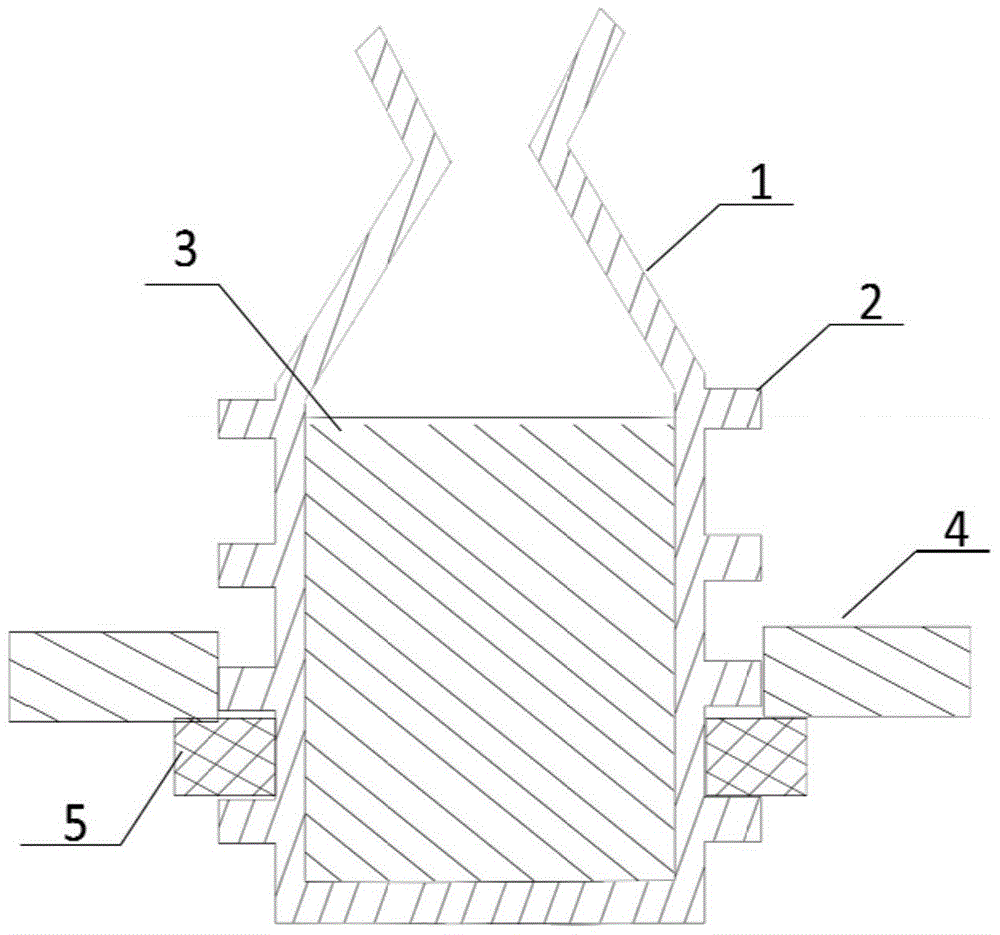

A led lighting device with integrated heatsink

InactiveCN103874884ALower final costEliminate thermal resistancePlanar light sourcesPoint-like light sourceEngineeringAlloy

The present invention concerns a LED (L) lighting device (D) with integrated heatising (2), comprising: a printed circuit (C) of the PCB ( Printed Circuit Board) or MCPCB (Metal Core Printed Circuit Board) type, arranged for electrically and mechanically supporting a LED (L) matrix, forming the light source of said device (D); a heatsink (2) that may be associated in construction to said printed circuit (C), comprising a plurality of cooling fins (3, 8, 13, 14), characterized in that said cooling fins (3, 8, 13, 14) are arranged for being placed into direct contact with said LEDs (L) and each single cooling fin (3, 8, 13, 14) is arranged for dissipating only the heat produced by the specific LEDs (L) applied thereon.; Heatsink (2) comprises cooling fins (3) with a cylindrical shape, (8) with lamellar structure or with prismatic shape with square bases (13) or rectangular bases (14) or with other regular shape, provided with ends (4) arranged for allowing the application of LEDs (L) and made out of high thermally conductive metals or out of composite alloys.

Owner:文森佐达拉斯科

Novel heat dissipation type light-emitting diode lighting structure and manufacturing method thereof

PendingCN110707079AImprove thermal conductivityImprove reliabilitySolid-state devicesSemiconductor devicesHemt circuitsEngineering

The invention discloses a novel heat dissipation type light-emitting diode lighting structure and a manufacturing method thereof, and belongs to the technical field of light emitting diodes. The novelheat dissipation type light-emitting diode lighting structure comprises an LED element and a heat dissipation assembly, and the heat dissipation assembly comprises a heat pipe unit, and a heat conduction insulating layer and a circuit layer which are sequentially arranged on the heat pipe unit from bottom to top. The circuit layer is electrically connected with the LED element, and the heat pipeunit is further provided with cooling fins. The beneficial effects of the present invention are that the light-emitting diode lighting structure is simple and stable in overall structure, simple in manufacturing process and low in manufacturing cost, the heat generated by the LED element can be rapidly transmitted to the heat pipe unit to be dissipated, the heat dissipation efficiency and the light-emitting efficiency of the LED element are improved, and the service life of the LED element is prolonged.

Owner:国网安徽省电力有限公司南陵县供电公司 +1

Chip packaging structure and chip packaging method

PendingCN109830465AImprove cooling efficiencyEliminate interfacial thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesWhole bodyInterfacial thermal resistance

The invention discloses a chip packaging structure and a chip packaging method for reducing interface thermal resistance to improve the heat dissipation performance of a chip. The chip packaging structure comprises a carrier board, a chip, a thermal conductive insulating layer coating the chip and a heat dissipating component, wherein the thermal conductive insulating layer and the heat dissipating component are integrally formed. The applicant accidentally discovers during an experiment that heat dissipation members such as a traditional first-level packaging structure, a heat sink and a heatbalancing plate can be integrally formed into a whole body by 3D printing so as to eliminate the interfaces of various original parts and correspondingly eliminate the interface thermal resistance, thereby improving the heat dissipation efficiency of the chip packaging structure.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

