Follow-up heat insulation ring thermal field structure for vertical oriented growth of polysilicon

A vertically oriented, heat-insulating ring technology, used in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as structural design defects, improve enterprise production capacity, improve verticality, and improve crystal surface structure and shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

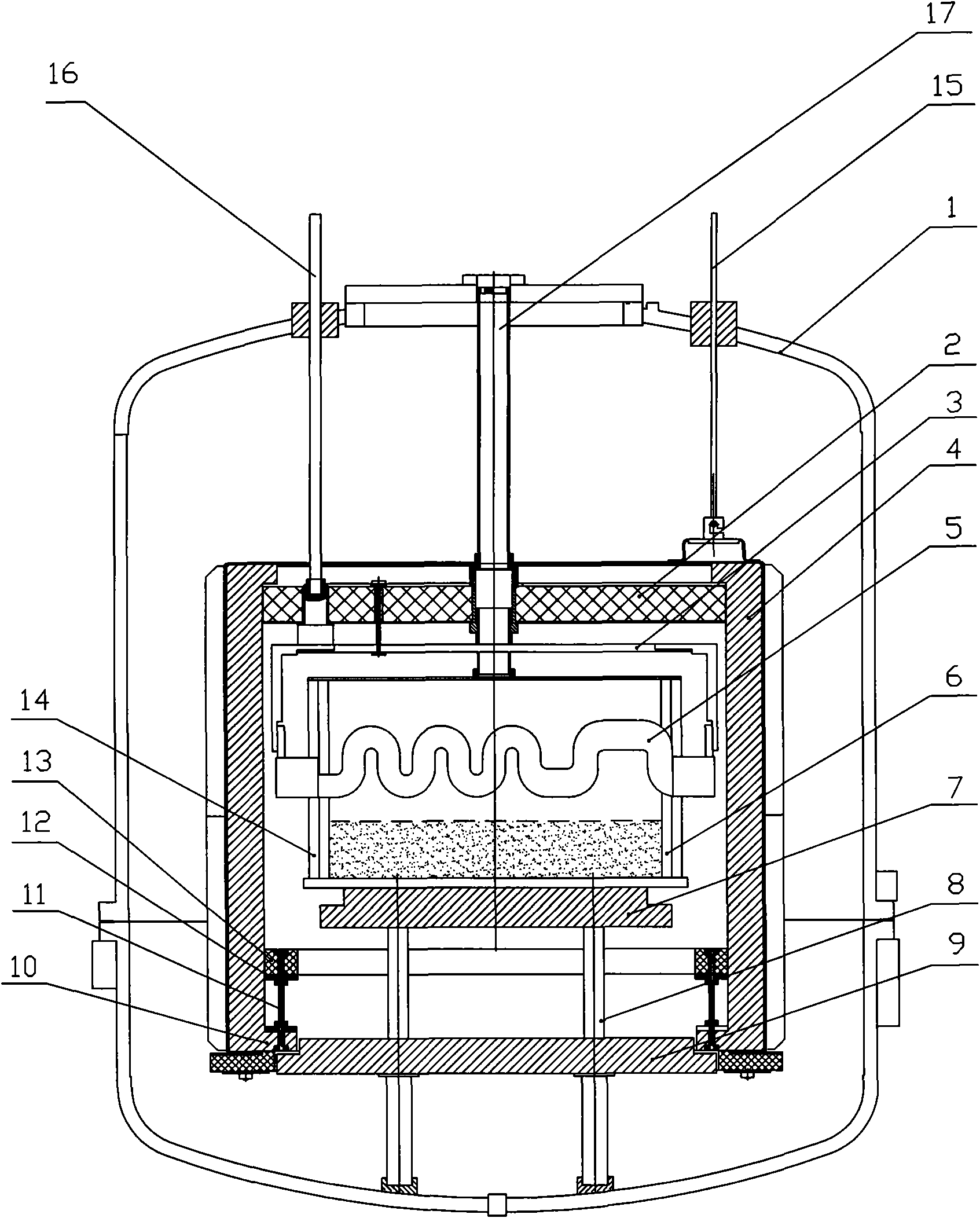

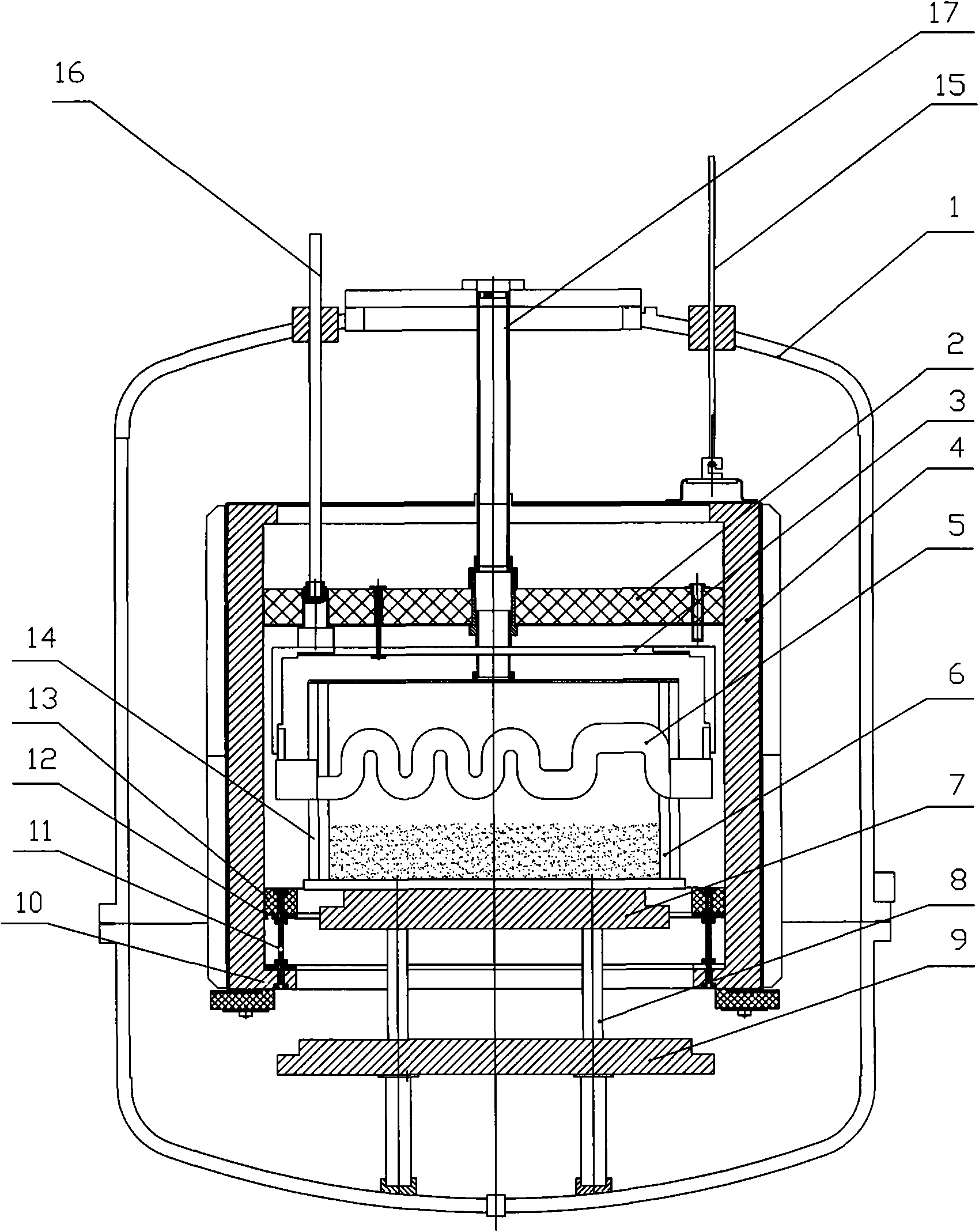

