Patents

Literature

30results about How to "Reduce the Mach number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

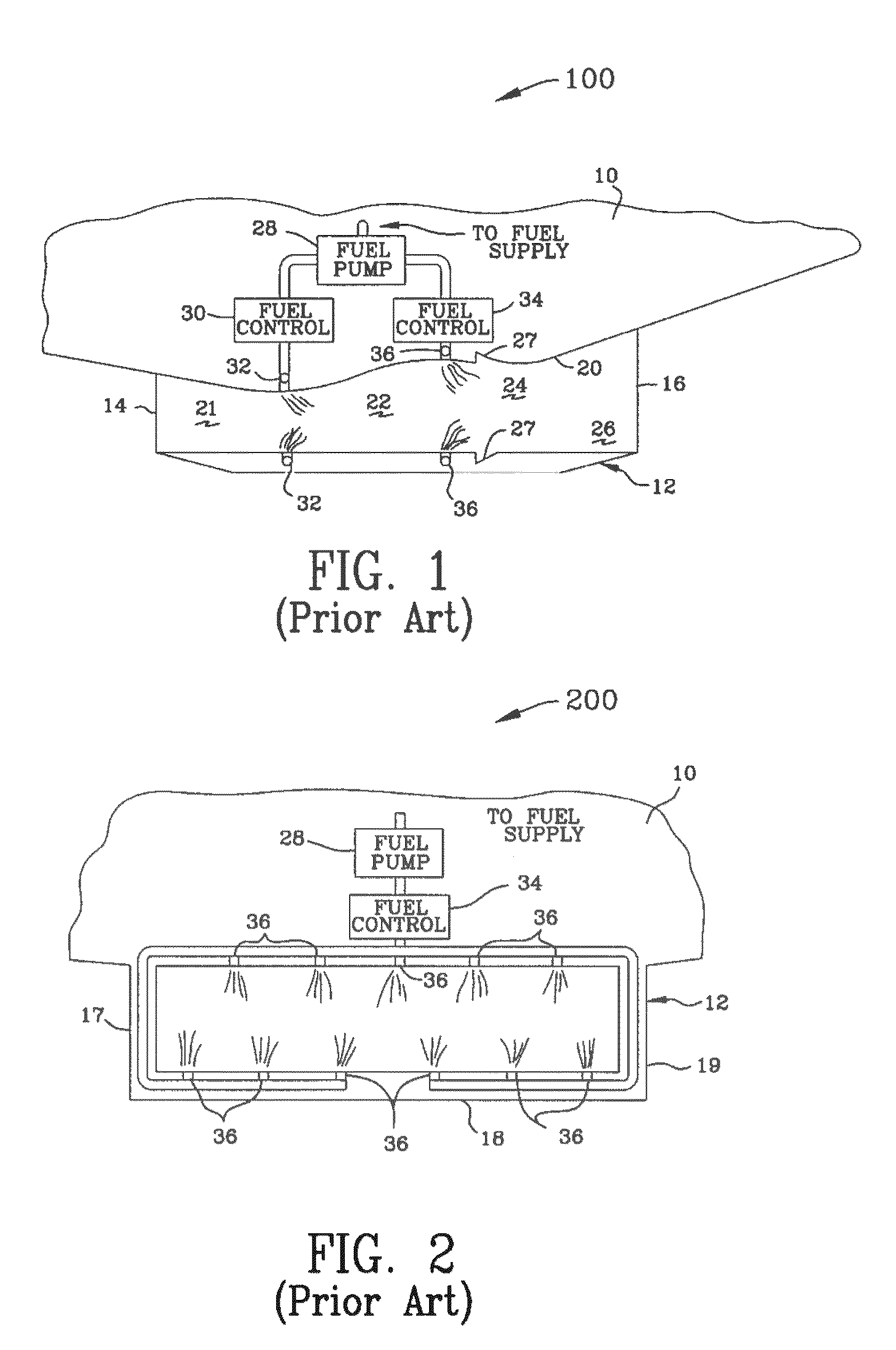

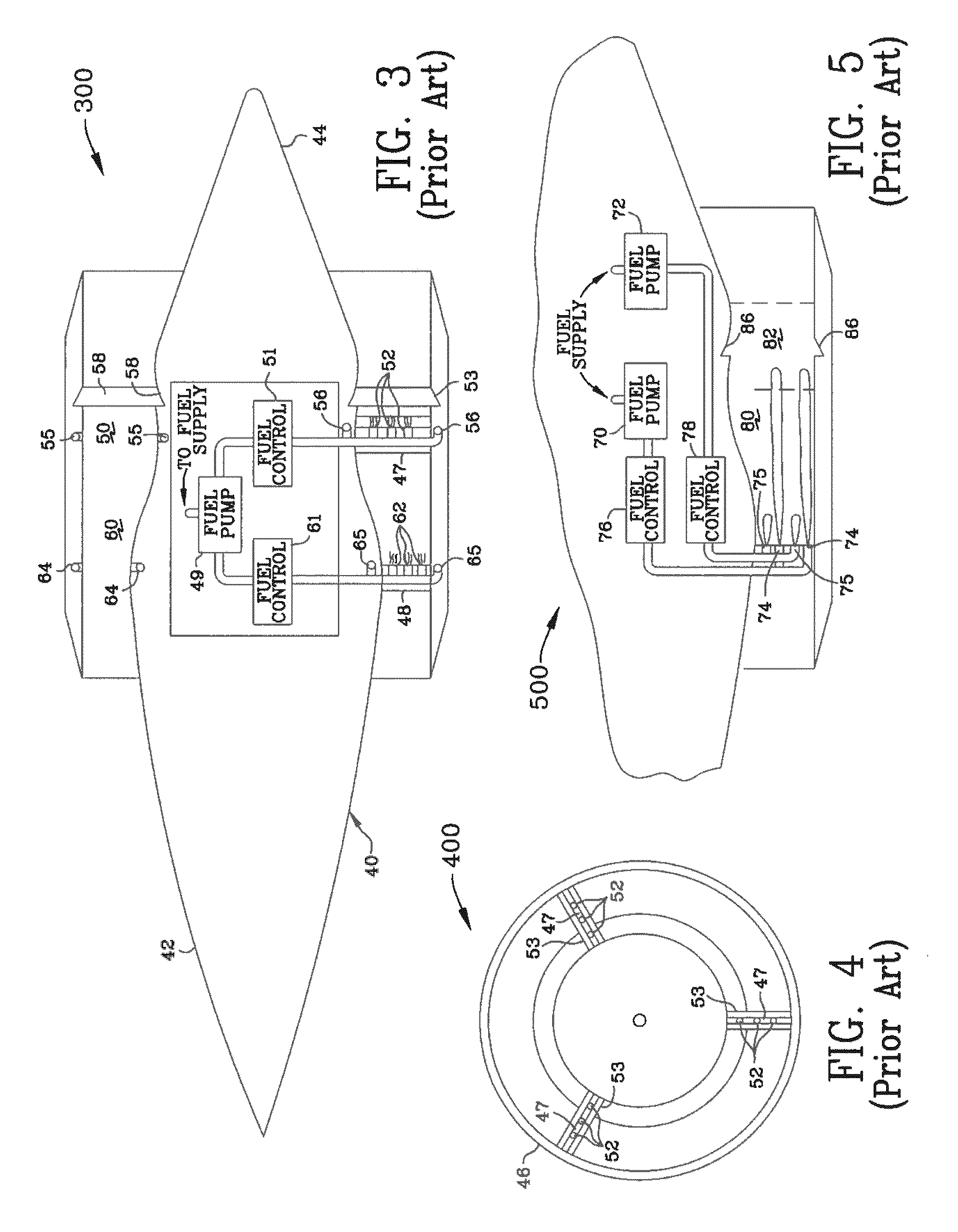

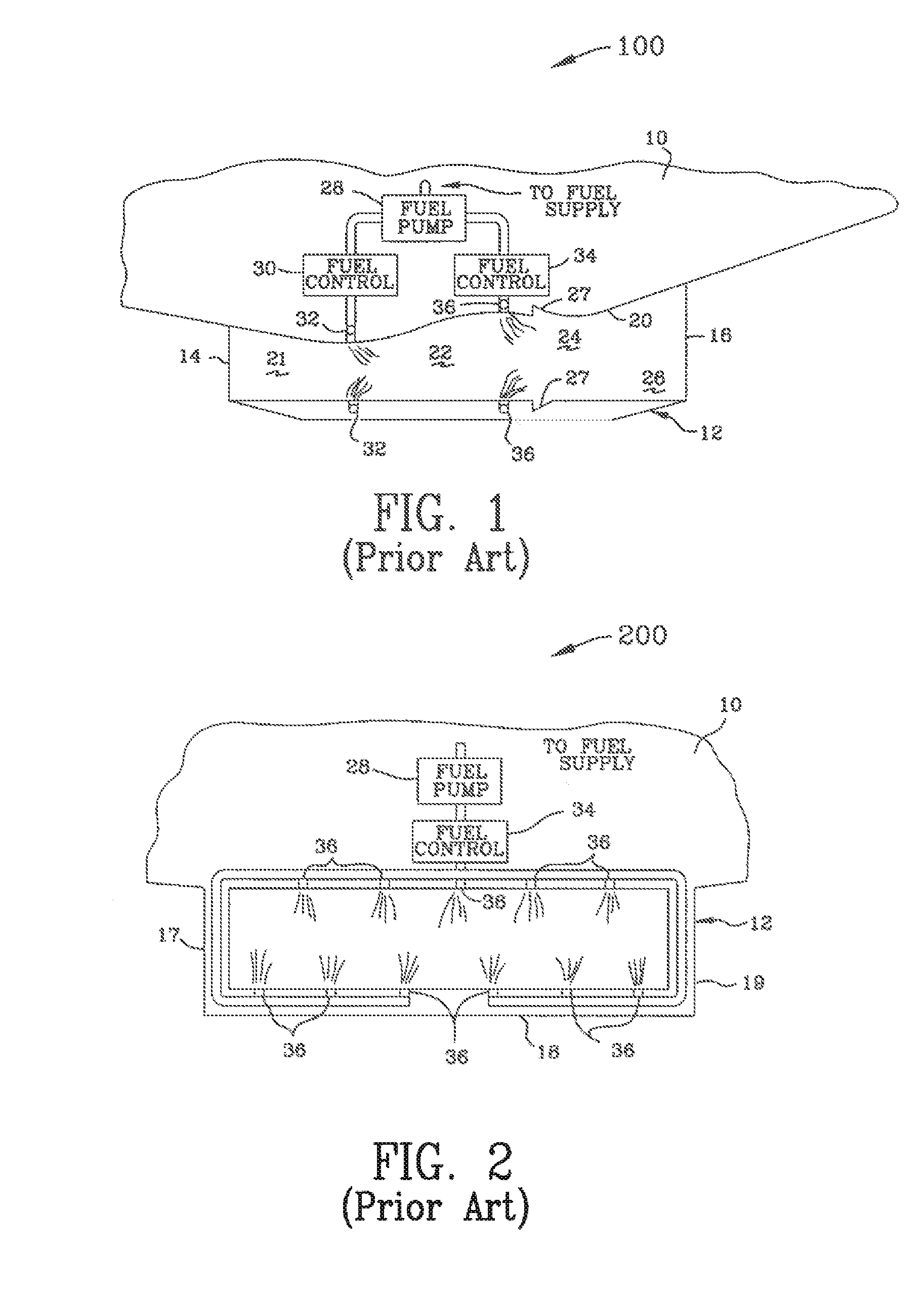

Low cost wind tunnel for supersonic and hypersonic aerothermal testing

The invention disclosed herein provides a subsonic wind tunnel capable for accurately maintaining a desired Mach number, pressure and temperature for use in aerothermal testing of materials. The invention allows the Mach number to be precisely controlled in the test section of the wind tunnel by employing a restricted outlet acting as a sonic throat for the wind tunnel. In the preferred embodiment, the restricted outlet is constructed to be variable in cross sectional area allowing a range of Mach numbers to be tested. The variable outlet is varied during the operation of the wind tunnel so that an actual trajectory with changing Mach numbers, pressure, and temperature is simulated.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