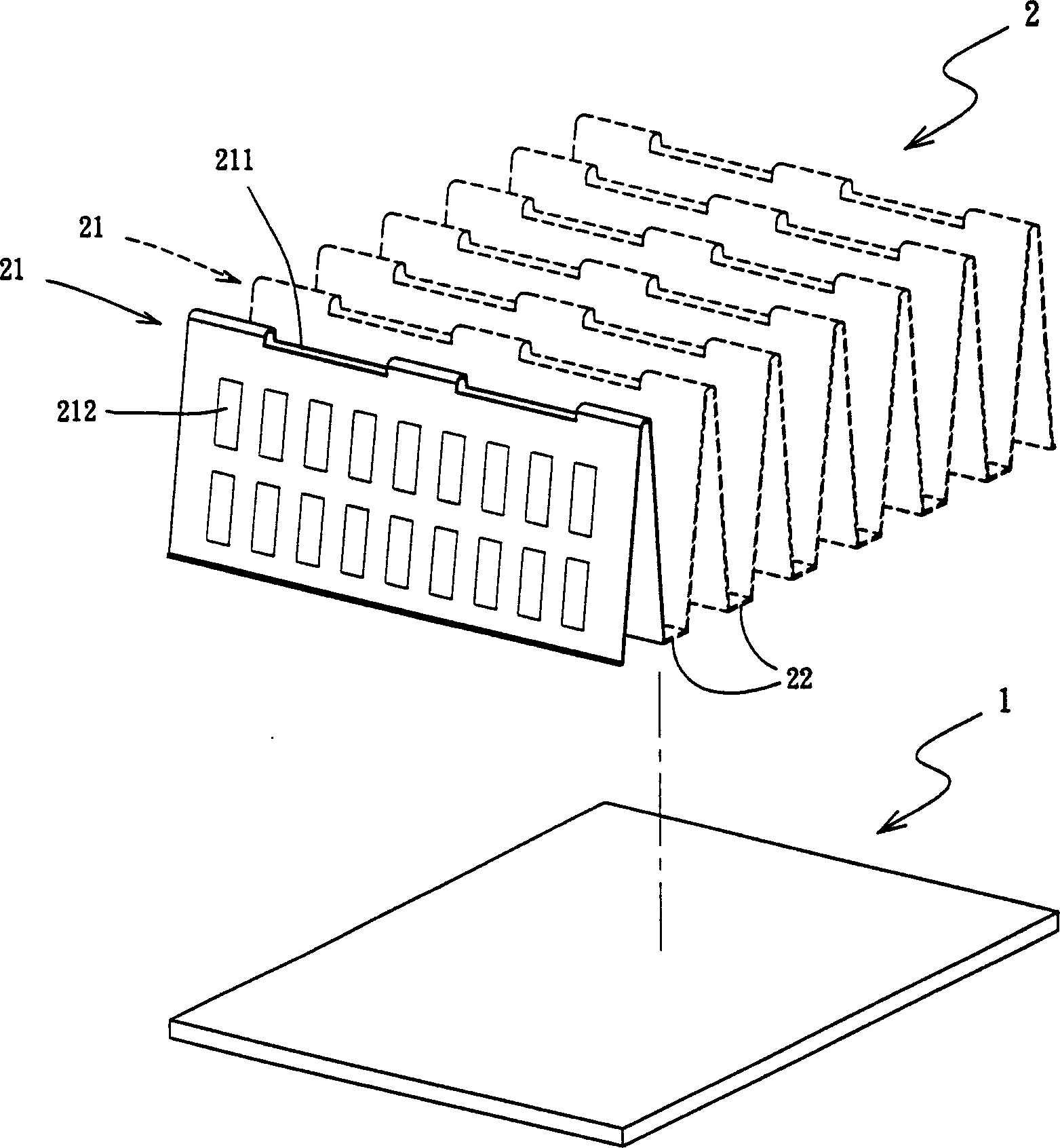

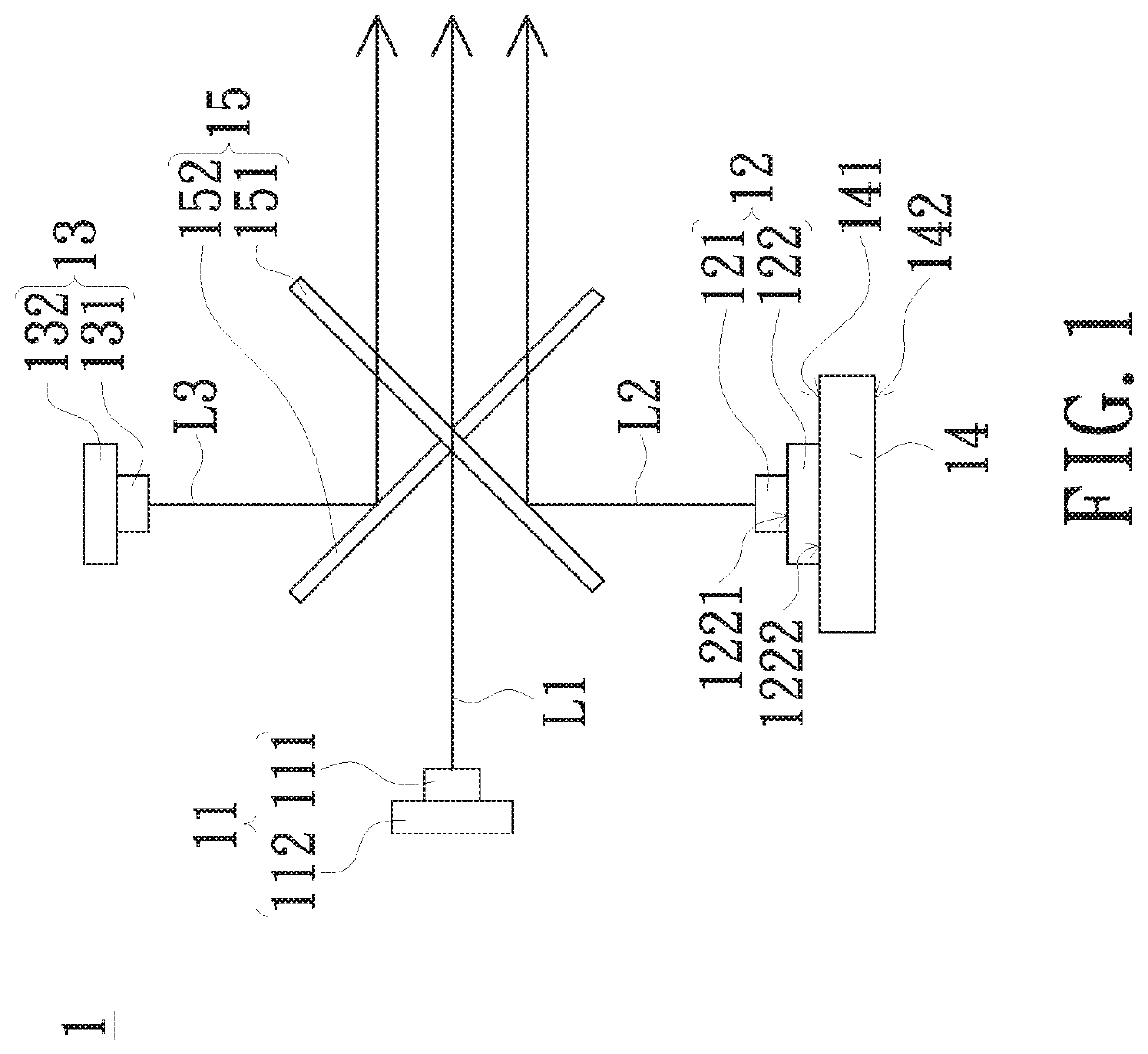

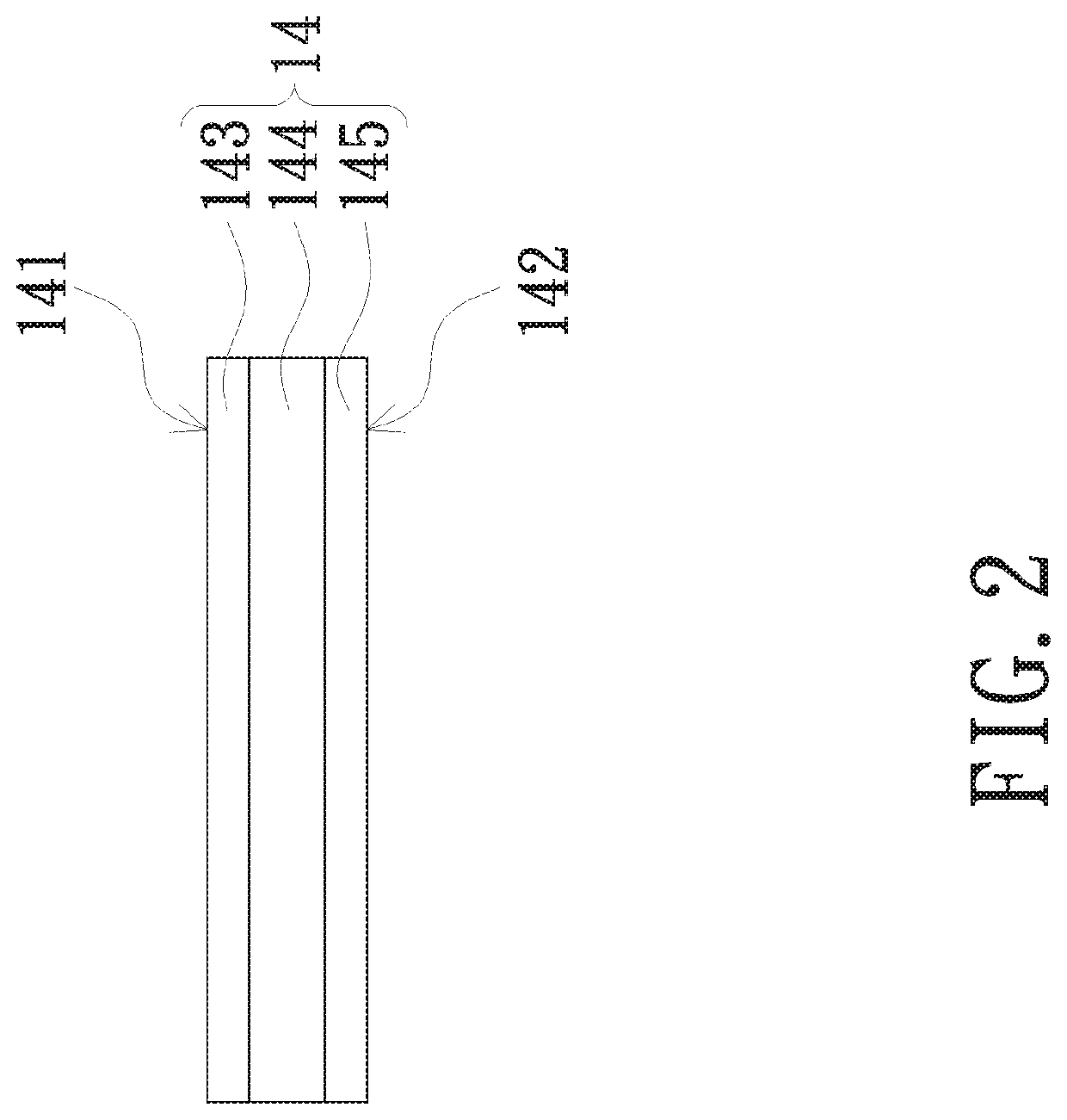

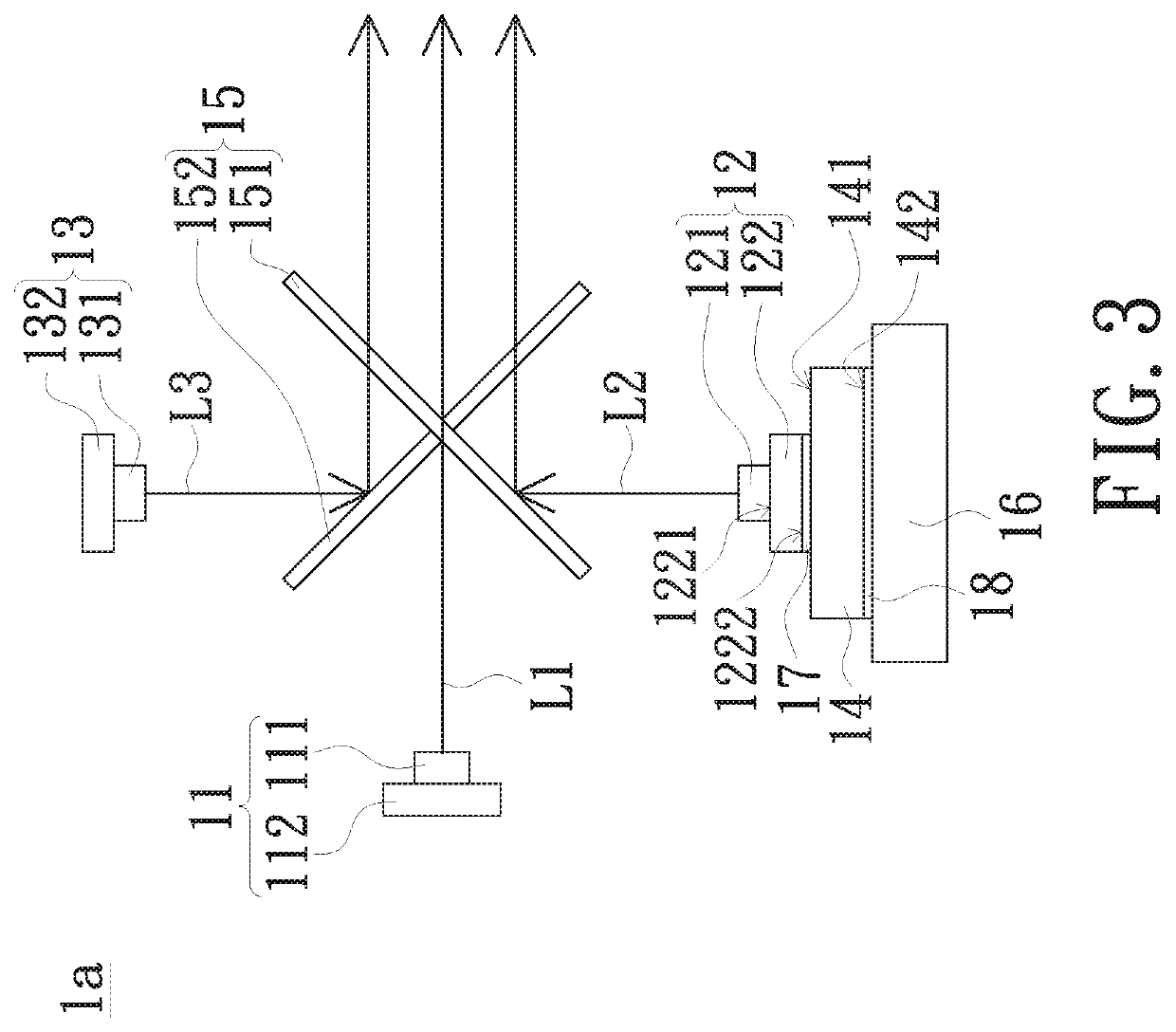

Illumination system and projection apparatus

InactiveUS20190339599A1Eliminate thermal resistanceImprove cooling efficiencyThermoelectric device with peltier/seeback effectProjectorsLight beamLighting system

An illumination system includes a green light source, a red light source, a blue light source, a first splitter, a second splitter, and a thermoelectric cooler. The first splitter is disposed downstream of the light sources, the first splitter being capable of reflecting a first color light beam and allowing a second color light beam to pass. The second splitter is disposed at the light paths of the light sources, and the second splitter being capable of reflecting a third color light beam and allowing the first color light beam and the second color light beam to pass, wherein the color of the first color light beam, the second color light beam, and the third color light beam are substantially different. The thermoelectric cooler is thermally coupled to the red light source, and neither the green light source nor the blue light source is thermally couple to any thermoelectric cooler.

Owner:YOUNG OPTICS

LED lamp bulb

InactiveCN104633486AImprove light outputImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsMicrometerLight reflection

The invention relates to an LED lamp bulb. The LED lamp bulb comprises a lamp holder, a transparent lamp cup and an LED chip array, and the outer surface of the transparent lamp cup is provided with a light reflection structure and a reflection layer which are used for reflecting light; the LED chip array is directly pasted to the inner surface of the transparent lamp cup; in addition, LED chips in the LED chip array comprise vestigial substrates which range from 0.1 micrometer to 1 micrometer.

