Method and apparatus for connecting straight line motor secondary side conductor and secondary side iron core

A technology of linear motor and connecting device, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., to achieve the effect of reducing processing difficulty, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

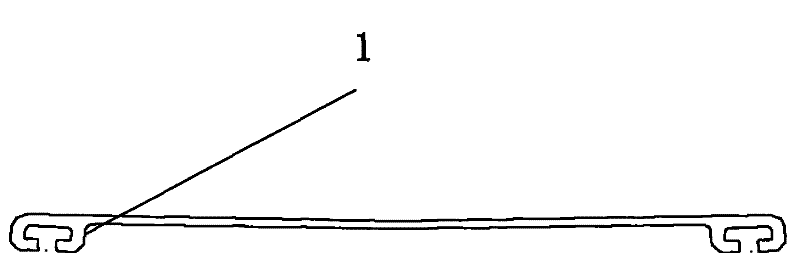

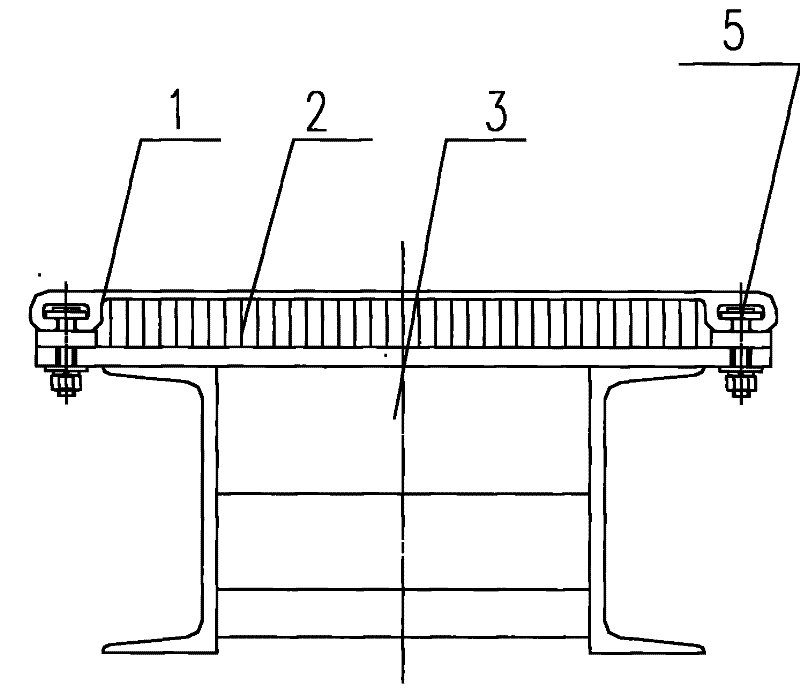

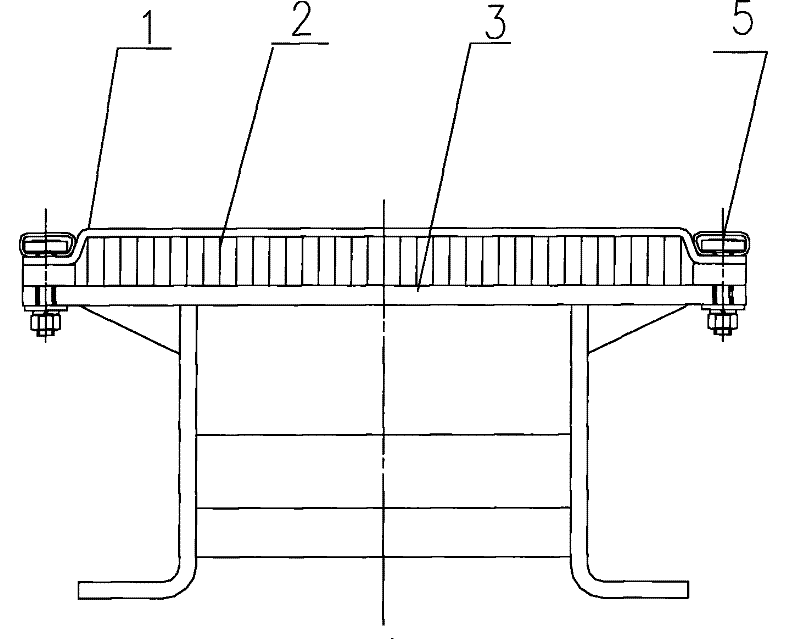

[0019] The accompanying drawing shows a schematic structural view of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0020] A connection method between a secondary conductor and a secondary iron core of a linear motor. The secondary conductor and the secondary iron core of the linear motor are fixed by means of an external pressure device that compresses the secondary conductor from the outside. The secondary conductor is in the shape of inline bending and molding with a blank holder, and the secondary conductor is directly fixed from the outer surface of the secondary conductor to the upset seat of the secondary core through a bolt pressing device.

[0021] The structure of the fixing device for the external pressure type secondary conductor is: a fixing device for the secondary conductor, including a secondary conductor 1 , a secondary iron core 2 and an upset seat 3 . The secondary conductor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com