Patents

Literature

33results about How to "Structural Shape Improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

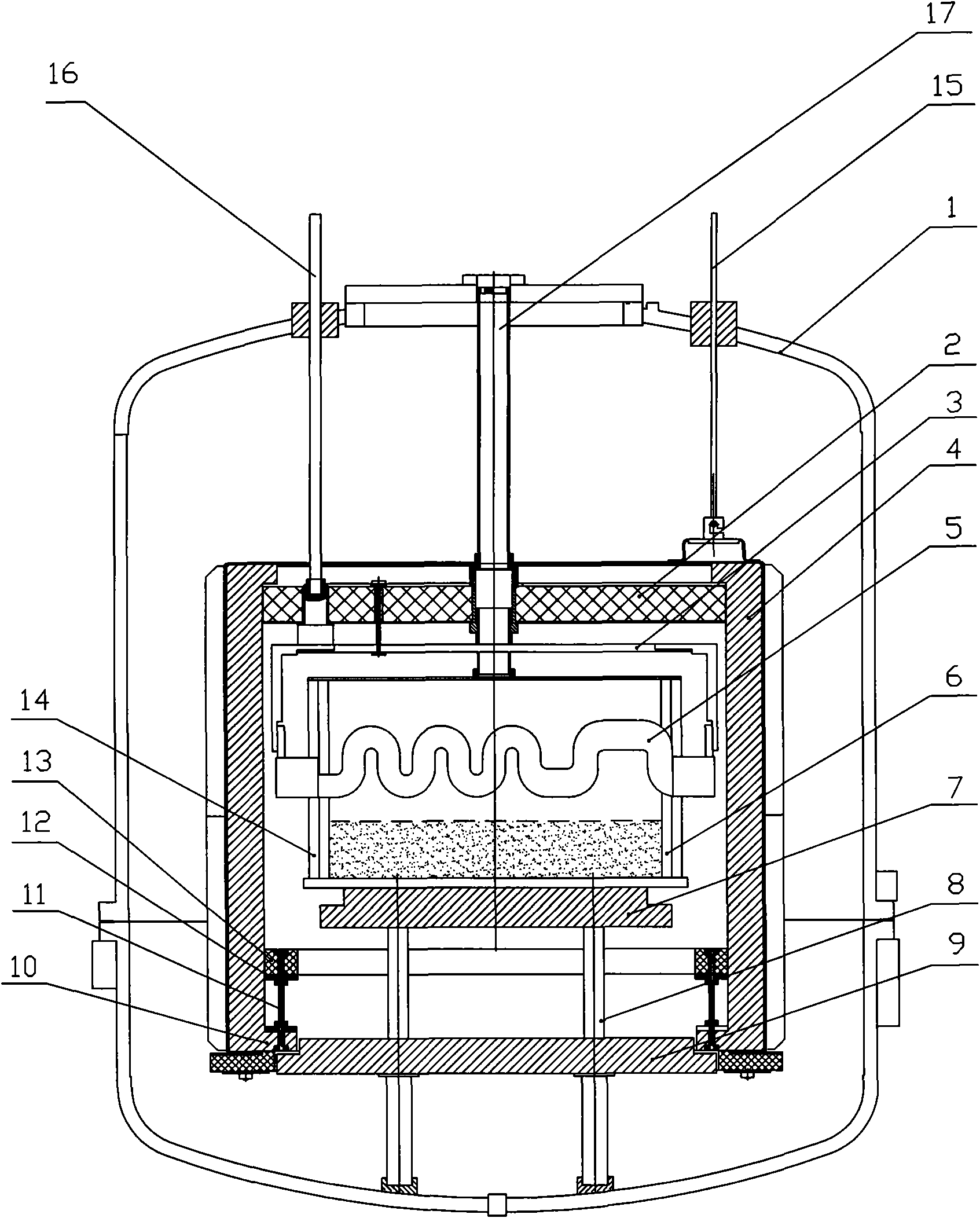

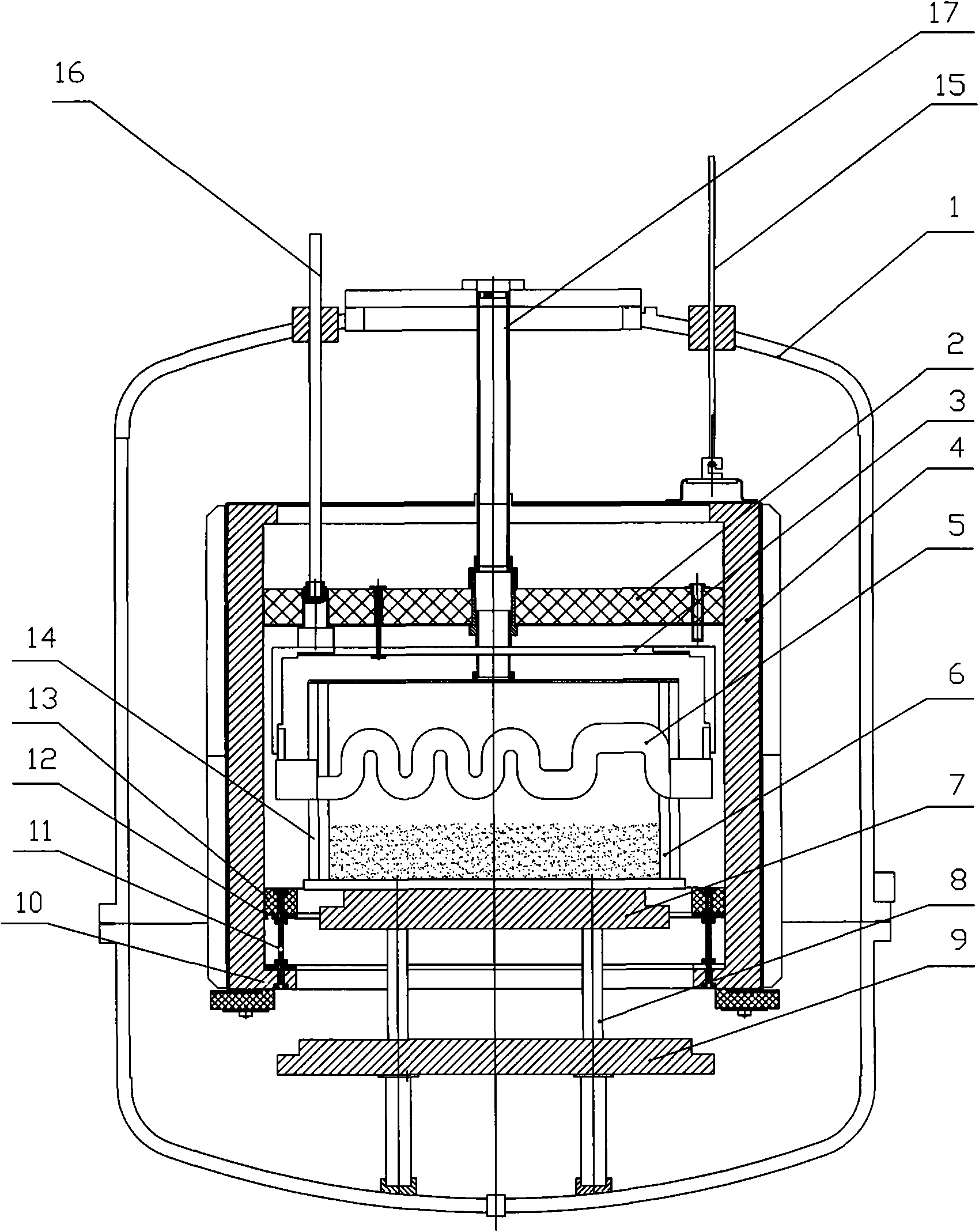

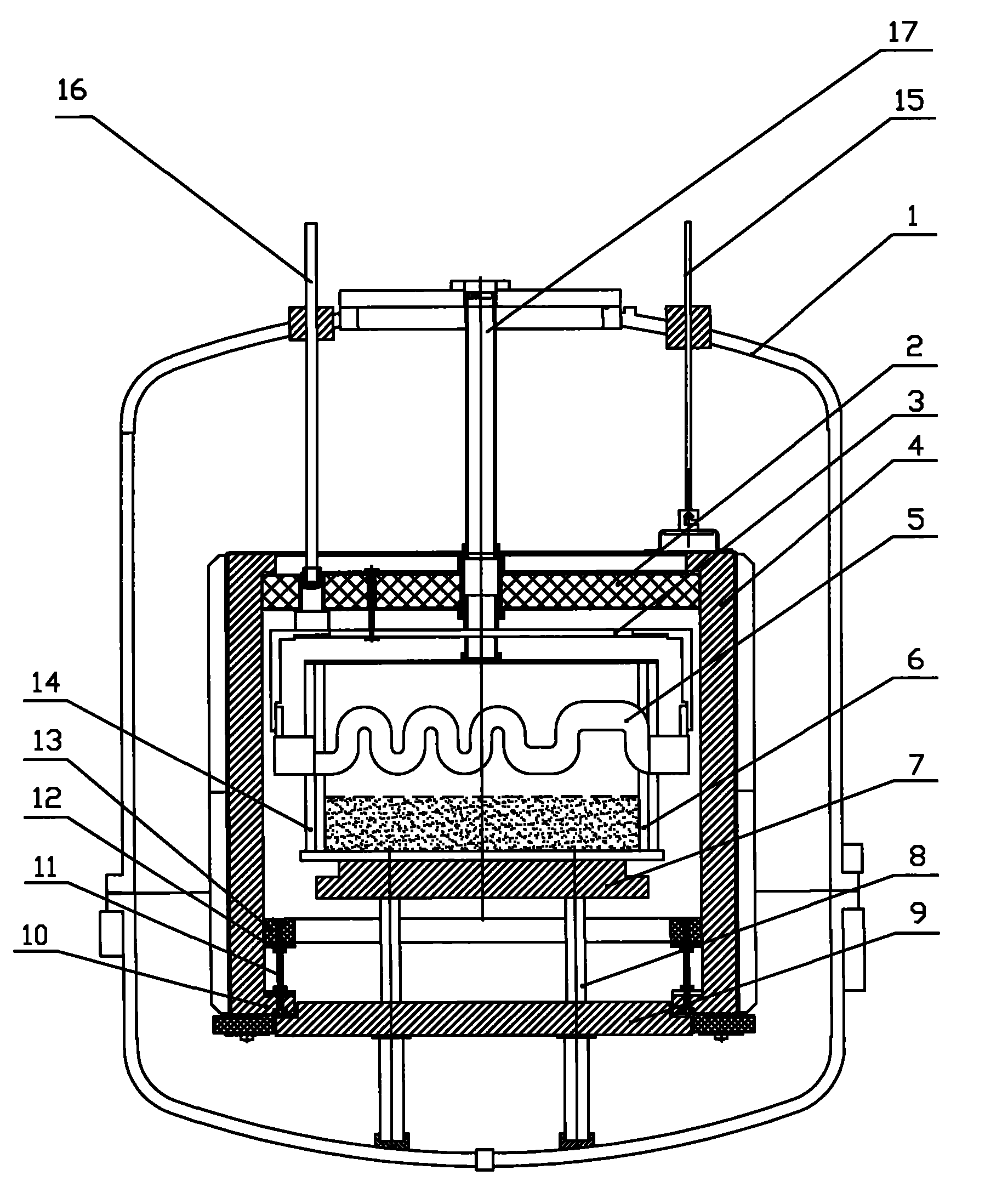

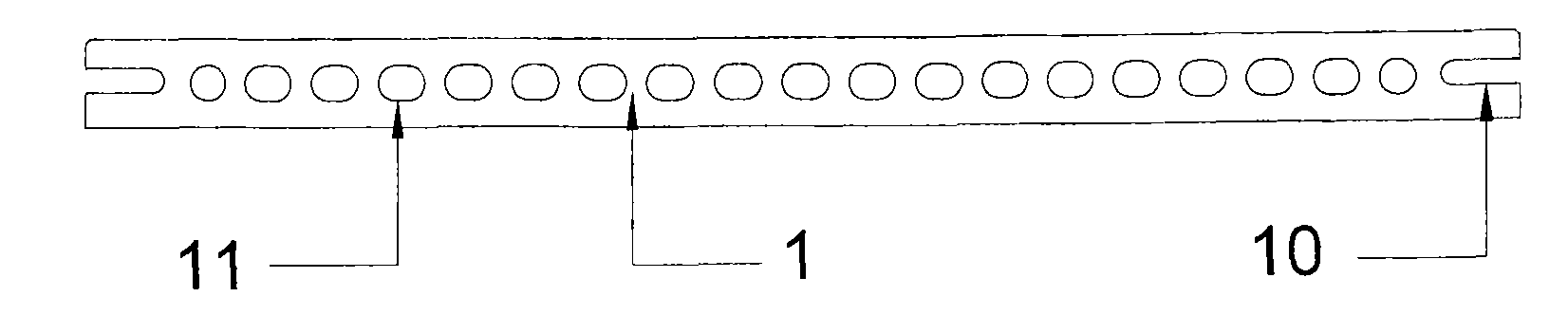

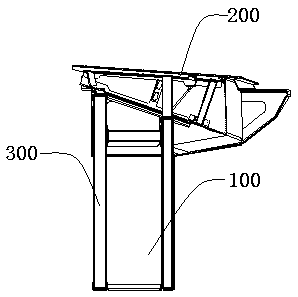

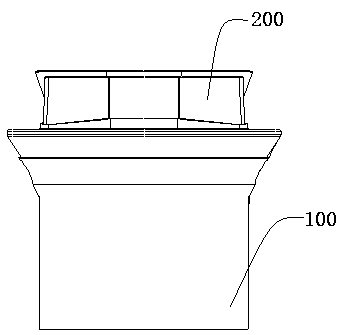

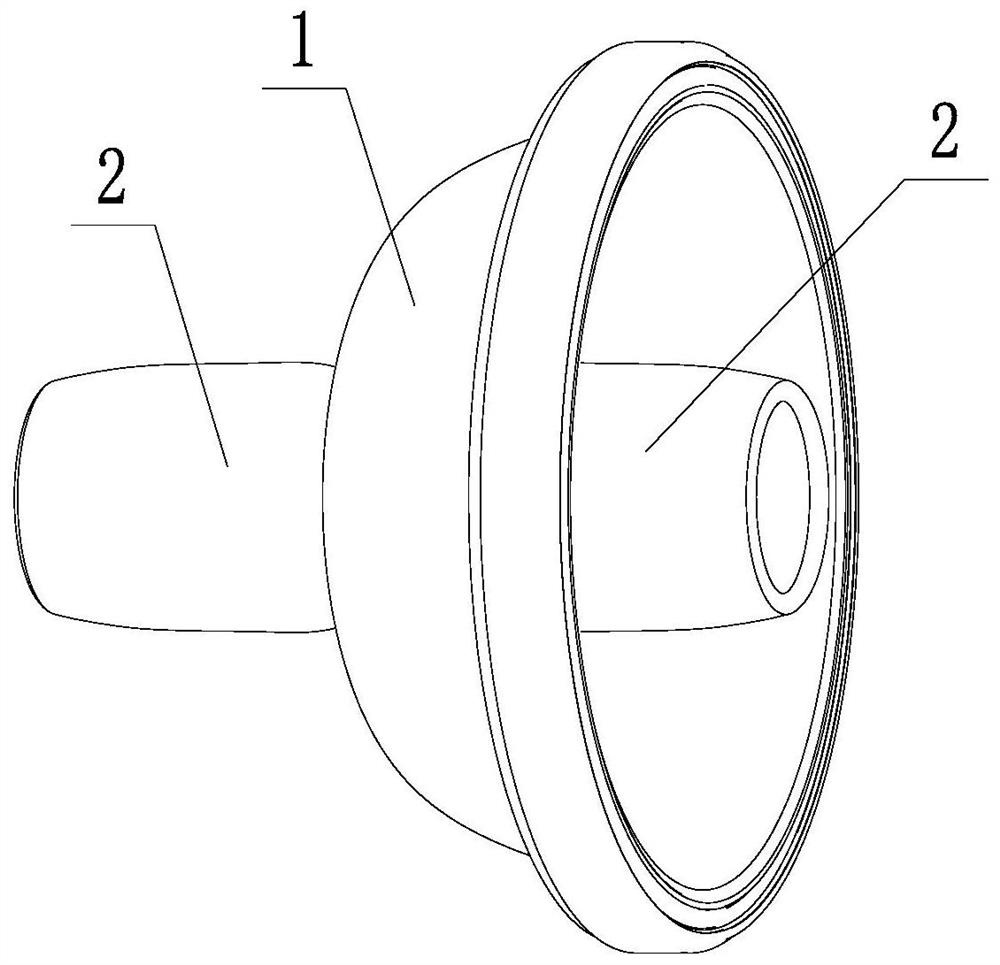

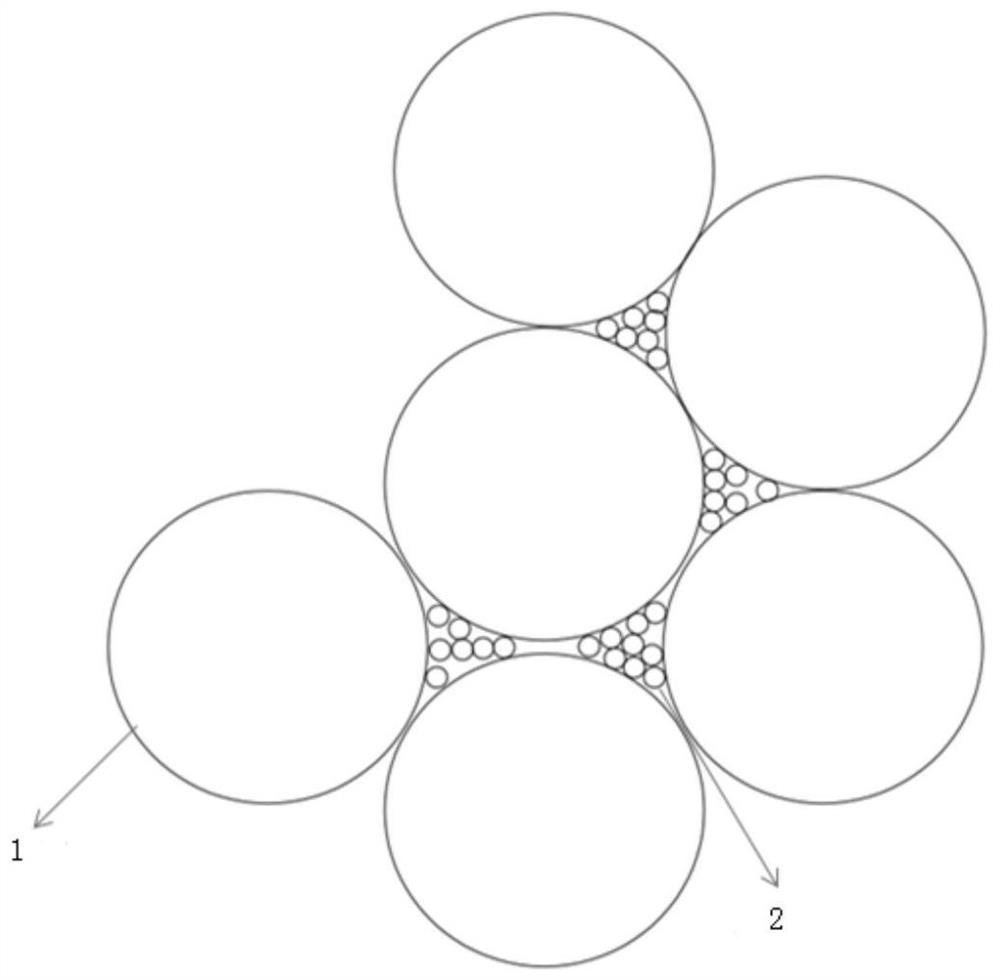

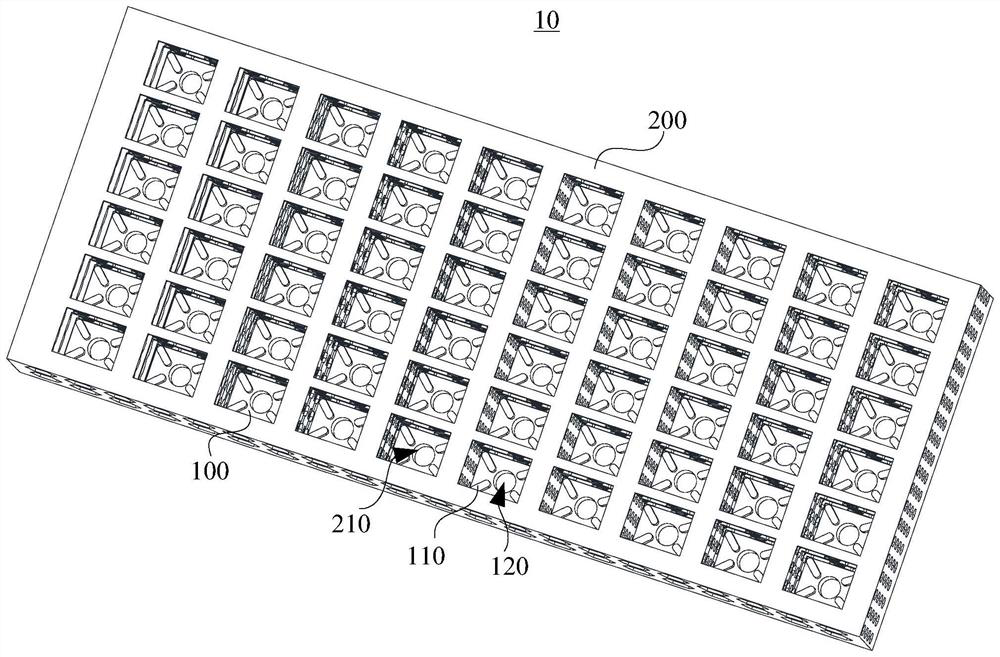

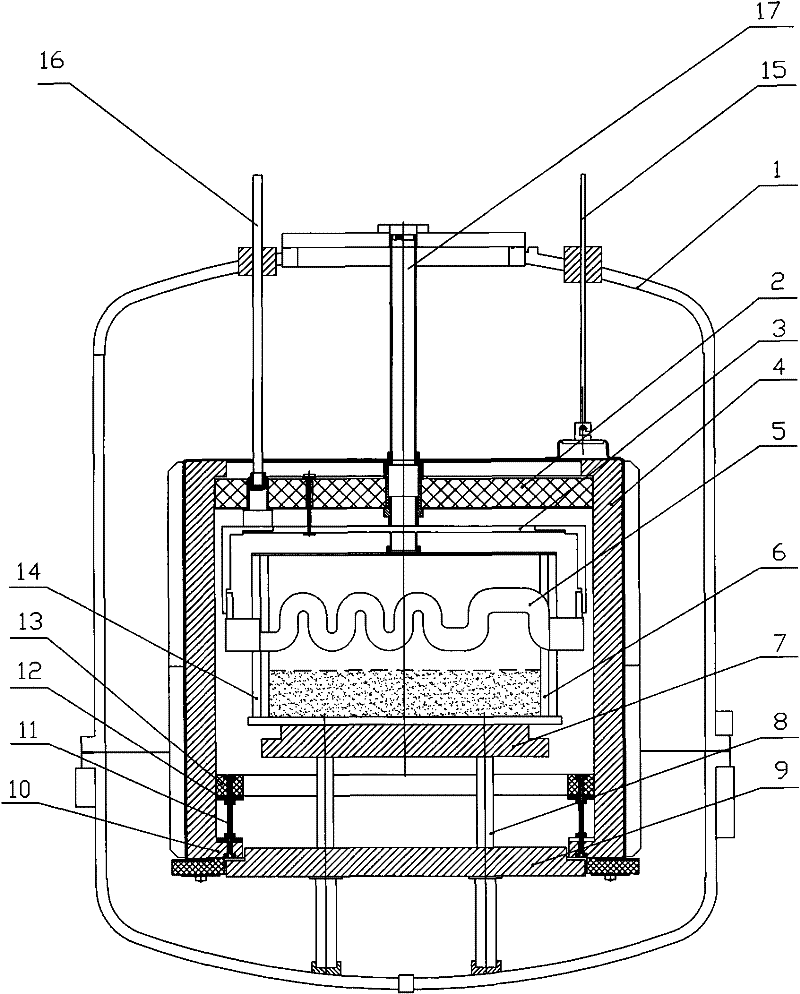

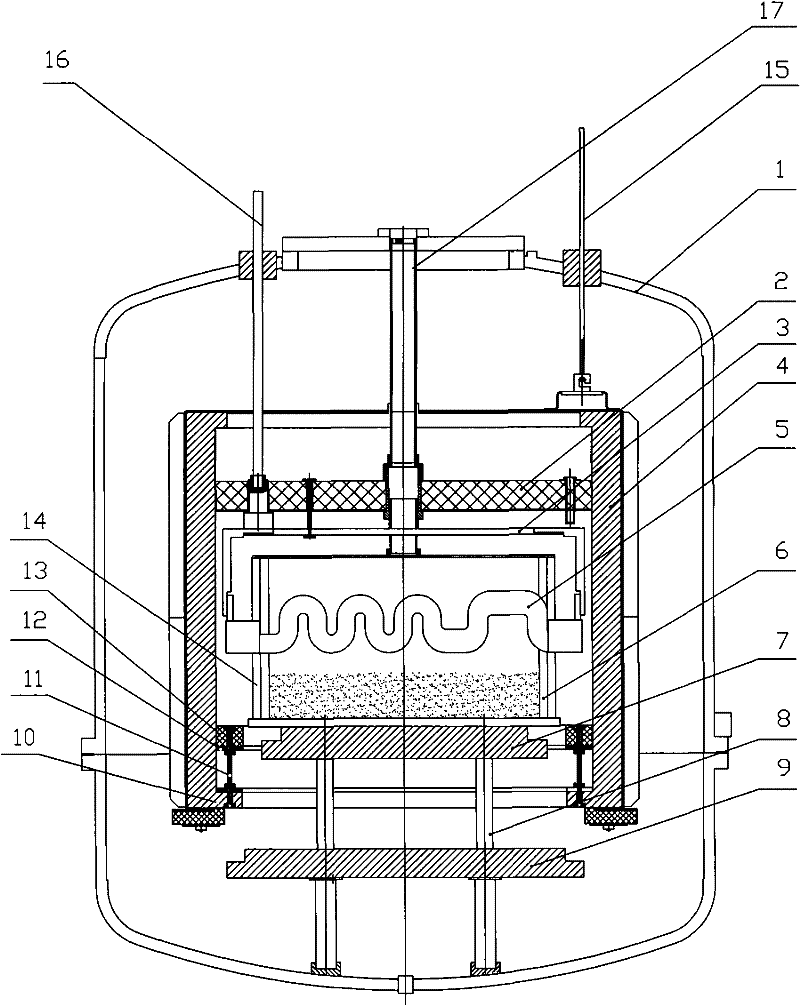

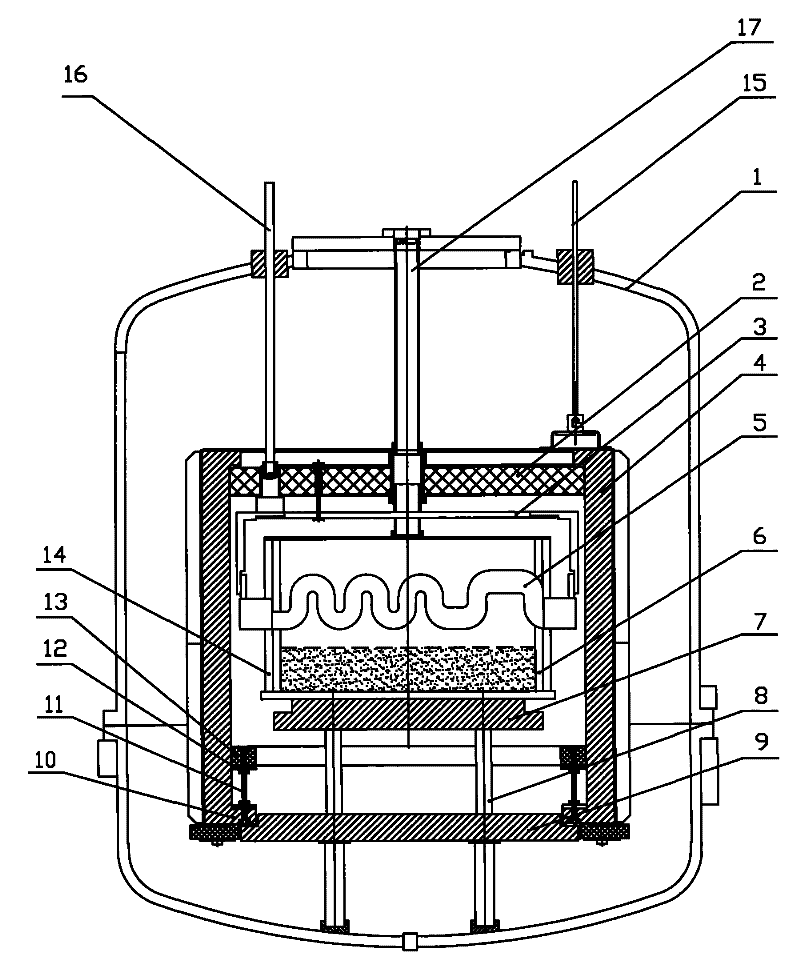

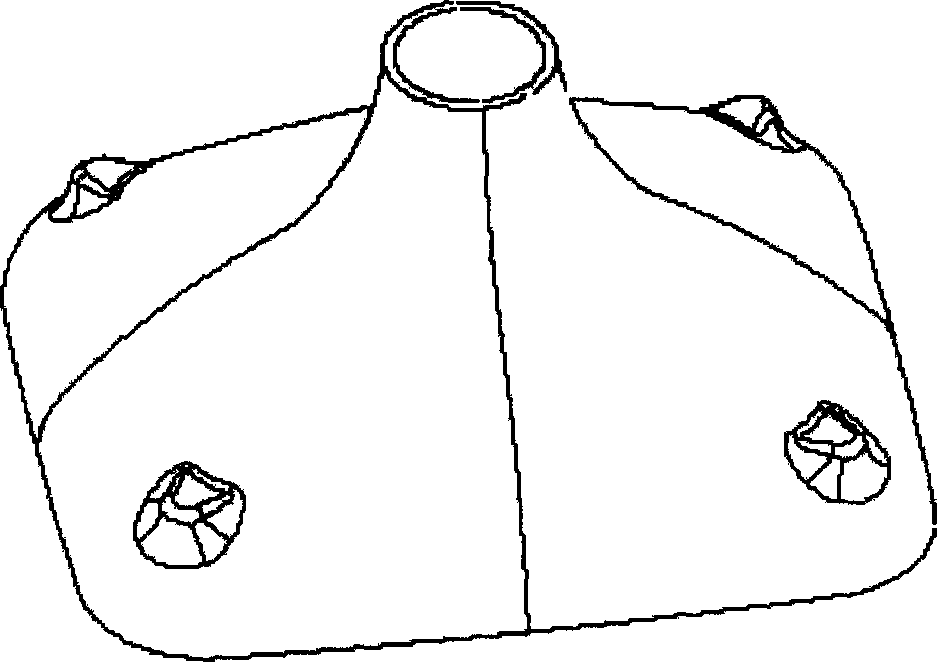

Follow-up heat insulation ring thermal field structure for vertical oriented growth of polysilicon