Owner:陈宗烈

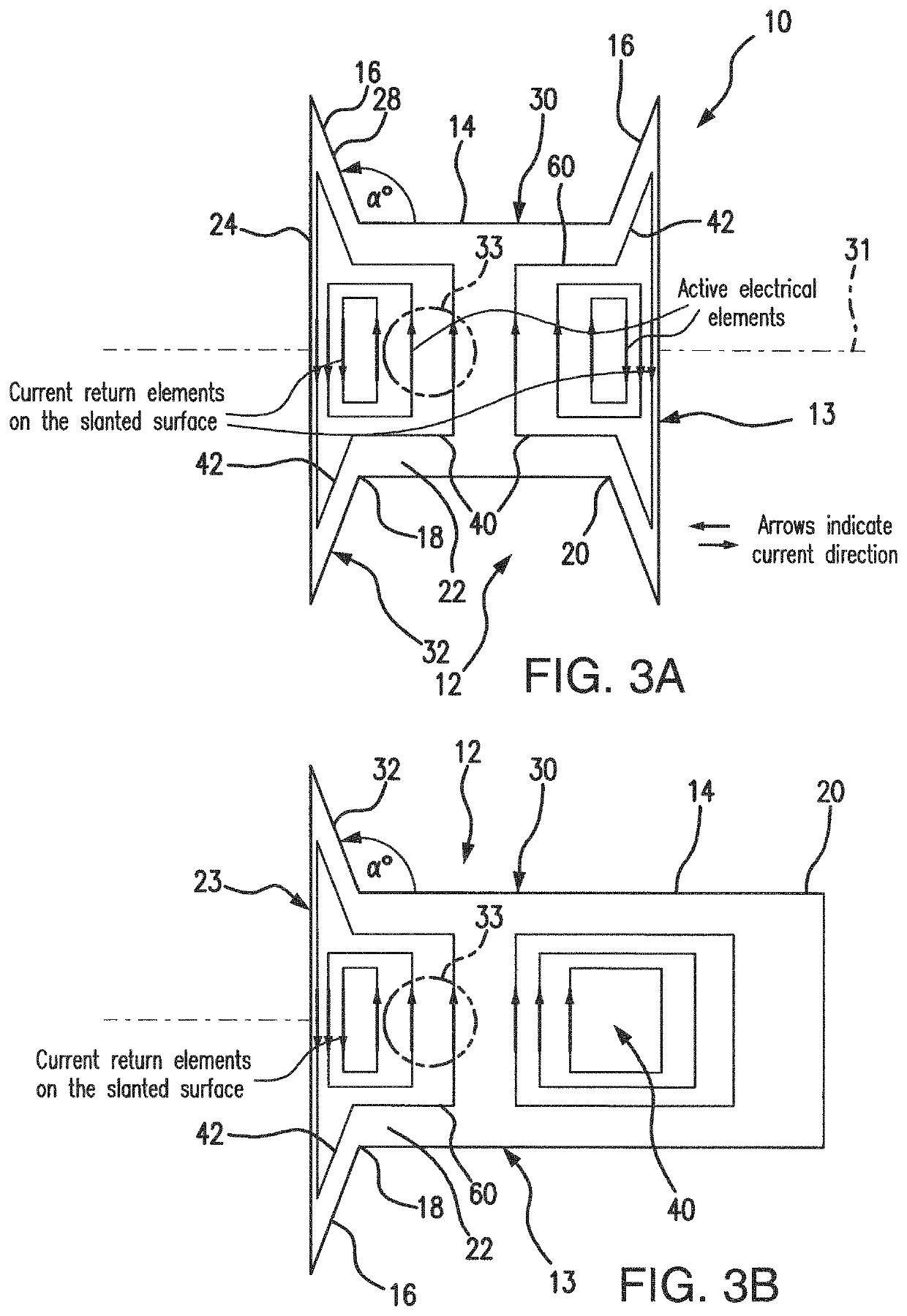

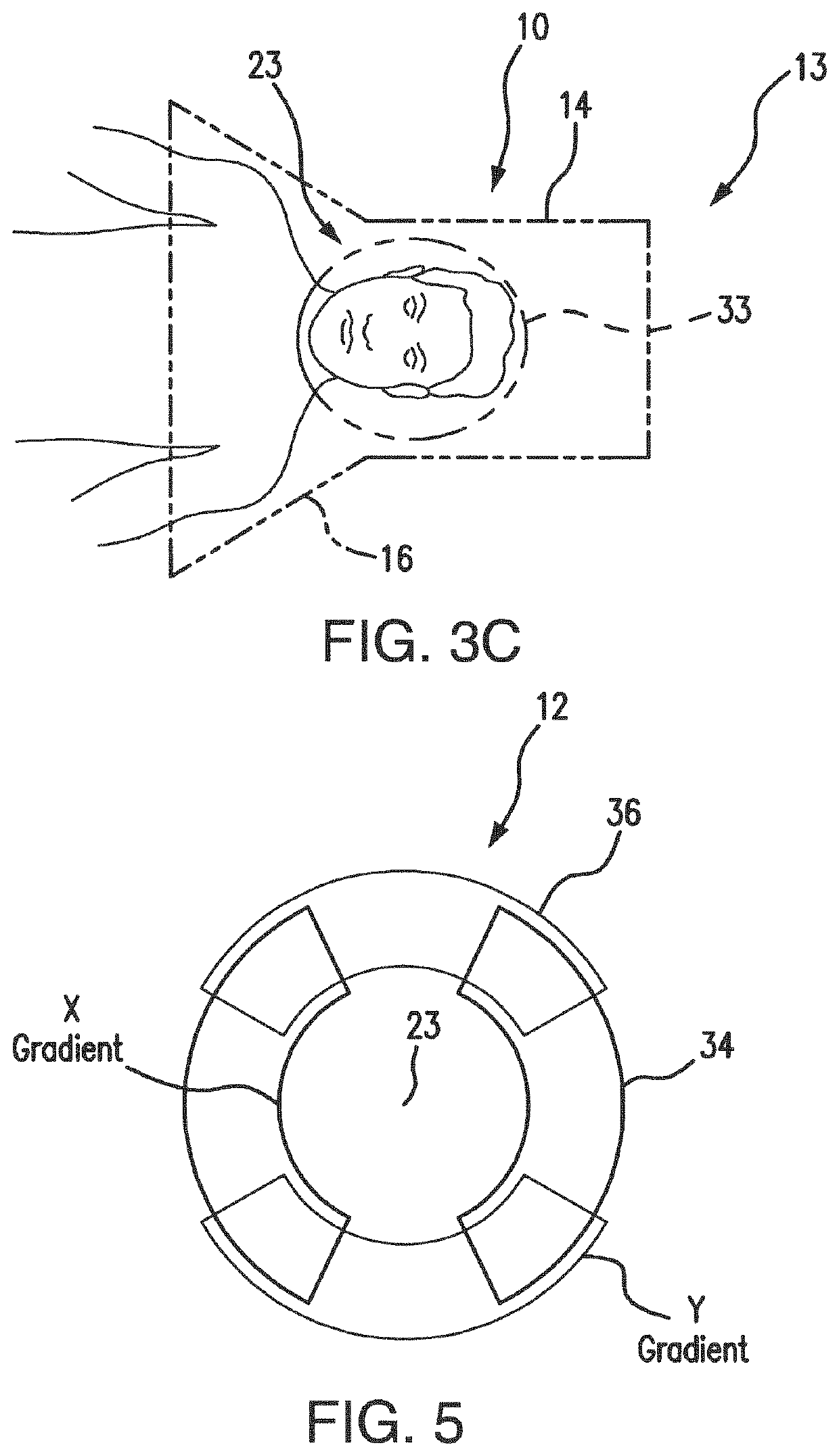

Gradient coil with external direct cooling for brain magnetic resonance imaging

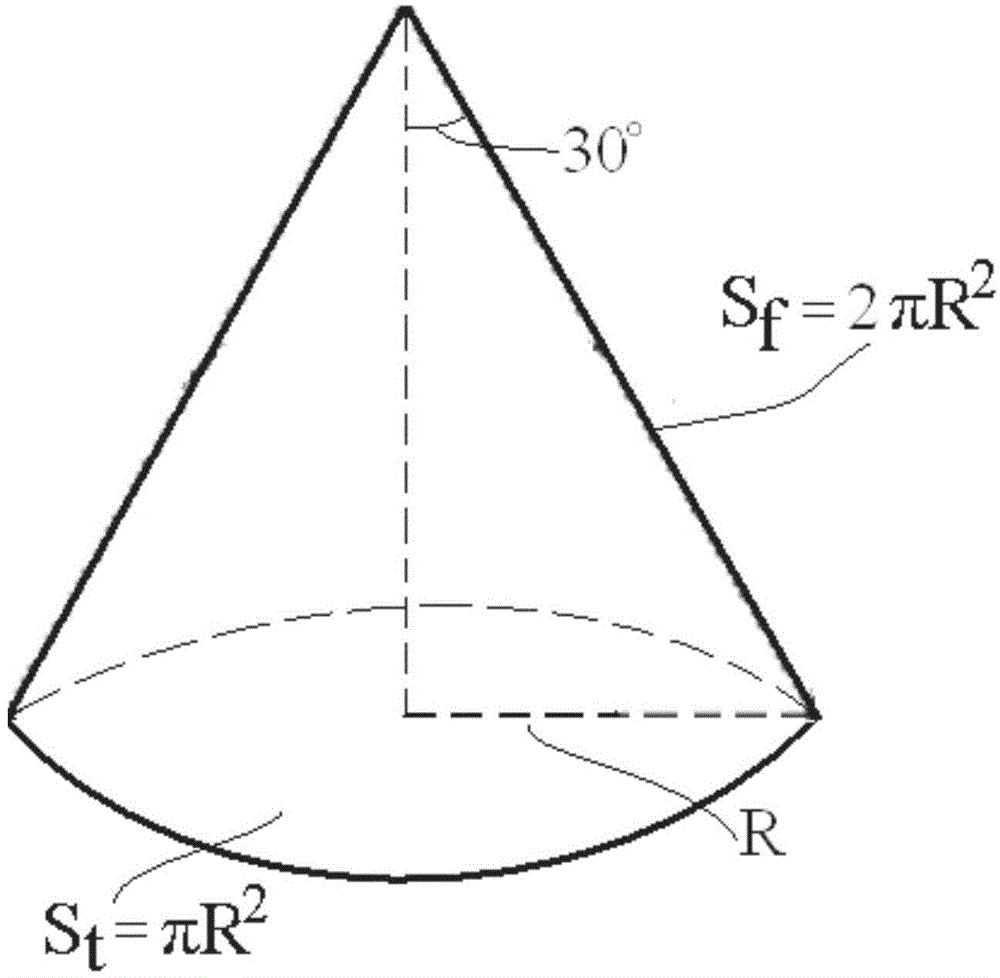

ActiveUS10739427B1Control clearanceStronger and more to resolutionMagnetic measurementsCoolant flowEngineering

The gradient coil assembly is designed to address a neck-shoulder clearance problem by configuring the coil holder housing with a cylindrical portion modified with a slanted surface and positioning current return elements of the coil pattern at the slanted surface, while positioning the active electrical elements on the cylindrical surface, thus eliminating influence of an undesired magnetic field generated by the current return elements, shortening the coil, and moving the homogeneous field gradient region toward the end of the cylindrical portion of the bore in the coil holder housing. The subject assembly operation is further improved by the direct external cooling approach, where a coolant flows in direct contact with electrical wires of the gradient coil inside the cooling channels in the surface of the coil holder housing.

