Circular preheater of permanent magnet rotary pump in single cavity, and assembly method

A permanent magnet rotor and pump cycle technology, applied in the direction of machine/engine, engine components, engine starting, etc., can solve the problems of reduced distance between inlet and outlet, unreasonable structure, etc., and achieve size reduction, volume and weight The effect of reducing and occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation and examples of the present invention will be described below in conjunction with the accompanying drawings.

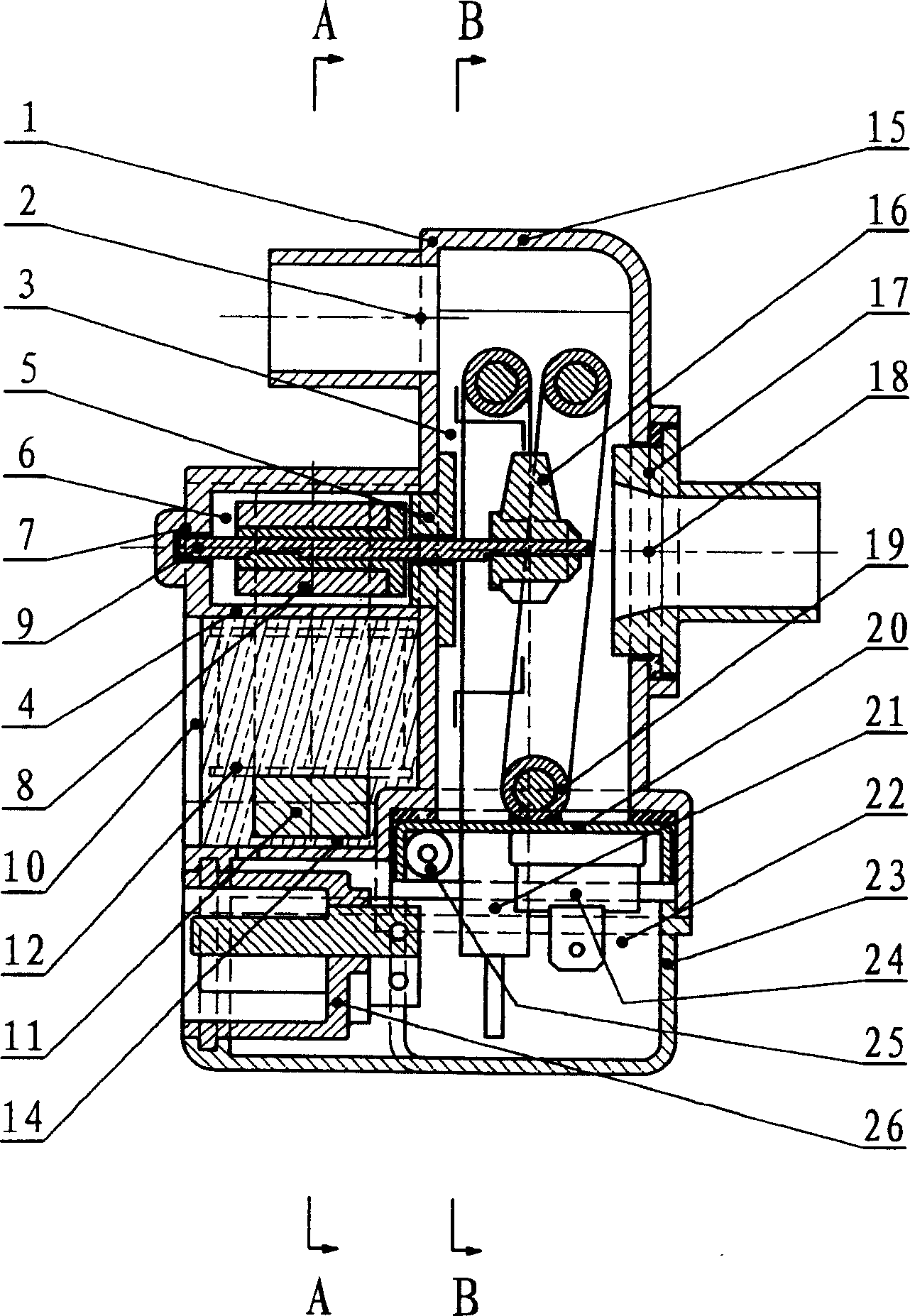

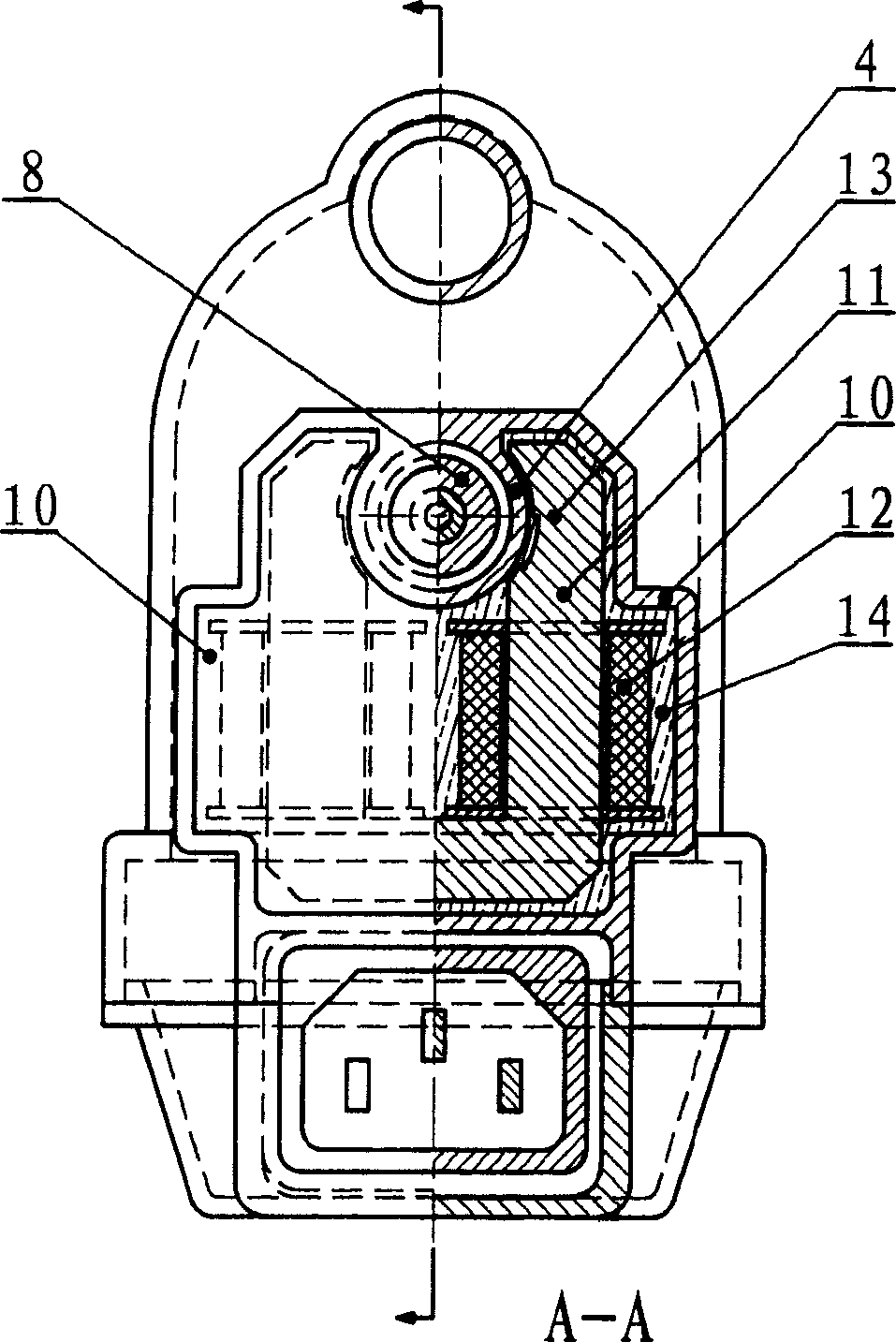

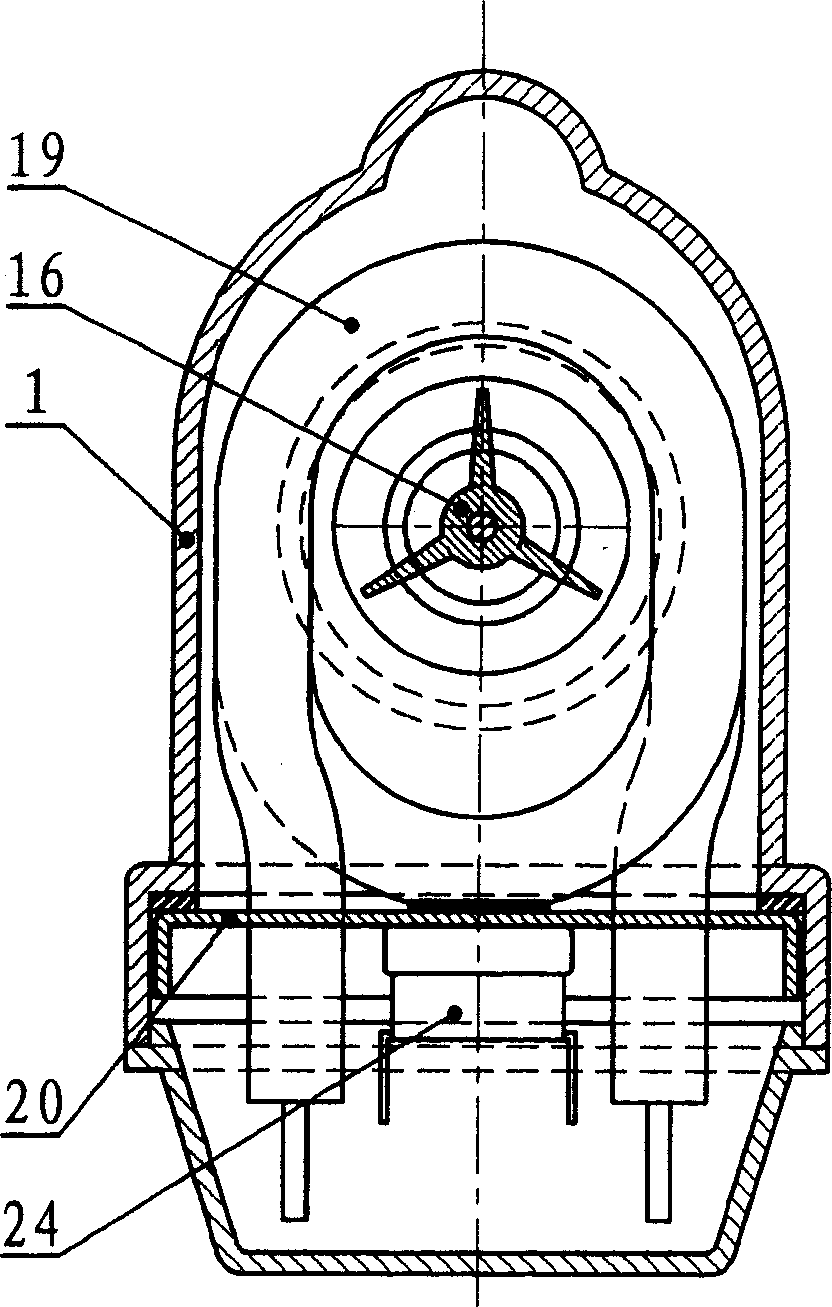

[0046] Depend on figure 1 , figure 2 , image 3 It can be seen that the main structure of the device of the present invention is a closed chamber, which communicates with the outside only through the inlet (18) and outlet (2) on it, and the chamber is divided into a smaller rotor chamber (6) and a larger heating chamber (3) two parts, the two parts communicate through the rotor cavity, the positional relationship between them is that the rotor cavity is on a side wall of the heating cavity (3), and the rotor cavity (6) and the rotor cavity shell (4) are formed by The rotor cavity mouth protrudes outside the heating cavity (3). Such a positional relationship shows that the rotor cavity opening is the interface between the rotor cavity (6) and the heating cavity (3). After the front bearing (5) is installed on the rotor cavity open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com