InactiveCN101775641ACrystal solidification process controlImprove temperature gradient distributionBy pulling from meltManufacturing technologyThermal insulation

The invention relates to the technical field of polysilicon ingot furnace designing and manufacturing, and aims to provide a follow-up heat insulation ring thermal field structure for the vertical oriented growth of polysilicon. The thermal field structure comprises a furnace chamber with a side surface enclosed heat insulation cage body, a crucible and a thermal field are arranged in the heat insulation cage body, and the upper end of the heat insulation cage body is connected with a lifting device; the upper part and the lower part of the heat insulation cage body are respectively provided with a top heat insulation board and a lower heat insulation body, wherein the top heat insulation board is fixedly suspended on an electrode, the lower heat insulation board and a heat exchange are fixed on a support column, the top heat insulation board and the upper end of the heat insulation cage body are movably connected, and the lower heat insulation board and the lower end of the heat insulation cage body are movably connected; and a circular follow-up heat insulation ring is fixed in the heat insulation cage body through a plurality of connecting devices. The follow-up heat insulation ring thermal field structure for the vertical oriented growth of polysilicon has reasonable design, can increase the grain size of polysilicon, reduce grain boundary and improve the verticality of the growing direction of polysilicon so as to improve the quality of polysilicon ingots, and simultaneously the follow-up heat insulation ring also plays the role of energy consumption reduction.

Owner:NINGBO JINGYUAN SOLAR ENERGY +1

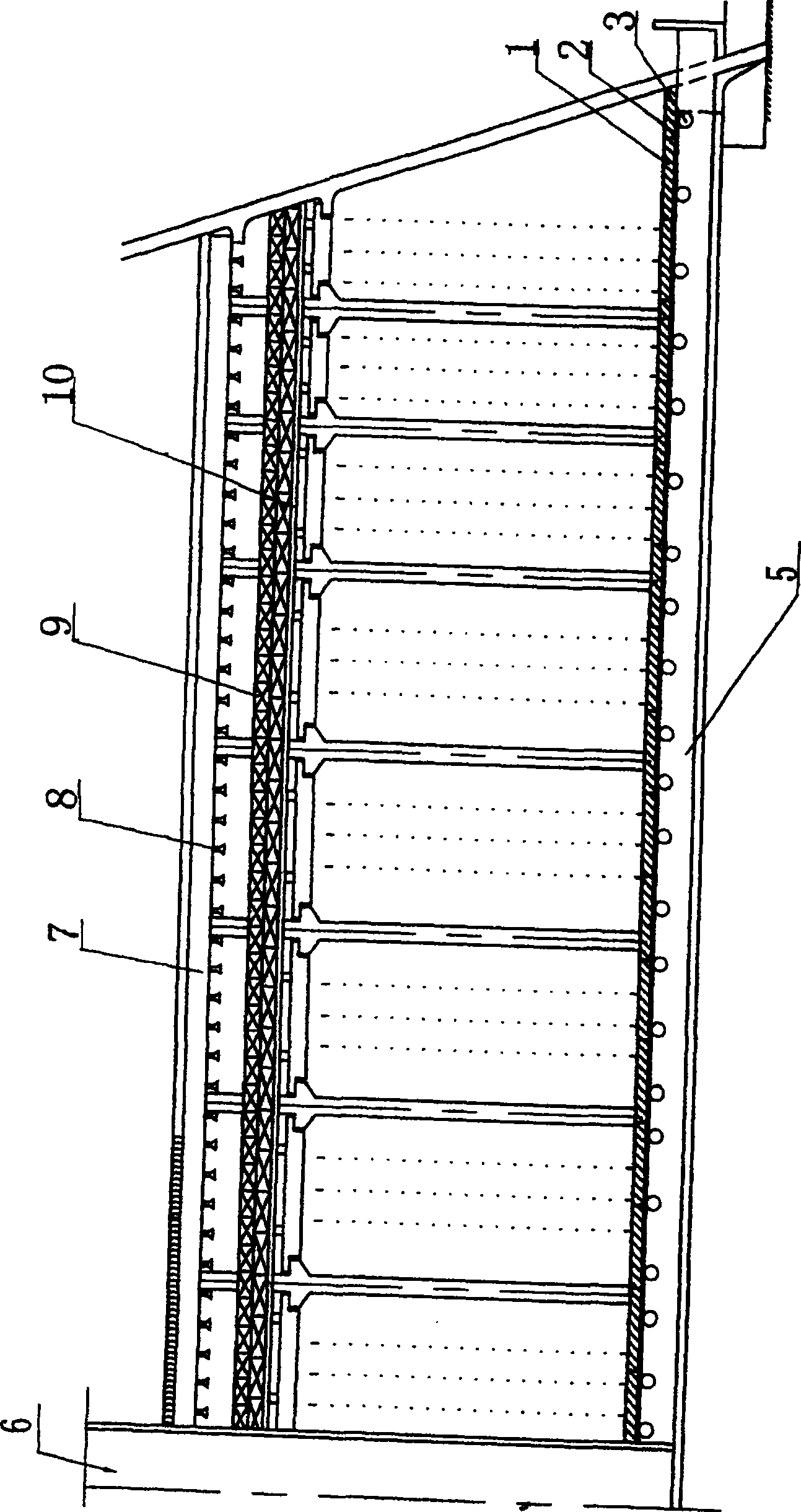

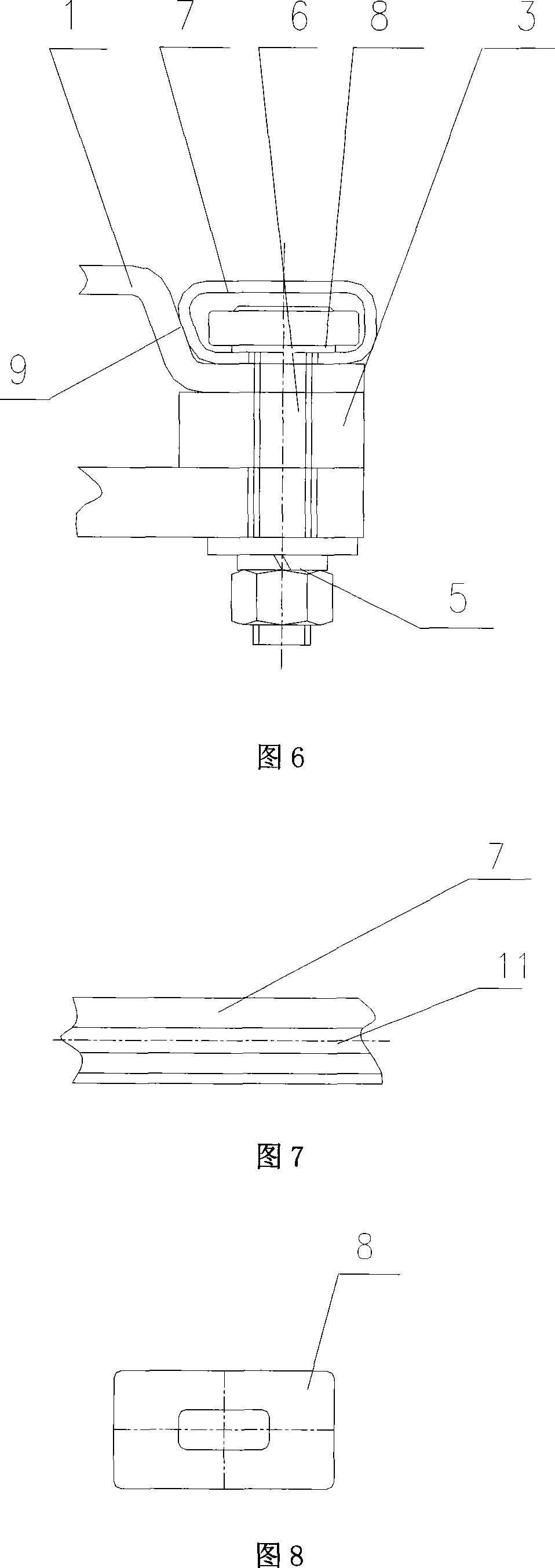

H-shaped ceramic plate and Mounting structure for H-shaped ceramic plate curtain wall

The invention discloses an H-shaped ceramic plate and a mounting structure for an H-shaped ceramic plate curtain wall. The mounting structure comprises a main structure, a vertical keel fixed on the main structure, a connecting piece fixed on the vertical keel, an H-shaped ceramic plate and a hanging piece, wherein the whole body of the H-shaped ceramic plate is of a cuboid shape, the upper and lower ends of the cuboid are provided with a concave notch respectively; the front end of the hanging piece is a clipping connection part matched with the concave notches; and the H-shaped ceramic plate is fixed on the connecting piece by the hanging piece. In the structure, the structural shape of the ceramic plate is improved, the H-shaped ceramic plate of which the upper and lower ends are provided with the concave notch respectively is obtained by optimization, so that the improved ceramic plate has the advantages of greatly reducing the deviation, greatly improving the quality and reducing the cost; and simultaneously, as for the mounting of the ceramic plate curtain, the precision is improved, the decorative beauty of the construction external curtain wall is improved, and the waterproof and thermal insulation properties of the ceramic plate curtain wall are enhanced, and favorable economic benefits are created.

Owner:沈英

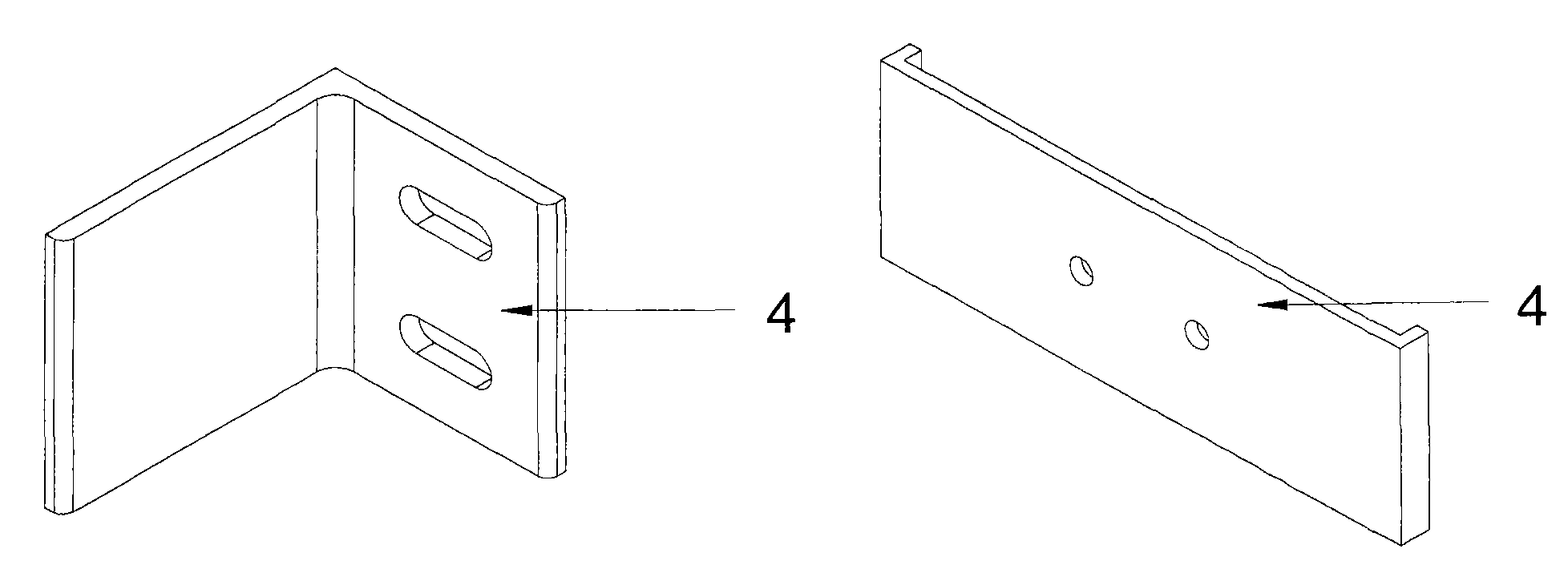

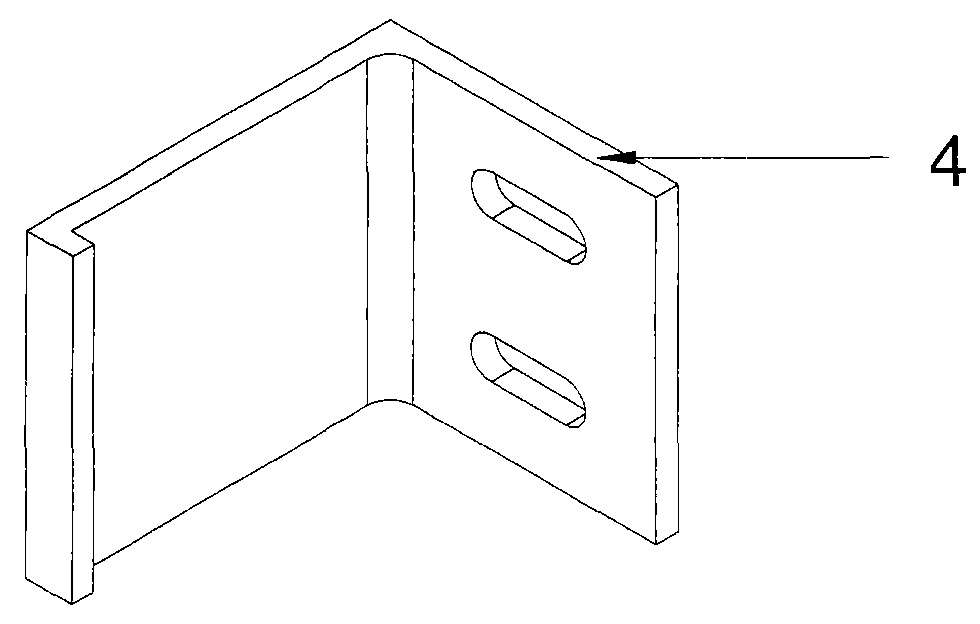

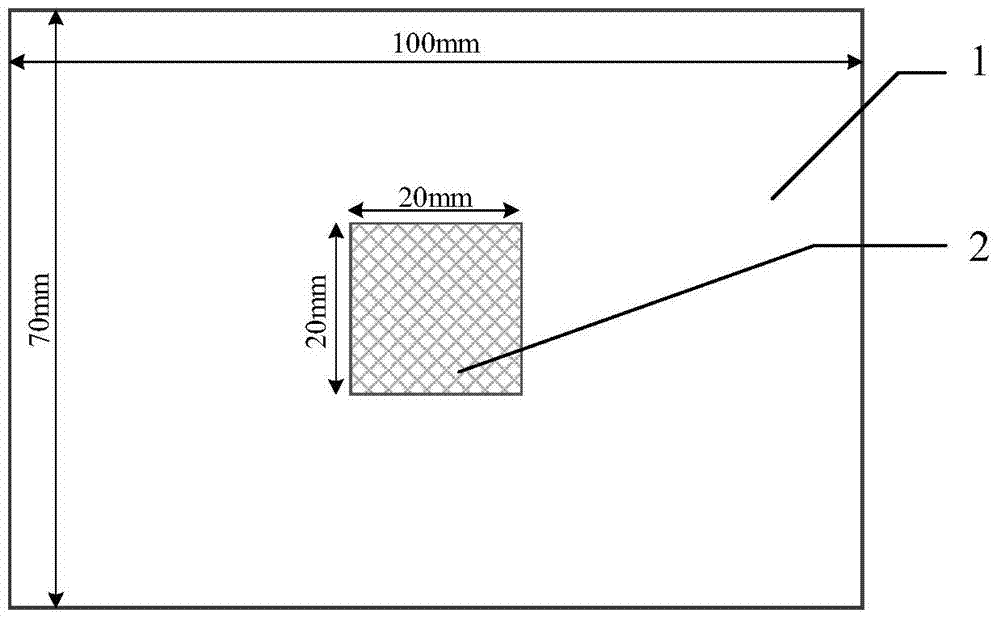

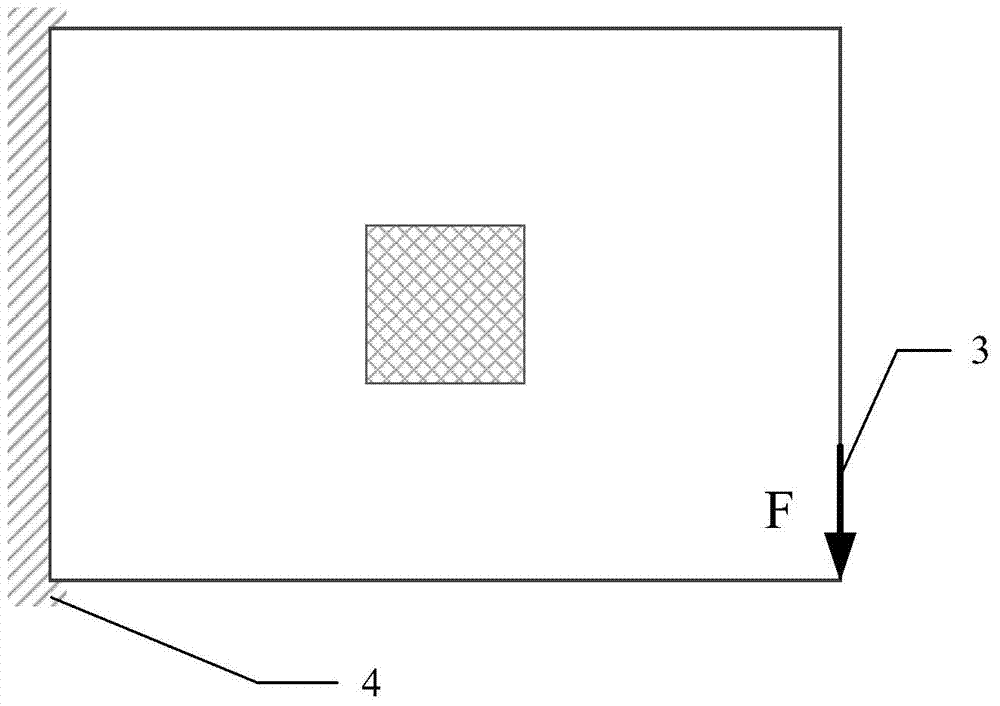

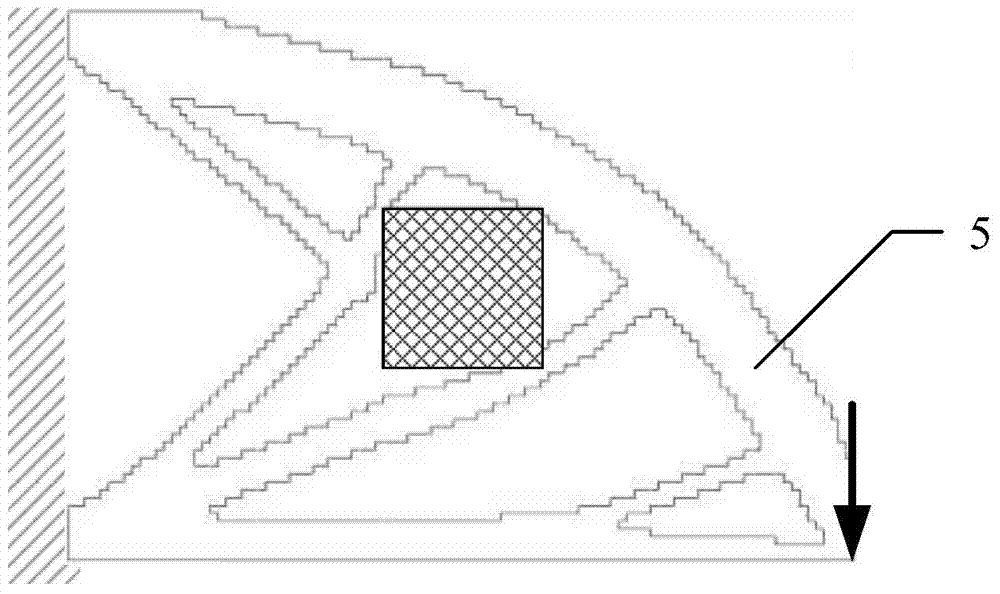

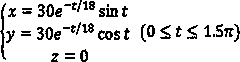

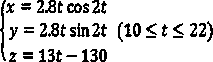

Method for topological optimization design of cantilever beam structure based on shape-preserved constraints

InactiveCN104765922AWarpage suppressionInhibit self-deformationSpecial data processing applicationsPresent methodStrain energy

The invention discloses a method for topological optimization design of a cantilever beam structure based on shape-preserved constraints and aims at solves the technical problem of poor precision in the present method for topological optimization design of a cantilever beam structure. The technical scheme comprises the steps: adopting a structural strain energy physics function and quantizing buckling deformation in a local area of the cantilever beam structure; utilizing a quantized strain energy numeric value as a constraint during optimization, giving an upper bound of the constraint and solving the flexibility of the strain energy constraint function in an accompanying method; meanwhile, introducing a constraint of material quantity, utilizing the whole rigidness of the cantilever beam structure as a target function, performing topological optimization, thereby obtaining a design result. By adopting the method, the deformation of the cantilever beam structure is effectively inhibited after the local area is stressed with load; meanwhile, the displacement form of the rigid body in the area is maintained and the shape-preserved design effect is realized. The optimization design result shows that the deformation capacity of the local area of the cantilever beam structure with the shape-preserved constraints is reduced to be 0.2% of the background art when the usage quantity of the same material is 40%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

