Large-caliber hard alloy drawing mould

A hard alloy and drawing die technology, applied in the field of alloy manufacturing, can solve the problems of fast wear and short service life of large-diameter cold draft die cores, and achieve the effects of long service life, improved service life and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

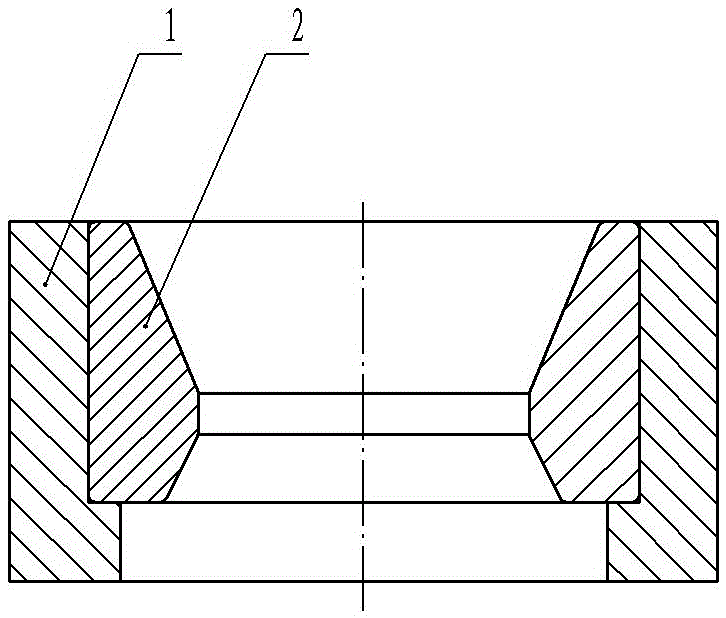

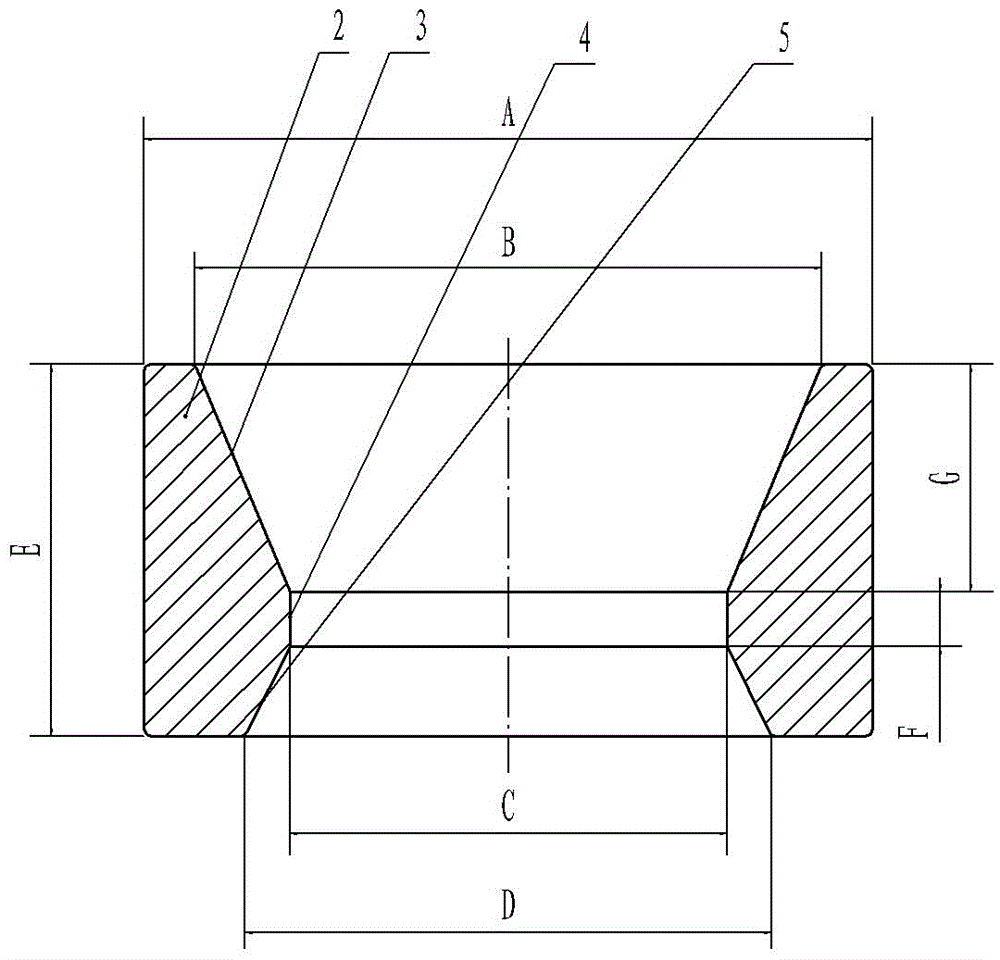

[0013] Embodiment 1: as Figure 1~Figure 2 As shown, this large-diameter hard alloy drawing die includes a mold base 1 and a mold core 2 set in the mold base 1. The mold core 2 is made of hard alloy, and the mold base 1 is made of high-speed steel; The core 2 is a cylinder with a through hole in the middle, and the through hole in the middle is composed of the inlet section 3 of the truncated cone, the sizing section 4 of the cylinder and the outlet section 5 of the truncated cone. The outer diameter dimension A of the mold core 2 is 640mm, and its thickness dimension G is 110 mm; the large end dimension B of the conical inlet section 3 is 590 mm, and the height dimension G of the truncated cone is 60 mm; the outer diameter dimension C of the cylindrical sizing section 4 is 550 mm, and its height dimension F is 20 mm; The large end dimension of the outlet section 5 of the truncated cone is 560 mm.

Embodiment 2

[0014] Embodiment 2: as Figure 1~Figure 2 As shown, for this large-diameter cemented carbide drawing die, the outer diameter dimension A of the core 2 is 680 mm, and its thickness dimension G is 130 mm; the large end dimension B of the conical inlet section 3 is 610 mm, and the height of the truncated cone is The dimension G is 70 mm; the outer diameter C of the cylindrical sizing section 4 is 560 mm, and its height F is 30 mm; the large end dimension of the truncated conical outlet section 5 is 580 mm, and the rest are the same as in the first embodiment.

Embodiment 3

[0015] Embodiment 3: as Figure 1~Figure 2 As shown, for this large-diameter cemented carbide drawing die, the outer diameter dimension A of the core 2 is 660 mm, and its thickness dimension G is 120 mm; the large end dimension B of the conical inlet section 3 is 600 mm, and the height of the truncated cone is The dimension G is 65 mm; the outer diameter dimension C of the cylindrical sizing section 4 is 555 mm, and its height dimension F is 25 mm; the large end dimension of the truncated conical outlet section 5 is 570 mm, and the rest are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Thickness dimension | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com