Glass cone for projection tube

A technology for projection and tube application in the direction of cathode ray/electron beam tube shell/container, which can solve problems such as scratches, small cracks, and wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings.

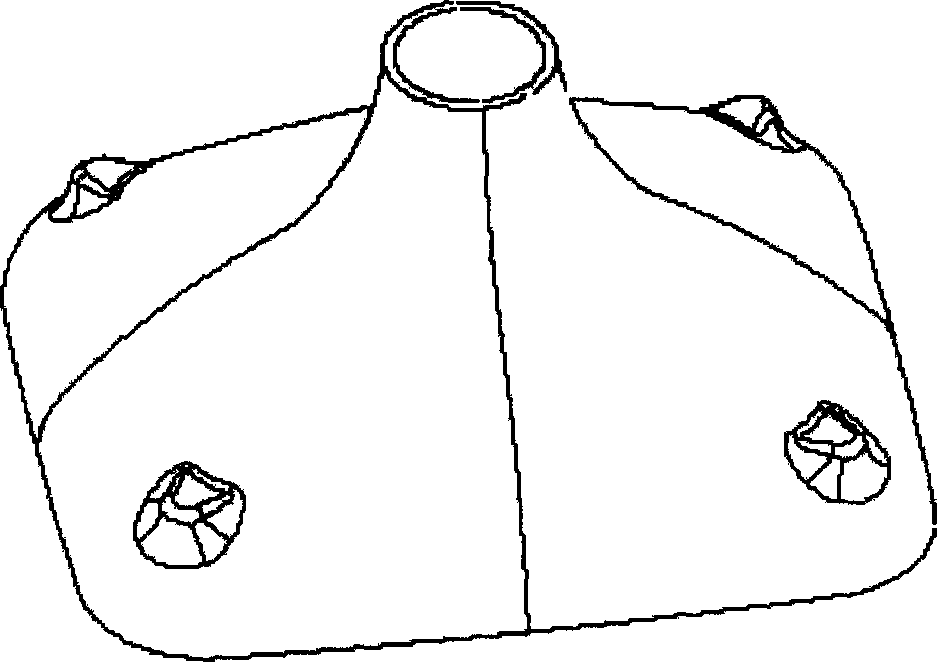

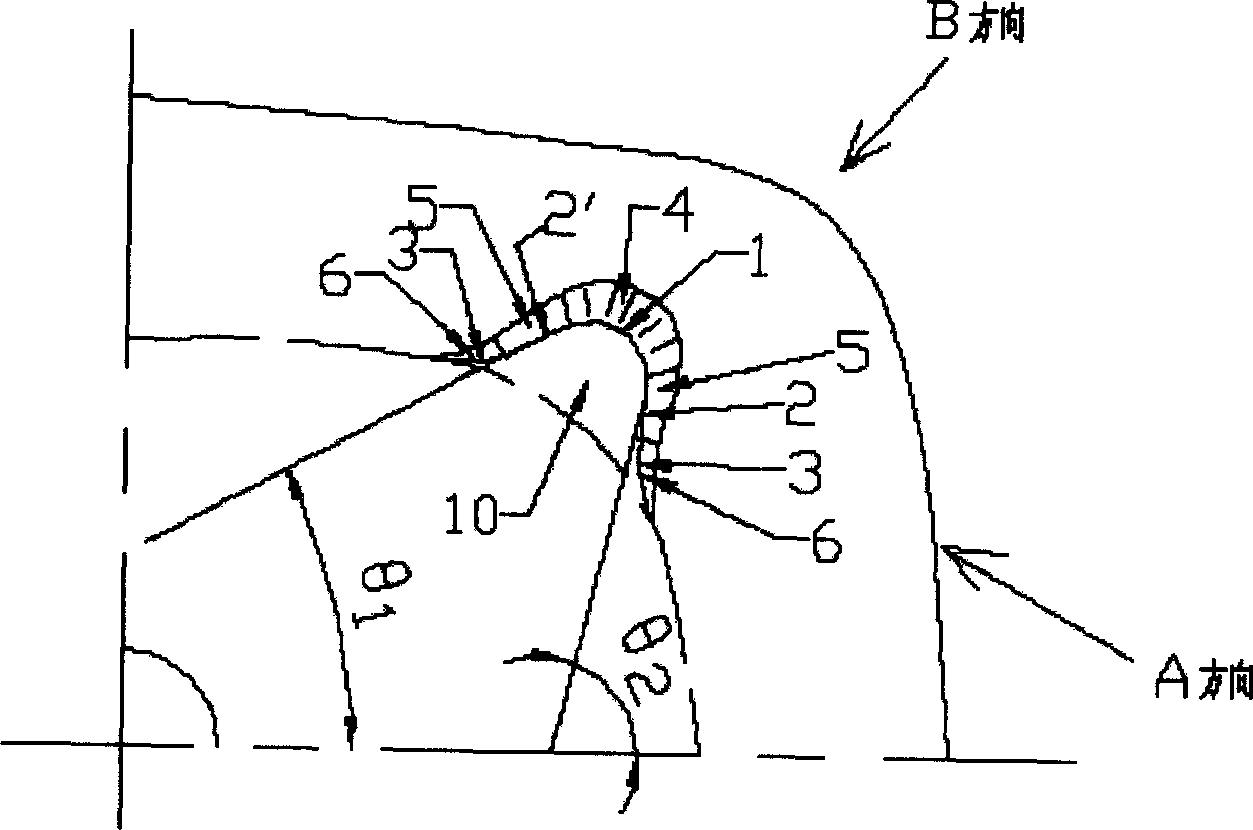

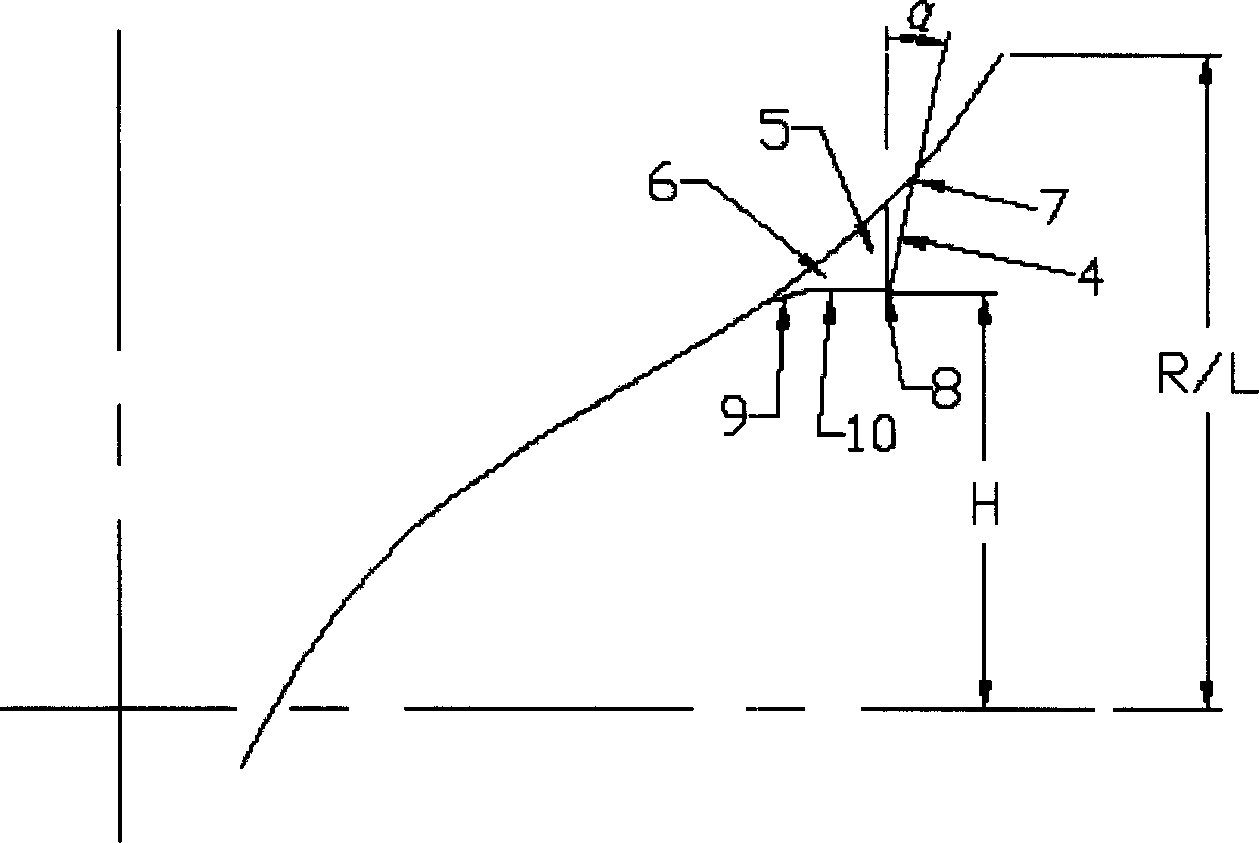

[0017] figure 1 A perspective view of a funnel for a projection tube. figure 2 It is a schematic diagram of the funnel fixing seat for the projection tube along the direction of the center axis of the funnel for the projection tube. see figure 1 and figure 2 , which has a plurality of fixing seats for fixing a cooling device, and each fixing seat is integrally protruded from a funnel-shaped projection tube with a substantially rectangular large opening at one end and a small circular opening at the other end. On the outer wall surface of the side wall portion, the end face of the fixed seat close to the circular small opening end of the funnel-shaped projection tube funnel is the reference end face 10, and the protruding ridge line of the reference end face 10 is defined by the first curve Part 1, second curved part 3 and straight part 2, 2', wherein the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com