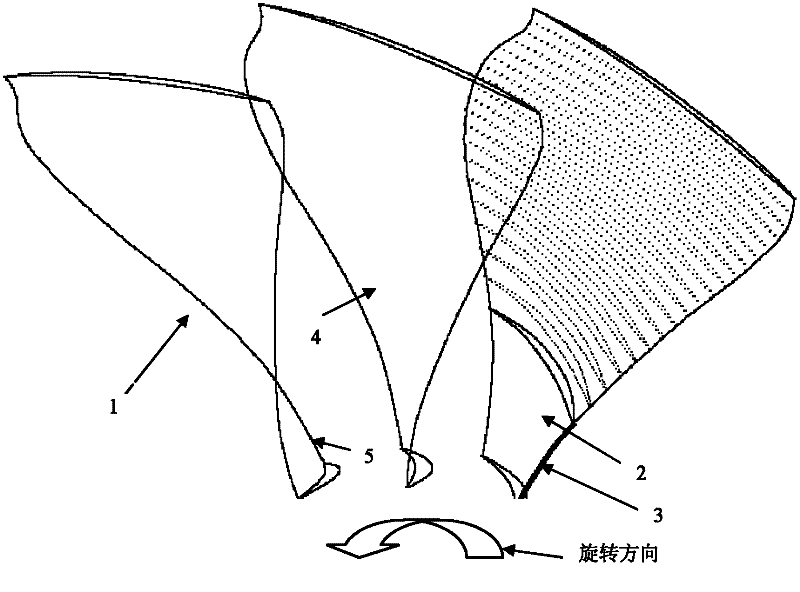

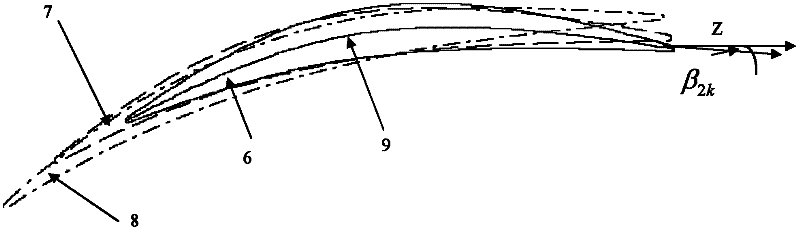

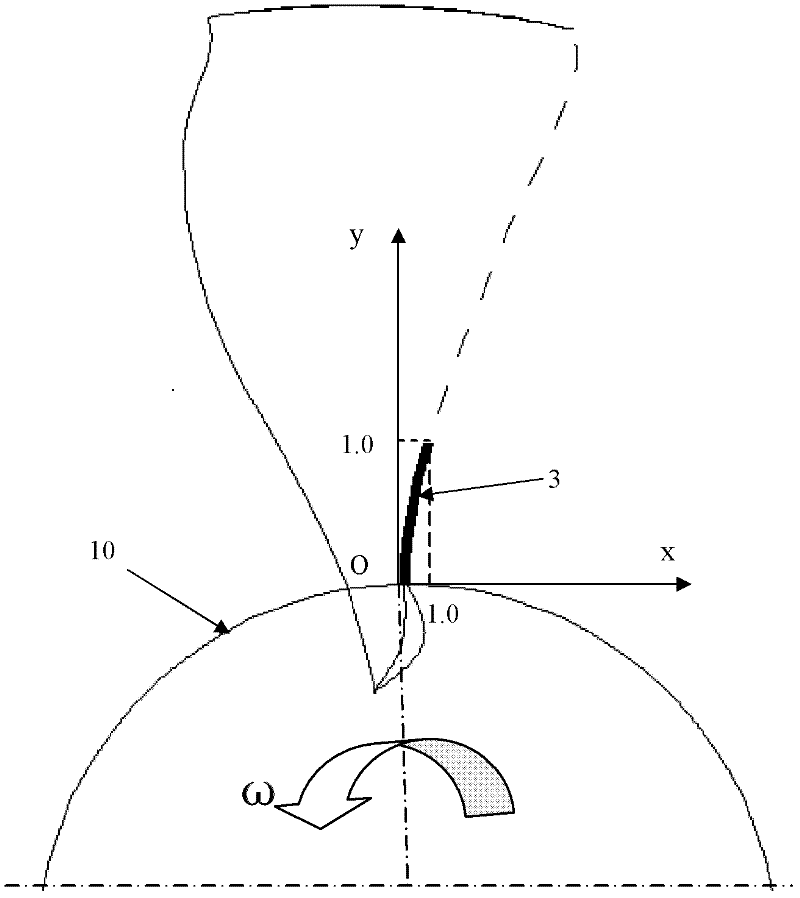

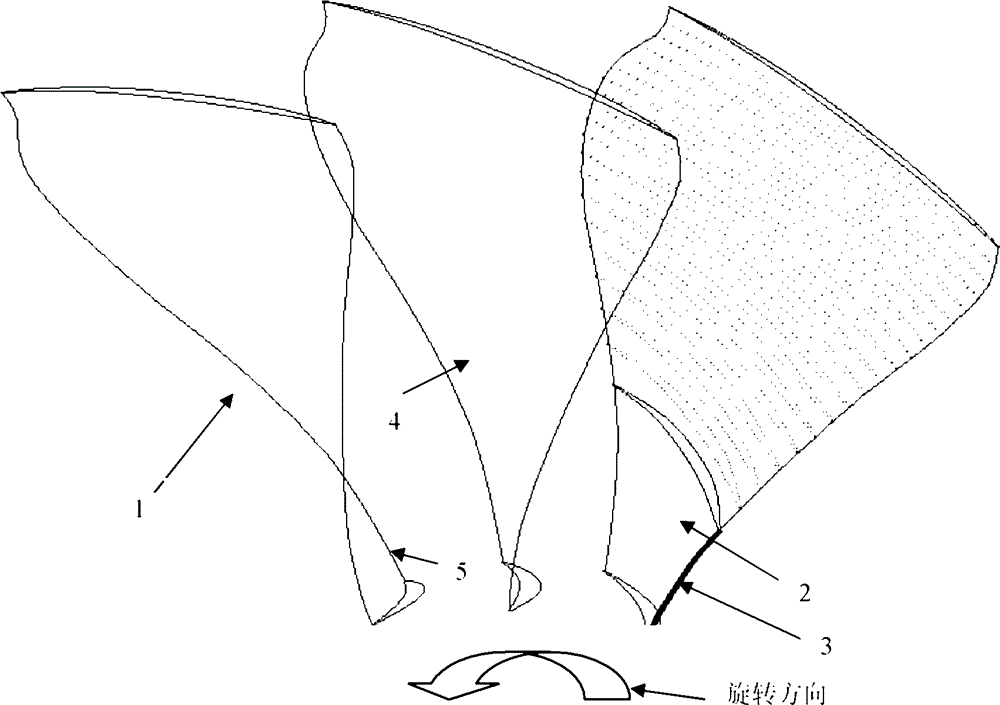

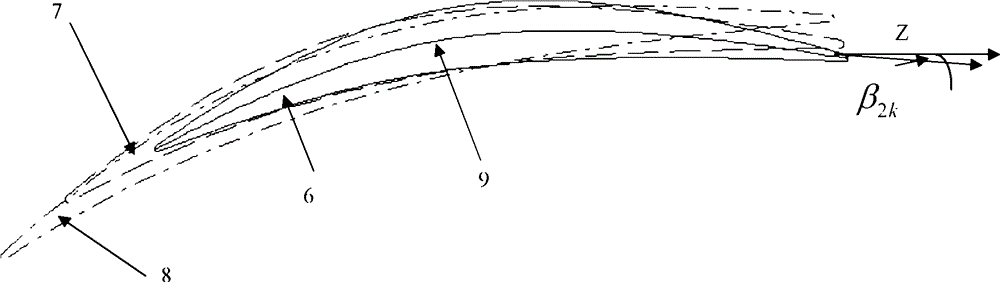

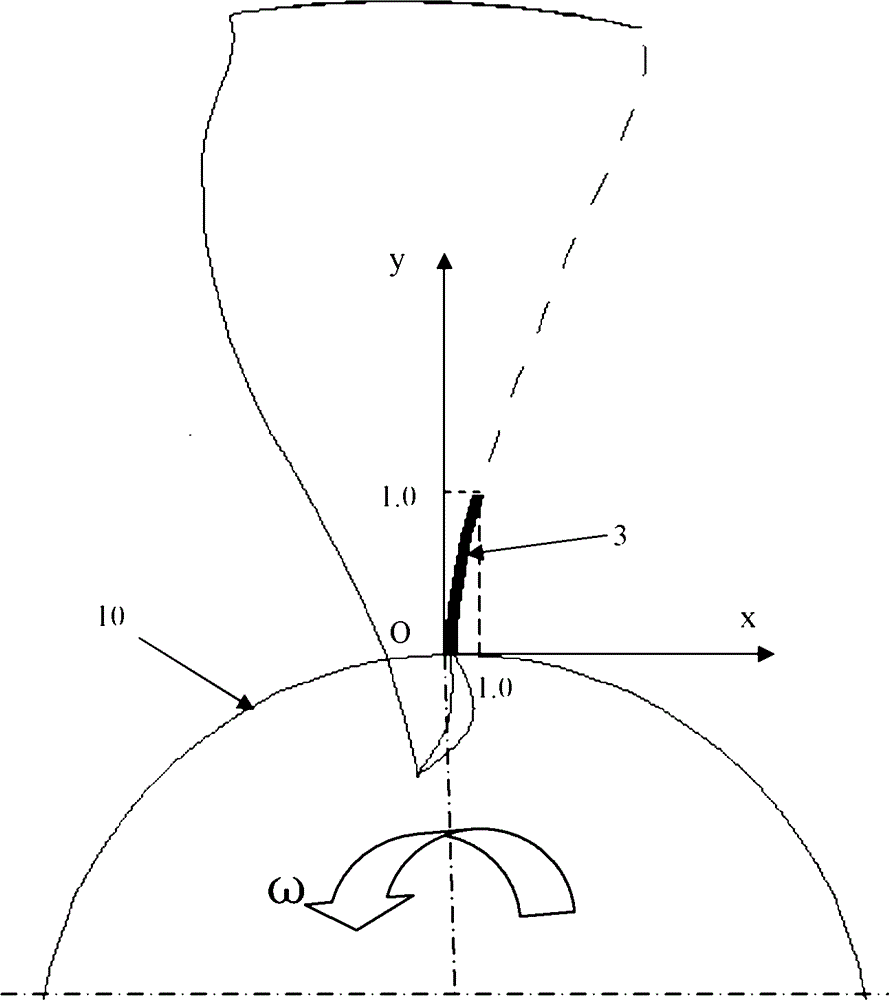

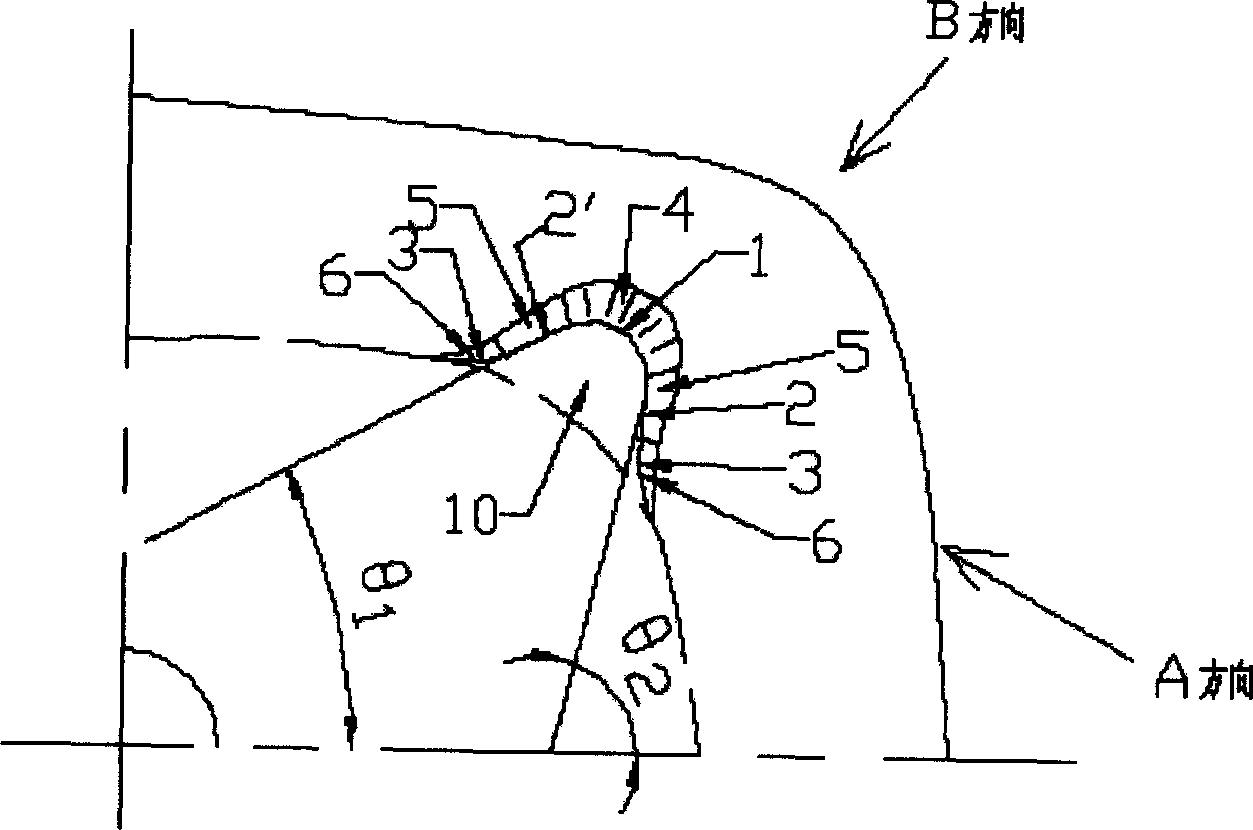

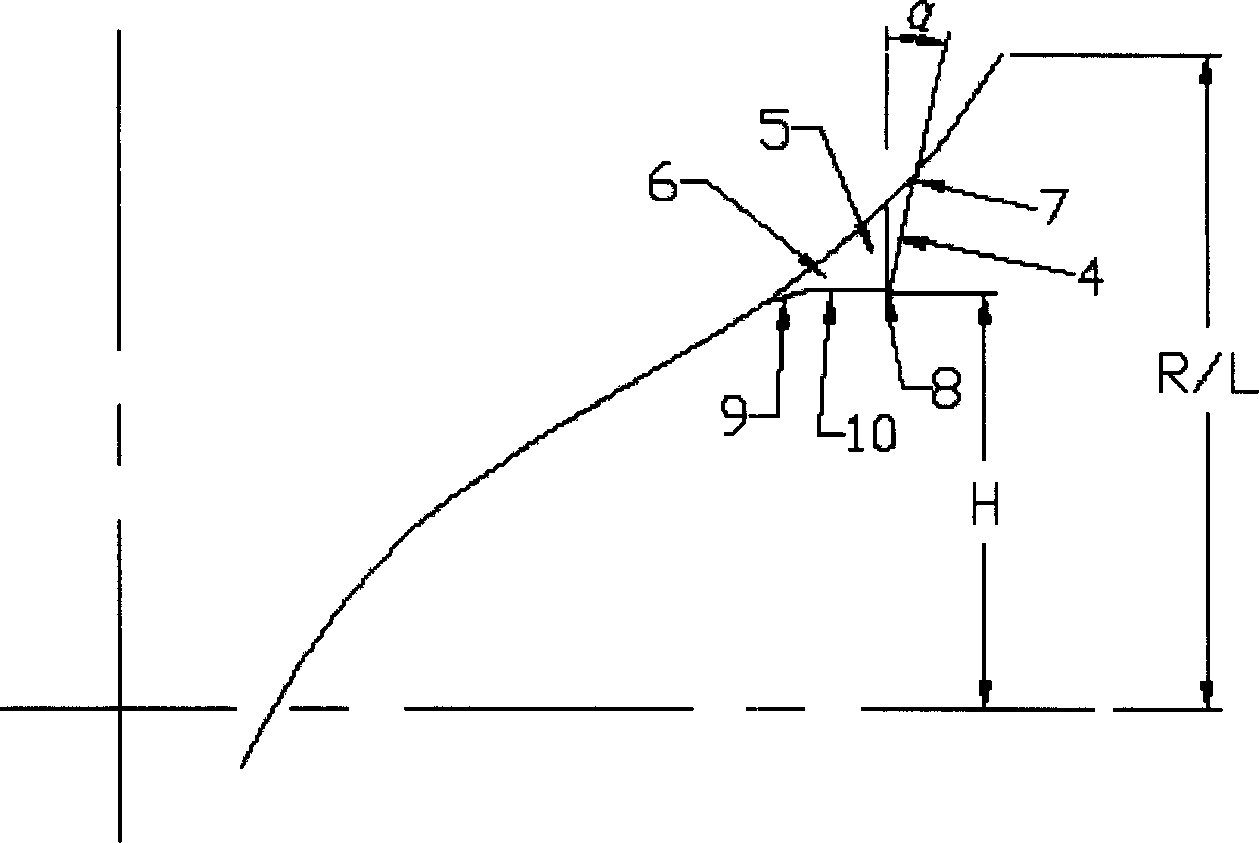

Pneumatic and structural feature considered three-dimensional geometric structure of fan blade of aircraft engine

InactiveCN102536327ATaking into account performance requirementsTaking structural requirements into accountBlade accessoriesMachines/enginesAviationAcute angle

The invention discloses a pneumatic and structural feature considered three-dimensional geometric structure of a large fan connotative blade of a civil aircraft engine. The rear section of a blade profile at the root part of the large fan which is designed traditionally has a larger bent corner, a smaller acute angle is formed by a trailing edge suction surface and a hub, low-energy gas is accumulated in the acute-angle area, the flow loss is great, and the smaller acute angle between the suction surface and the hub is not beneficial to the structure modeling of the root stretching section of the blade. According to the invention, the change of an outlet metal corner of an element blade profile of the large fan connotative blade (which is the part within 20% of a blade height of the large fan blade) along the blade height is mainly optimized and a distribution curve of the outlet metal corner of a connotative blade and a projection curve of a trailing edge line in a plane vertical to the axial direction are fit. Through the verification of three-dimensional CFD (Computational Fluid Dynamics), the pneumatic and structural feature considered three-dimensional geometric structure disclosed by the invention has the advantages that the flow separation in the acute-angle area formed by the trailing edge suction surface of the fan and the hub can be effectively reduced, the fan connotative efficiency can be increased, a good entrance condition is provided for a pressure boosting grade, and the blade at the root part and the hub are relatively almost vertical, so that convenience is provided for the installation of the blade on a wheel disc.

Owner:BEIHANG UNIV

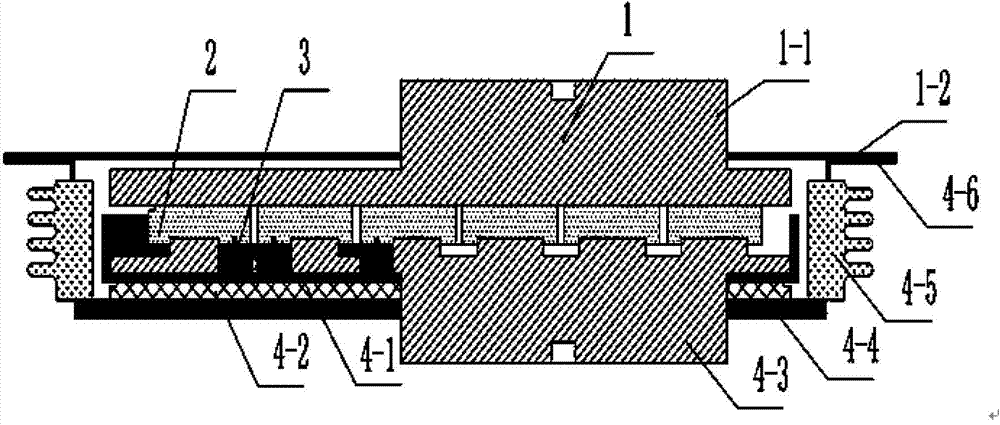

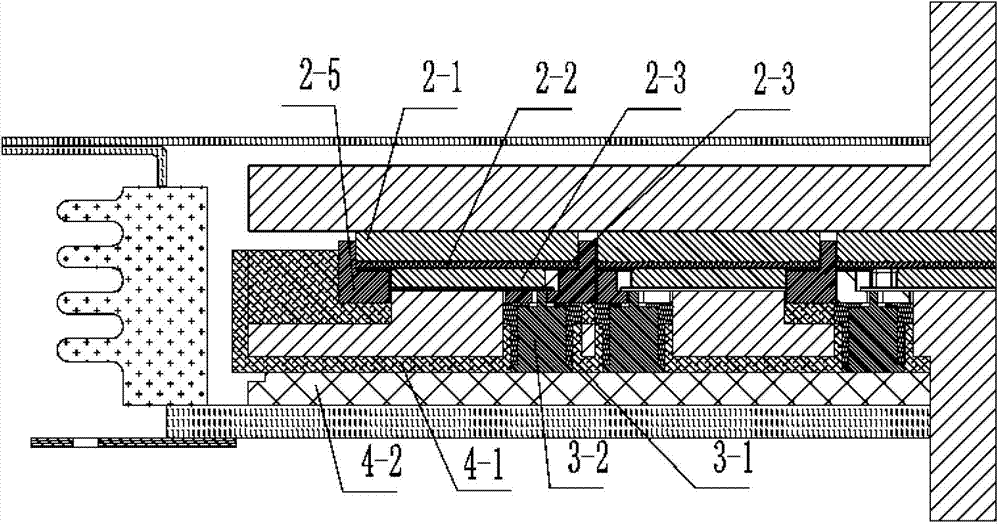

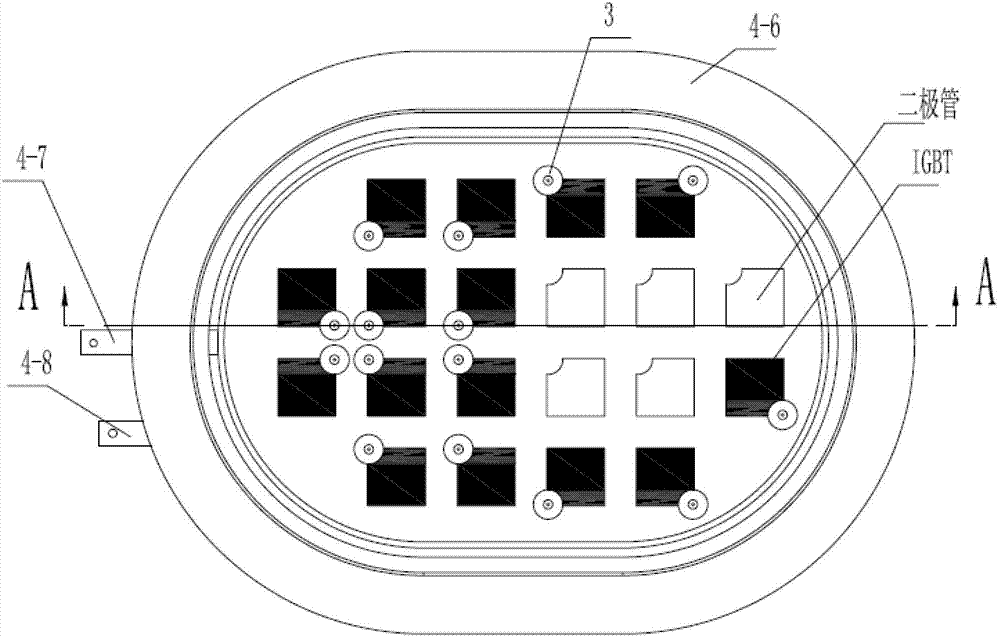

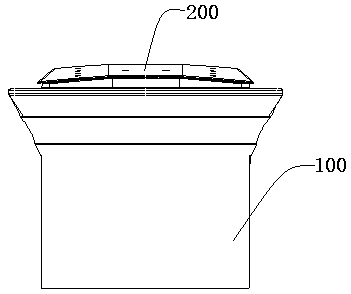

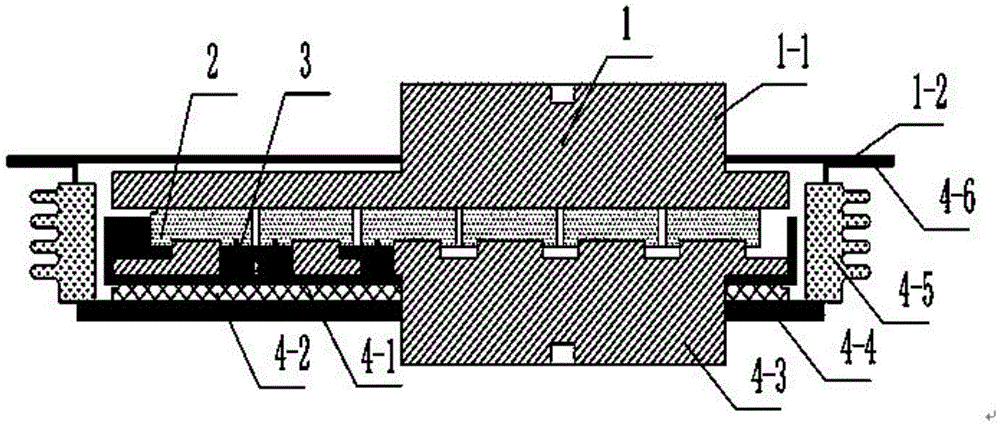

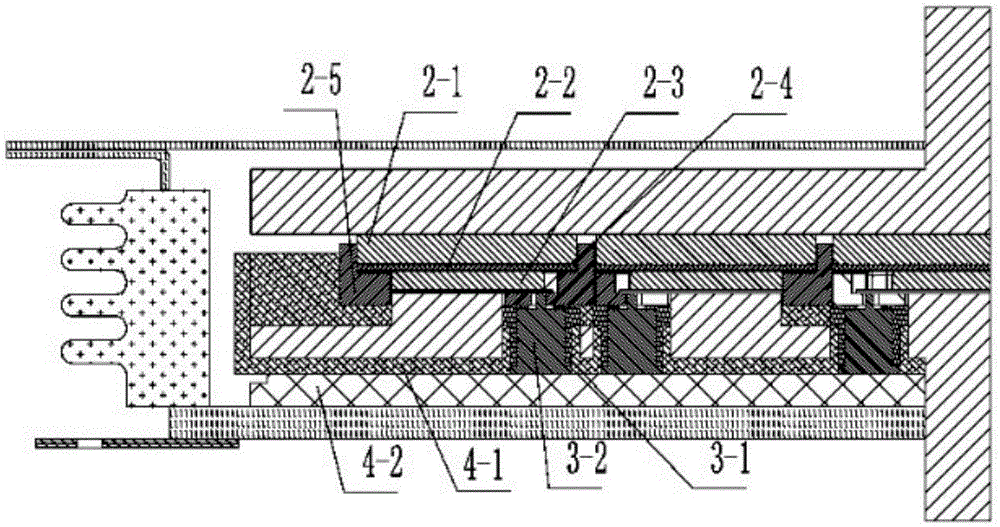

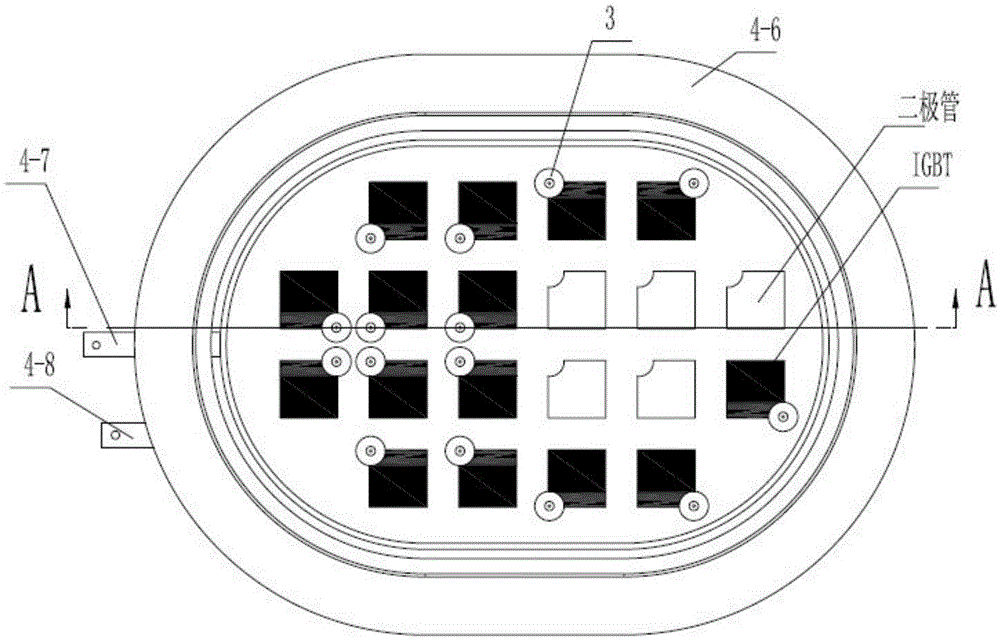

High-power press-fitted IGBT packaging module

ActiveCN103545269AGood antioxidant propertiesImprove electrical conductivitySemiconductor/solid-state device detailsSolid-state devicesHigher PowerEngineering

The invention relates to the technical field of microelectronic packaging, in particular to a high-power press-fitted IGBT packaging module comprising a top cover, a submodule, gate pins, and a bottom base. The bottom base is covered with the top cover. The submodule is disposed between the top cover and the bottom base. The gate pins are disposed in sockets of an insulating bottom plate. The submodule comprises a top molybdenum plate, a chip, a bottom molybdenum plate, a conducting sliver plate and a PBI high-performance plastic frame. The top molybdenum plate, the chip, the bottom molybdenum plate and the conducting sliver plate are sequentially press-fitted from top to bottom in a recess of the PBI high-performance plastic frame. The upper surface of the top molybdenum plate contacts with the lower surface of the top cover through electrodes. The lower surface of the conducting sliver plate in the submodule is press-fitted to the upper surface of a middle projection of the bottom base. The high-power press-fitted IGBT packaging module has the advantages that production and assembly is simpler, connection reliability is better, and radiating performance is better.