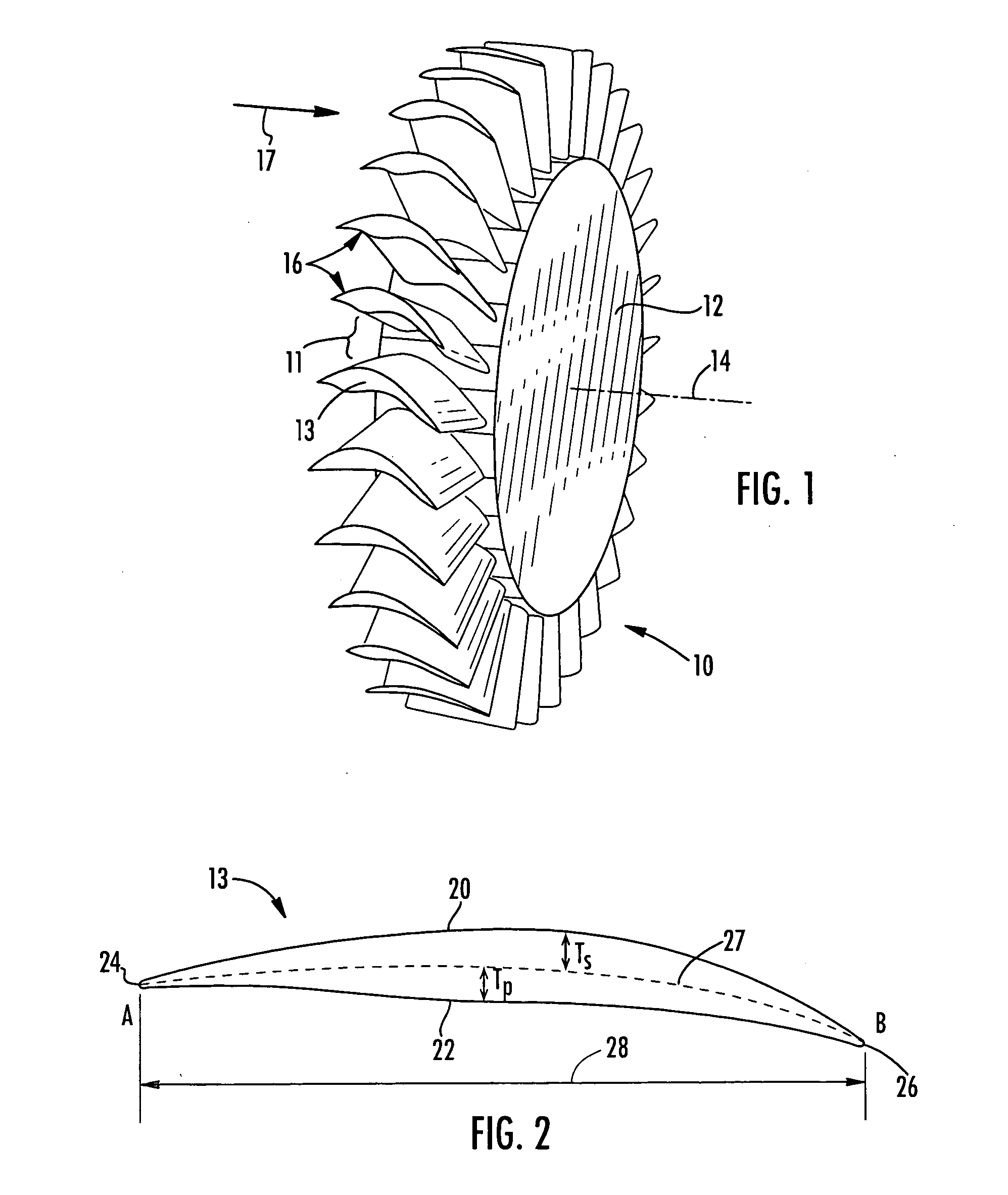

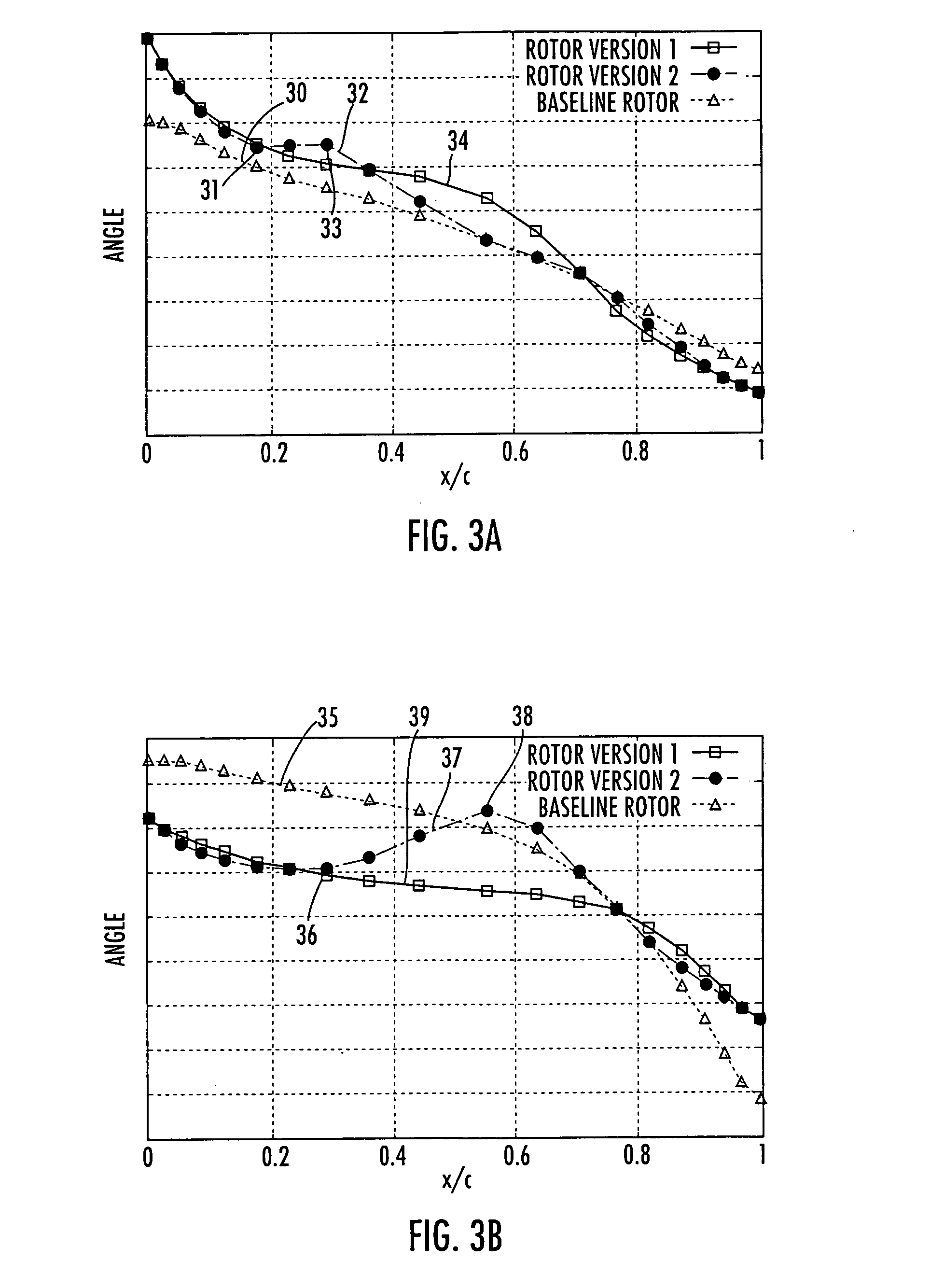

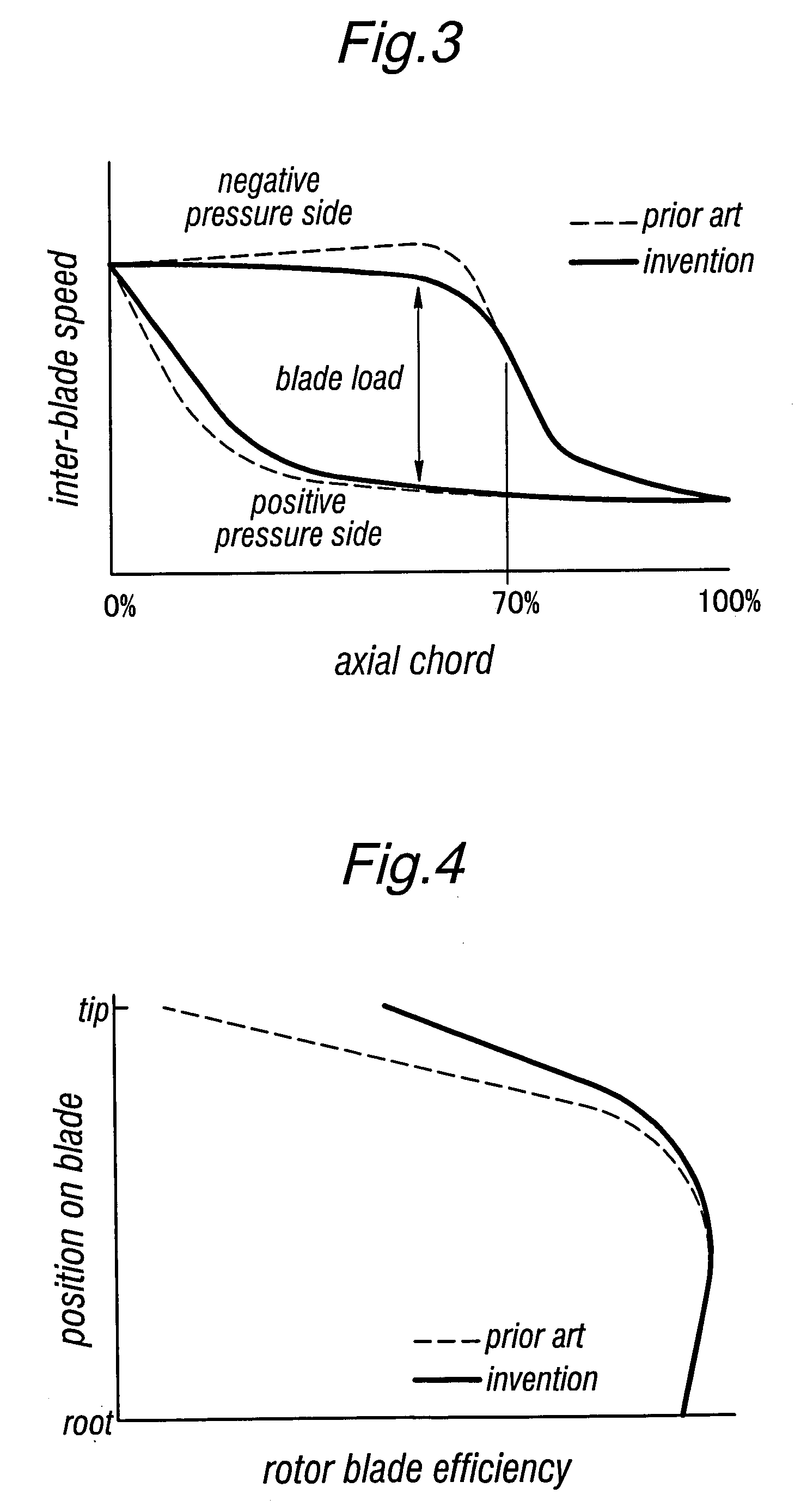

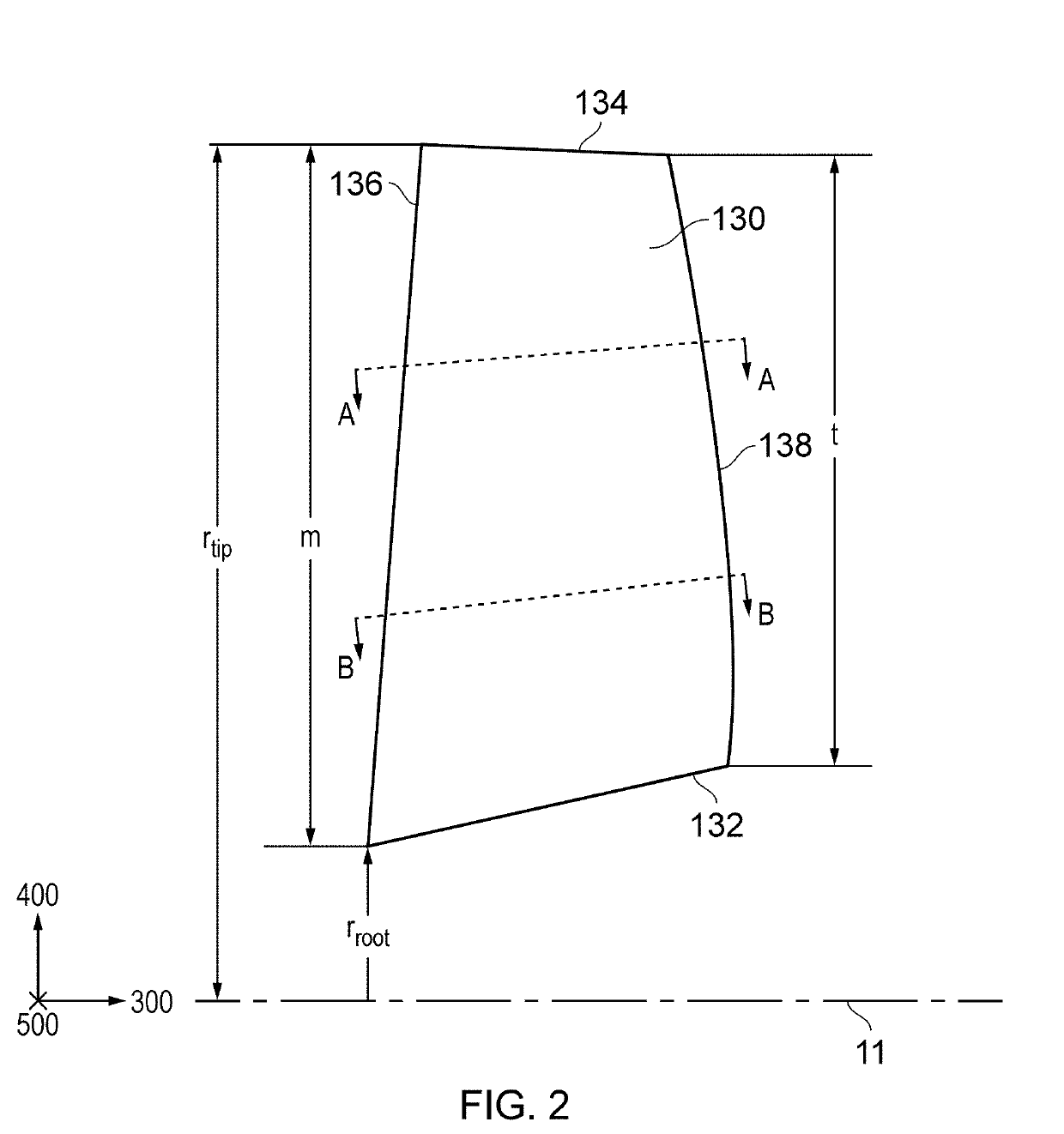

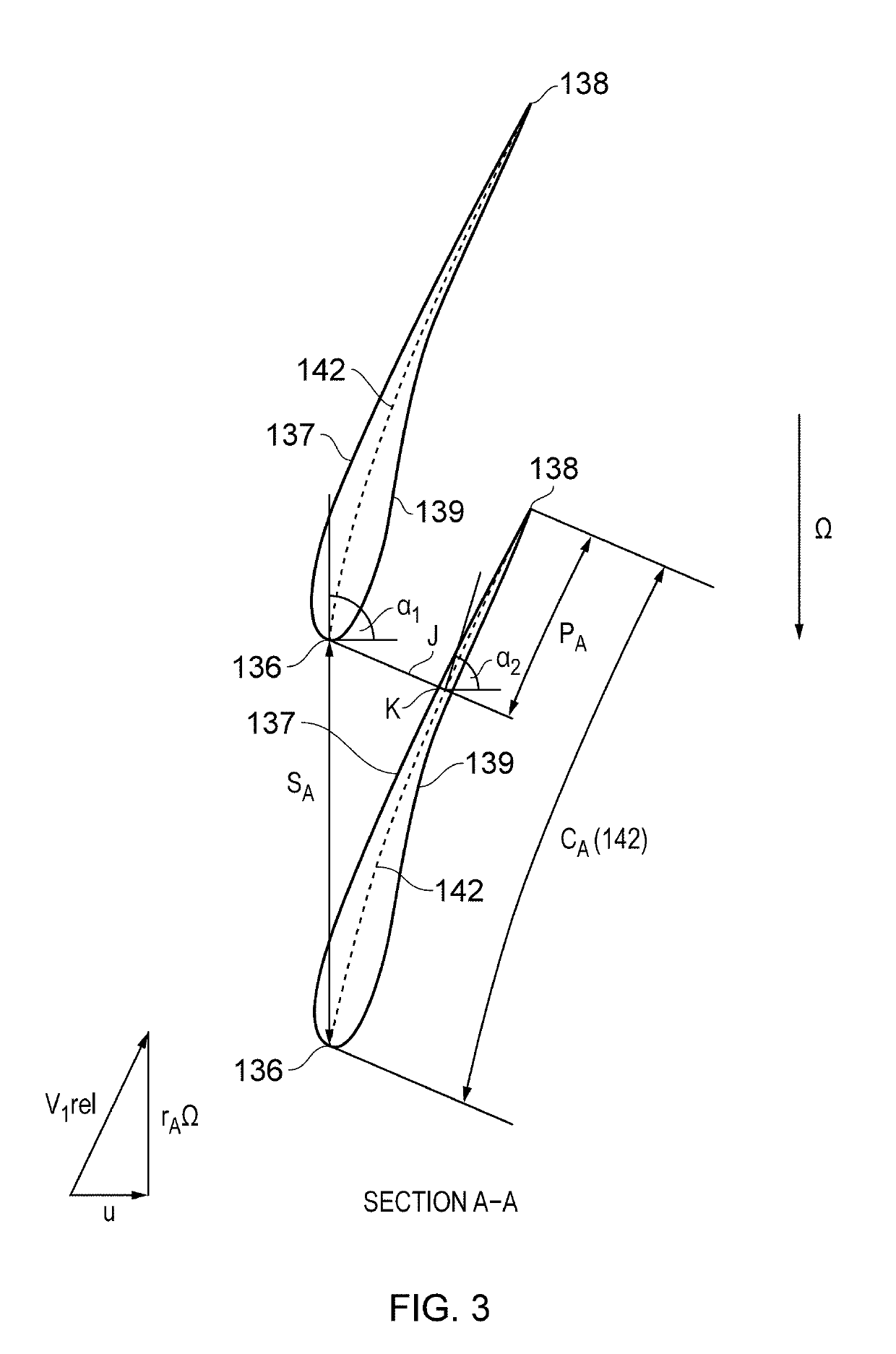

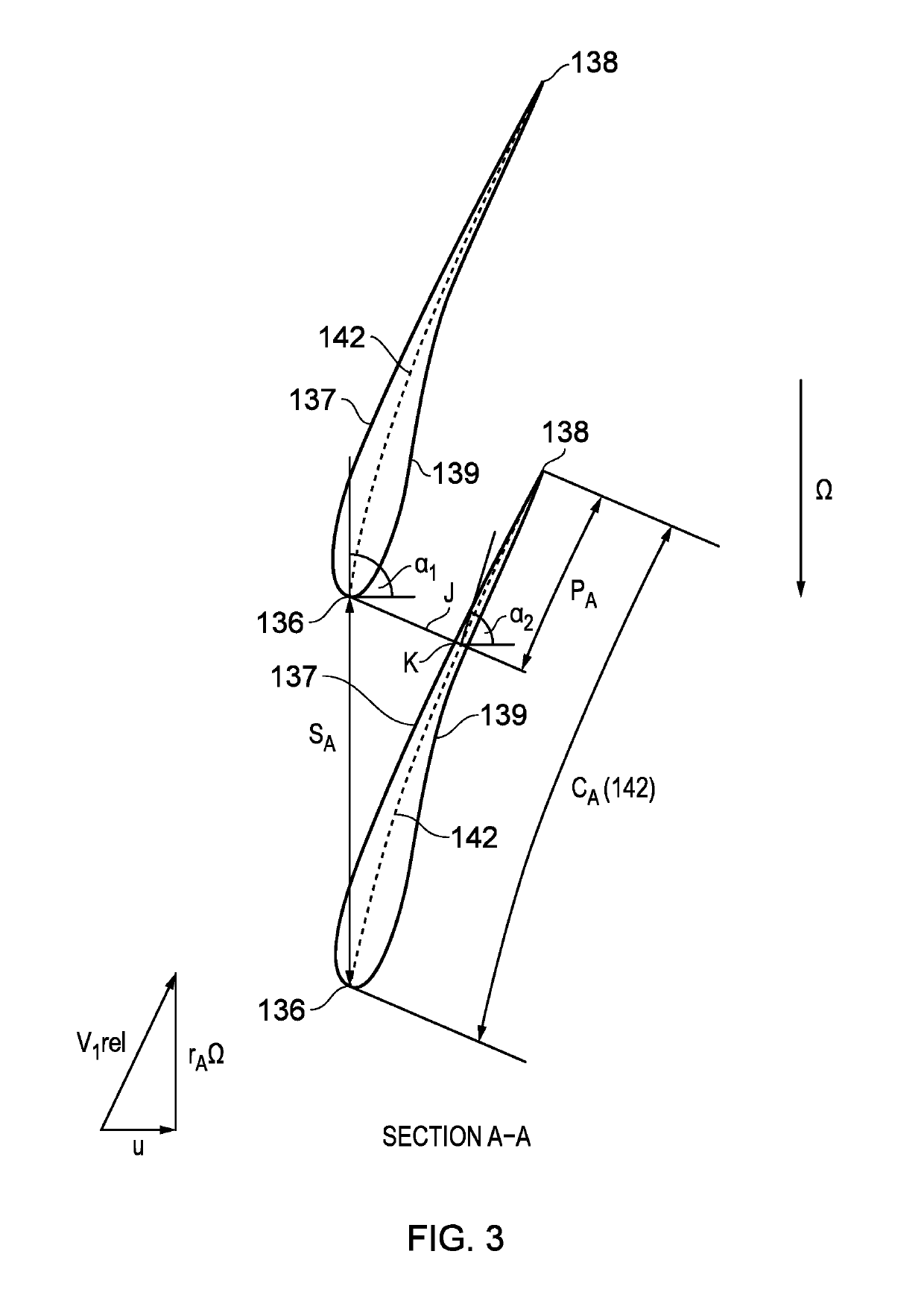