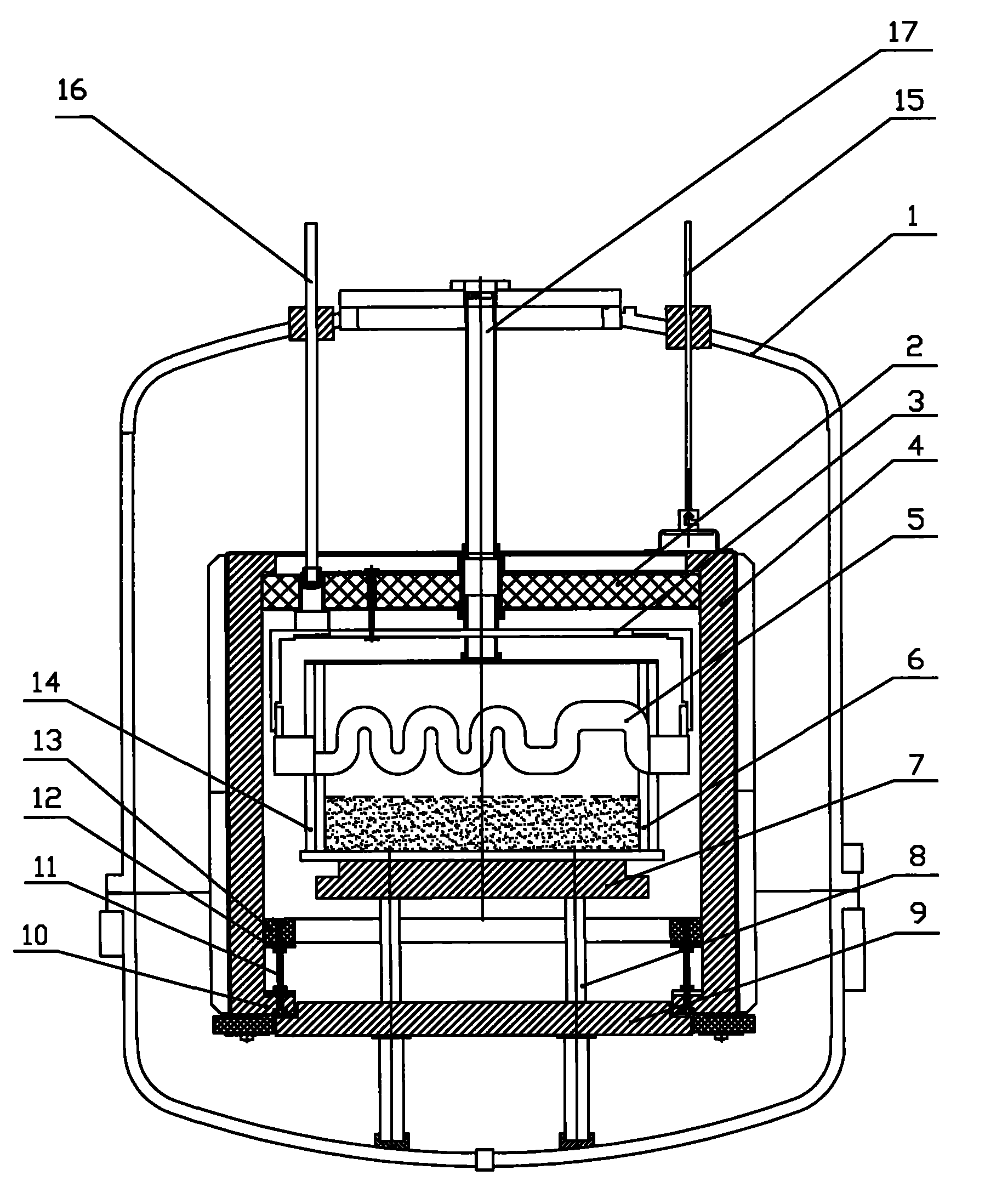

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] The heat field structure of the moving heat insulating ring in this embodiment includes a crucible 6 placed in the furnace chamber 1, and the heat field of the crucible 6 includes a top heater 3, a side heater 5 and a heat exchange platform at the bottom of the crucible 6 7, wherein the top heater 3 and the side heater 5 are fixed on the electrode 16; the furnace chamber 1 is provided with a side-enclosed heat insulation cage 4, and the crucible 6 and the thermal field are placed in the heat insulation cage In the body 4, the upper end of the heat insulation cage body 4 is connected with the lifting device 15; the top heat insulation board 2 and the lower heat insulation layer 9 are respectively arranged on the top and bottom of the heat insulation cage body 4, wherein the top heat insulation board 2 is fixed and suspended on the electrode 16, and the argon gas input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com