Owner:STATE GRID CORP OF CHINA +2

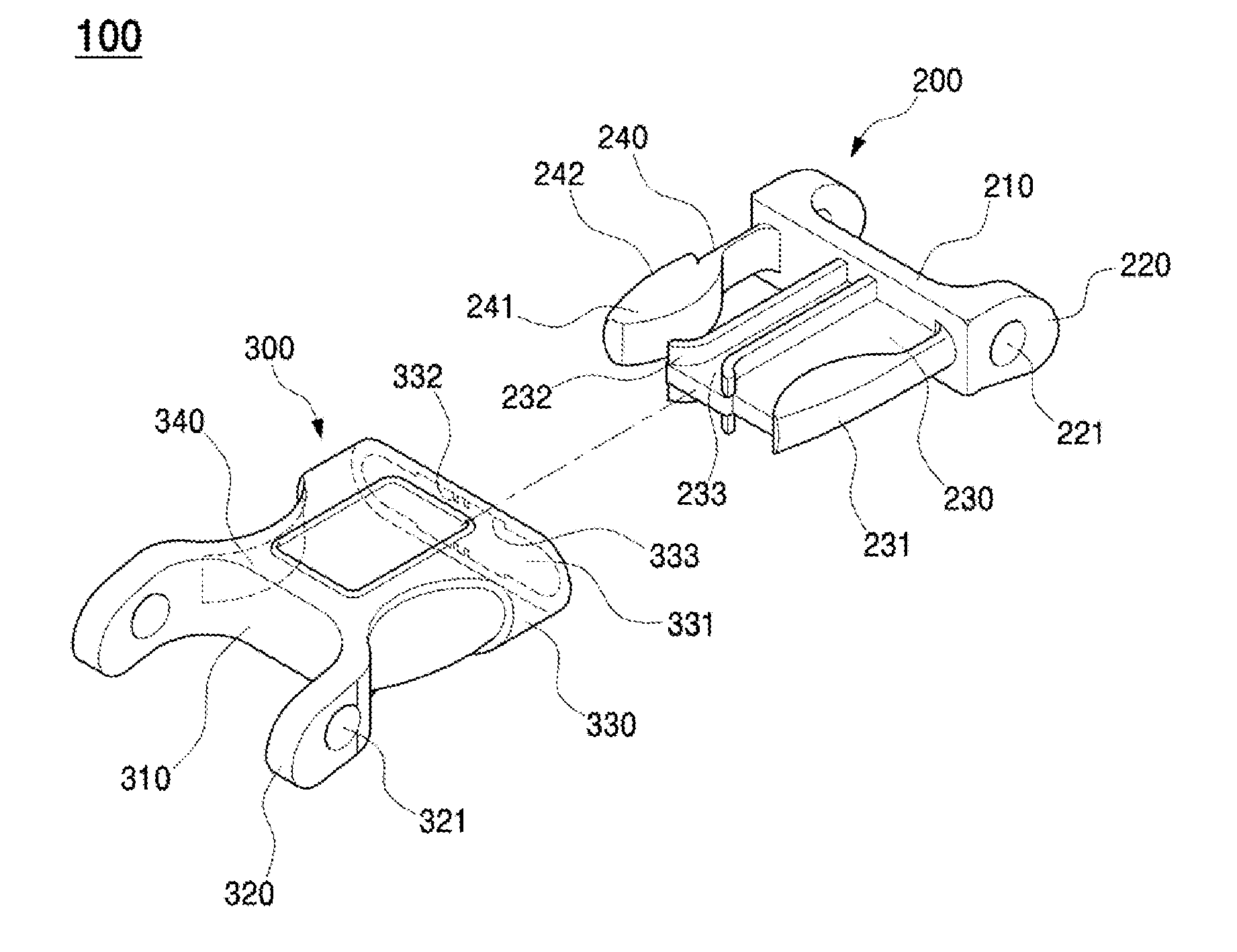

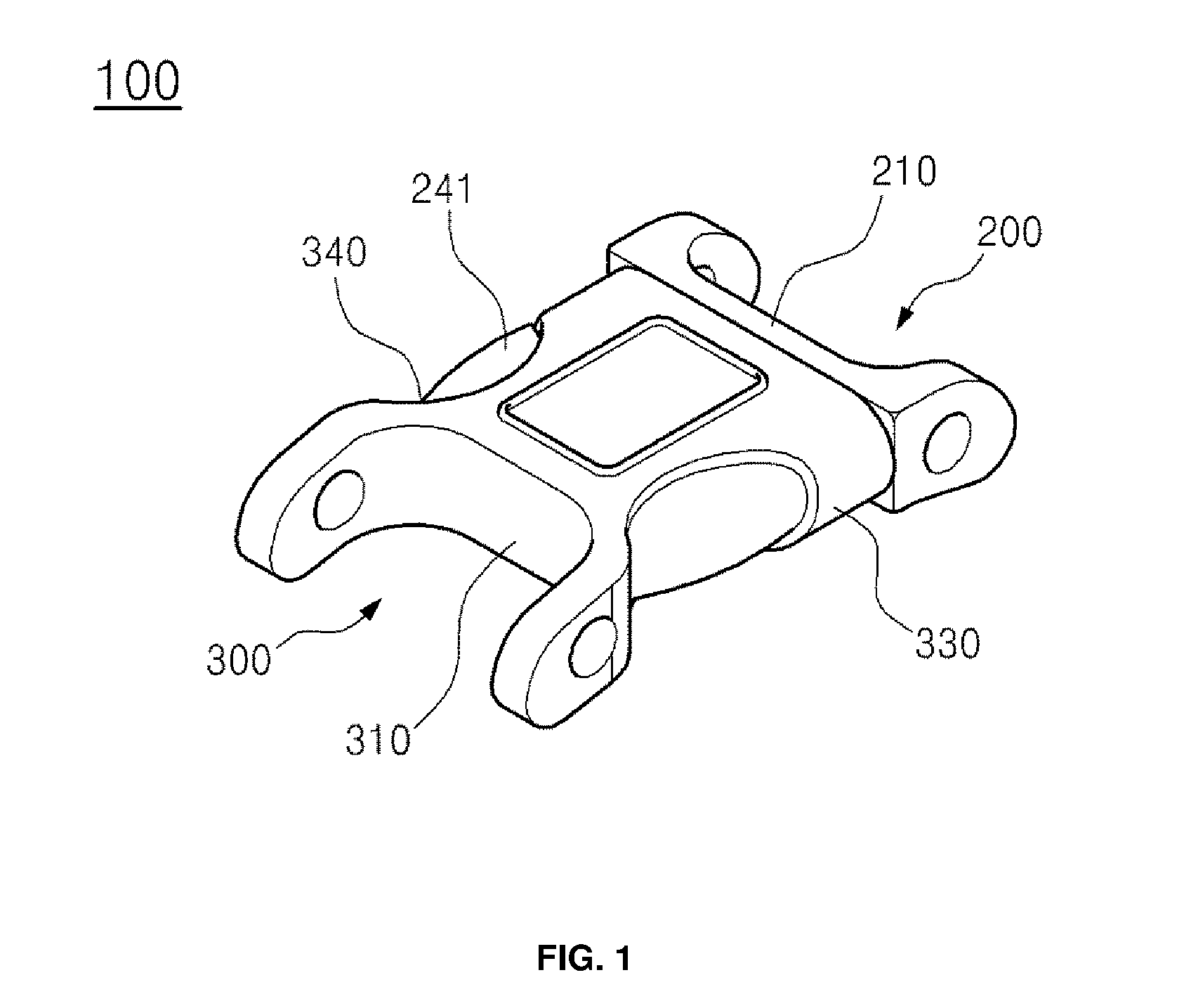

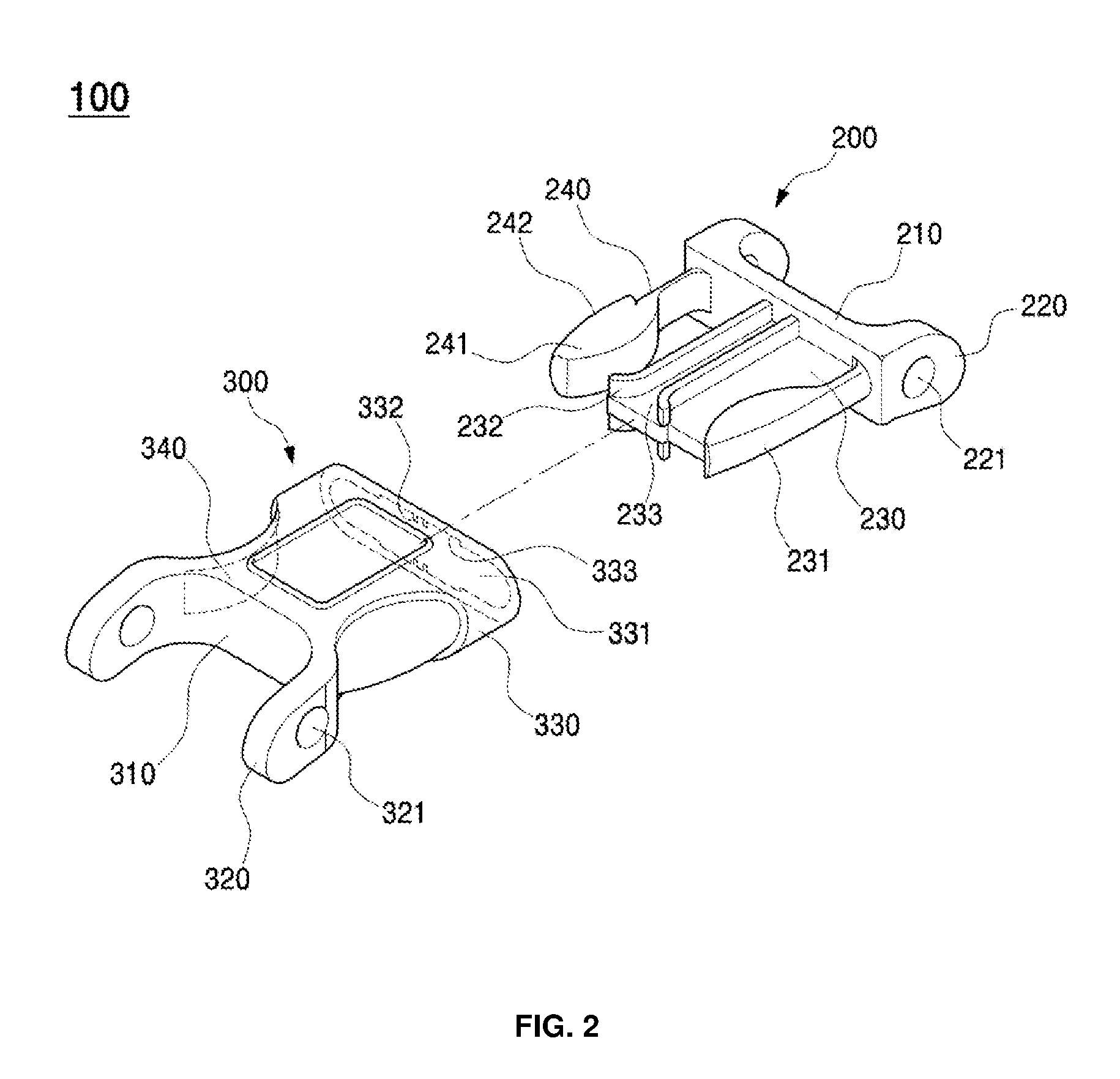

Buckle having easy separation operation

InactiveUS20160374436A1Simple structureEasy to useSnap fastenersClothes buttonsEngineeringMechanical engineering

Owner:KYOUNGDO

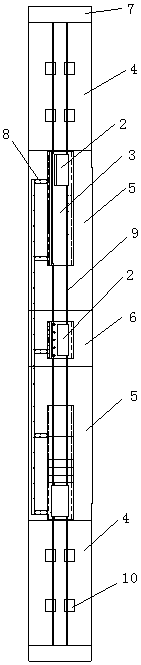

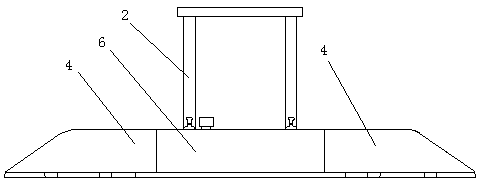

High speed train model wind tunnel test standard roadbed

InactiveCN108132132AWith characteristicsWith progressAerodynamic testingComputer moduleModular design

The invention provides a high speed train model wind tunnel test standard roadbed. According to the scheme, the high speed train model wind tunnel test standard roadbed comprises a fixed supporting base module, a slide supporting base module and a roadbed edge module. The fixed supporting base module, the slide supporting base module and the roadbed edge module are provided with mutually matched slide rails. The fixed supporting base module is fixedly provided with a supporting base. The slide supporting base module is provided with a slide table. The slide table is arranged on a guide rail and can freely slide along the guide rail. The slide table is fixedly provided with the supporting base. The fixed supporting base module, the slide supporting base module and the roadbed edge module can mutually and freely docked. According to the scheme, segmented and modular design of the roadbed is adopted, and the slide rails are arranged and the space between the supporting bases can be adjusted so that pneumatic testing of different length of train models under the same roadbed can be met, the error of the pneumatic influence caused by different roadbeds can be eliminated and the problemof the influence of different roadbed outline structures on the test data can be effectively solved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

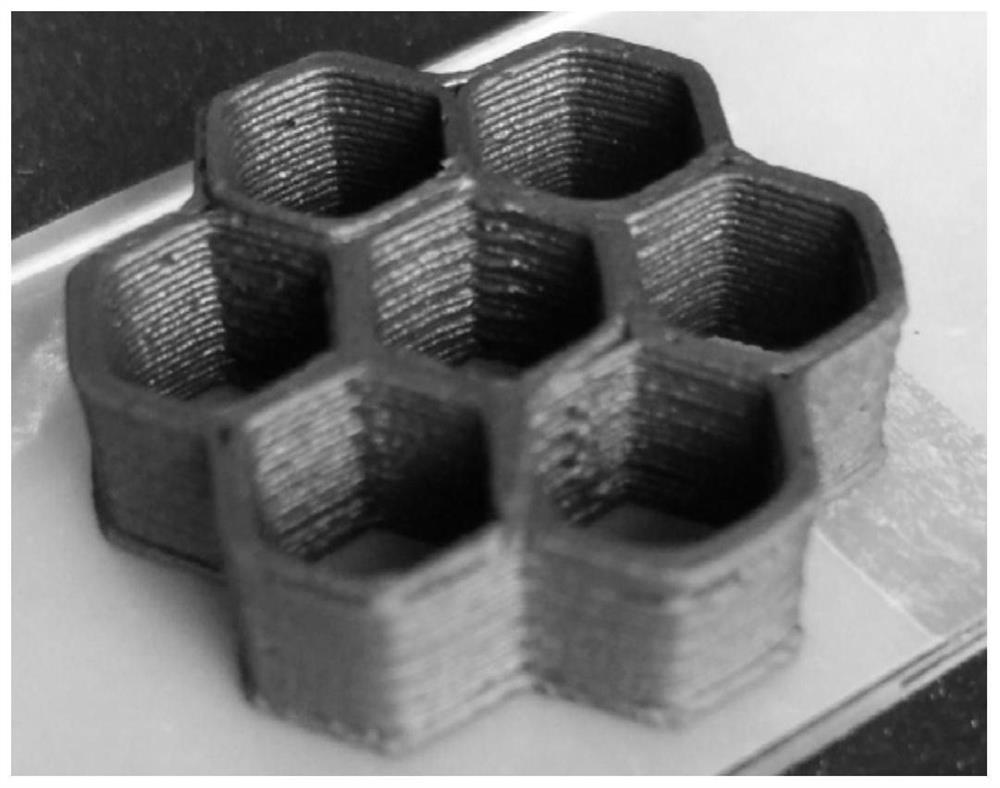

Float-type drop energy-eliminating noise-reducing device

InactiveCN100533033CControl Secondary NoiseStructural Shape ImprovementSound producing devicesCooling towerHoneycomb

A floating energy dissipation and noise reduction device, which is composed of a noise reduction honeycomb panel, a supporting frame, and a floating body. The noise reduction honeycomb panel is arranged on the supporting frame, and the floating body is arranged under the supporting frame. Placed in the pool of the cooling tower, the distance between the lower end of the noise-reducing honeycomb panel and the water surface of the pool is 100-110 mm; the noise-reducing honeycomb panel is composed of several pieces of PVC plastic molding boards, and there are several open ends on it. Special-shaped pipes, each special-shaped pipe is provided with a collection pipe, an inclined-surface noise reduction pipe, and a curved energy-dissipating pipe from top to bottom, and multi-stage energy-dissipating grooves and shunt grooves are arranged on the curved surface energy-dissipating pipe; the supporting frame is made of several FRP I-shaped Profiles, connecting rods, and spacers are connected into a frame structure; since the device is placed in the pool of the cooling tower, the distance between the lower end surface of the noise-reducing honeycomb panel and the water surface of the pool is a constant value, which can effectively prevent the secondary noise of falling water generated, and the noise reduction effect is stable.

Owner:常州金坛塑料厂

Efficient dust remover-filter of suction sweeper

ActiveCN106139805AImprove dust removal efficiencyImprove sedimentation filtration efficiencyCombination devicesCycloneThree stage

The invention discloses an efficient dust remover-filter of a suction sweeper, characterized by comprising a sweeping suction system, a three-stage filter system and a dust remover outlet system; the sweeping suction system is composed of a main brush (1) and a dust collection box (2); the three-stage filter system is composed of a filter mesh (8), a cyclone pre-filtering air passage (3) and a cartridge filter (4); the dust remover outlet system includes a down-inducing air passage (6), a dust remover outlet (7) and a vacuum fan (5); by providing the three-stage filter system and modifying the shape of the filter air passage, cyclone flow and centrifugal force for dust-bearing gas filtering process are increased, and improved dust removal efficiency and prolonged life are imparted to the dust remover of the sweeper; experiments and simulation analysis show that dust-bearing gas entering the cyclone pre-filtering air passage has a capturing and precipitating rate of up to 98% for grits having a particle size of 0.1-1.5 mm.

Owner:SHANDONG PENGXIANG AUTOMOBILE

Unmanned hidden console of railway locomotive cab

PendingCN109532895AOpen and close operation is convenient and controllableStructural Shape ImprovementLocomotivesEavesDisplay device

Owner:常州今创电工有限公司

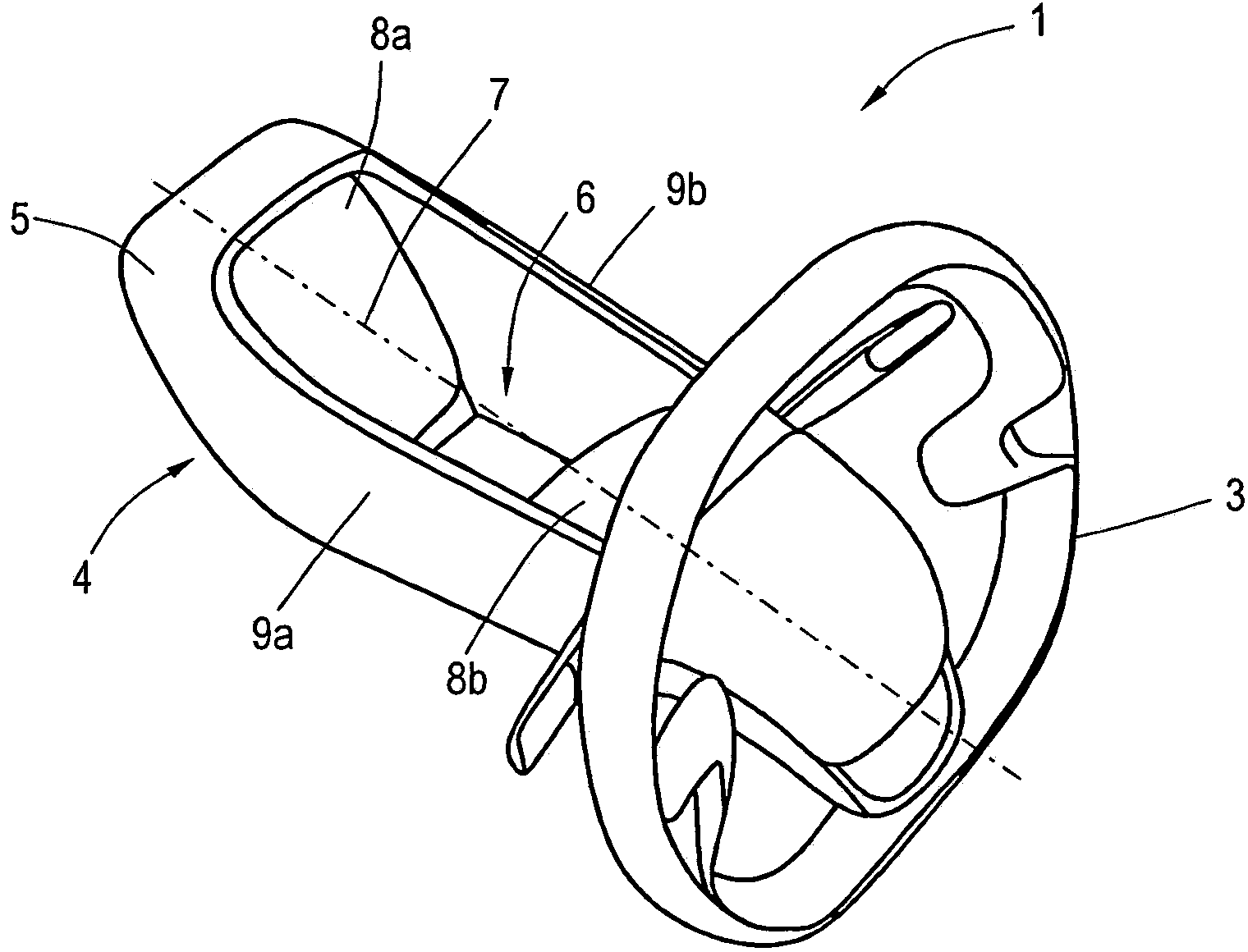

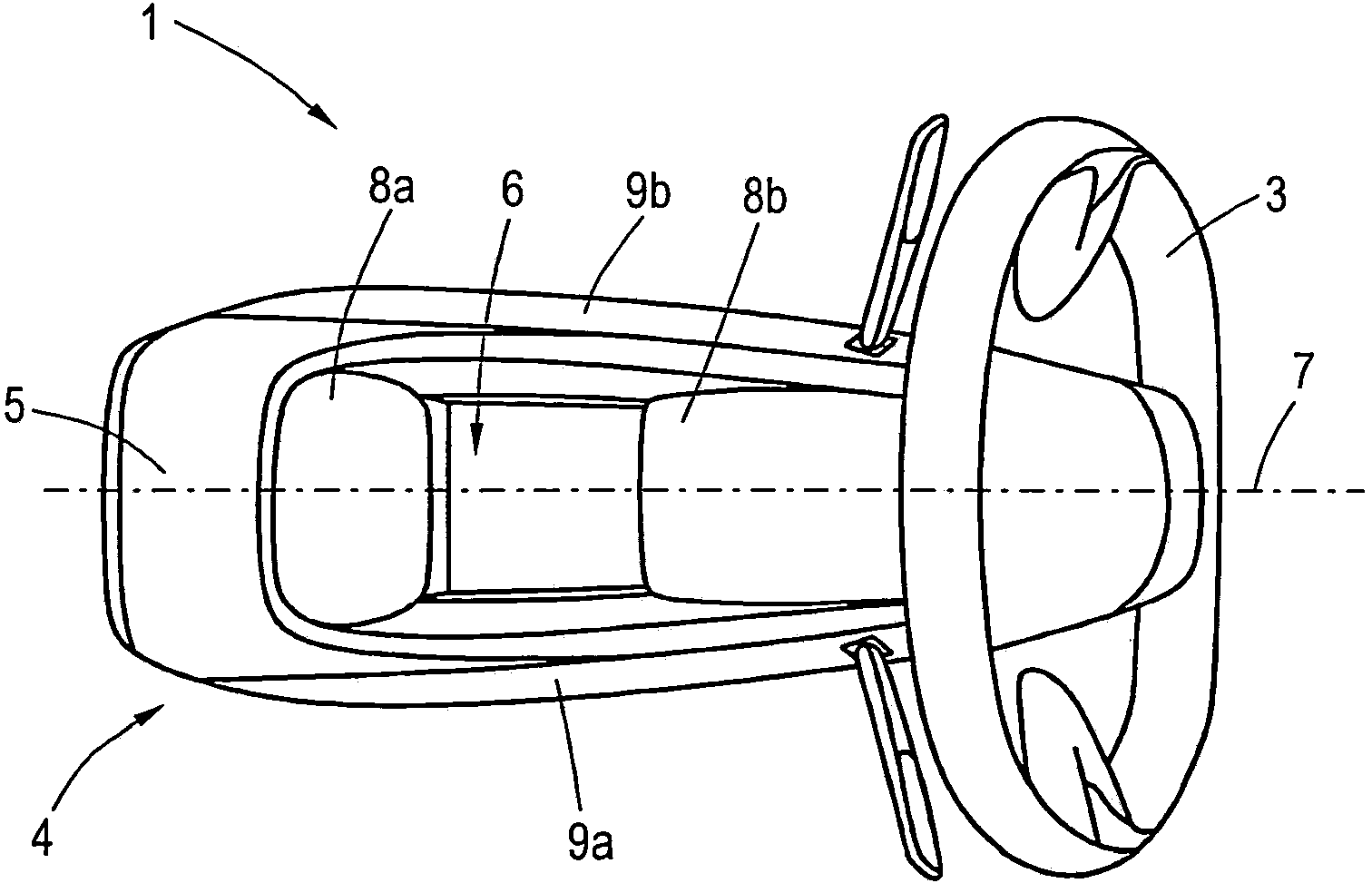

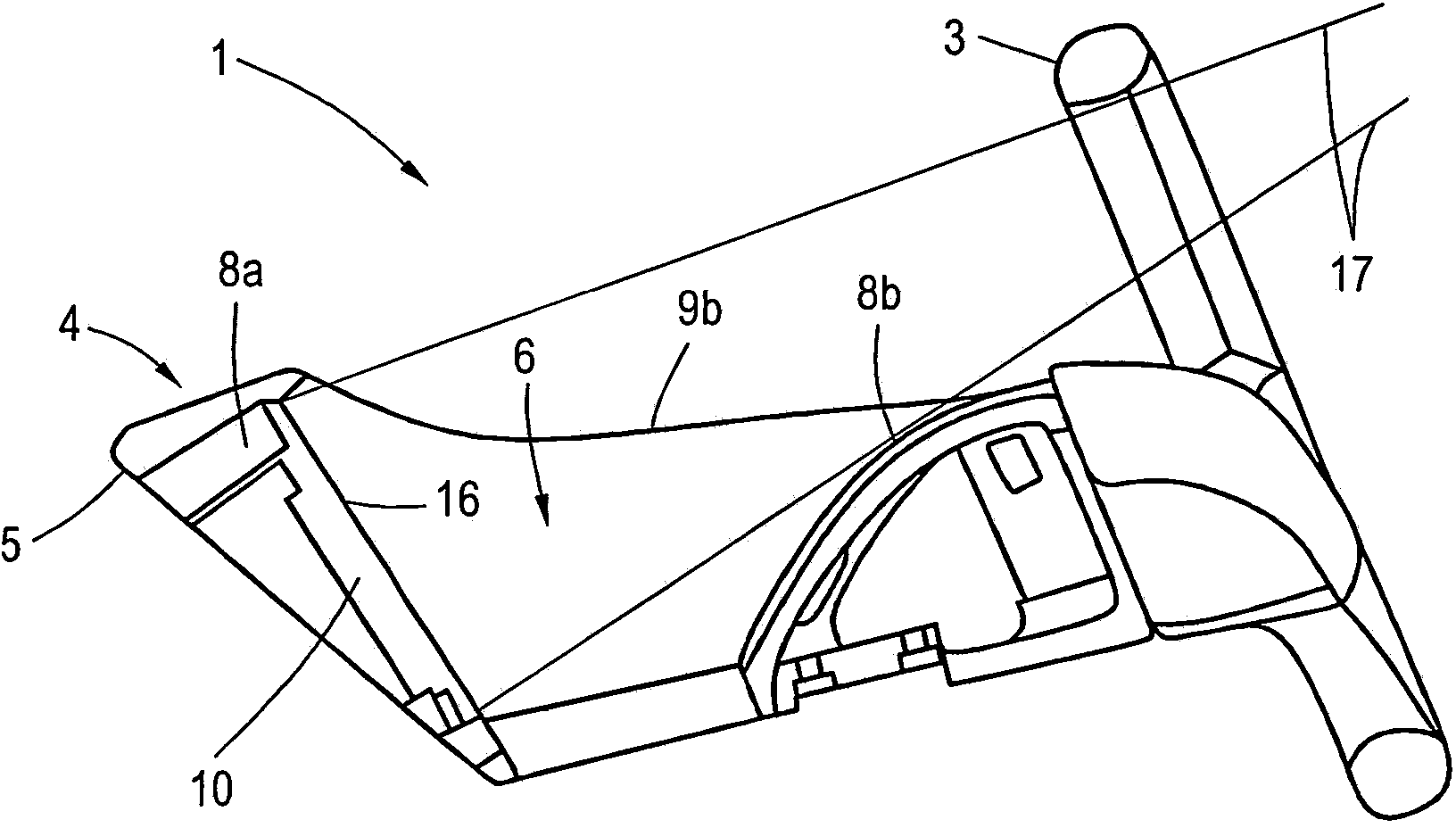

Steering wheel arrangement for a motor vehicle

InactiveCN103796902AImproved structural space utilizationEasy to demouldHand wheelsSteering columnsSteering wheelSteering column

A steering wheel arrangement (1) for a motor vehicle, comprising a steering wheel (3) which is coupled in terms of movement to a steerable axle of the motor vehicle via a steering axle (2), which steering wheel (3) is arranged rotatably on a steering column (4) having a housing body (5), wherein the housing body (4) has at least one upwardly open recess (6) which is bounded at least by two opposite walls (8a, 8b) extending transversely with respect to the longitudinal centre axis (7) of the housing body (5).