Owner:UNITED STATES OF AMERICA +1

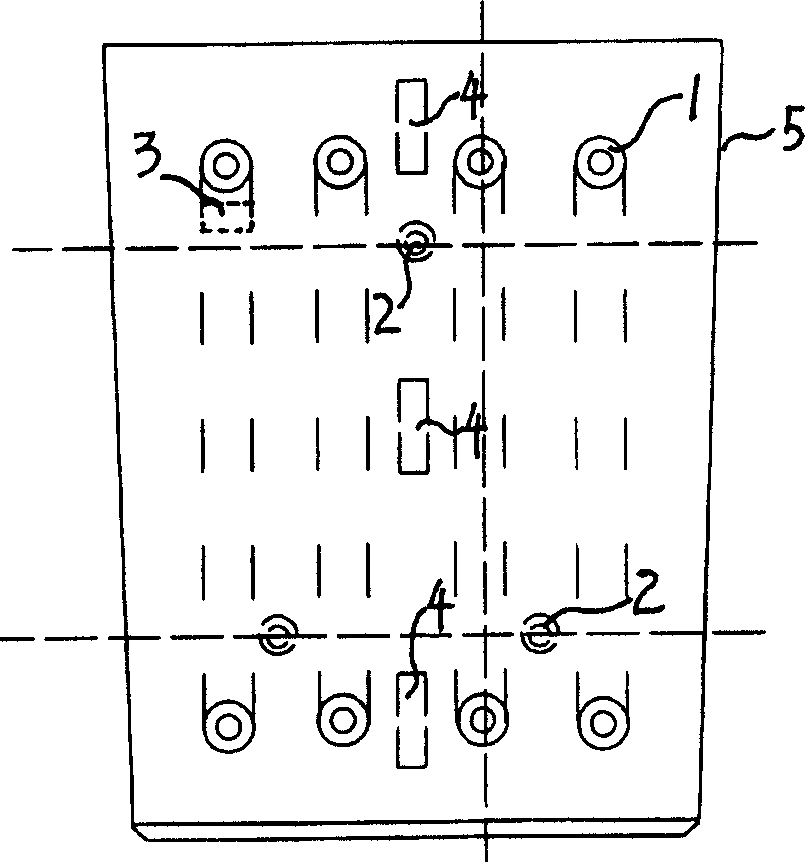

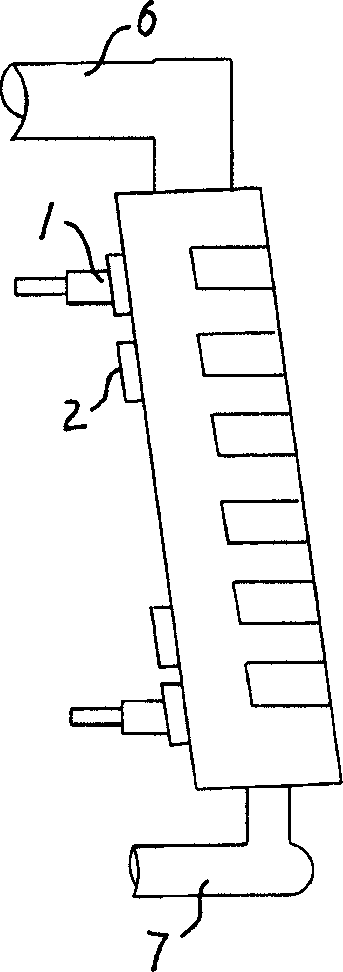

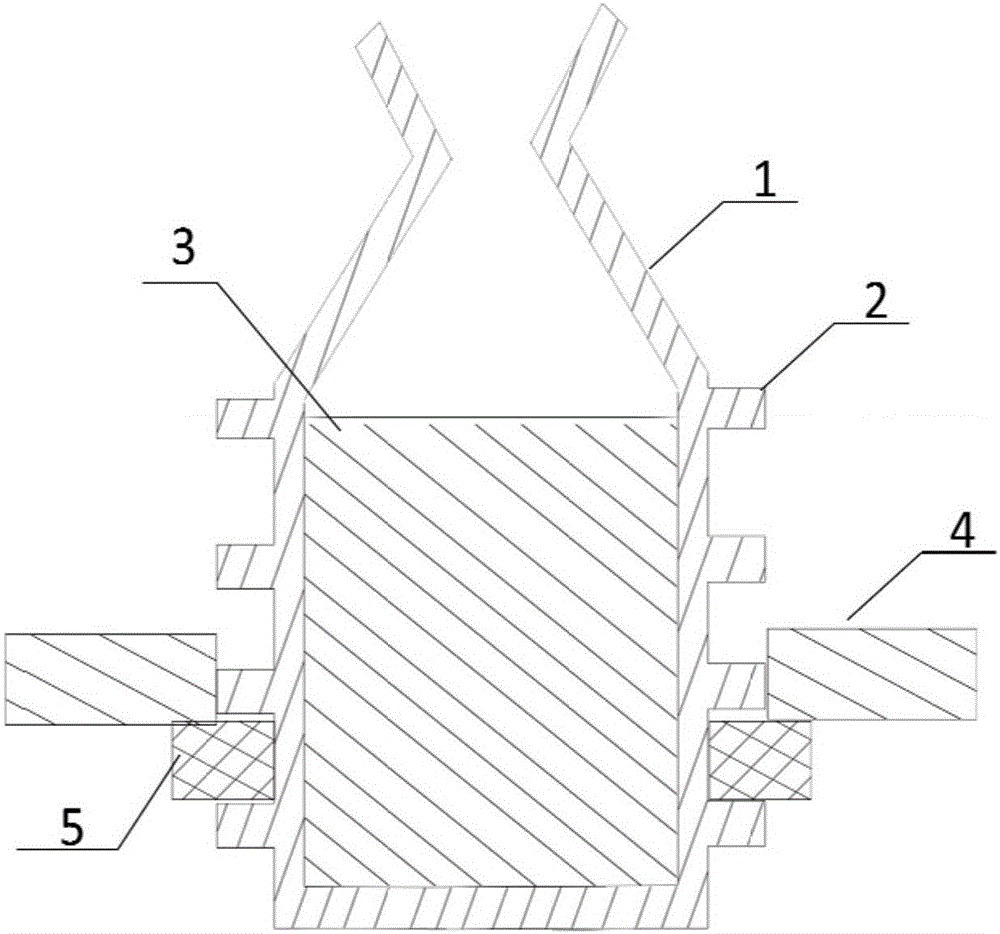

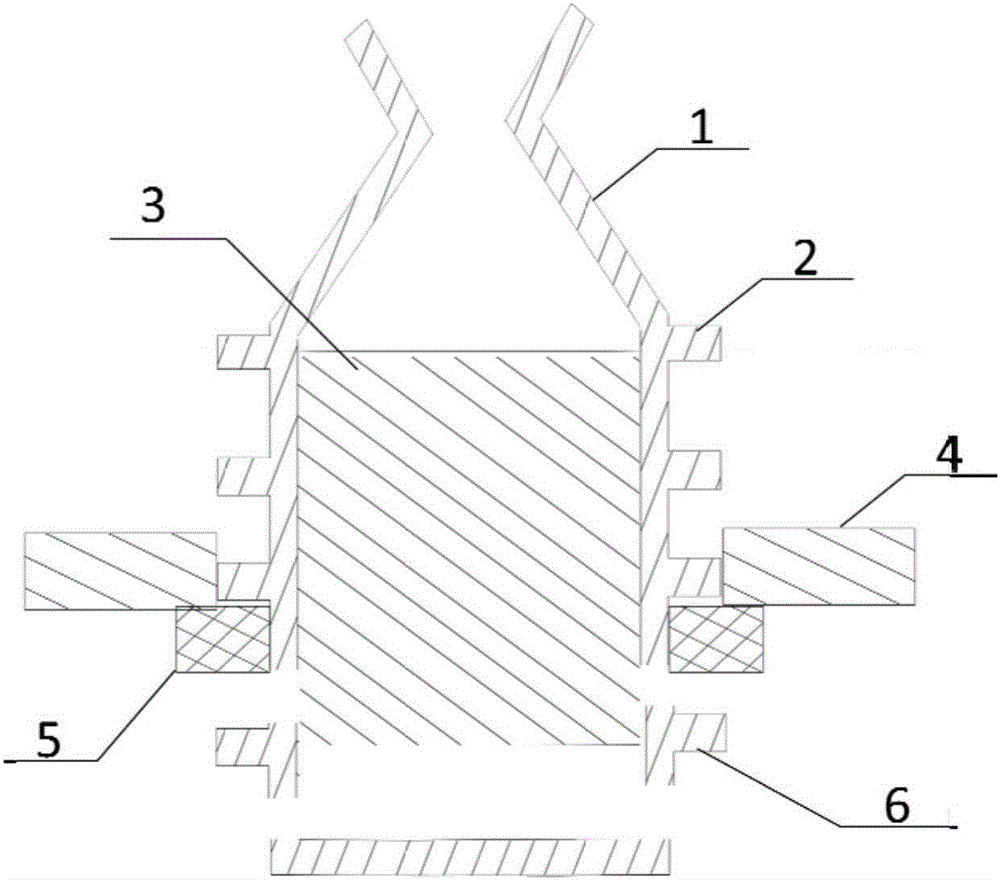

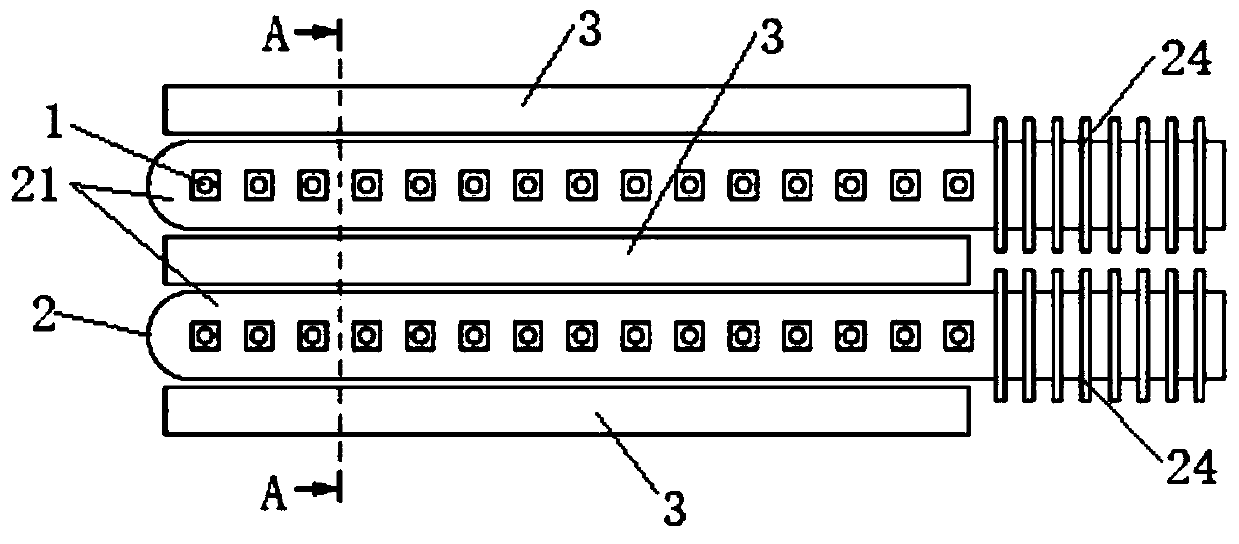

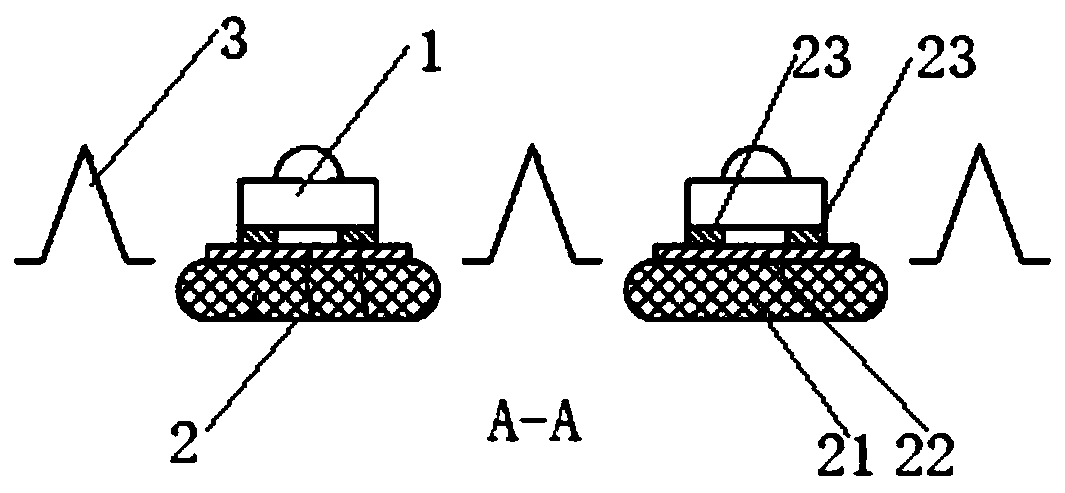

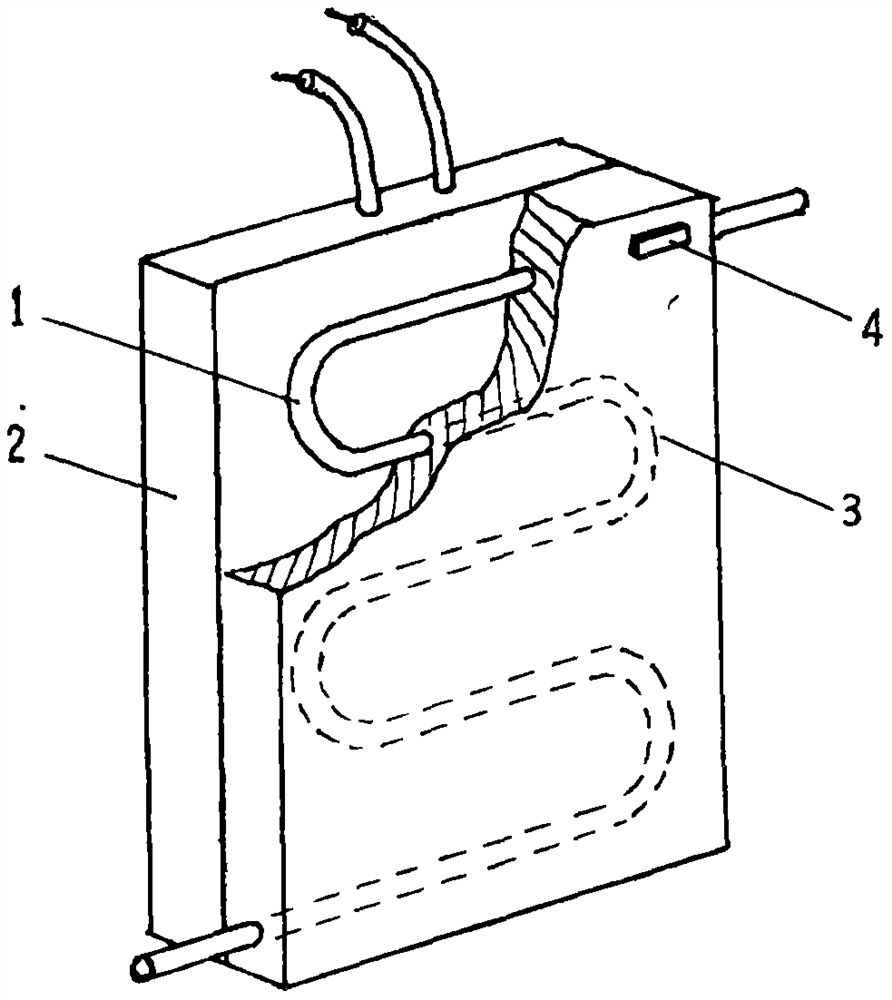

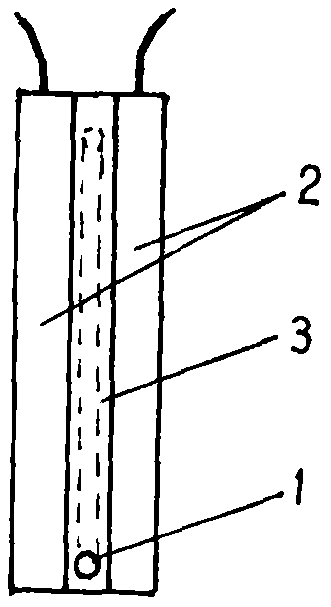

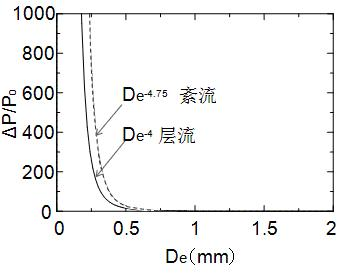

Rapid water sample heater

PendingCN112594920AAvoid defectsSolve the shortcomings of low heat exchange efficiency and low heatPreparing sample for investigationWater heatersThermodynamicsMetallic aluminum

