A high-strength blended chair rocking gear and its manufacturing method

A manufacturing method and blending technology, applied in other manufacturing equipment/tools, engine components, turbines, etc., can solve problems such as excessive volume and insufficient mechanical properties of gear parts, and achieve large design space and multiple material choices. , enrich the effect of the swing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

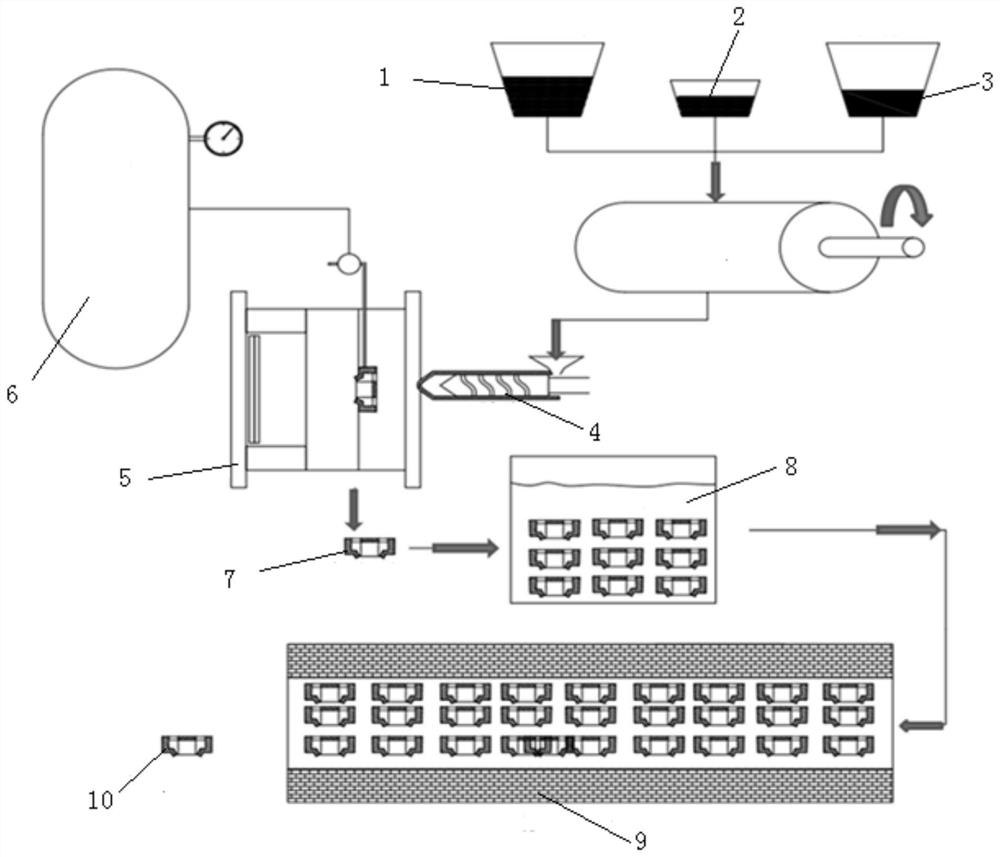

[0028] figure 1 It is a schematic flow chart of the manufacturing method of the high-strength blended chair rocking gear in the embodiment of the present invention.

[0029] See figure 1 , the manufacturing method of the high-strength blended chair rocking gear provided by the present invention comprises the following steps:

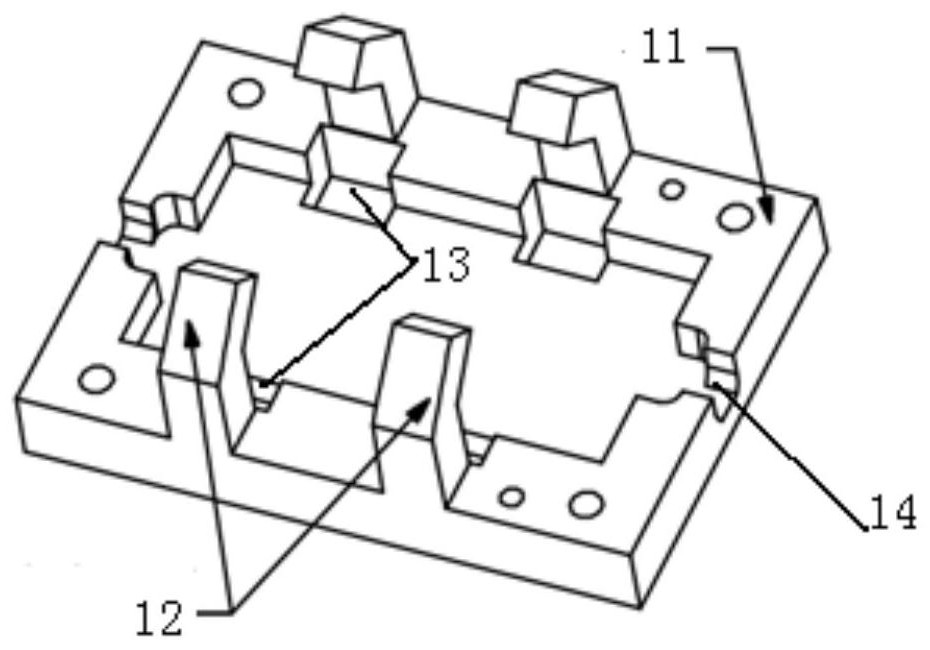

[0030] S1: Design a matching injection mold 5 according to the pre-designed structure of the gear member 10, and then process and manufacture the injection mold 5;

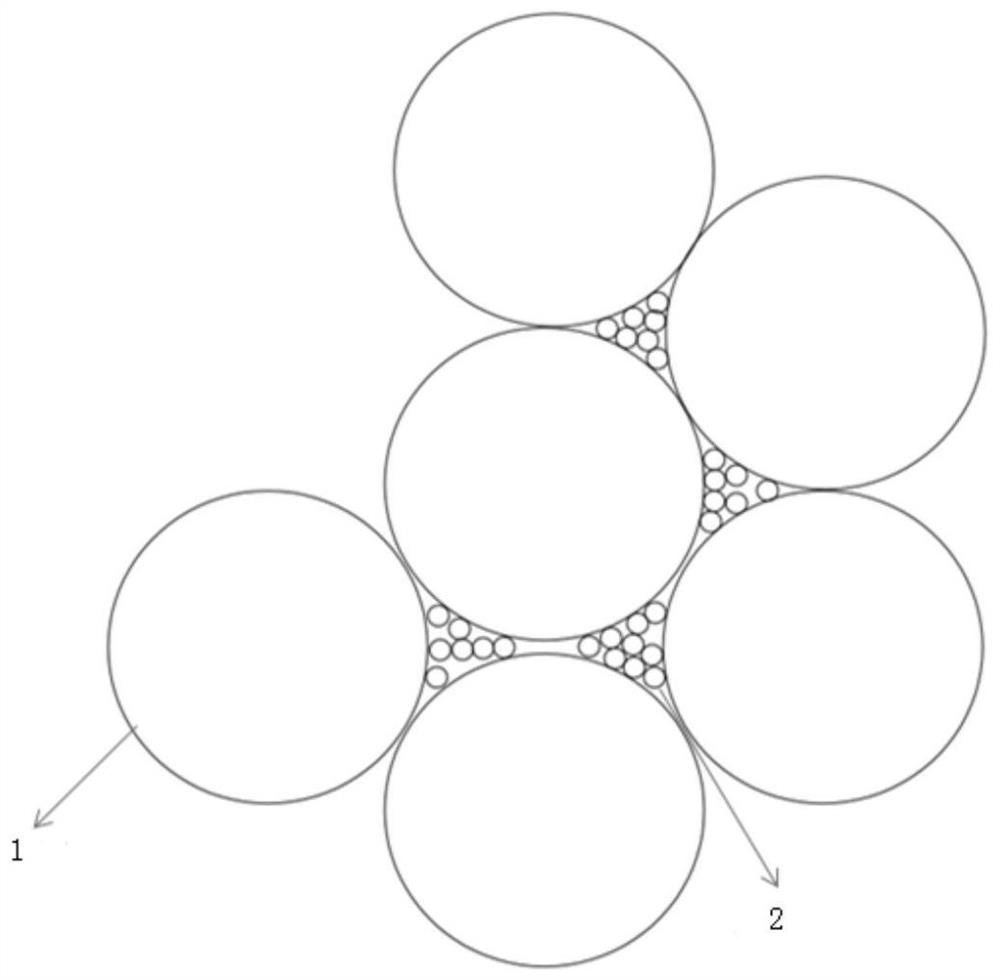

[0031] S2: Fully mix the metal powder and the binder 3, and then granulate;

[0032] S3: inject the mixture after granulation in step S2 into preform 7 by injection mold 5 in step S1;

[0033] S4: putting the preform 7 obtained in step S3 into the extraction solution 8, and removing the adhesive 3;

[0034] S5: Put the preform 7 from which the binder 3 has been r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com