Owner:AUDI AG

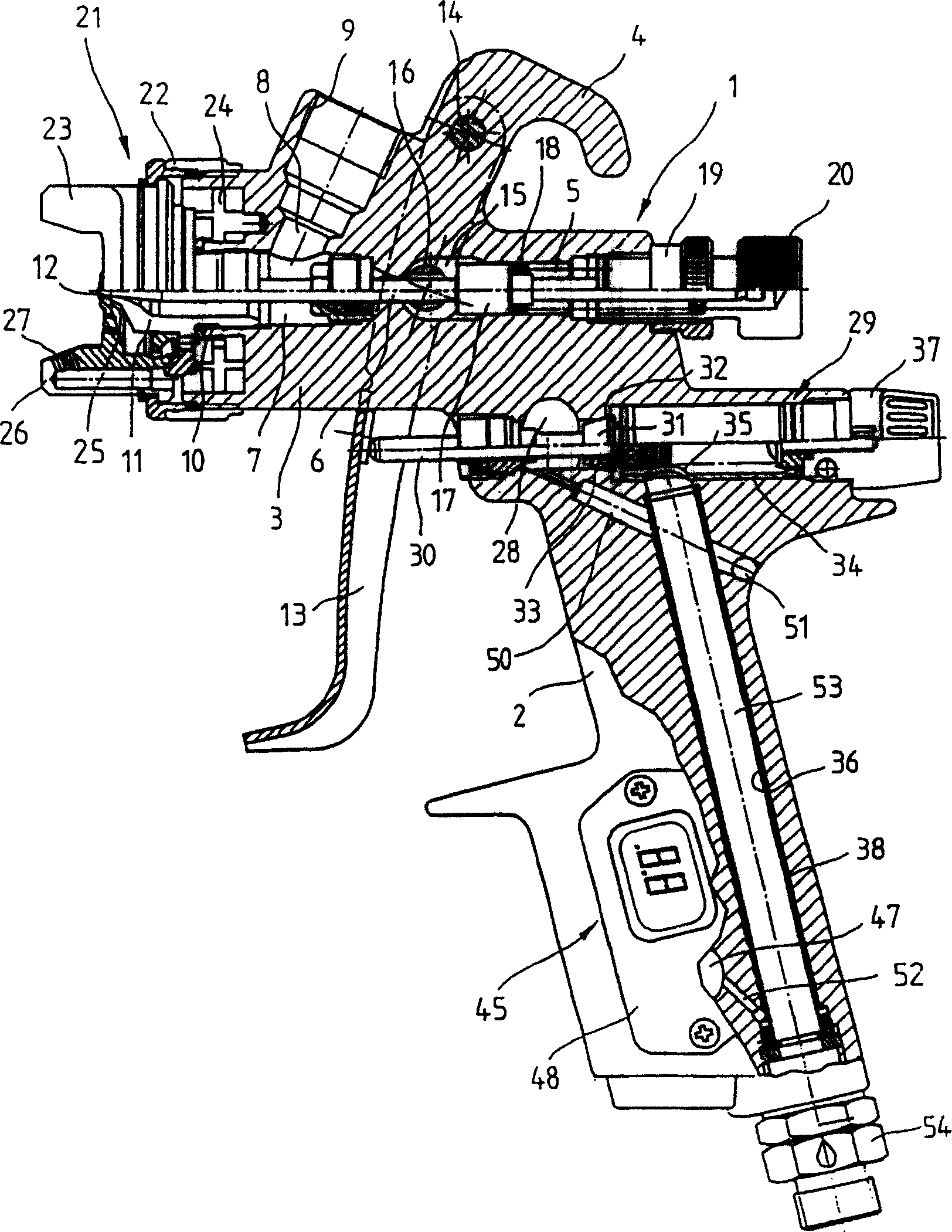

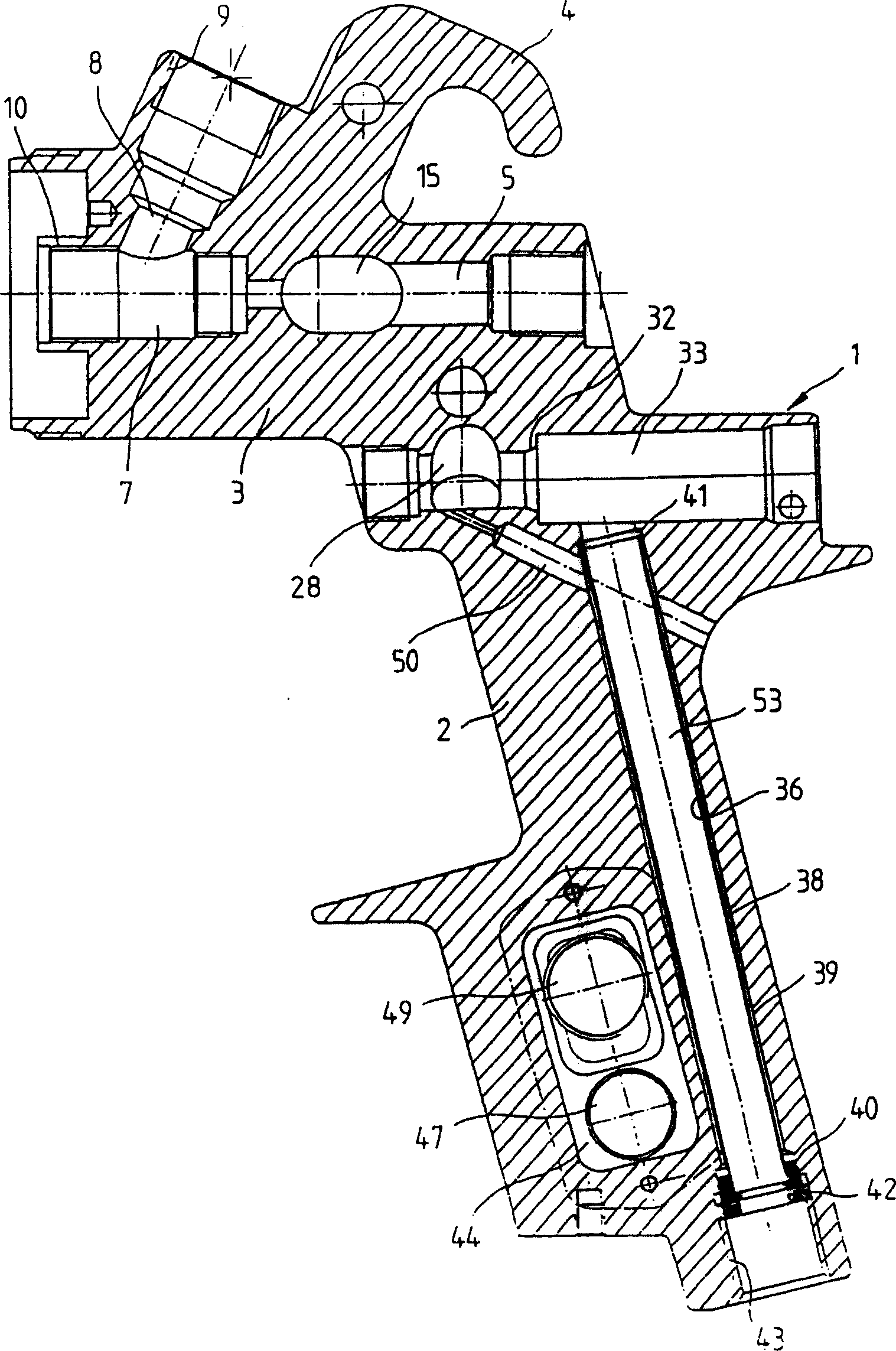

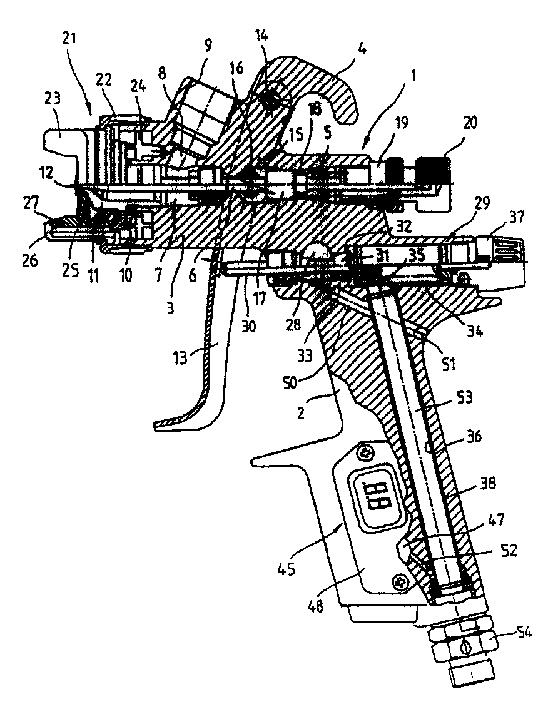

Paint jetting gun

InactiveCN1225315CExtended service lifeStructural Shape ImprovementLiquid spraying apparatusPistonIntermediate space

The invention relates to a paint spray gun with a paint nozzle placed on a gun body, an air nozzle placed around the paint nozzle, a compressed air valve placed within a piston borehole in the gun body, a compressed air borehole running through a handgrip of the gun body to the piston borehole, and a pressure-sensing and pressure display device placed in the hand grip. For sensing and displaying the spray pressure, a tube is placed in the compressed air borehole at a distance from its inner wall. The tube forms, in the interior, a channel for the compressed air supply to a part of the piston borehole placed upstream of the compressed-air valve, and borders an intermediate space between its exterior and the inner wall of the compressed air borehole. The intermediate space is connected via a first connecting channel with a pressure chamber placed downstream of the compressed-air valve and via a second connecting channel with a pressure gauge chamber in the handgrip allocated to the pressure-sensing and pressure display device.

Owner:SATA GMBH & CO KG

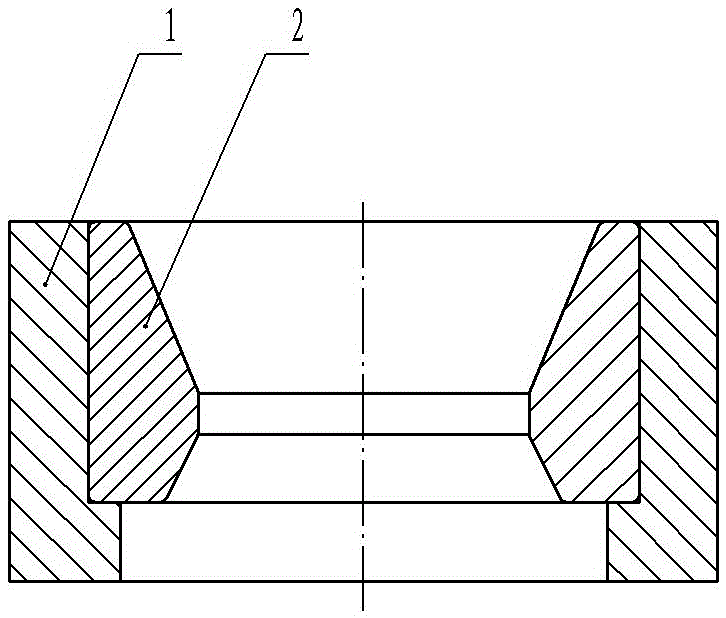

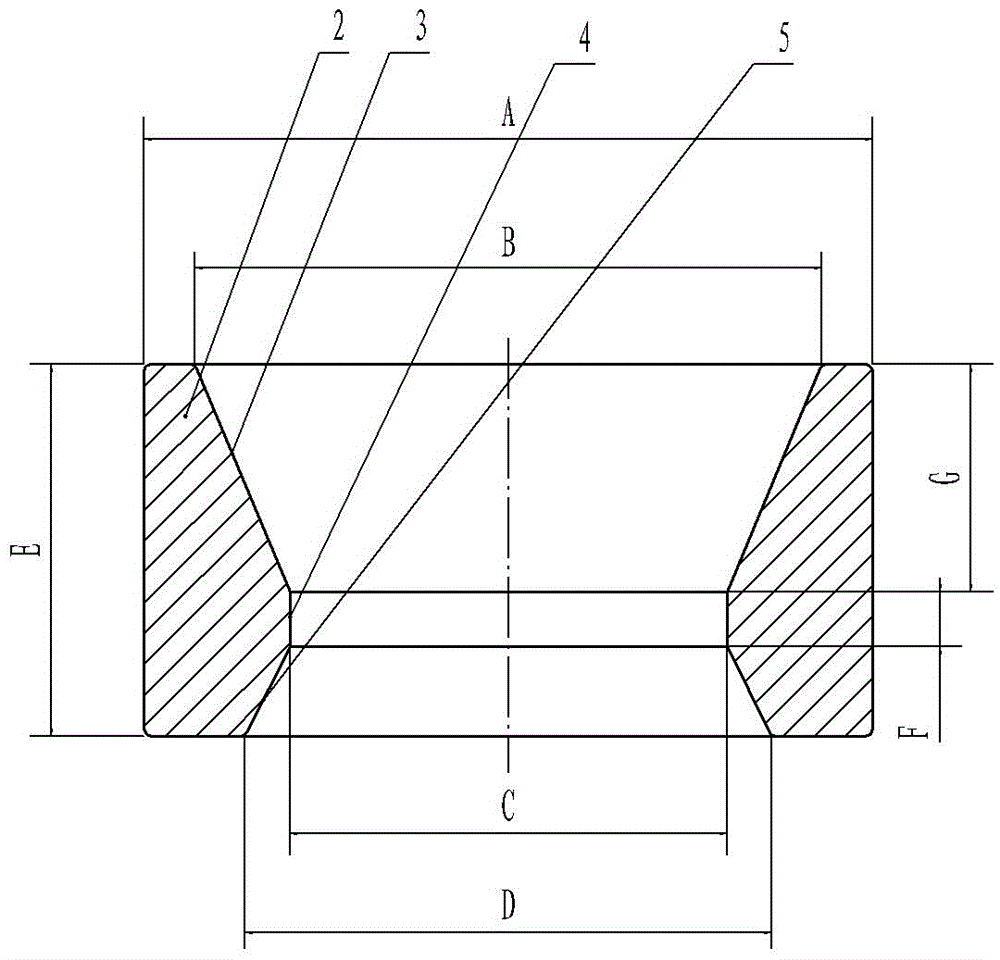

Large-caliber hard alloy drawing mould

The invention discloses a large-caliber hard alloy drawing mould, and relates to the technical field of alloy manufacturing. The large-caliber hard alloy drawing mould comprises a mould base and a mould core which is sleeved by the mould base, wherein the mould core is a cylinder with a through hole in middle; and the through hole in middle consists of a circular truncated cone inlet section, a cylindrical sizing section and a circular truncated cone outlet section. The large-caliber hard alloy drawing mould can solves the problems that wear of the mould core of a current large-caliber cold-drawing mould is quick, and the service life of the current large-caliber cold-drawing mould is short.

Owner:LIUZHOU CITY TONGJIN AUTOMOBILE PARTS MFG CO LTD

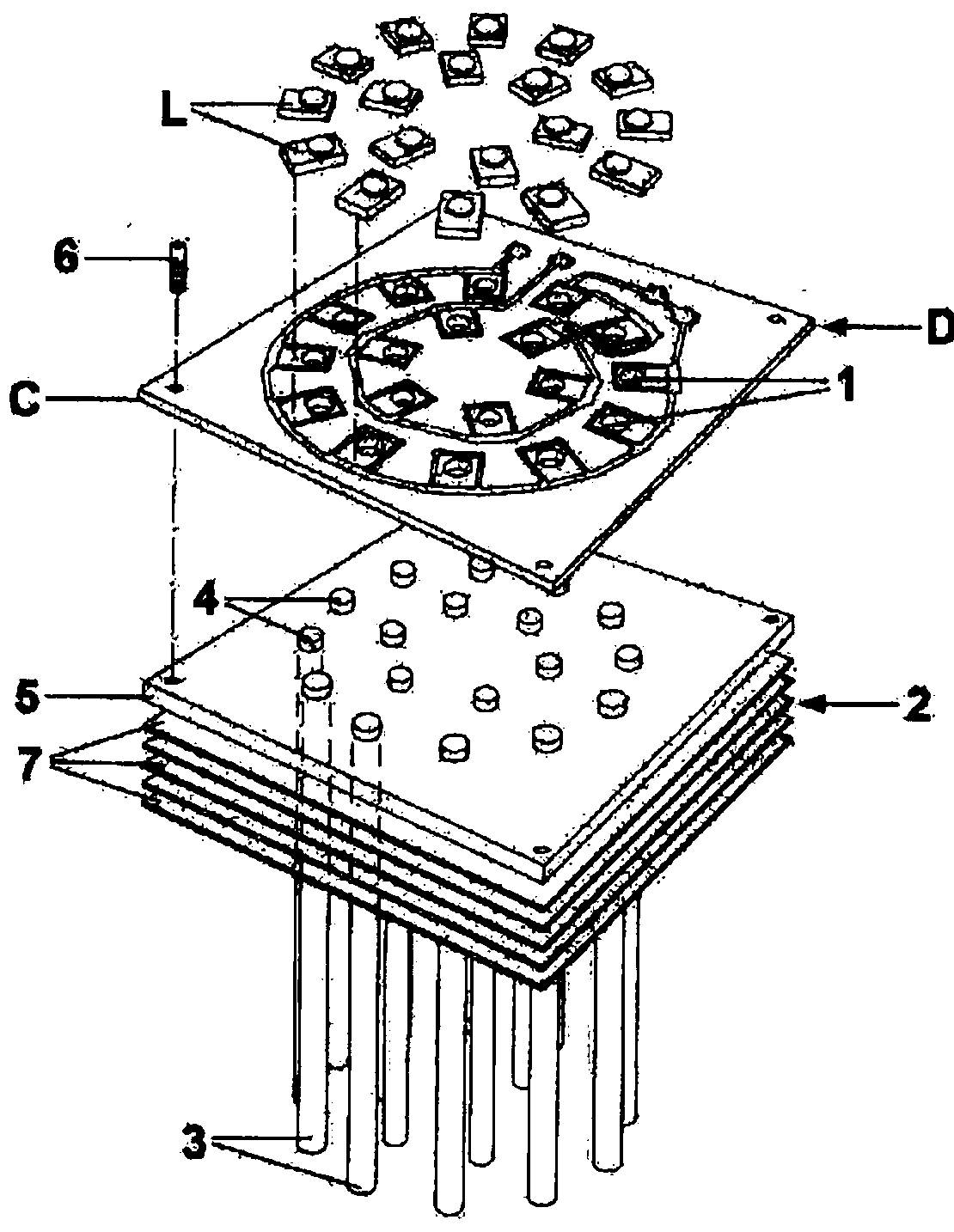

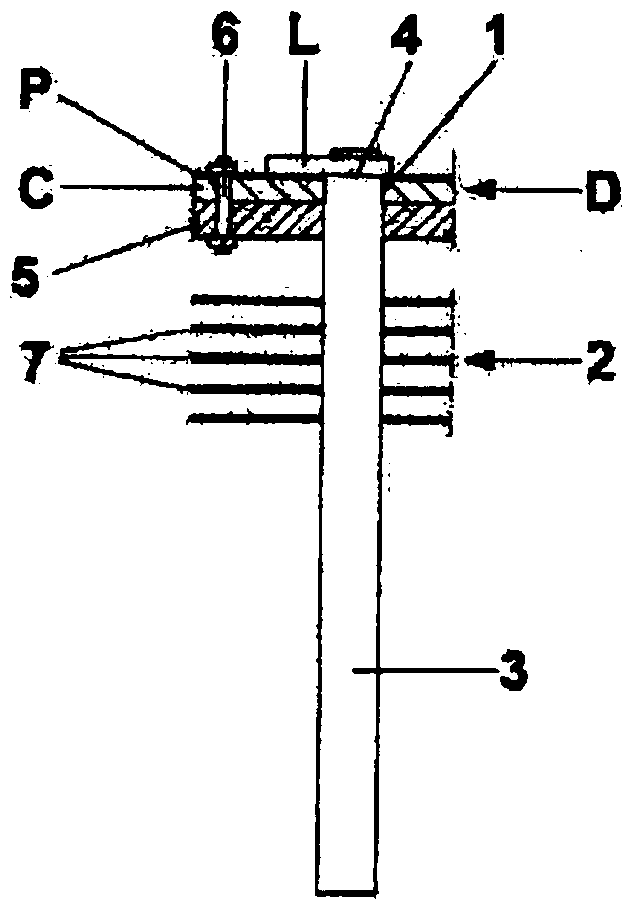

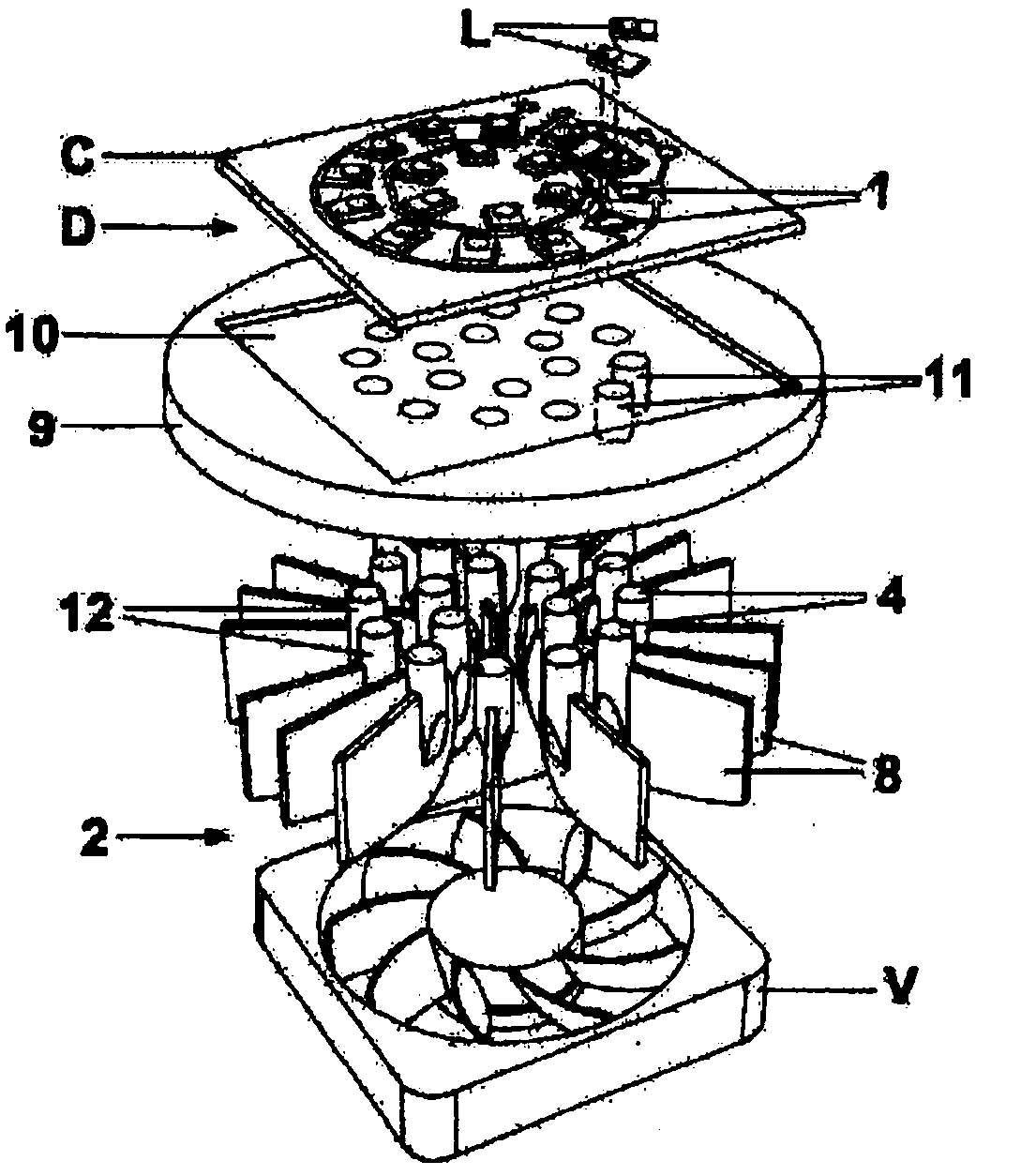

A led lighting device with integrated heatsink

InactiveCN103874884ALower final costEliminate thermal resistancePlanar light sourcesPoint-like light sourceEngineeringAlloy

The present invention concerns a LED (L) lighting device (D) with integrated heatising (2), comprising: a printed circuit (C) of the PCB ( Printed Circuit Board) or MCPCB (Metal Core Printed Circuit Board) type, arranged for electrically and mechanically supporting a LED (L) matrix, forming the light source of said device (D); a heatsink (2) that may be associated in construction to said printed circuit (C), comprising a plurality of cooling fins (3, 8, 13, 14), characterized in that said cooling fins (3, 8, 13, 14) are arranged for being placed into direct contact with said LEDs (L) and each single cooling fin (3, 8, 13, 14) is arranged for dissipating only the heat produced by the specific LEDs (L) applied thereon.; Heatsink (2) comprises cooling fins (3) with a cylindrical shape, (8) with lamellar structure or with prismatic shape with square bases (13) or rectangular bases (14) or with other regular shape, provided with ends (4) arranged for allowing the application of LEDs (L) and made out of high thermally conductive metals or out of composite alloys.