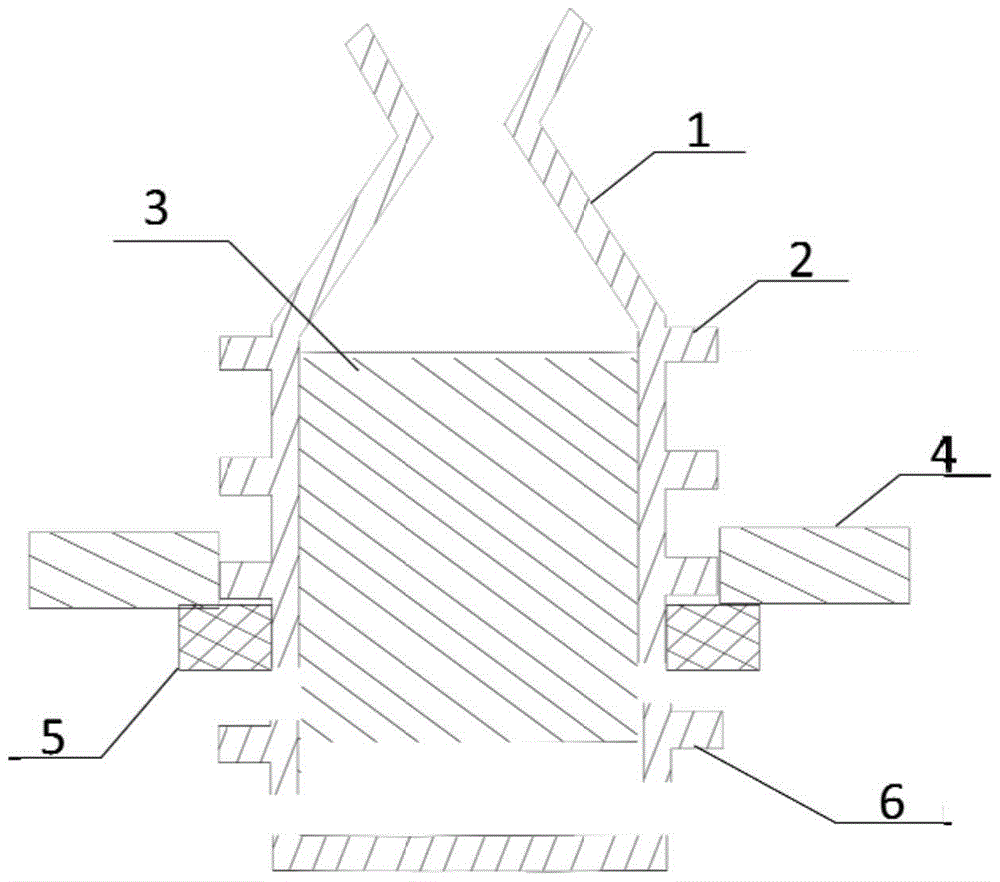

The invention discloses a rapid water sample heater. The rapid water sample heater is composed of a heat exchange tube 1 attached to the surfaces of heat sources 2 or clamped between the two heat sources, a heat conducting medium 3 filling all gaps between the heat exchange tube and the heat sources, and a temperature sensor 4, and the rapid water sample heater is characterized in that the heat conducting medium between the heat exchange tube and the heat sources uses tin-based alloy, and known heat conducting oil, or a metal aluminum casting method in which "thermal resistance" may exist is replaced.