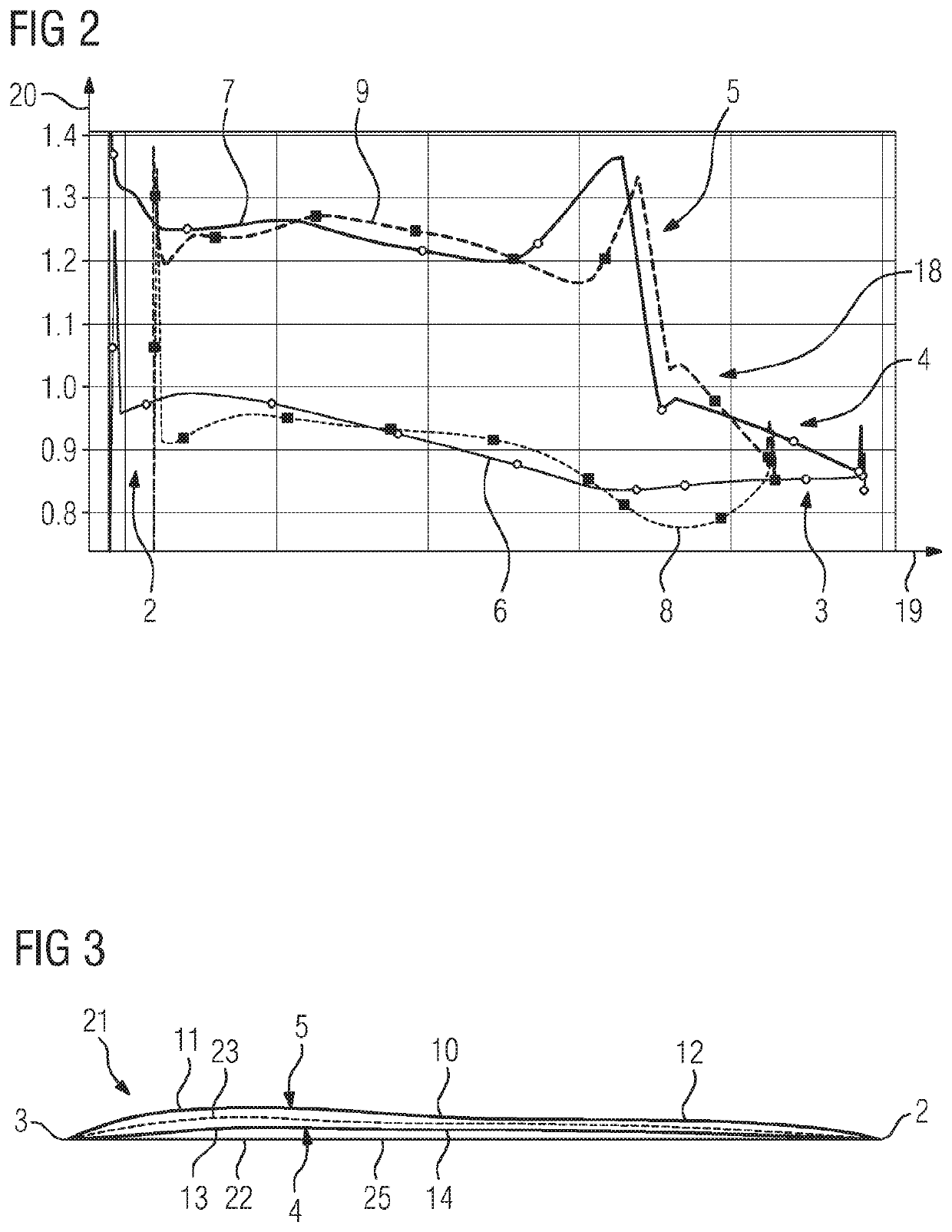

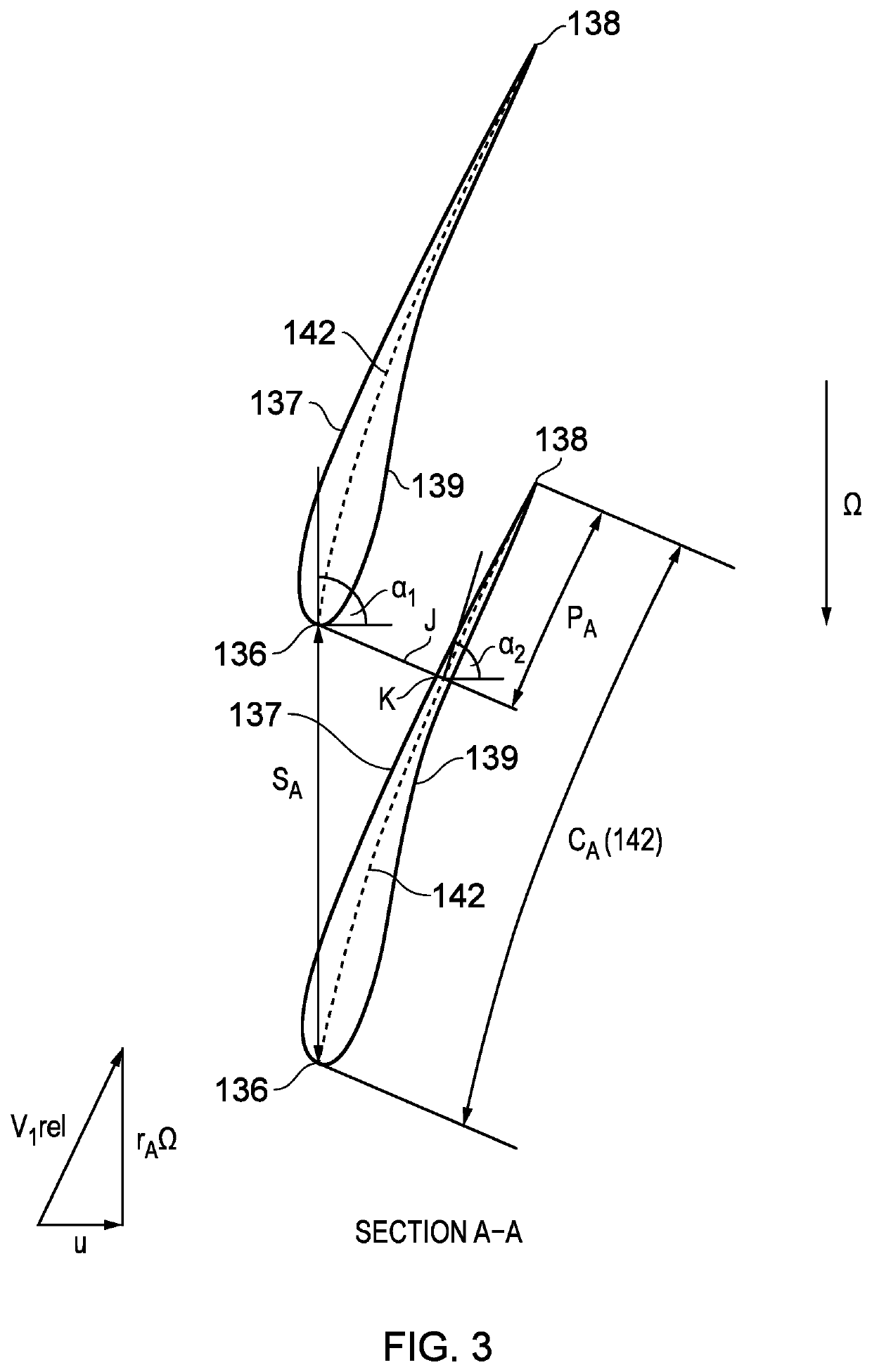

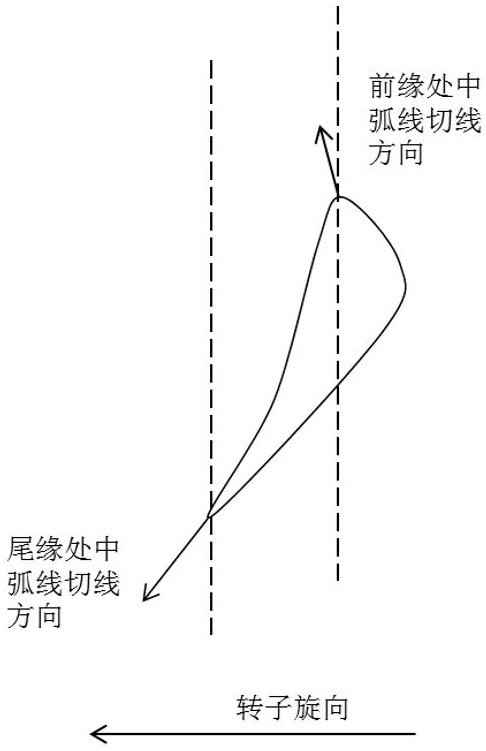

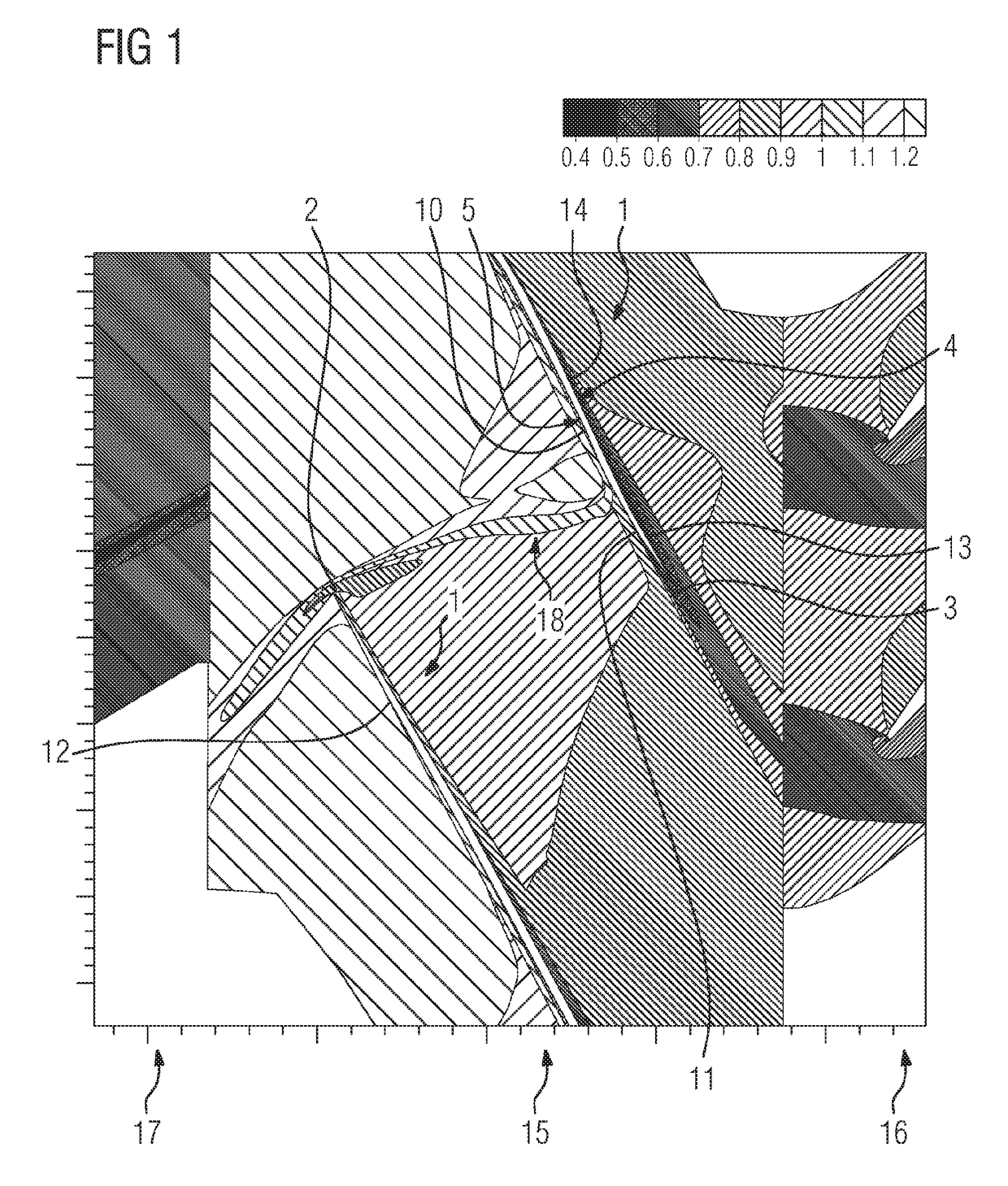

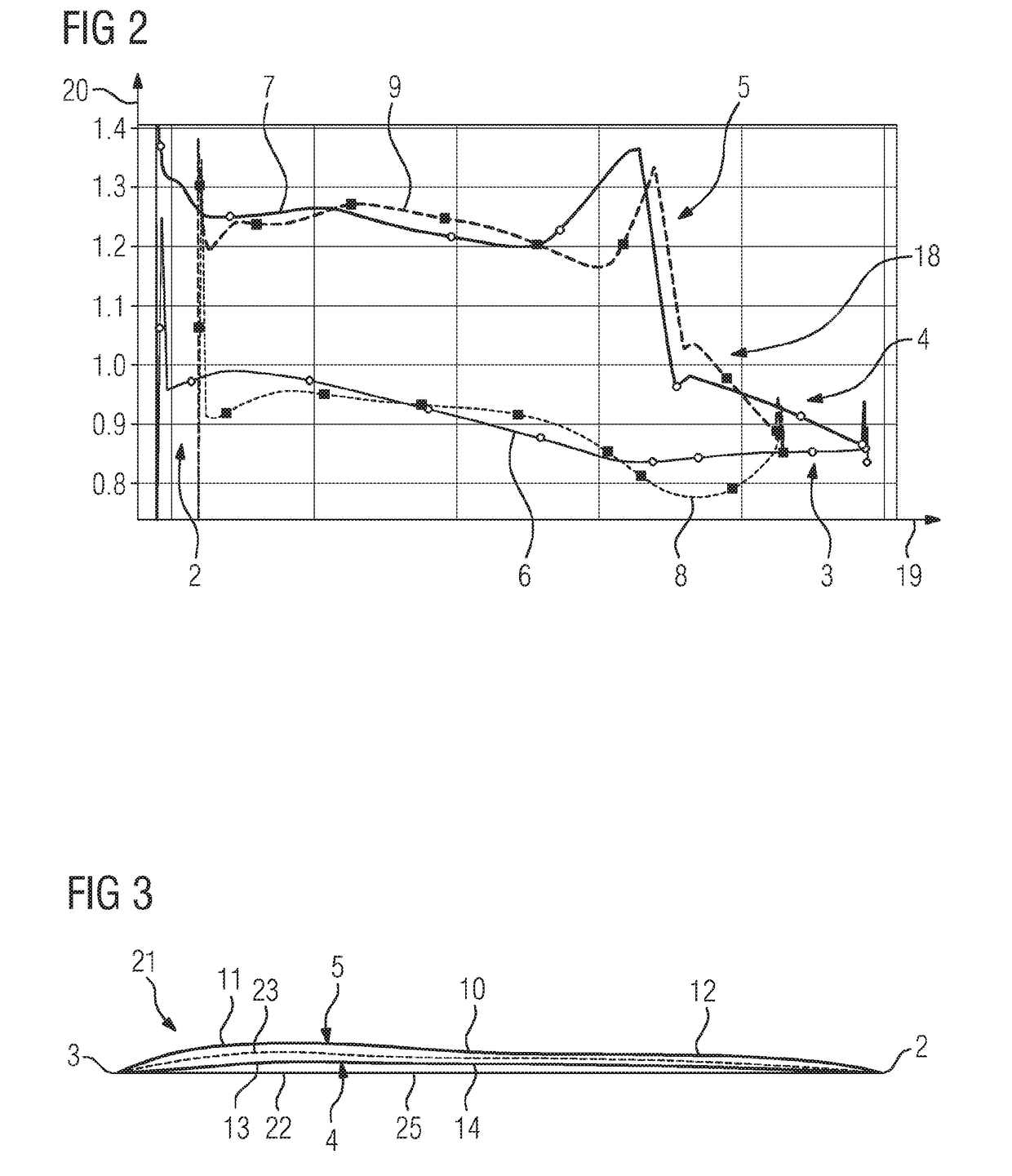

Transonic compressor rotors with non-monotonic meanline angle distributions

InactiveUS20080118362A1Improve efficiencySimple designSupersonic fluid pumpsPump componentsShock waveLeading edge

Airfoils are provided having non-monotonic meanline angle distributions and local negative camber along a length of the meanline between a point on a leading edge of the airfoil and a point on the trailing edge of the airfoil. The improved airfoil shape decreases the peak of a Mach number of a shock wave that develops in a passage between adjacent airfoils and attenuates or eliminates the shock wave at the suction surface of the airfoil within the passage. A blade constructed by this type of airfoil provides improved fluid flow in the passages between the airfoils, increased efficiency and an improved stall margin, among other benefits.