Owner:文森佐达拉斯科

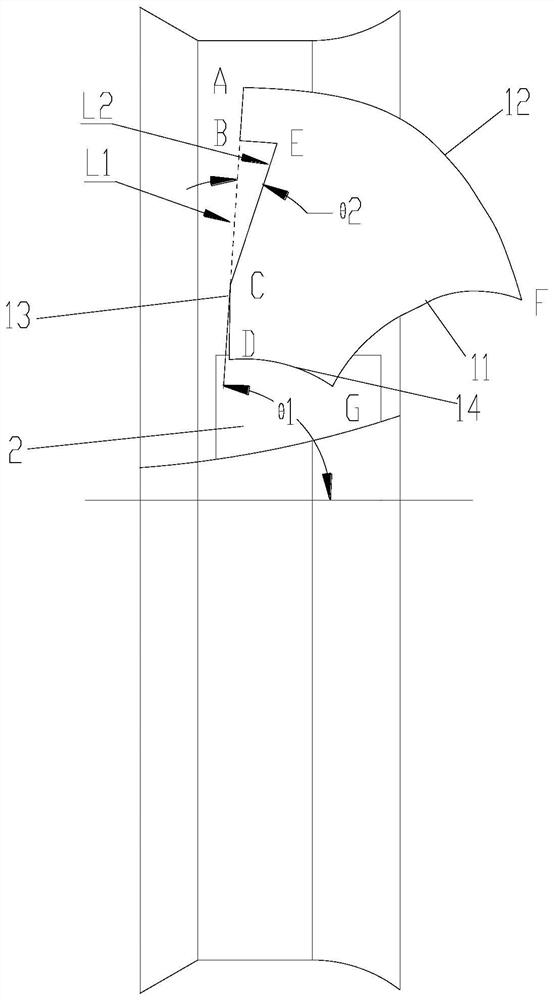

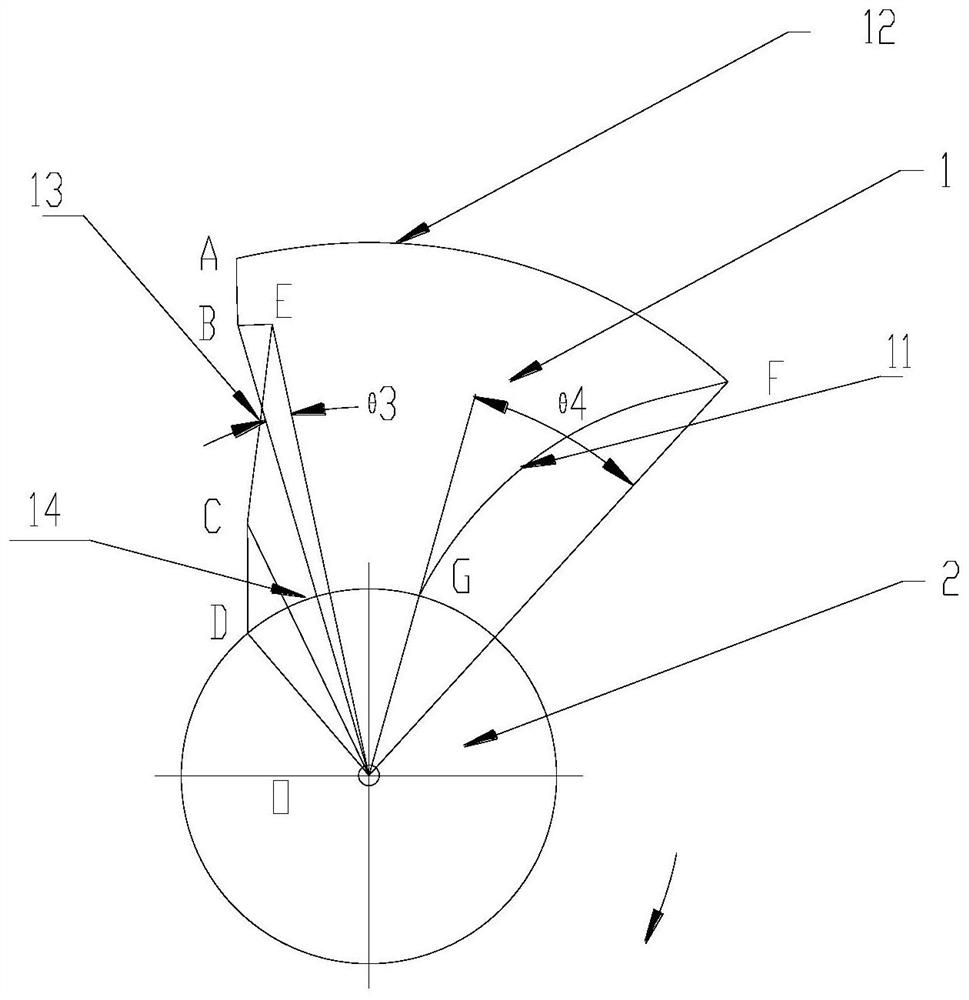

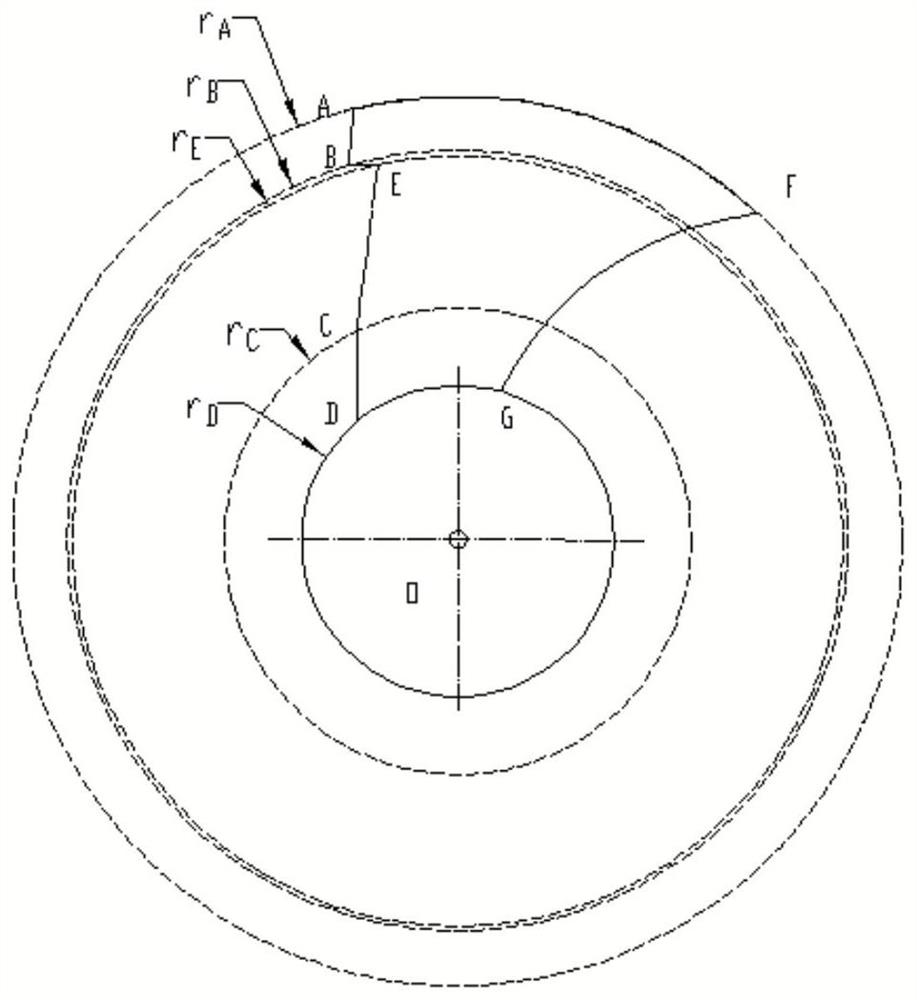

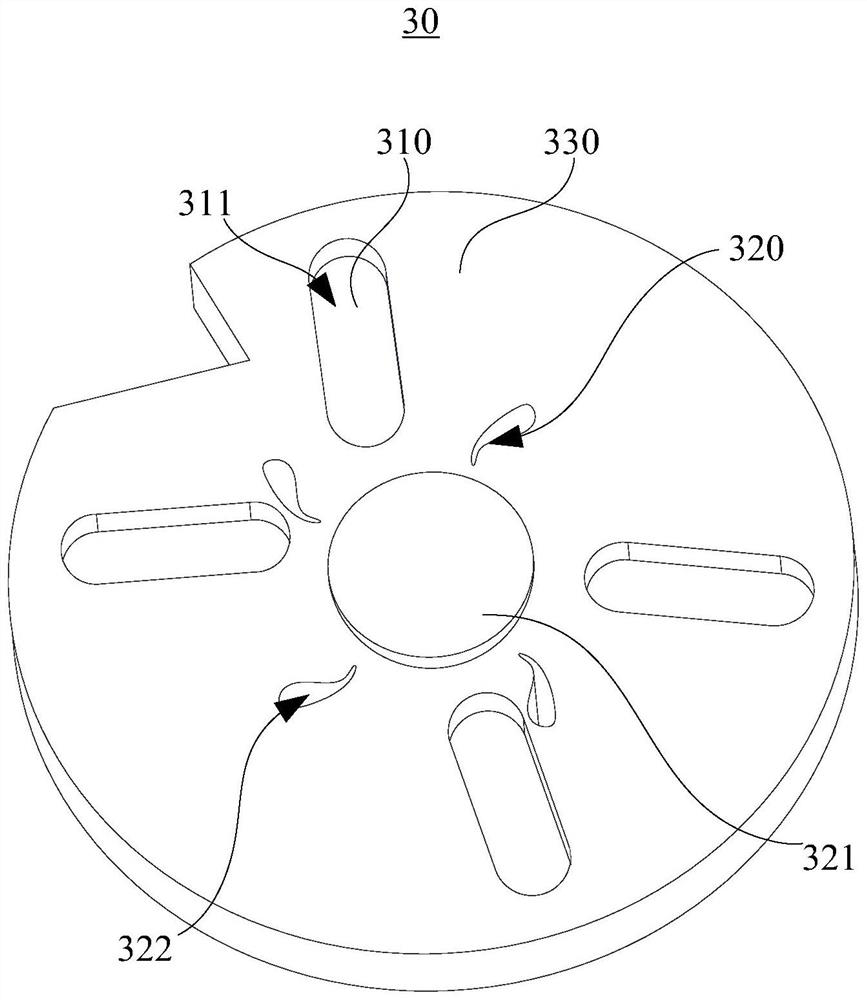

Axial flow fan blade, axial flow fan and air conditioner

PendingCN112096656AImproved trailing edge structureStructural Shape ImprovementPump componentsPumpsRotational axisEngineering

The invention provides an axial flow fan blade, an axial flow fan and an air conditioner. The axial flow fan blade comprises a plurality of blades and a hub, the plurality of blades are arranged at intervals in the circumferential direction of the hub, each blade comprises a front edge, an outer edge, a rear edge and an inner edge, and each rear edge comprises a connecting line AB, a connecting line BE, a connecting line EC and a connecting line CD which are sequentially connected end to end. A plane passing through the rotating axis of the blade is set as a first plane, and the blade is circumferentially projected to the first plane in the rotating direction of the blade to form a first contour line. On the first contour line, a point A, a point B and a point C are located on a same straight line L1, and the included angle theta 1 is formed between the straight line L1 and the rotating axis of the blade and is larger than or equal to 75 degrees and smaller than or equal to 120 degrees; and the projection of the connecting line EC is a line segment, the line segment is located on a straight line L2, and the included angle between L2 and L1 is theta 2, and theta 2 is larger than 0 degree and smaller than or equal to 30 degrees. According to the axial flow fan blade, turbulence of the tail edge of the axial flow fan blade can be improved and reduced, aerodynamic noise of the fanblade can be reduced, and the efficiency of the fan can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

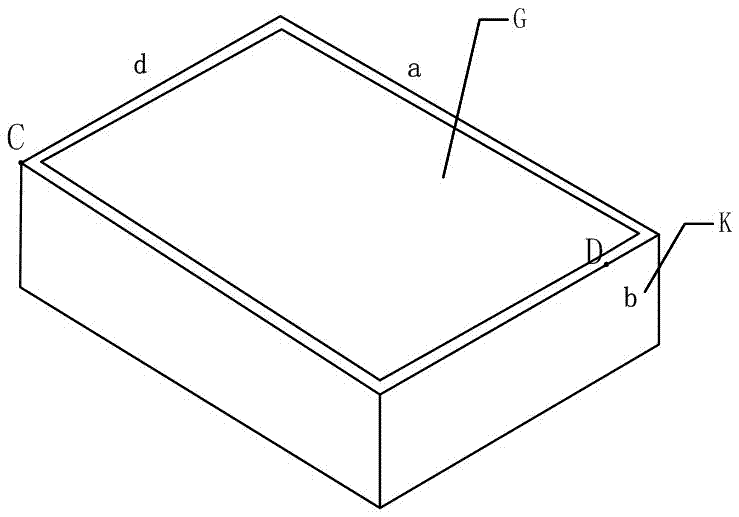

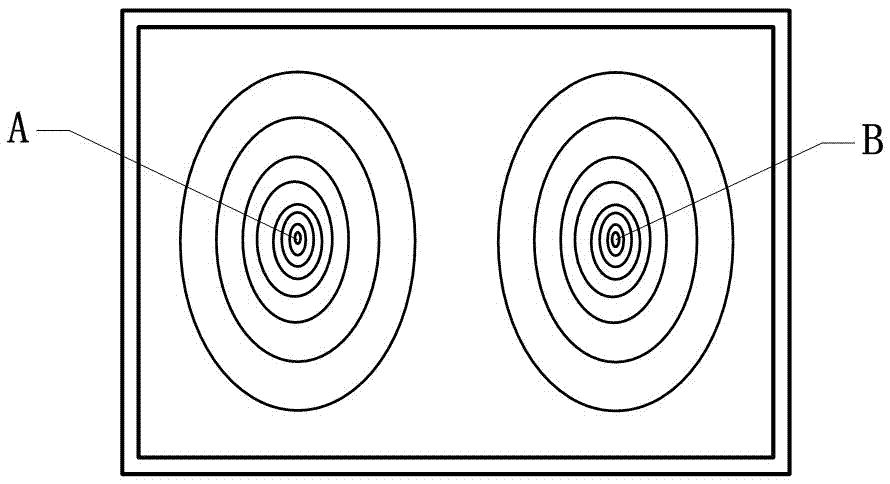

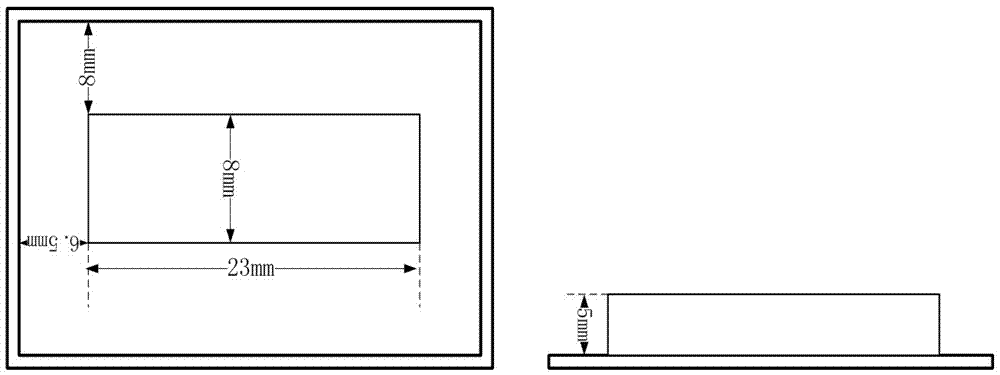

Microwave cavity stability optimization method independent of circuit and miniaturization microwave assembly obtained based on the same

InactiveCN105449333AImprove stabilityDoes not affect the external structure sizeResonatorsMicrowave cavityMiniaturization

The invention provides a microwave cavity stability optimization method independent of a circuit and a miniaturization microwave assembly obtained based on the same. The microwave cavity stability optimization method is independent of the structural form and layout of the internal circuit of the microwave cavity; and the stability of the microwave cavity is improved by optimizing the resonance mode of the cavity. In addition, the miniaturization microwave assembly obtained based on the microwave cavity stability optimization method comprises a box body and a cover plate; and a boss is arranged below the cover plate. The length, width, and height of the cavity of the box body are a, b, and c and the length, width, and height of the boss are at, bt, and ct, wherein the at / a is larger than 0 and is smaller than 1, the bt / b is larger than 0 and is smaller than 1, the ct / c is larger than 0 and is smaller than 1. The microwave cavity stability optimization method and the miniaturization microwave assembly have the following beneficial effects: on the basis of the designed cover plate structural form, the Q value of the cavity is reduced and the resonant frequency of the cavity is beyond the working band; the cavity mode optimization is realized by uing the cavity space fully; and the assembly stability is improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

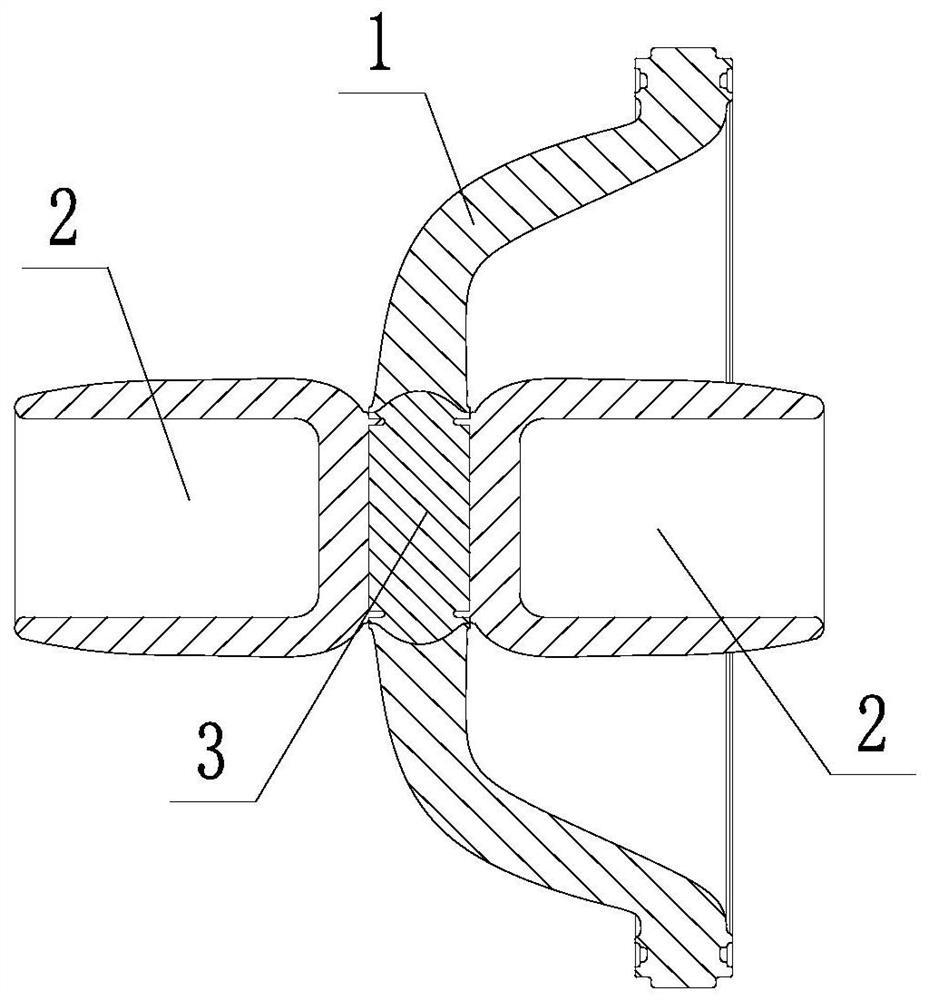

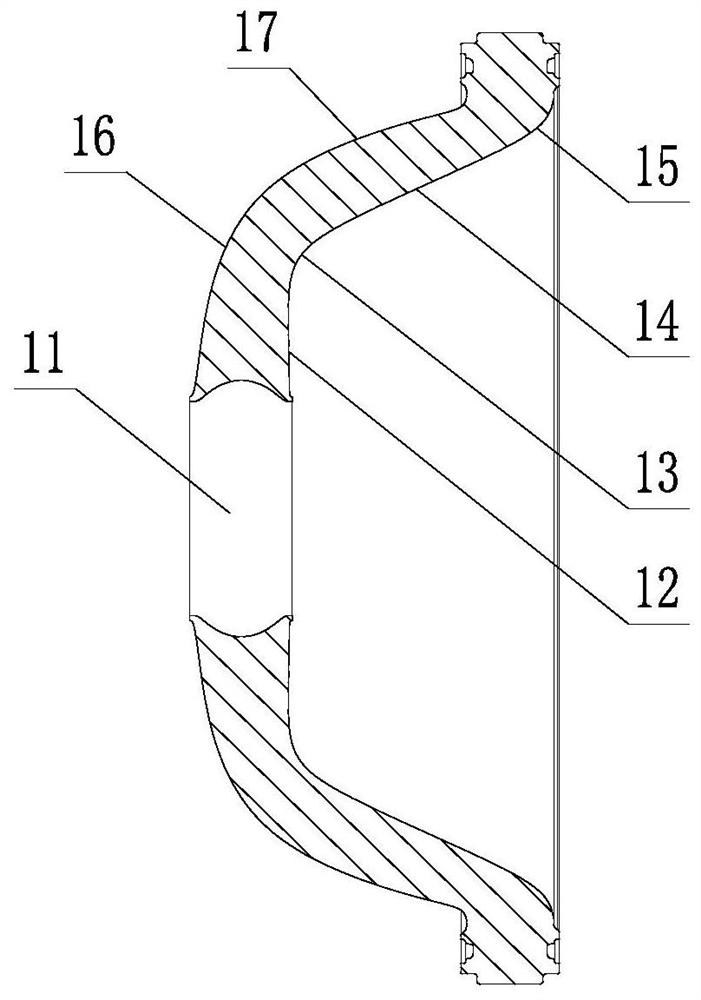

Basin-type insulator combined structure suitable for gas-insulated metal-enclosed power transmission line

PendingCN112863785AStructural Shape ImprovementImprove electrical performanceInsulatorsPhysicsVacuum casting

The invention discloses a basin-type insulator combined structure suitable for a gas-insulated metal-enclosed power transmission line. The basin-type insulator combined structure comprises a basin-type insulator, a high-voltage shielding case and a central insert, wherein the concave surface contour line of the basin-type insulator is sequentially divided into a first concave surface straight line section, a first concave surface arc section, a second concave surface straight line section and a second concave surface arc section from the center side to the circumferential side and forms a smooth transition type contour line, the convex surface contour line of the basin-type insulator is sequentially divided into a first convex surface arc section and a second convex surface arc section from the center side to the circumferential side and forms a smooth transition type contour line, the contour line of the outer surface of the high-voltage shielding case is sequentially divided into a first outer surface arc section, an outer surface linear section and a second outer surface arc section from the root portion side to the end portion side and forms a smooth transition type contour line, the contour line of the joint surface of the central insert and the central insert mounting hole of the basin-type insulator adopts a single joint arc section, the basin-type insulator is made of an epoxy resin, and the center insert and the basin-type insulator are manufactured in an integrated vacuum casting mode.