Owner:大连科欣仪表研究所

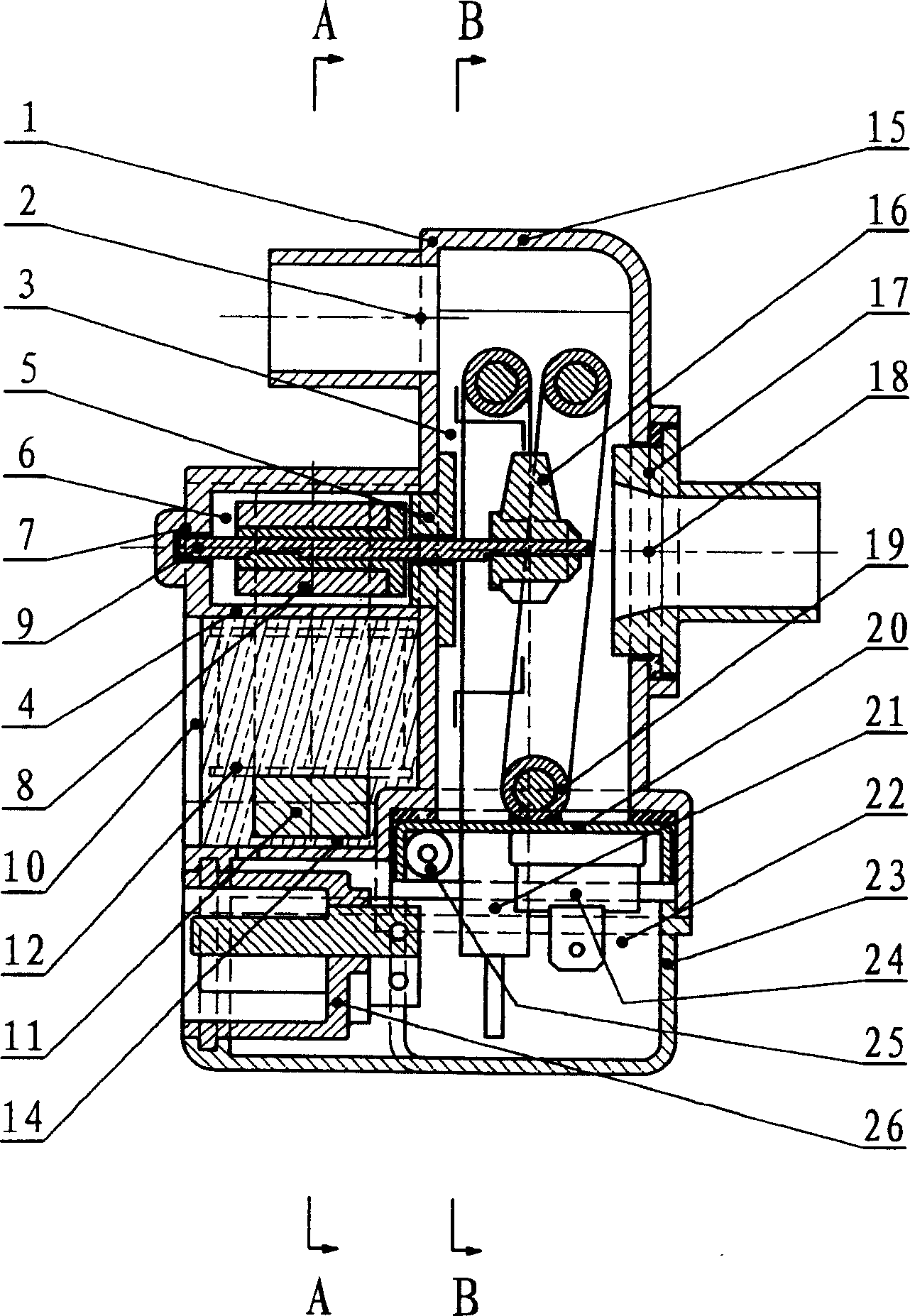

Cyclic preheater for single cavity permanent-magnet rotor pump and assembly method thereof

InactiveCN1664352AThere will be no problem of poor heat dissipationEfficient take awayMachines/enginesEngine startersPermanent magnet rotorImpeller

The invention relates to a single cavity permanent-magnet rotor pump cycle preheater and the installation method that belongs to the preheating field for the engine of automobile. The feature is that: the cavity is made up of cavity main body, front cover and electric heating pipe fixed disk; the cavity main body is manufactured by the method of plastic injecting modeling and rotor cavity, outlet, front cover mouth, electric heating pipe mouth, stator groove are set on it; the permanent-magnet rotator, front bearing and impeller are installed into the heating cavity from the front cove mouth. The spirality part of the electric heating pipe is installed in the heating cavity from heating pipe mouth. The stator is fixed in stator groove. The temperature sensors are installed on the out side of the electric heating pipe fixed disk. The junction box is installed under the fixed disk and the stator groove. The electric heating pipe component should be installed first.