Owner:SIEMENS ENERGY INC

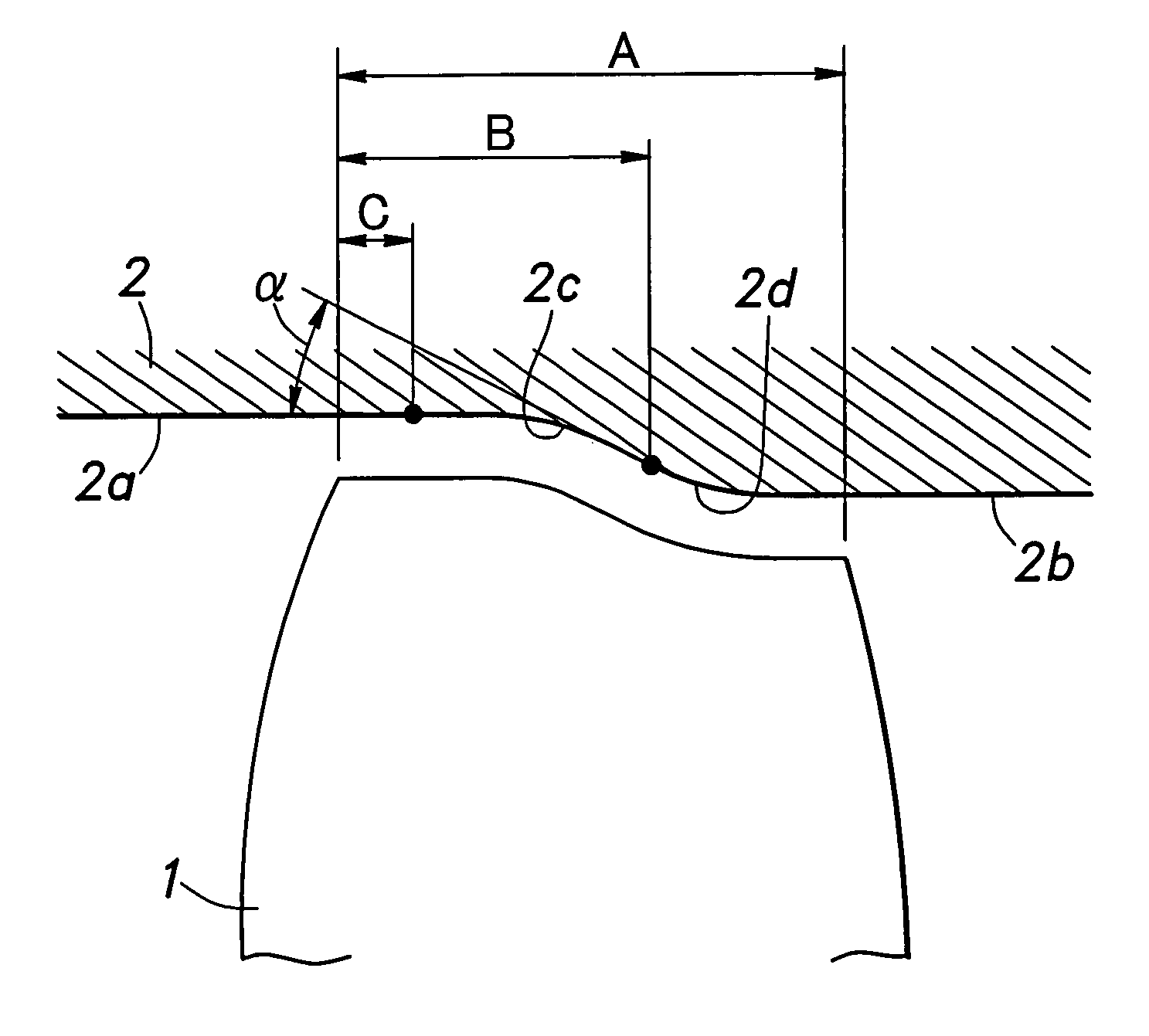

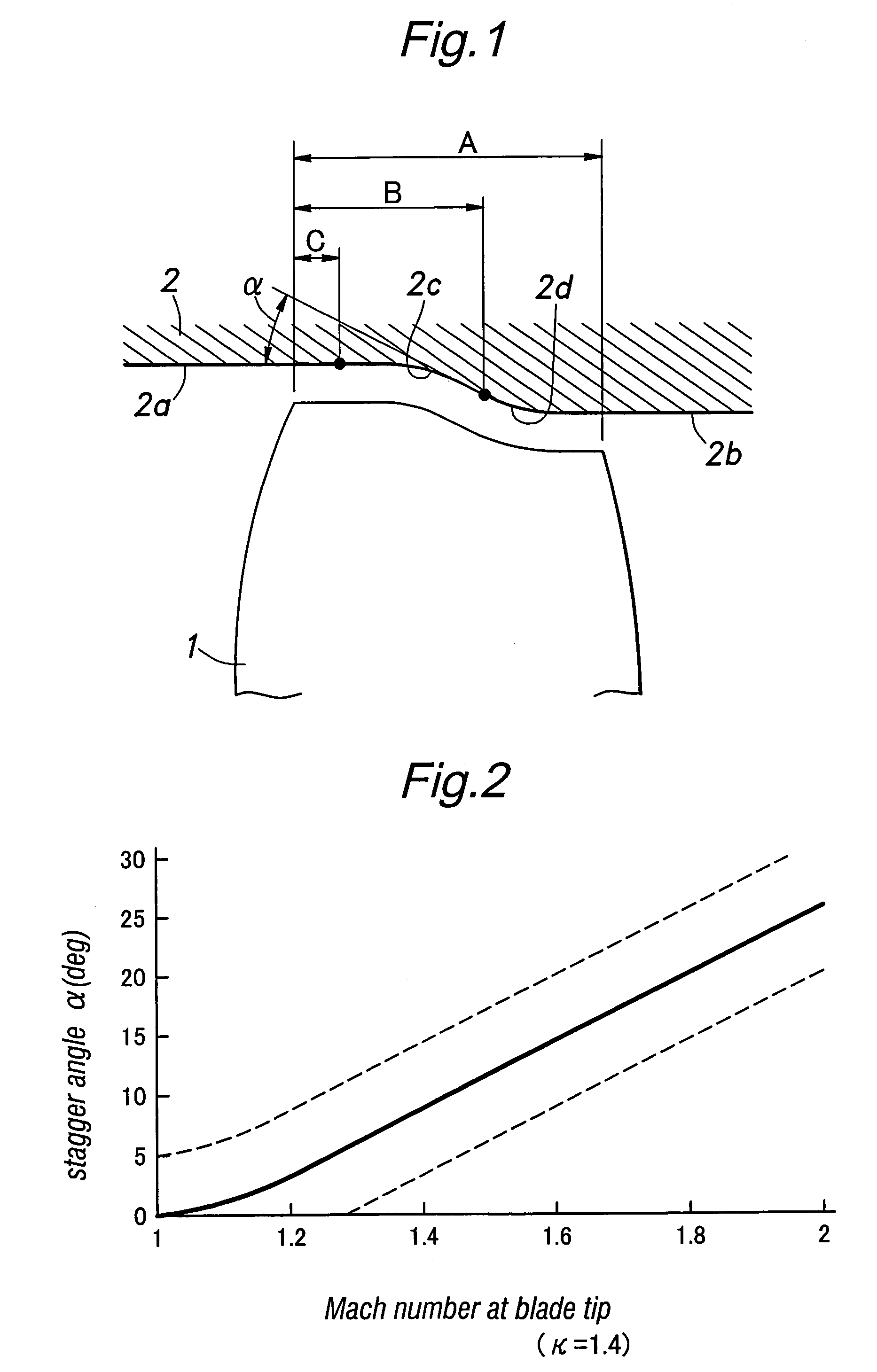

Axial flow compressor

InactiveUS7004722B2Improve efficiencyWide operatingSupersonic fluid pumpsPump componentsAxial compressorEngineering

At least part of the inner circumferential wall of the outer casing is provided with a concave surface opposing the rotor blade tips as seen in a longitudinal section. Typically, each of the rotor blades is provided with aerofoil section, and the compressor is designed as a transonic axial flow compressor. Thereby, a compressive wave is produced upstream of