Owner:SHENYANG POLYTECHNIC UNIV

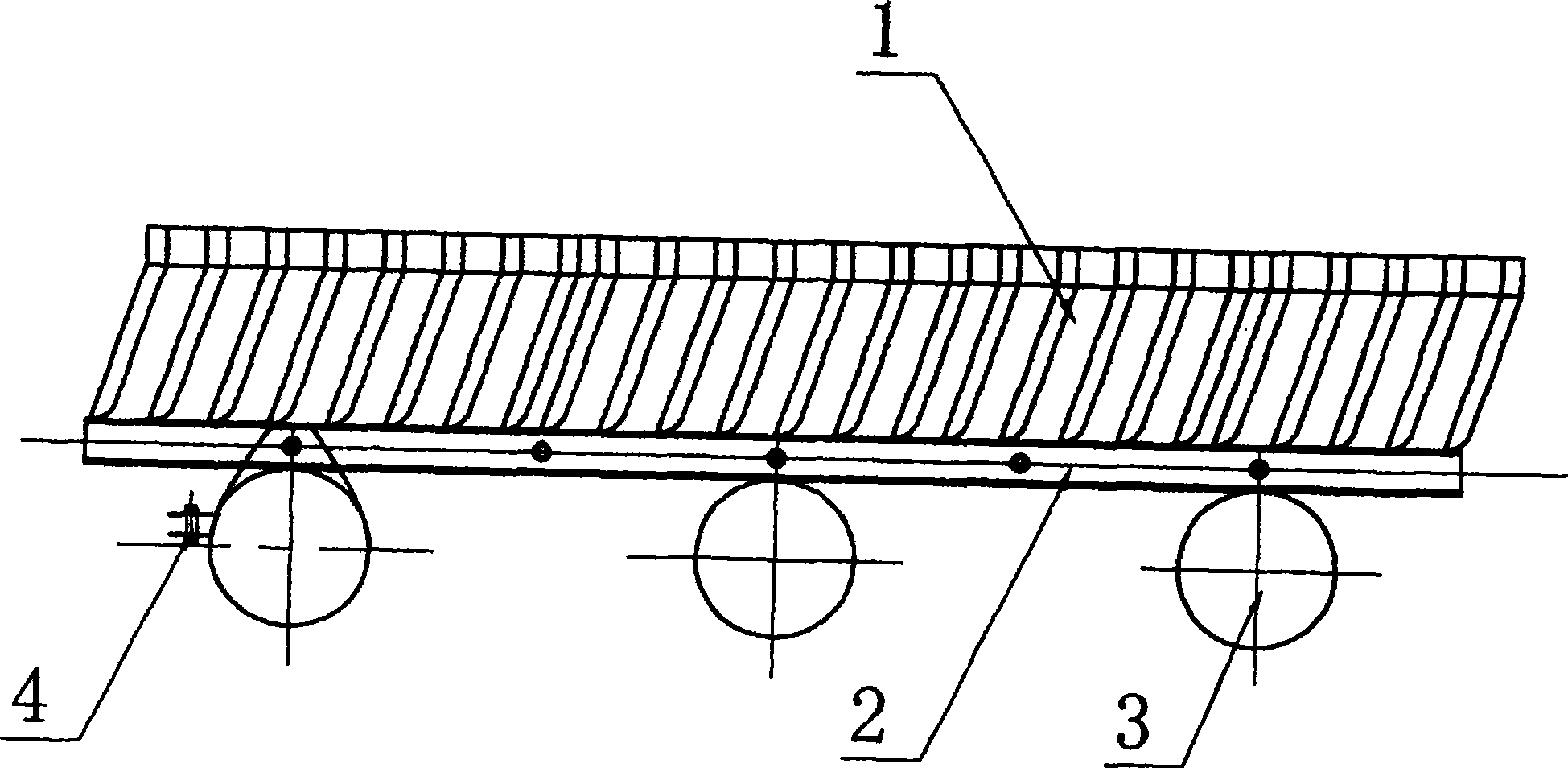

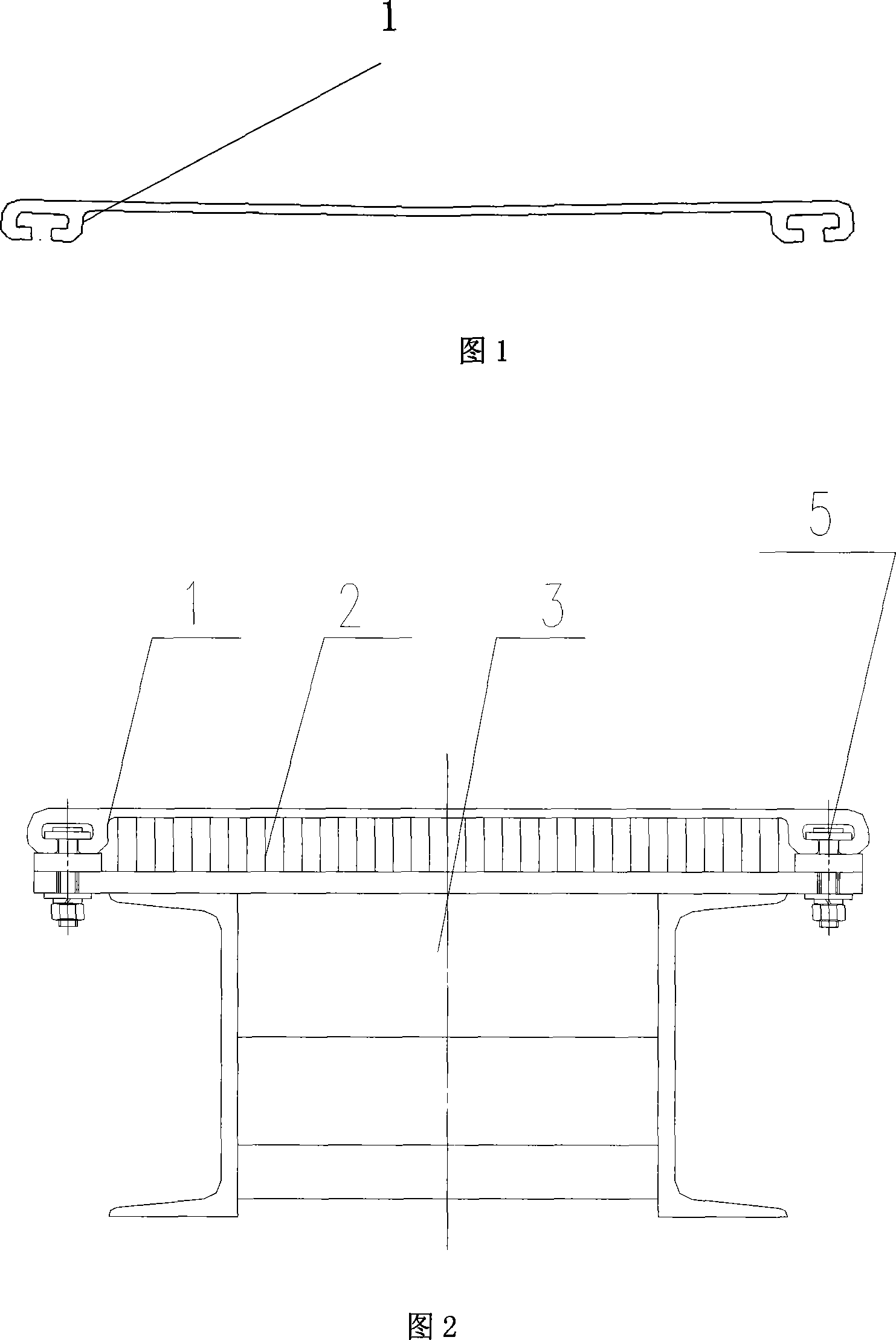

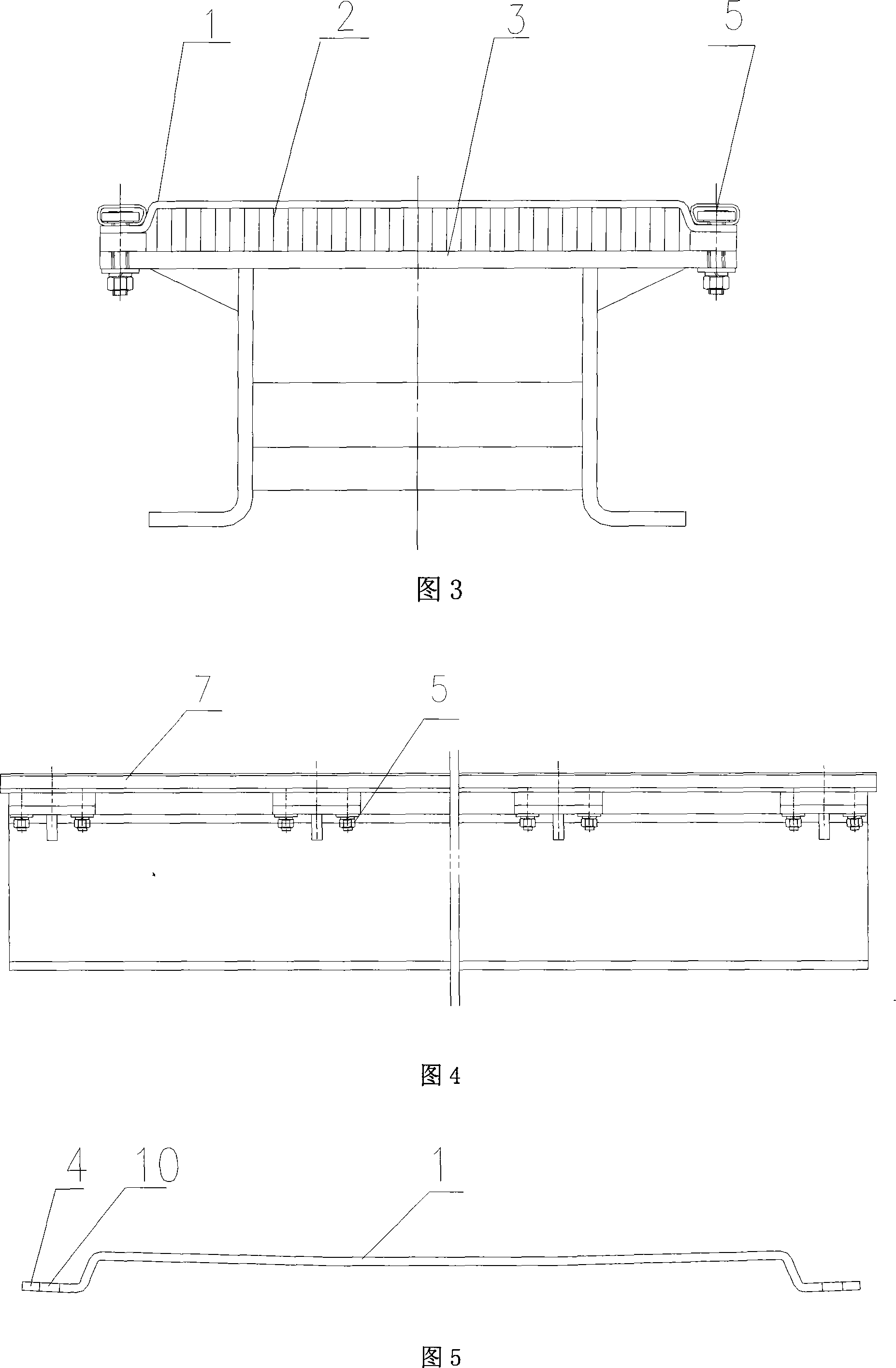

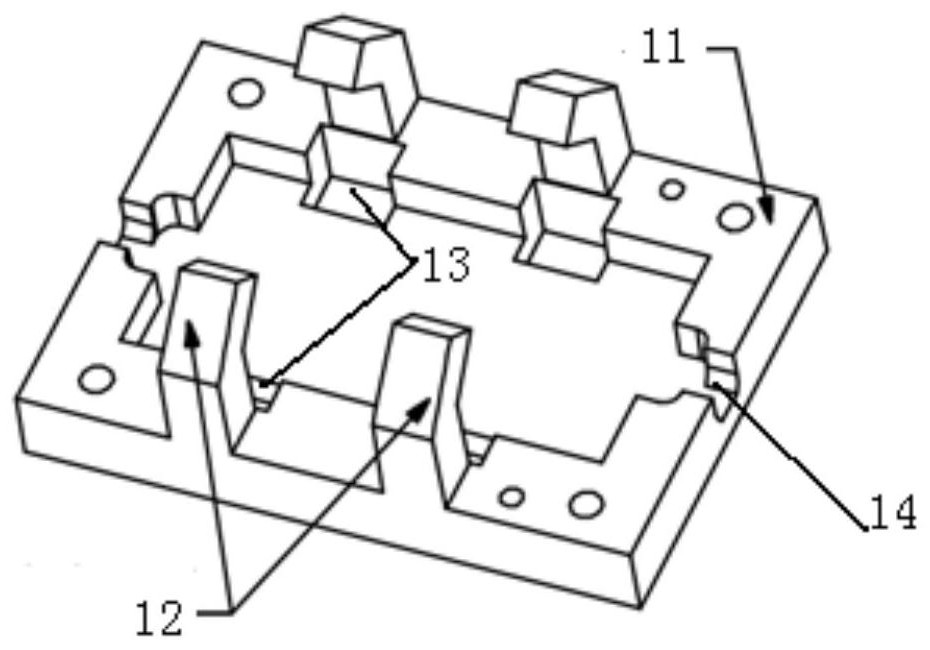

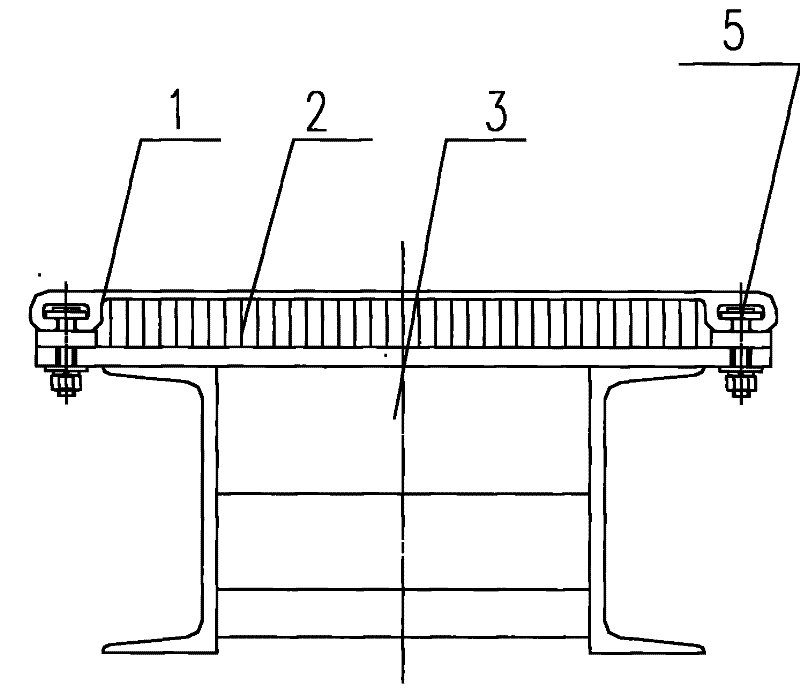

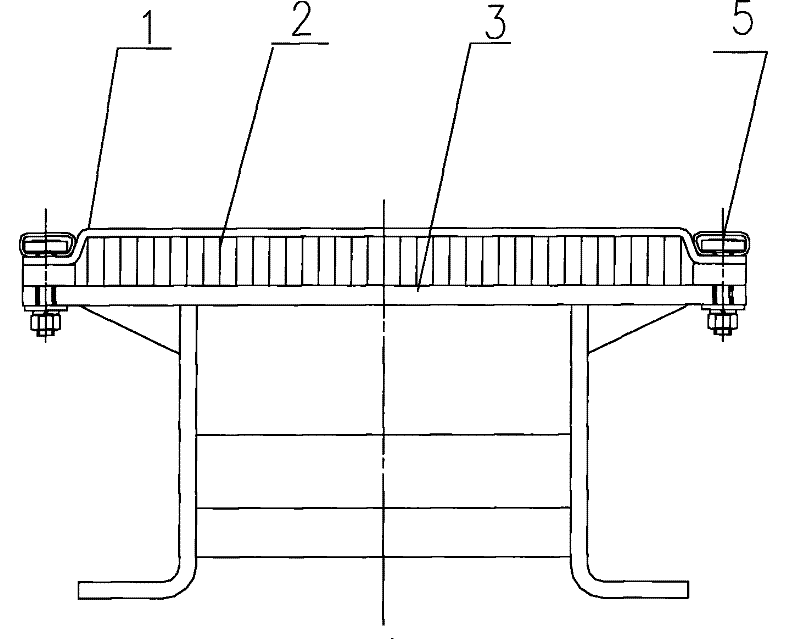

Method and apparatus for connecting straight line motor secondary side conductor and secondary side iron core

ActiveCN101083424AStructural Shape ImprovementReduce processing difficultyWindingsPropulsion systemsExternal pressureEngineering

The invention relates to a connection method of the hypo-side conductor of the straight line motor and the hypo-side iron core and its equipment, the hypo-side conductor of the straight line motor and the hypo-side iron core used the external pressure pattern to be fixed fixedly, the hypo-side conductor through the bolt compact installment directly fixed on the hypo-side iron core base from the out surface of the hypo-side conductor. The fix installment of the hypo-side conductor includes the hypo-side conductor, the hypo-side iron core and the base. The hypo-side conductor covers out of the hypo-side iron core. The inter surface of the hypo-side conductor cling with the base of the hypo-side iron core. The outface of the hypo-side conductor press side joint with the compaction bolt installment, and the compaction bolt installment fixed on the base of the hypo-side iron core.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

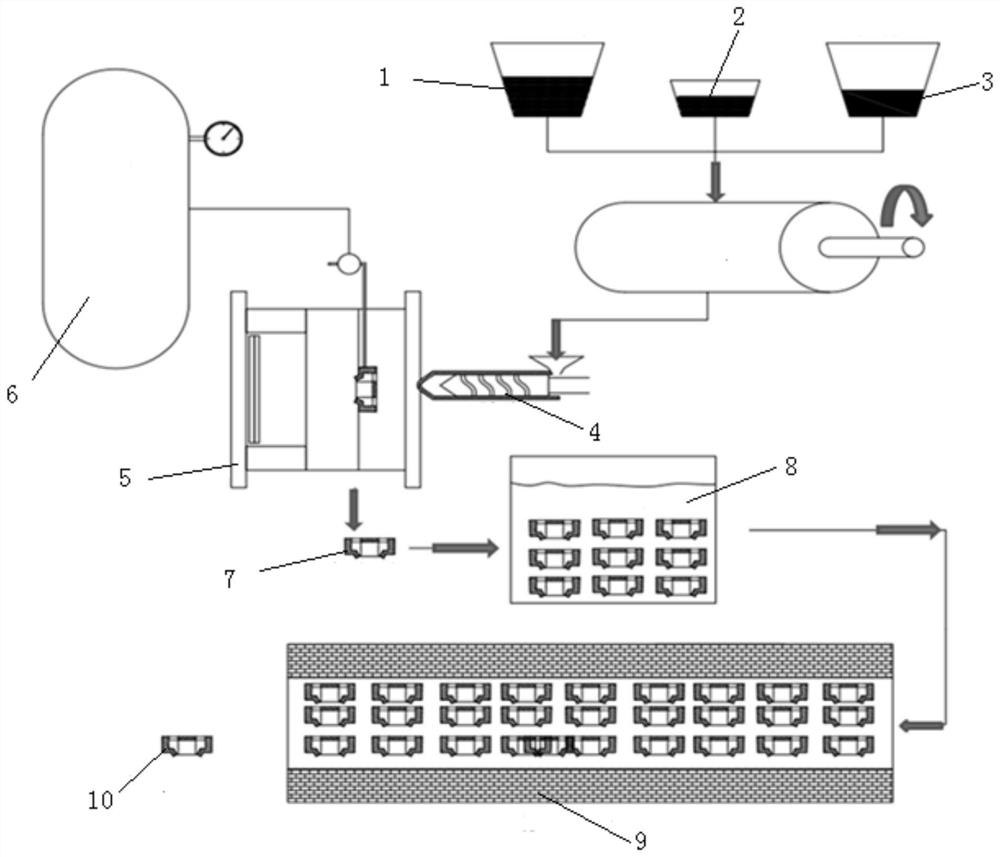

A high-strength blended chair rocking gear and its manufacturing method

ActiveCN109894618BRich swing functionMeet actual needsTurbinesOther manufacturing equipments/toolsAdhesiveMetal alloy

The invention discloses a high-strength blended chair swing gear and a manufacturing method thereof, comprising the following steps: S1: designing a matching injection mold according to a pre-designed gear structure, and then processing and manufacturing the injection mold; S2: Fully mix the metal powder and the binder, and then granulate; S3: Inject the granulated mixture into a preform through an injection mold; S4: Put the preform into the extraction liquid, and remove the binder; S5: putting the prefabricated body without the binder into the sintering furnace for sintering to obtain the gear member. The high-strength blended chair swing gear and its manufacturing method provided by the present invention replace the existing aluminum die-casting or zinc die-casting manufacturing process, adopt new metal alloy powder injection molding, and greatly improve the various aspects of the swing gear. Mechanical performance, enriching the structural shape of gear parts, bringing various design styles to chair designers.

Owner:嘉兴市永泰五金塑料有限责任公司

Pneumatic and structural feature considered three-dimensional geometric structure of fan blade of aircraft engine

InactiveCN102536327BImprove efficiencyReduce the Mach numberBlade accessoriesMachines/enginesAviationAcute angle

The invention discloses a pneumatic and structural feature considered three-dimensional geometric structure of a large fan connotative blade of a civil aircraft engine. The rear section of a blade profile at the root part of the large fan which is designed traditionally has a larger bent corner, a smaller acute angle is formed by a trailing edge suction surface and a hub, low-energy gas is accumulated in the acute-angle area, the flow loss is great, and the smaller acute angle between the suction surface and the hub is not beneficial to the structure modeling of the root stretching section of the blade. According to the invention, the change of an outlet metal corner of an element blade profile of the large fan connotative blade (which is the part within 20% of a blade height of the large fan blade) along the blade height is mainly optimized and a distribution curve of the outlet metal corner of a connotative blade and a projection curve of a trailing edge line in a plane vertical to the axial direction are fit. Through the verification of three-dimensional CFD (Computational Fluid Dynamics), the pneumatic and structural feature considered three-dimensional geometric structure disclosed by the invention has the advantages that the flow separation in the acute-angle area formed by the trailing edge suction surface of the fan and the hub can be effectively reduced, the fan connotative efficiency can be increased, a good entrance condition is provided for a pressure boosting grade, and the blade at the root part and the hub are relatively almost vertical, so that convenience is provided for the installation of the blade on a wheel disc.

Owner:BEIHANG UNIV

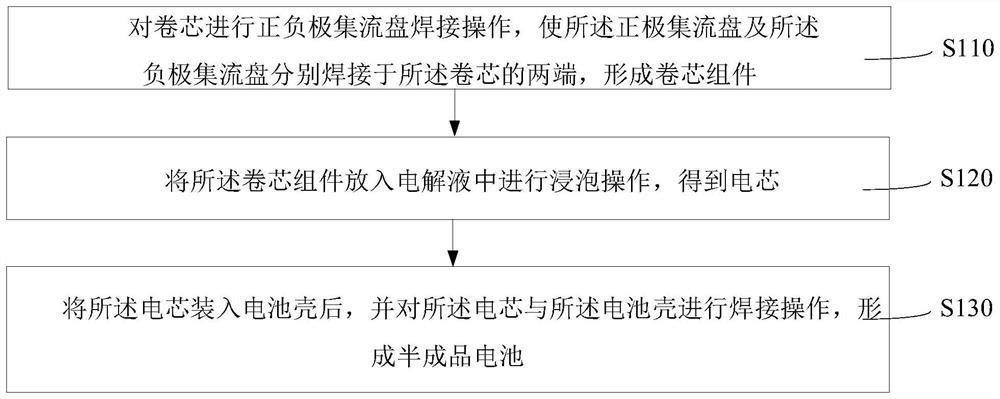

Full-tab battery preparation process and full-tab battery

PendingCN114744380AQuality assuranceReduce manufacturing costPrimary cell manufactureFinal product manufactureElectrolytic agentProcess engineering

The invention provides a full-tab battery preparation process and a full-tab battery. The preparation process of the full-tab battery comprises the following steps: welding positive and negative current collecting plates on a roll core, so that the positive current collecting plate and the negative current collecting plate are respectively welded at two ends of the roll core to form a roll core assembly; the roll core assembly is put into an electrolyte for soaking operation, and a battery core is obtained; after the battery cell is arranged in the battery shell, the battery cell and the battery shell are welded, and a semi-finished battery is formed. As the roll core assembly is soaked, the electrolyte can quickly enter the interior of the roll core, the liquid injection efficiency of the roll core assembly is improved, the roll core can comprehensively and fully absorb the electrolyte, the use amount of the electrolyte actually required by each roll core is further ensured, and the service life of the roll core assembly is prolonged. Therefore, the accuracy of the electrolyte required by the single roll core is improved.

Owner:东莞凯德新能源有限公司

Thermal field structure of moving thermal insulation ring for vertically oriented growth of polysilicon

InactiveCN101775641BCrystal solidification process controlImprove temperature gradient distributionBy pulling from meltManufacturing technologyInsulation layer

Owner:NINGBO JINGYUAN SOLAR ENERGY +1

Glass cone for projection tube

InactiveCN1588610AStructural Shape ImprovementAvoid scratchesCathode-ray/electron-beam tube vessels/containersCrest lineEngineering

The fixing base of glass cone of projection tube used for fixing cooler which is fit on outside surface of side wall of glass cone used for reference end surface of fixing base includes first curve section, second curve section and straight-line section, the first and second curve section are smoothly connected by the straight-line section, the straight-line section is smooth connected on outside wall surface of side wall of funnel-shaped glass cone through the second curve section. The side wall section is formed by stretching bulged crest line forming reference end surface along center axial direction of the funnel-shaped glass cone in an angle, both reference end surface and side wall section of the fixing base are smooth connected with the outside surface of projection tube used glass cone.