Owner:于佳衣

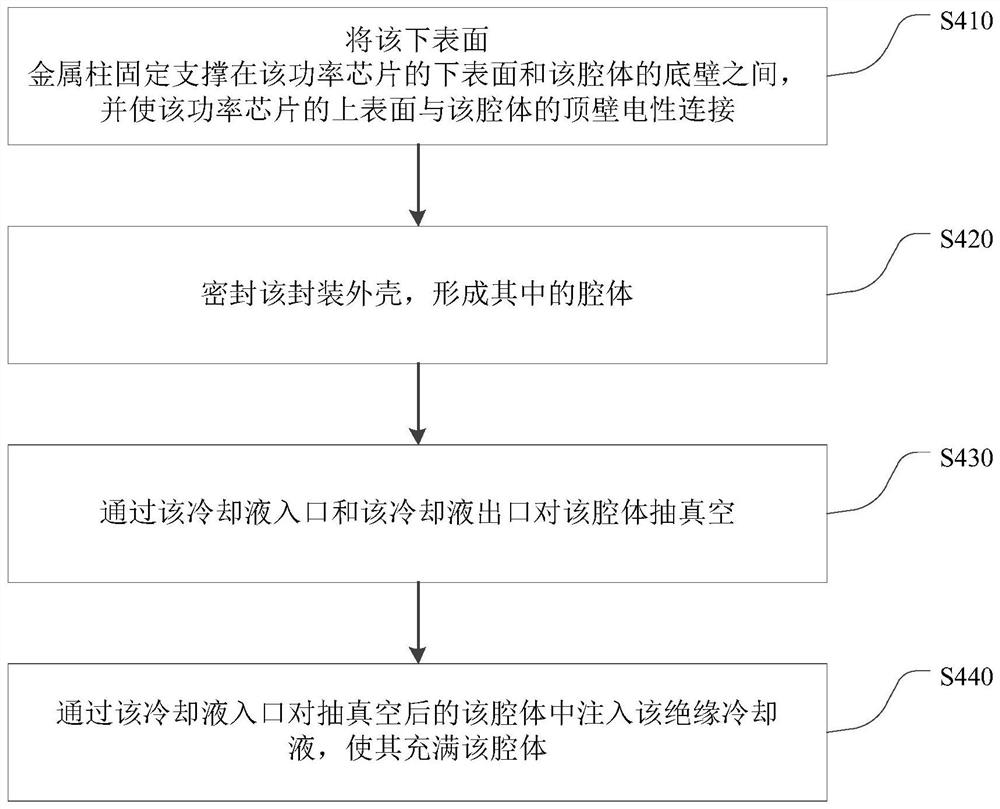

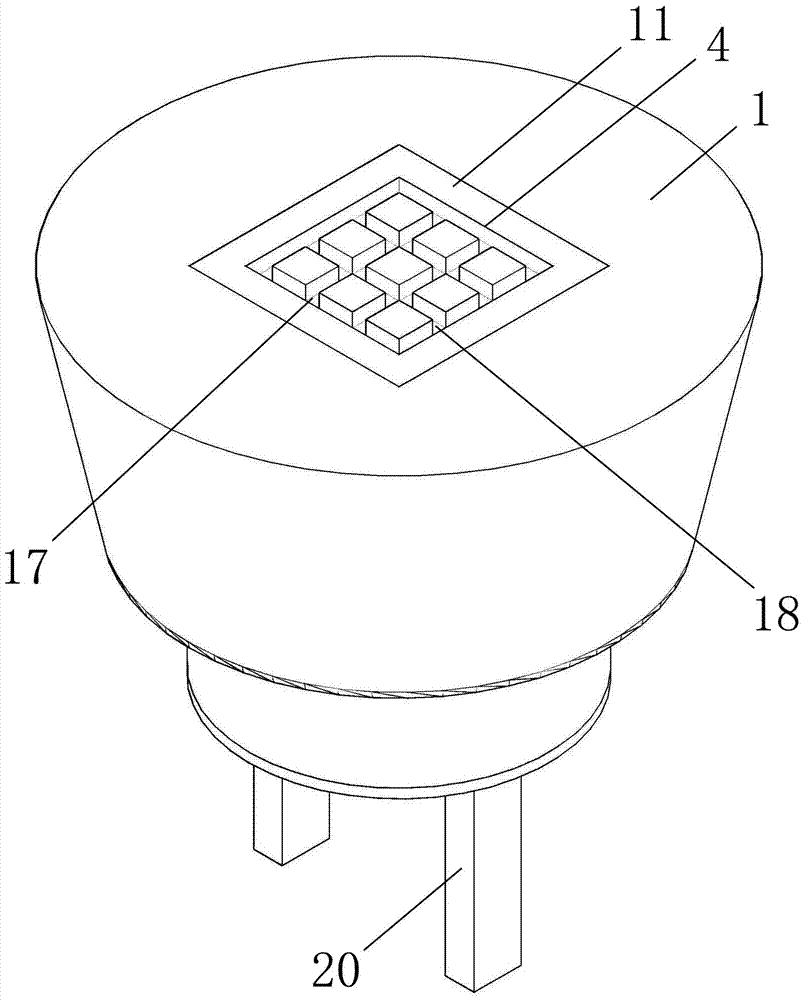

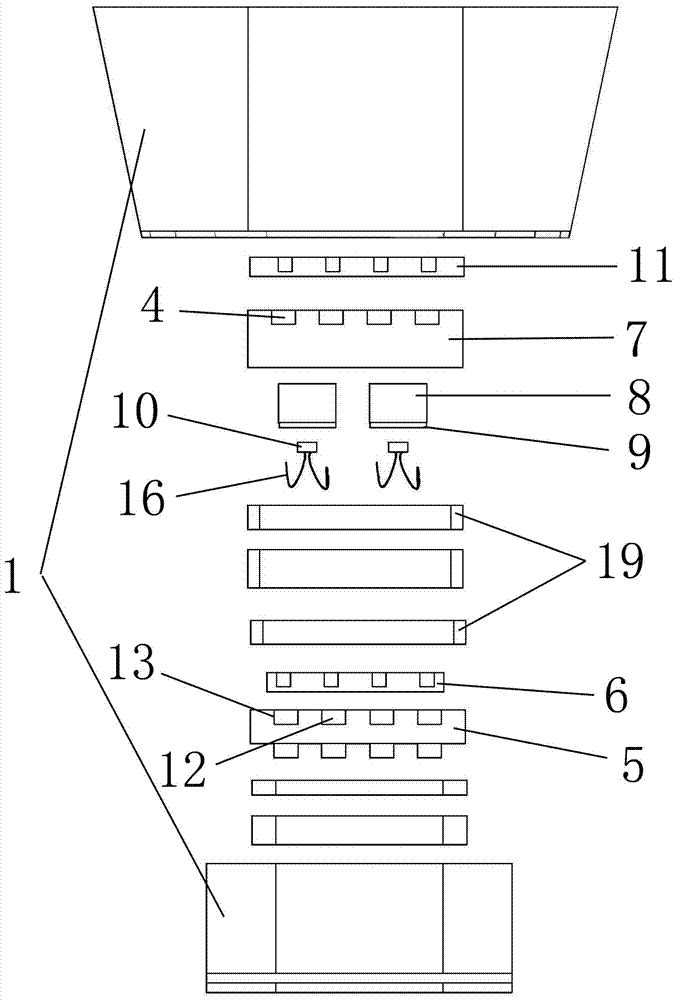

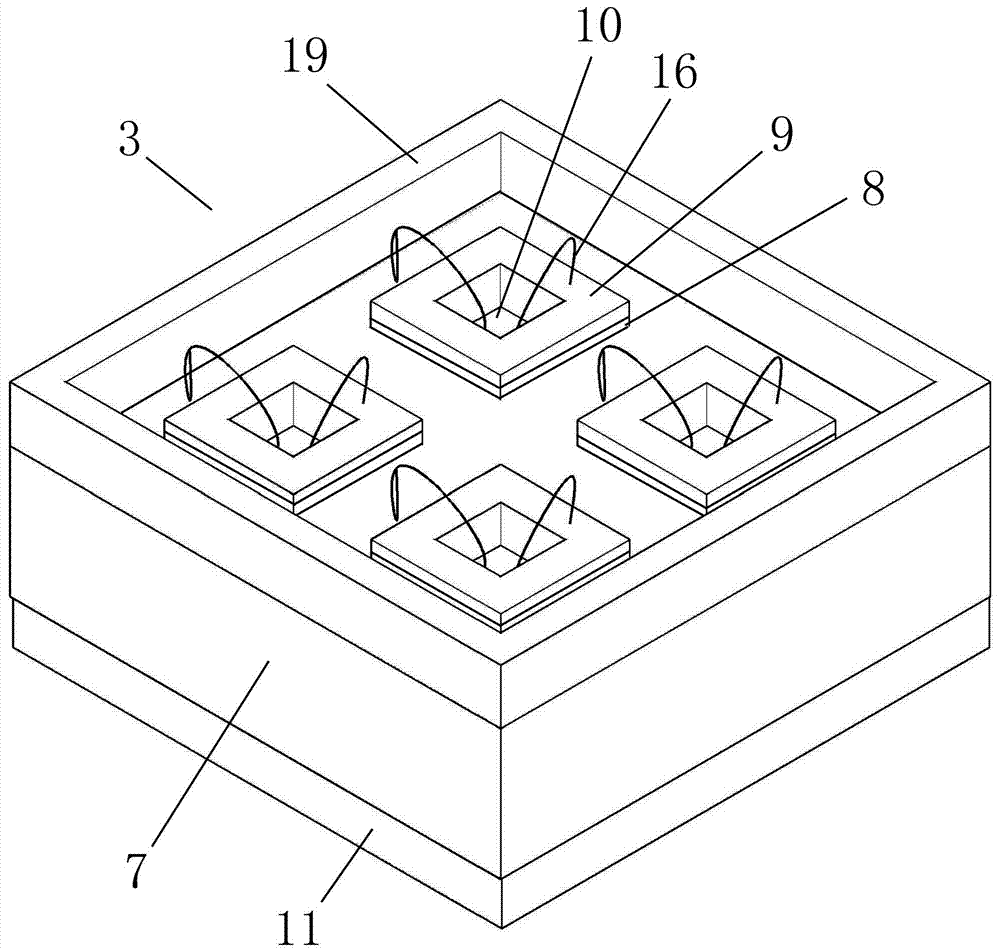

Power module packaging structure and manufacturing method thereof

PendingCN112289761AEliminate thermal resistanceImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesHigh densityHemt circuits

The invention provides a power module packaging structure and a manufacturing method thereof. The power module packaging structure comprises: at least one power chip; a packaging shell provided with acavity for accommodating a insulating cooling liquid and the power chip; and a cooling liquid inlet and a cooling liquid outlet which are formed in the packaging shell and are communicated with the cavity. The power chip is fixedly supported above the bottom wall of the cavity through a lower surface metal column located on the lower surface of the power chip, and the power chip is electrically connected with an external circuit through the lower surface metal column. By means of the packaging structure, the power chip can be directly and completely immersed in the insulating cooling liquid,heat can be dissipated on all surfaces of the power chip, heat dissipation paths are increased, and the heat dissipation problem of the high-density power module is solved.

Owner:湖南国芯半导体科技有限公司

A kind of sapphire printed circuit board led lamp and manufacturing method thereof

ActiveCN104613379BAchieve preparationImprove cooling effectNon-electric lightingPoint-like light sourceEffect lightThermal adhesive

The invention relates to a lamp, in particular to an LED lamp with high-efficiency heat dissipation function; it includes a housing, a light guide module and a light emitting module. It includes a first sapphire substrate and a reflective layer. The reflective layer light-emitting module includes a second sapphire substrate, a light-shielding layer, a metal conductive layer, a light-emitting module, and an anti-reflection layer. The beneficial effects of the present invention are reflected in the following: the present invention provides a The sapphire printed circuit board LED lamp with heat dissipation function, by setting the heat dissipation structure on the sapphire printed circuit board, directly carries out crystal bonding, wire bonding and dispensing on the sapphire printed circuit board, realizes the production of LED light-emitting modules, and eliminates the need for traditional printed circuit boards. The thermal resistance generated by the adhesive is used to improve heat dissipation efficiency, and a light-shielding layer is provided on the printed circuit board to ensure the luminous flux of the light-emitting module, prevent light leakage, and keep the light bright. The structure is simple and the cost is low.

Owner:DONGGUAN BRIGHT LED ELLECTRONICS LTD

Manufacture method of microchannel heat exchange body of heat exchanger

ActiveCN102095284AGuaranteed diffusionGuaranteed normal formationEvaporators/condensersProcess engineeringHeat transfer efficiency

The invention discloses a manufacture method of a microchannel heat exchange body of a heat exchanger, belonging to the technical filed of heat transfer and heat exchange. The manufacture method comprises the following steps of: obtaining a set of optimized refrigeration media and a hydraulic diameter of a working fluid microchannel by calculation and analysis based on the use condition of a heatpump system, then respectively machining and forming the refrigeration media, the working fluid microchannel and a baffle plate layer, carrying out surface treatment, and separating and overlaying a refrigeration media layer from a working fluid microchannel layer through baffle plates to form a plurality of microchannel units; increasing both the temperature and the pressure after placing the overlaid microchannel units in a vacuum cavity to generate atomic diffusion on the surfaces of the refrigeration media layer, the working fluid microchannel layer and the baffle plate layer until atoms are combined into a whole with a homogeneous structure. The heat exchanger applying the manufacture method has higher heat exchange efficiency than the traditional products.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

Cast-iron cooling wall and manufacturing method thereof

InactiveCN100457923CImprove heat transfer efficiencyImprove thermal conductivityCooling devicesFurnace cooling arrangementsCarbon coatingDuctile iron

The invention relates to a new type low thermal resistance cast iron cooling wall. The feature is that the identity material of cooling wall is nodular cast iron or gray cast iron and the cooling water channel in cooling wall is made up from pure copper. The clearance between the cooling wall identity and the outer wall of pure copper pipeline is below 0.1mm. The manufacture method includes the following steps: fixing the molded pure copper pipeline into the sand box; casting by molten iron of nodular cast iron or gray cast iron, and taking inertia vapor cooling to copper pipeline to molding. The invention eliminates the thermal resistance caused by anti seepage carbon coating layer to make the heat exchange efficiency sharply increase and prolong the useful life of cooling wall.

Owner:NANJING NANGANG IND DEV CO LTD

A solar photovoltaic receiver for a dish-type high-magnification concentrating system

ActiveCN104916724BReduce temperature riseImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesHigh concentrationConcentration cell

Owner:泰州市海创新能源研究院有限公司

a led light bulb

InactiveCN104633486BImprove light outputImprove cooling effectLighting heating/cooling arrangementsGlobesMicrometerLight reflection

The invention relates to an LED lamp bulb. The LED lamp bulb comprises a lamp holder, a transparent lamp cup and an LED chip array, and the outer surface of the transparent lamp cup is provided with a light reflection structure and a reflection layer which are used for reflecting light; the LED chip array is directly pasted to the inner surface of the transparent lamp cup; in addition, LED chips in the LED chip array comprise vestigial substrates which range from 0.1 micrometer to 1 micrometer.

Owner:陈宗烈

Investment casting precision casting method for improving solidification and heat dissipation conditions of directional solidification castings

ActiveCN105033180BSpeed up coolingImprove performanceFoundry mouldsFoundry coresCrystal structureSingle crystal

The invention belongs to the technical field of precision casting of directional solidification column crystal or single crystal test bars, and relates to a fired mold precision casting method for improving solidification heat dissipation conditions of a directional solidification casting. In the directional column crystal or single crystal test bar manufacturing process, selected mold shell materials are the same as universal mold shell materials. The shape of a mold shell is changed, the equal-distance variable cross section is increased, and a plurality of equal-distance rectangular grooves are formed. When the directional solidification test bars and the mold shell move to the position below a heat insulation plate together, mechanical expansion rings arranged in a directional solidification furnace are inlaid in the equal-distance rectangular grooves of the mold shell; the mechanical expansion rings expand downwards to remove the part, below the grooves, of the mold shell; the lower end of the directional solidification casting is in direct contact with cooling media, so that the heat exchange conditions of the directional solidification test bars and the cooling media are improved; and therefore, the cooling speed of the directional solidification casting and the temperature gradient of a solid-liquid interface are greatly improved, the dendritic crystal structure of the directional solidification casting is refined, dendritic segregation is reduced, and the mechanical property of the casting is remarkably improved.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com