High speed train model wind tunnel test standard roadbed

A wind tunnel test, high-speed train technology, applied in the direction of aerodynamic test, machine/structural component test, measuring device, etc., can solve the problem of large aerodynamic error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

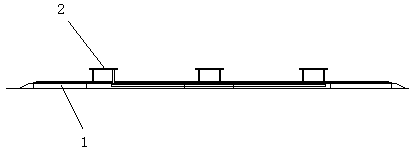

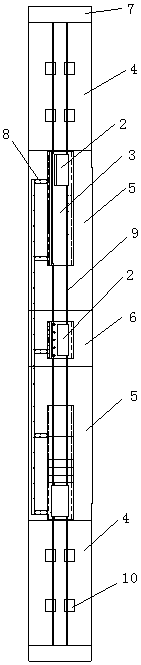

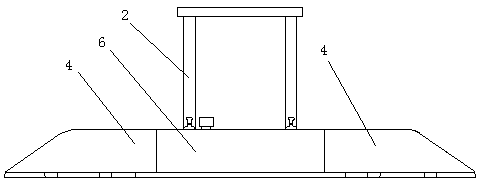

[0022] Embodiment 1: Three-vehicle marshalling subgrade wind tunnel test, two sets of sliding support module are respectively connected to both ends of the fixed support module, and then two groups of subgrade edge modules are respectively connected to both ends of the sliding support module.

[0023] Adjust the sliding table to ensure that the distance between the support bases meets the test requirements, install the high-speed train car model on the support bases, bury all the connecting cables in the wiring grooves, and then conduct the wind tunnel test.

[0024] If you need to replace other types of train models, you only need to adjust the sliding table so that the distance between the support seats can adapt to the length of the car to be replaced, and then install the replaced car on the support seat to carry out the wind tunnel test.

Embodiment 2

[0025] Example 2: A wind tunnel test for a one-and-a-half-car marshalling subgrade. Two groups of subgrade edge modules are installed on the fixed support base modules, and then one and a half marshalling cars are installed on the support base to carry out the wind test.

[0026] In the conversion process of the three-car formation and the one-and-a-half-car formation, the conversion can be realized quickly only by removing the sliding support module, which can greatly save the roadbed layout time.

[0027] This scheme establishes a unified high-speed train model test platform to realize the comparability of high-speed train test data in different periods. At present, especially in the wind tunnel tests of high-speed trains carried out by different domestic high-speed train development units, the subgrade shapes and structures used are different, and the subgrades used by the same unit in different periods of tests are also different. Through comparative research, it is found ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com