Owner:HENAN ANCAI HI-TECH

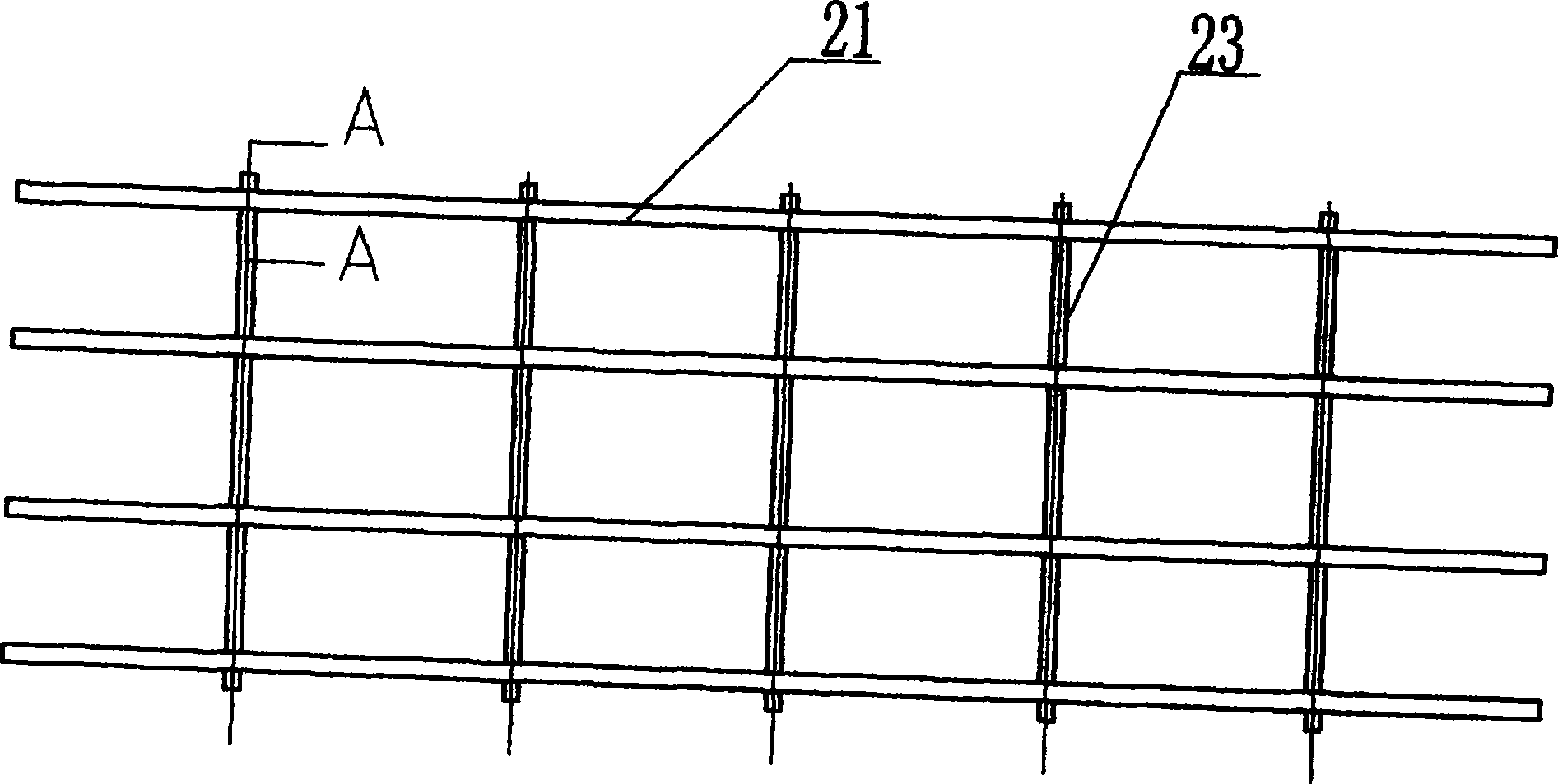

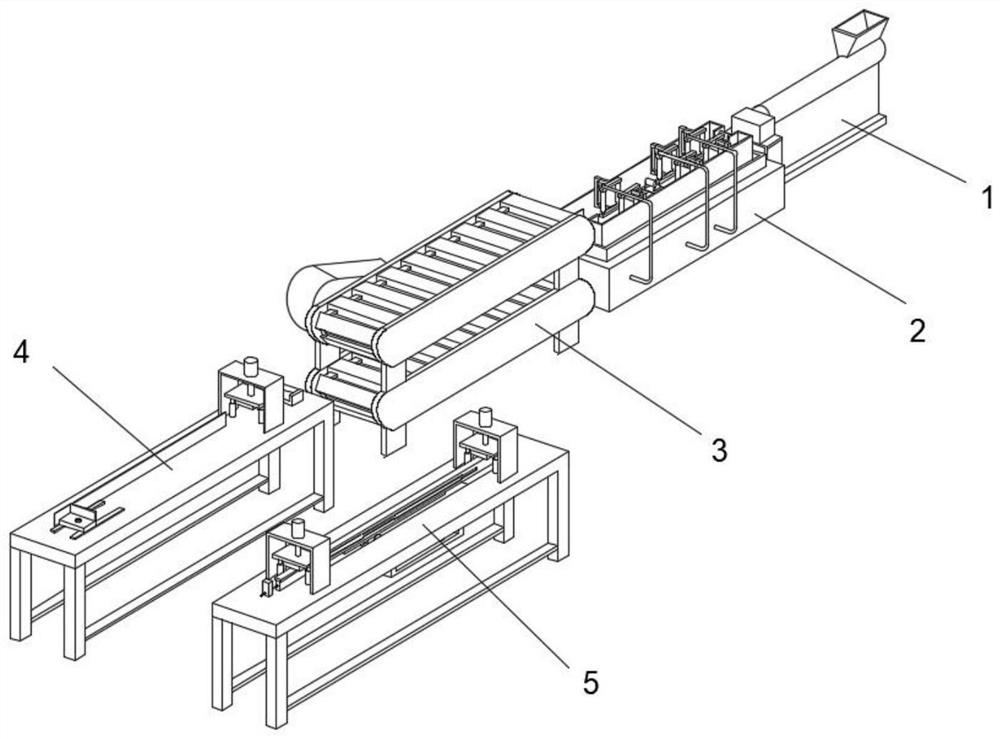

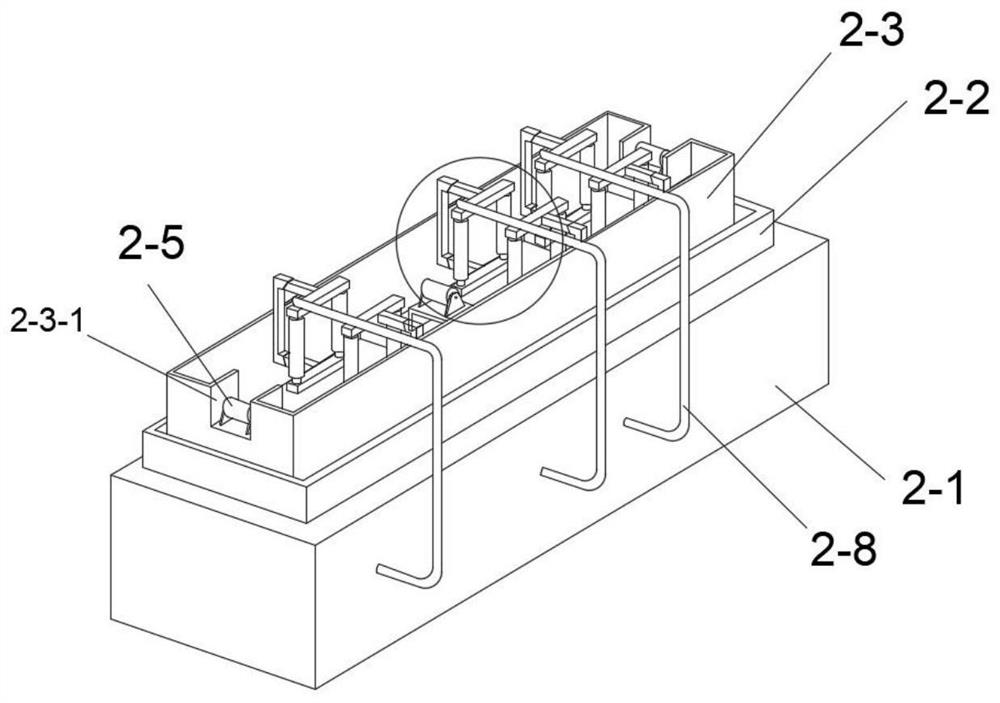

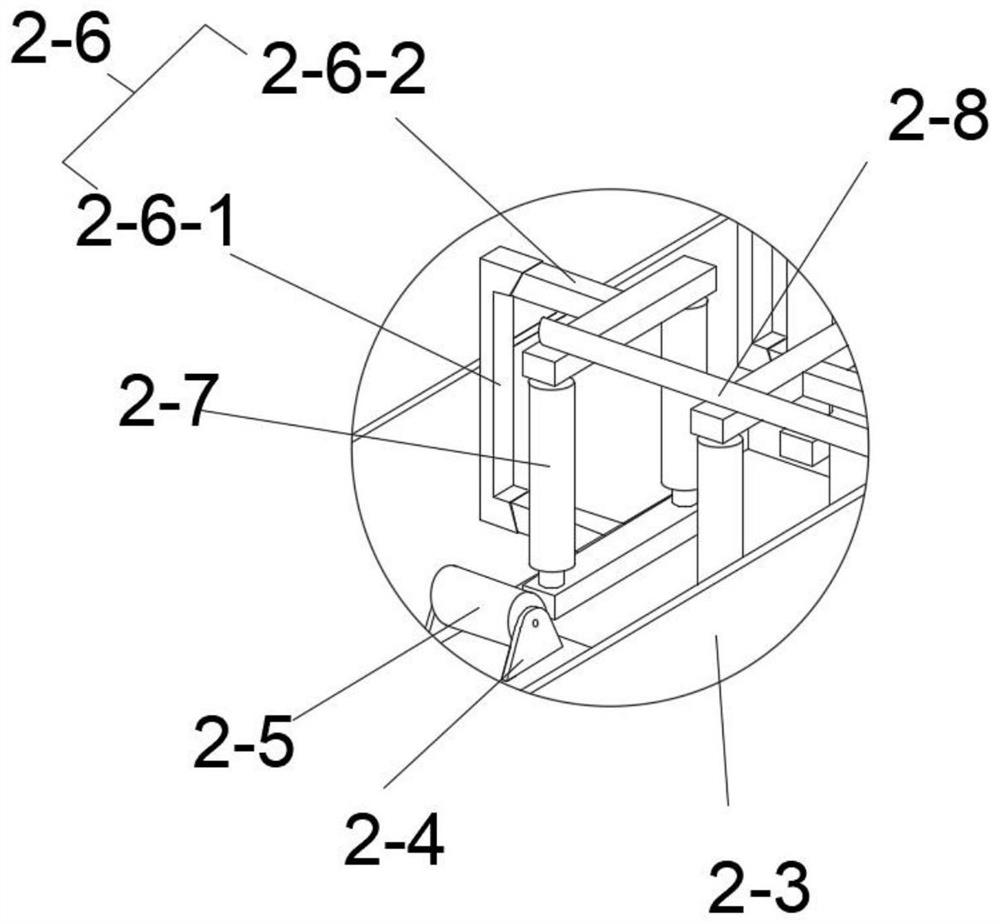

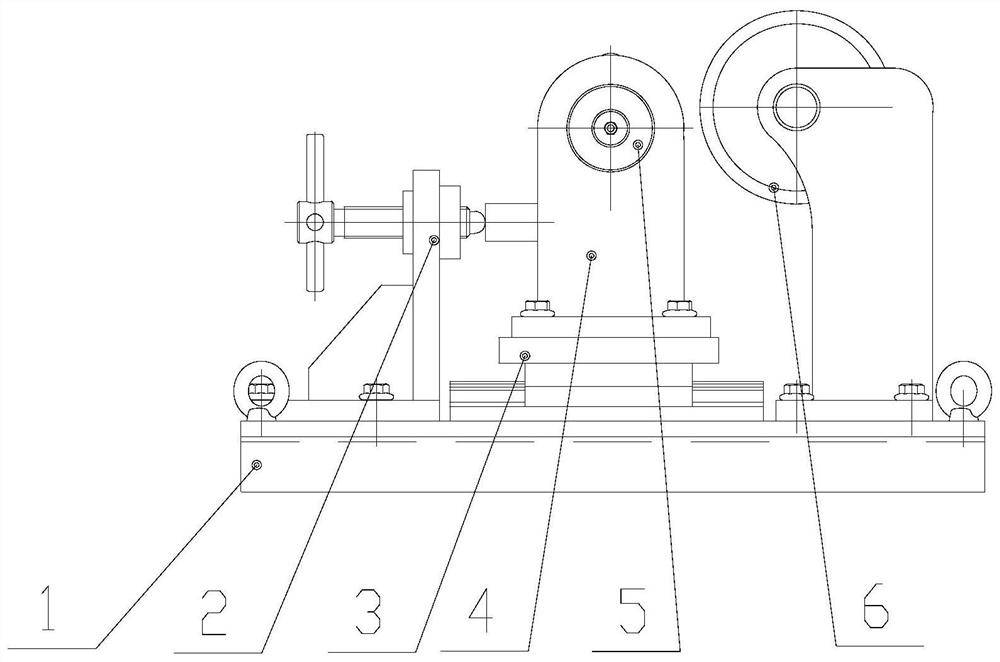

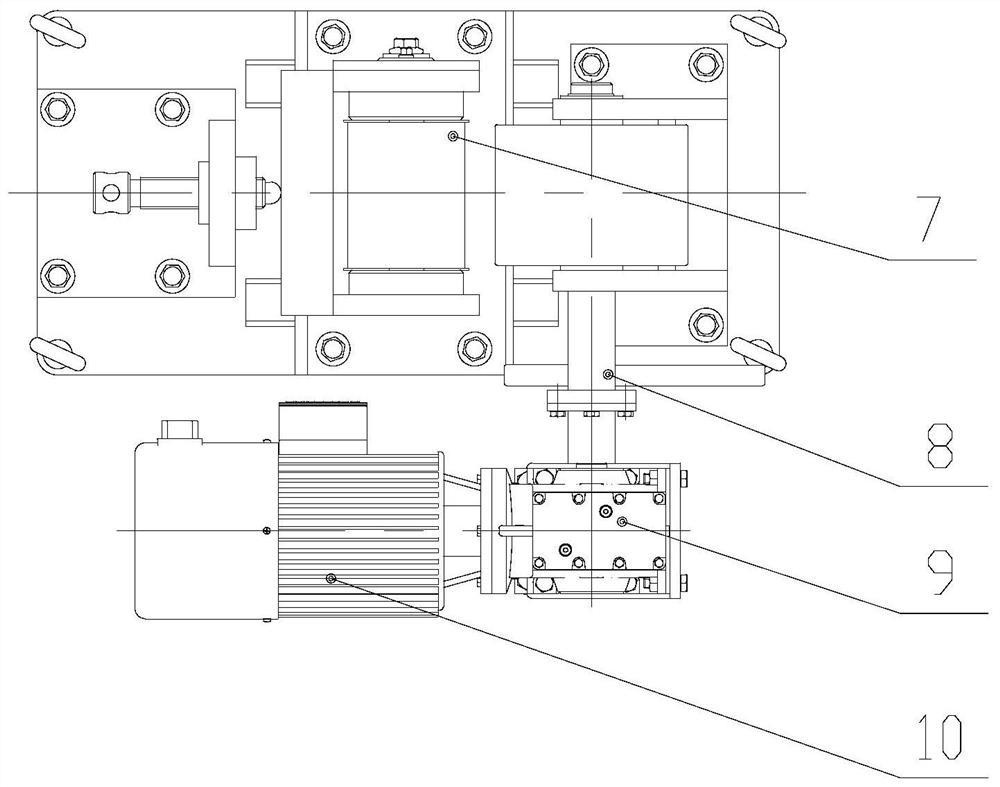

Preparation system and process of high-molecular plastic shutter

ActiveCN113199722ACompact processSmall footprintDomestic articlesMetal working apparatusPunchingCooling effect

The invention discloses a preparation system of a high-molecular plastic shutter. The preparation system comprises an extruder, a cooler, a traction machine, a cut-off machine and a punching machine, wherein the cooler is arranged at one end of the extruder, and the cooler comprises a water tank, an outer water tank, an inner water tank, a bottom support, a bottom roller, a side support, a side roller and a water spraying pipe; the traction machine is arranged at one end of the cooling machine, and the traction machine and the cooling machine are arranged in the same direction; the cut-off machine is arranged at one end of the traction machine, and the cut-off machine and the traction machine are arranged in the same direction; and the punching machine is arranged at one side of the cut-off machine, and the punching machine and the cut-off machine are arranged in parallel. The process flow is compact, and the occupied area of equipment is small; the cooling effect on the profile is strong, the profile can be continuously and circumferentially clamped and shaped at the two sides, and the percent of pass of products is guaranteed; and punching of the profile is convenient and fast, and the punching efficiency is high.

Owner:元鼎饰材实业(镇江)有限公司

A high-power crimping igbt package module

ActiveCN103545269BImprove antioxidant capacityImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesContact pressureEngineering

The invention relates to the technical field of microelectronic packaging, in particular to a high-power crimping type IGBT packaging module. Upper cover, sub-module, gate pin, lower base, the upper cover is covered on the lower base, the sub-module is set between the upper cover and the lower base, and the gate pin is set in the groove of the insulating bottom plate in the lower base Inside. The sub-module includes a top molybdenum sheet, a chip, a bottom molybdenum sheet, a conductive silver sheet and a PBI high-performance plastic frame, and the top molybdenum sheet, a chip, a bottom molybdenum sheet and a conductive silver sheet in the groove surface of the PBI high-performance plastic frame Pressing sequentially from top to bottom, the upper surface of the top molybdenum sheet is in electrode contact with the lower surface of the upper cover, and the lower surface of the conductive silver sheet in the sub-module is crimped with the upper surface of the boss in the lower base. The invention has the advantages of simpler manufacture and assembly, better connection reliability, better heat dissipation performance and the like.

Owner:STATE GRID CORP OF CHINA +2

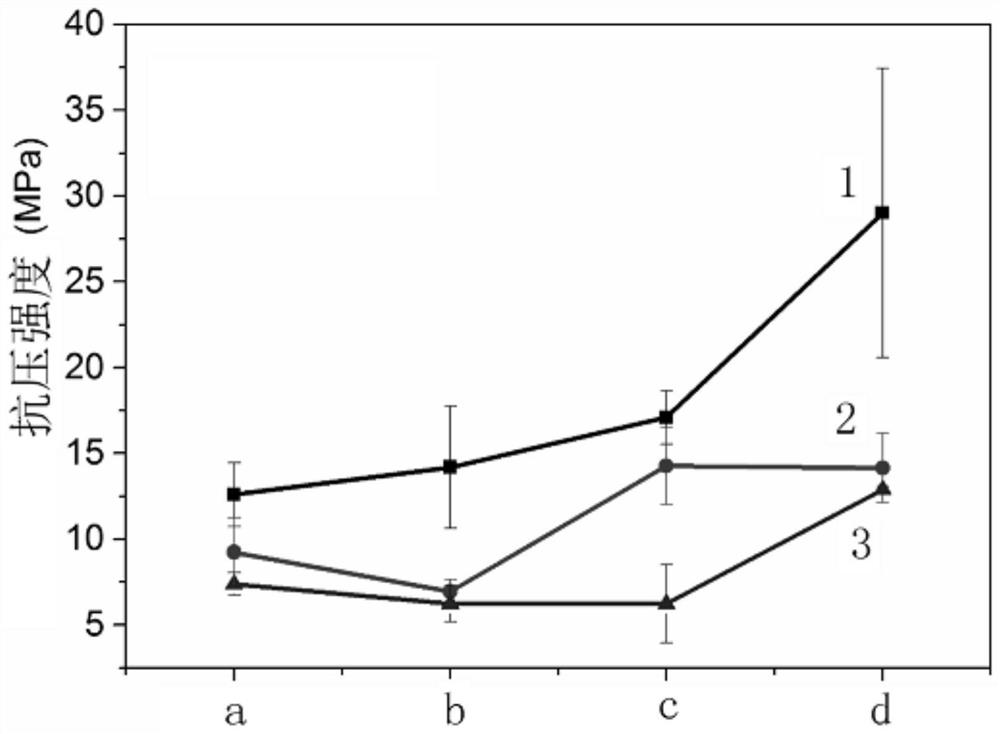

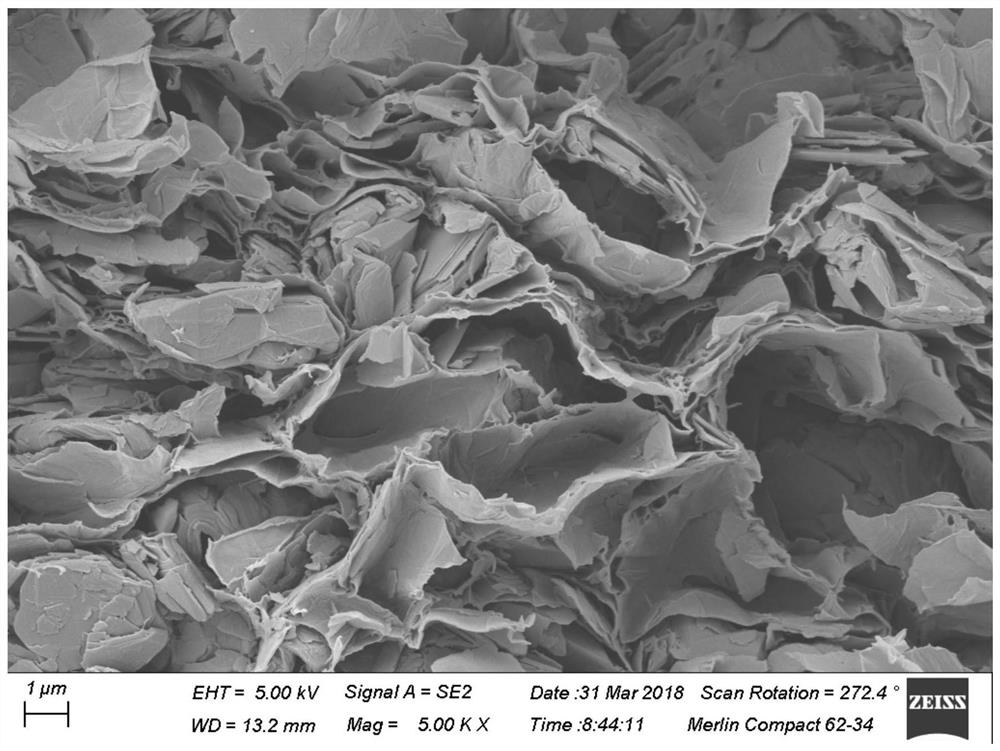

A method for 3D printing high temperature resistant graphene-based conductive structures

ActiveCN110171973BImprove rheologyGood shear thinning effectAdditive manufacturing apparatusCarbon compounds3d printGraphite oxide

A method for 3D printing a high temperature resistant graphene-based conductive structure, and the invention relates to a method for 3D printing a conductive structure. The invention solves the problems that the existing graphene-based electrode slurry has low solid phase content and shrinks and deforms after molding, which makes the structure difficult to maintain the design shape and accuracy. Preparation methods: 1. Preparation of graphene oxide; 2. Preparation of graphene oxide / graphite 3D printing slurry; 3. Graphene oxide / graphite 3D printing molding; 4. 3D printing graphene oxide / graphite high temperature reduction. The invention is used for 3D printing a high temperature resistant graphene-based conductive structure.

Owner:HARBIN INST OF TECH

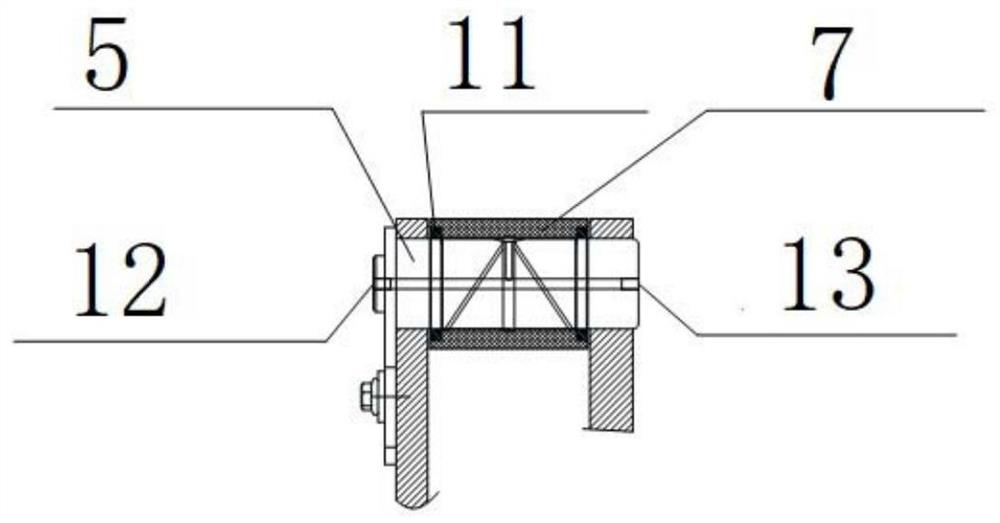

Visual shaft sleeve lubrication test device for engineering machinery

PendingCN111796077AIntuitive observation of continuityStructural Shape ImprovementMaterial testing goodsEngineeringMechanical equipment

The invention relates to a visual shaft sleeve lubrication test device for engineering machinery, and belongs to the technical field of engineering machinery equipment. The device comprises a machinebase assembly, a pressure applying device, a sliding seat, a shaft seat, a hinge pin shaft, a transparent shaft sleeve and a pressure applying steel wheel device; the shaft seat for mounting the hingepin shaft is arranged on the sliding seat; the pressure applying device for pushing the sliding seat to move is arranged on one side of the sliding seat, and the pressure applying steel wheel deviceis arranged on the other side of the sliding seat; the periphery of the hinge pin shaft is sleeved with the transparent shaft sleeve; and the pressing steel wheel device is correspondingly arranged onthe outer circumference of the transparent shaft sleeve. The high-strength transparent material shaft sleeve is adopted, and the continuity and durability of a lubricating oil film generated by a grease outlet mode of the hinge pin shaft and a transparent shaft sleeve lubricating oil groove are visually observed. By changing the pressure between the transparent shaft sleeve and the pressing steelwheel, the purpose of simulating the stress condition of the actual working condition is achieved. The lubricating mechanism of engineering machinery hinge pin shaft lubricating grease is studied, ahinge pin shaft matched with engineering machinery, a lubricating oil channel of a shaft sleeve and a lubricating oil groove are developed, and the engineering machinery hinge point can work permanently and efficiently.

Owner:龙工(上海)机械制造有限公司

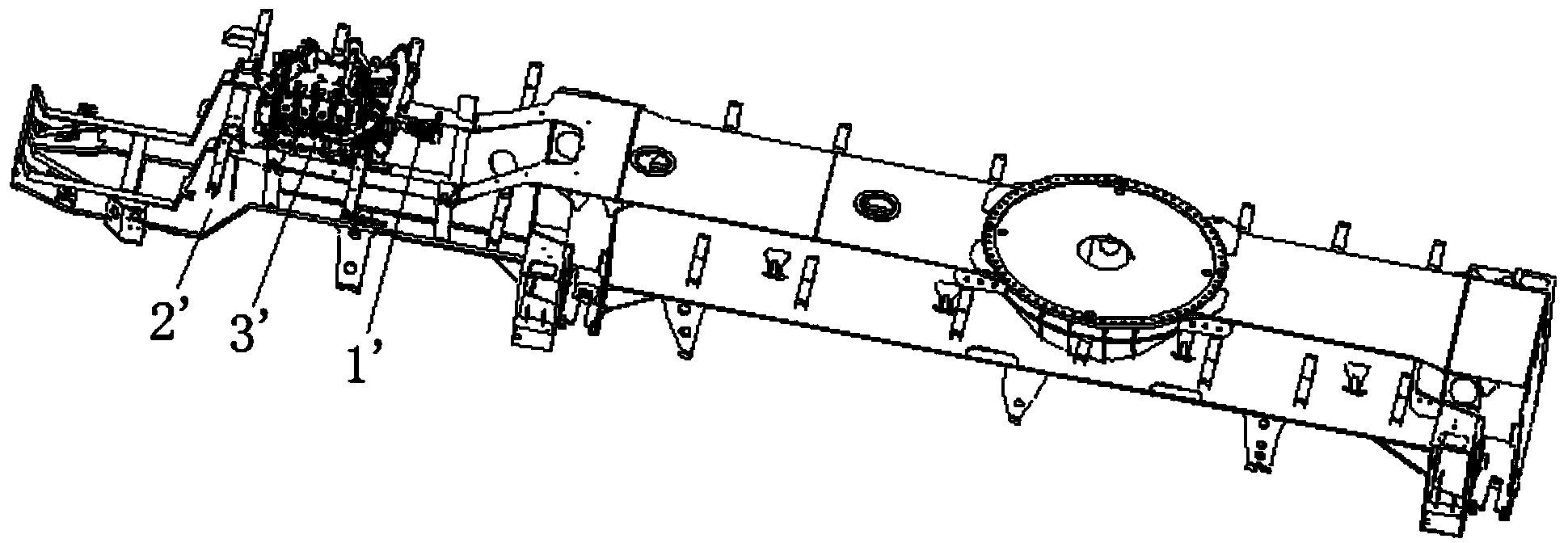

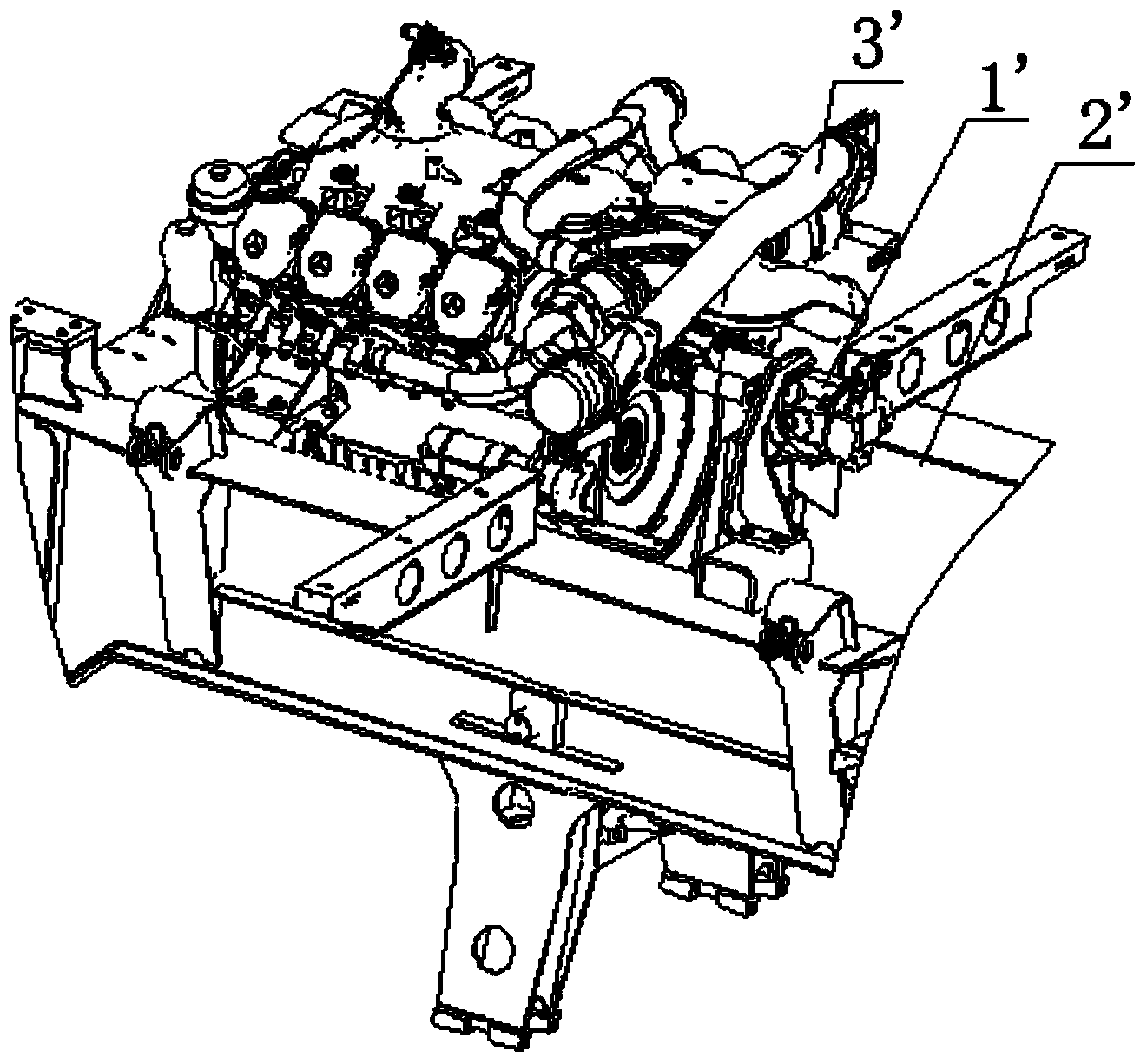

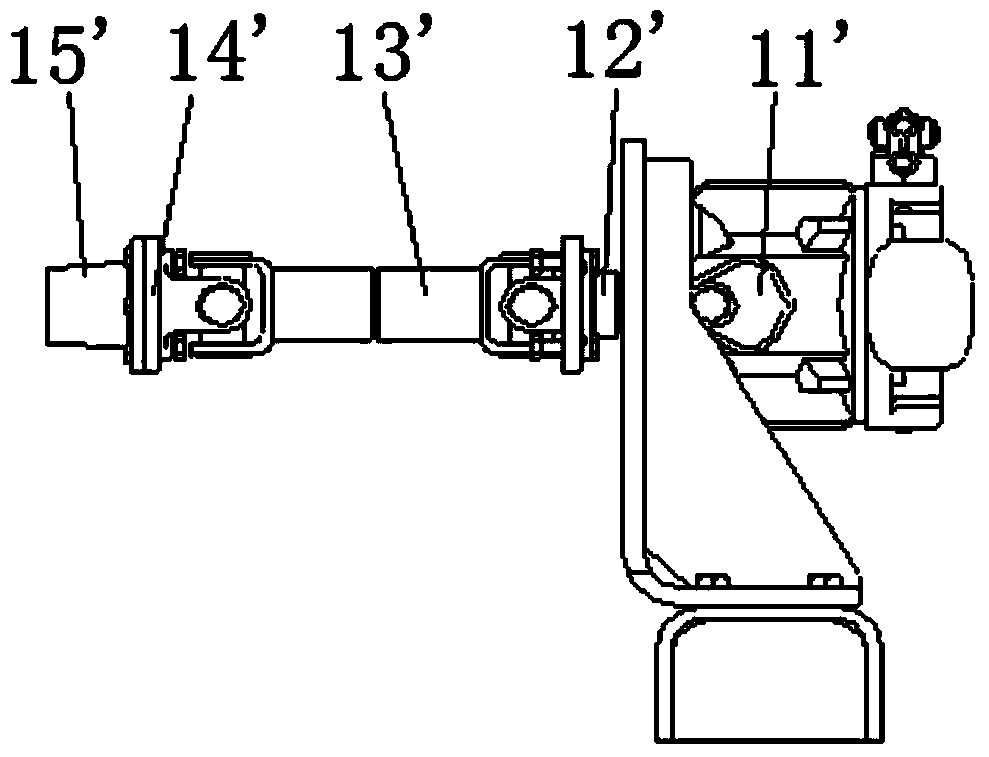

Oil pump device for automobile crane

ActiveCN103395367AImprove load stabilityIncrease contact areaControl devicesCantileverPower take-off

The invention relates to an oil pump device for an automobile crane. The oil pump device comprises an oil pump, wherein the power input end of the oil pump is connected with a transmission shaft via a first adapting plate, and the other end of the transmission shaft is connected with a power take-off device via a second adapting plate; the oil pump is arranged on an oil pump support; the oil pump support is arranged on an automobile frame via an auxiliary support, and the oil pump support is an L-shaped bend board; a shaft hole is formed in one sideboard of the oil pump support; the power output end of the oil pump penetrates through the shaft hole and then is connected with the first adapting plate, and another sideboard of the oil pump support is used for being fixedly connected with the auxiliary support; both the two sideboards of the oil pump support are vertical to the ground; the auxiliary support comprises a box-type structure fixedly arranged on the automobile frame; a connecting board is fixedly connected with the sideboards of the oil pump support. The oil pump device for the automobile crane is shortened in the cantilever length of the oil pump support, improves the working stability of the oil pump device under the alternate load action, and eliminates a potential safety hazard of unbalancing of the transmission shaft.

Owner:XUZHOU HEAVY MASCH CO LTD

Method and apparatus for connecting straight line motor secondary side conductor and secondary side iron core

ActiveCN101083424BStructural Shape ImprovementReduce processing difficultyWindingsPropulsion systemsElectrical conductorElectric machine

The invention relates to a connection method of the hypo-side conductor of the straight line motor and the hypo-side iron core and its equipment, the hypo-side conductor of the straight line motor and the hypo-side iron core used the external pressure pattern to be fixed fixedly, the hypo-side conductor through the bolt compact installment directly fixed on the hypo-side iron core base from the out surface of the hypo-side conductor. The fix installment of the hypo-side conductor includes the hypo-side conductor, the hypo-side iron core and the base. The hypo-side conductor covers out of the hypo-side iron core. The inter surface of the hypo-side conductor cling with the base of the hypo-side iron core. The outface of the hypo-side conductor press side joint with the compaction bolt installment, and the compaction bolt installment fixed on the base of the hypo-side iron core.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

A high-efficiency dust-removing and filtering device for a sweeping-suction sweeper

ActiveCN106139805BImprove dust removal efficiencyImprove sedimentation filtration efficiencyCombination devicesCycloneFiltration

The invention discloses a high-efficiency dust-removing and dust-filtering device for a sweeping-suction type sweeper, which is characterized in that it is composed of a sweeping-suction system, a three-stage filtering system and a dust-removing device outlet system; the sweeping-suction system consists of a main brush (1) and a collector A dust box (2) is formed; the three-stage filtration system is composed of a filter screen (8), a cyclone pre-filtering air duct (3) and a filter element filter (4); the outlet system of the dust removal device includes a lower air duct (6). ), the outlet of the dust removal device (7) and the vacuum fan (5); by setting up a three-stage filtration system and improving the shape of the filter air duct, the swirl flow and centrifugal force during the filtration of dust-laden gas are increased, and the dust removal efficiency of the dust removal device of the sweeper is improved. and service life; test and simulation analysis show that the dust-laden gas entering the cyclone pre-filter air duct captures and settles 98% of the gravel with a particle size of 0.1 to 1.5 mm.

Owner:SHANDONG PENGXIANG AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com