A led lighting device with integrated heatsink

A technology of LED lighting and integrated heat sink, applied in the field of lighting, can solve the problem of increasing the final cost ratio of lighting equipment, and achieve the effect of reducing the final cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

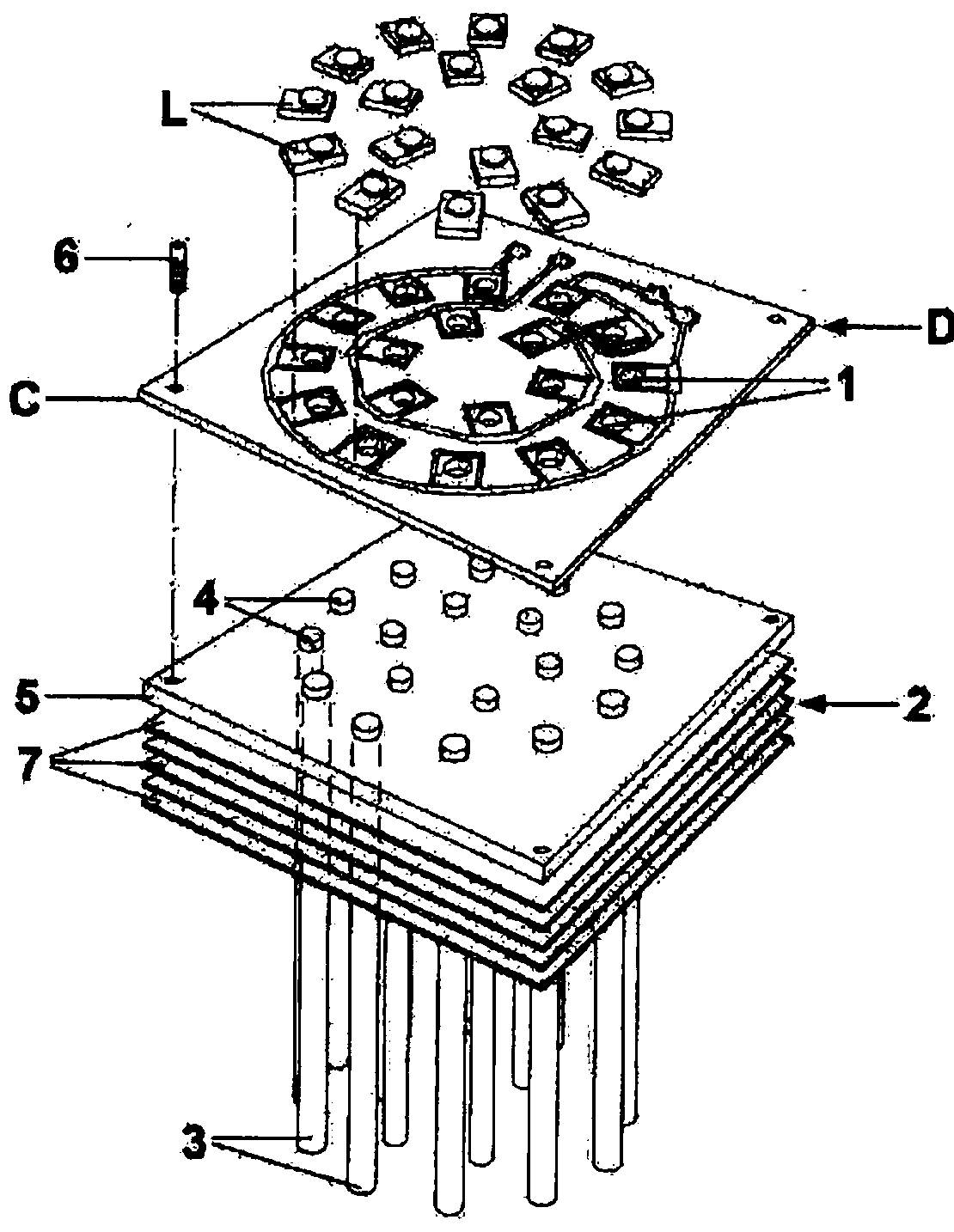

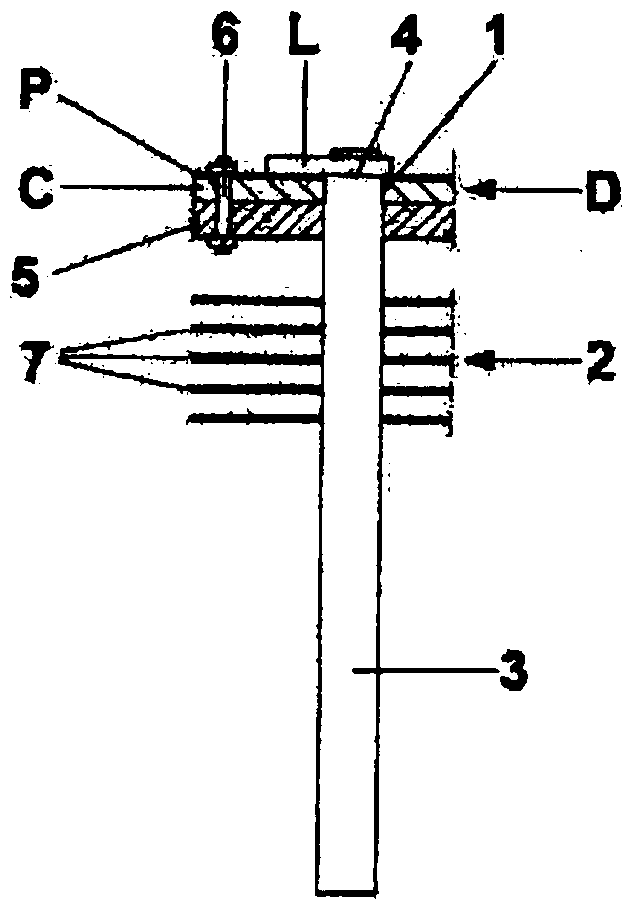

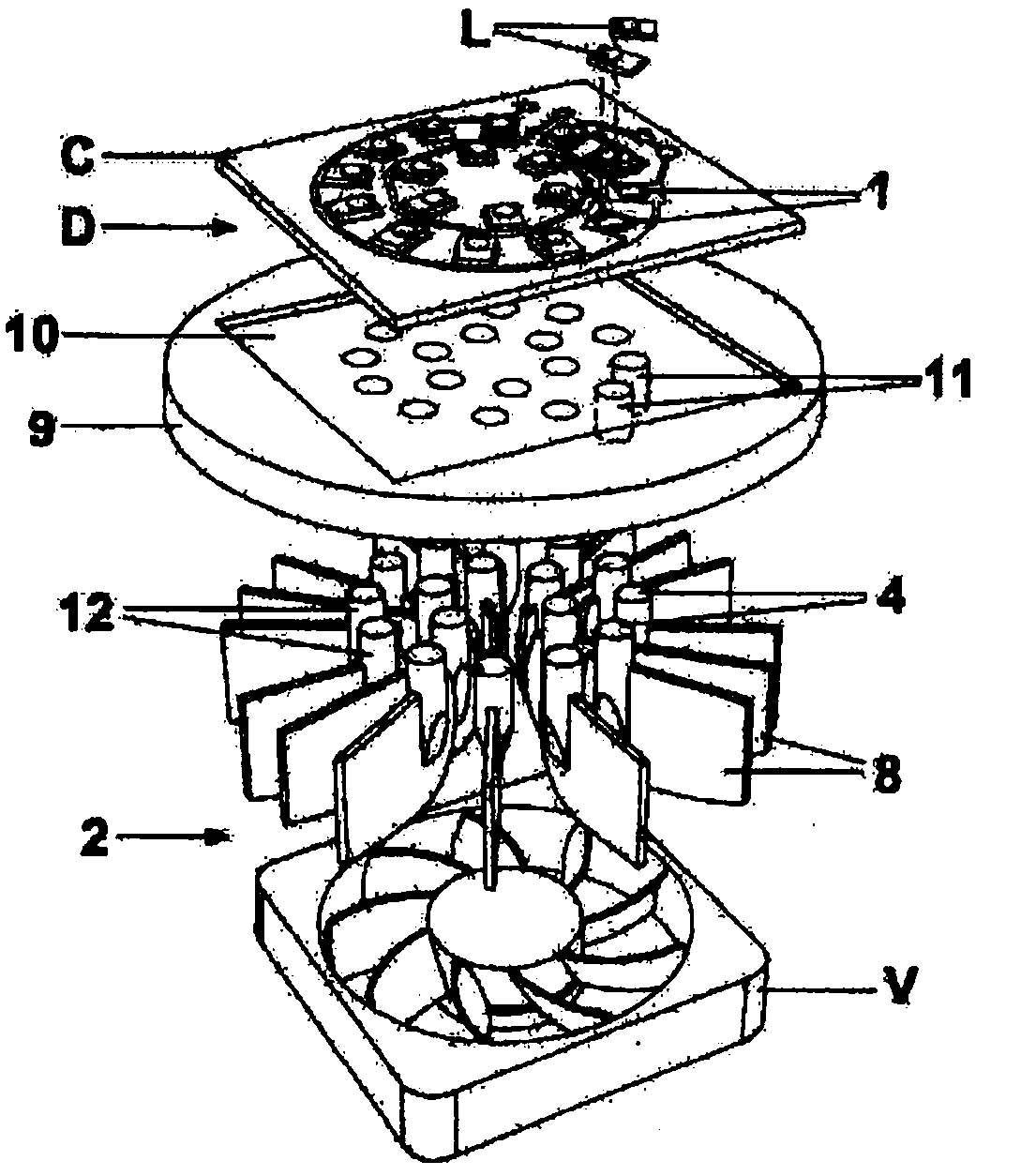

[0035] according to figure 1 and figure 2 In detail, the lighting equipment of the present invention mainly includes:

[0036] - A printed circuit C of the PCB (printed circuit board) or MCPCB (metal core printed circuit board) type, having the function of driving and controlling a matrix of LEDs L, forming the source of illumination for this device D, comprising a housing 1, having a circular hole shape or any other lamp shape of regular geometry configured to accommodate the cooling fins of a specific heat sink 2;

[0037] - a heat sink 2 may be associated with said printed circuit C, comprising a plurality of cooling fins 3, symbolically cylindrical in shape, provided with upper terminals 4, which may be inserted into a corresponding housing 1 of said printed circuit C, attaching the LED forming the source of illumination of the device D directly onto said printed circuit C;

[0038] - a connecting plate 5, included in the structure of said heat sink 2, which is configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com