the shockwave so that the Mach number of the flow entering the shockwave can be reduced. As a result, the shockwave is made less severe, and the shockwave loss can be reduced. In particular, because the concave surface is provided in the casing wall as opposed to the case where the concave surface is provided in the negative pressure side of the rotor blade, the reduction in the performance owing to the change in the angle of the airflow entering the passage defined by the concave surface under a partial load condition can be avoided.

Owner:HONDA MOTOR CO LTD

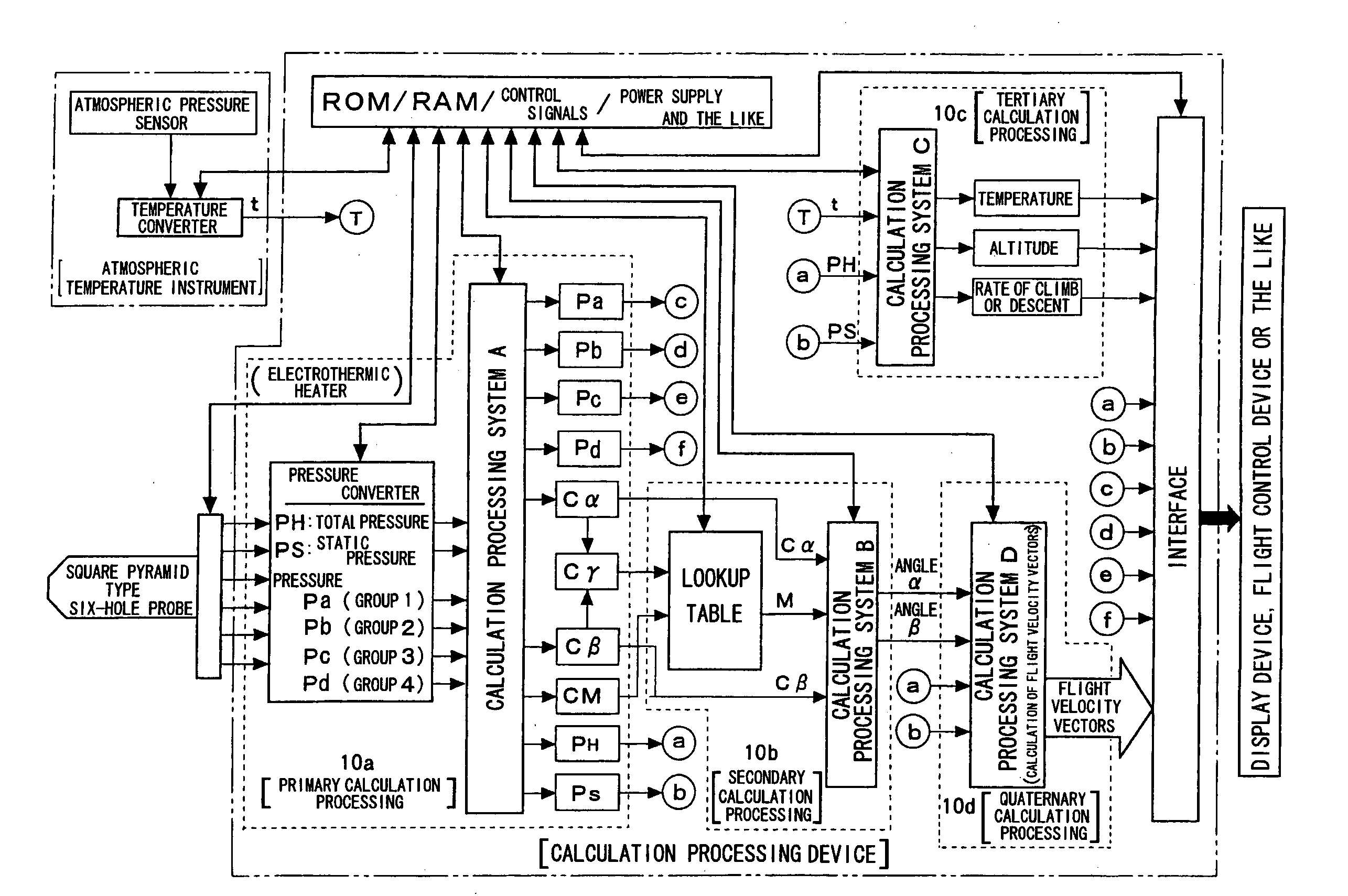

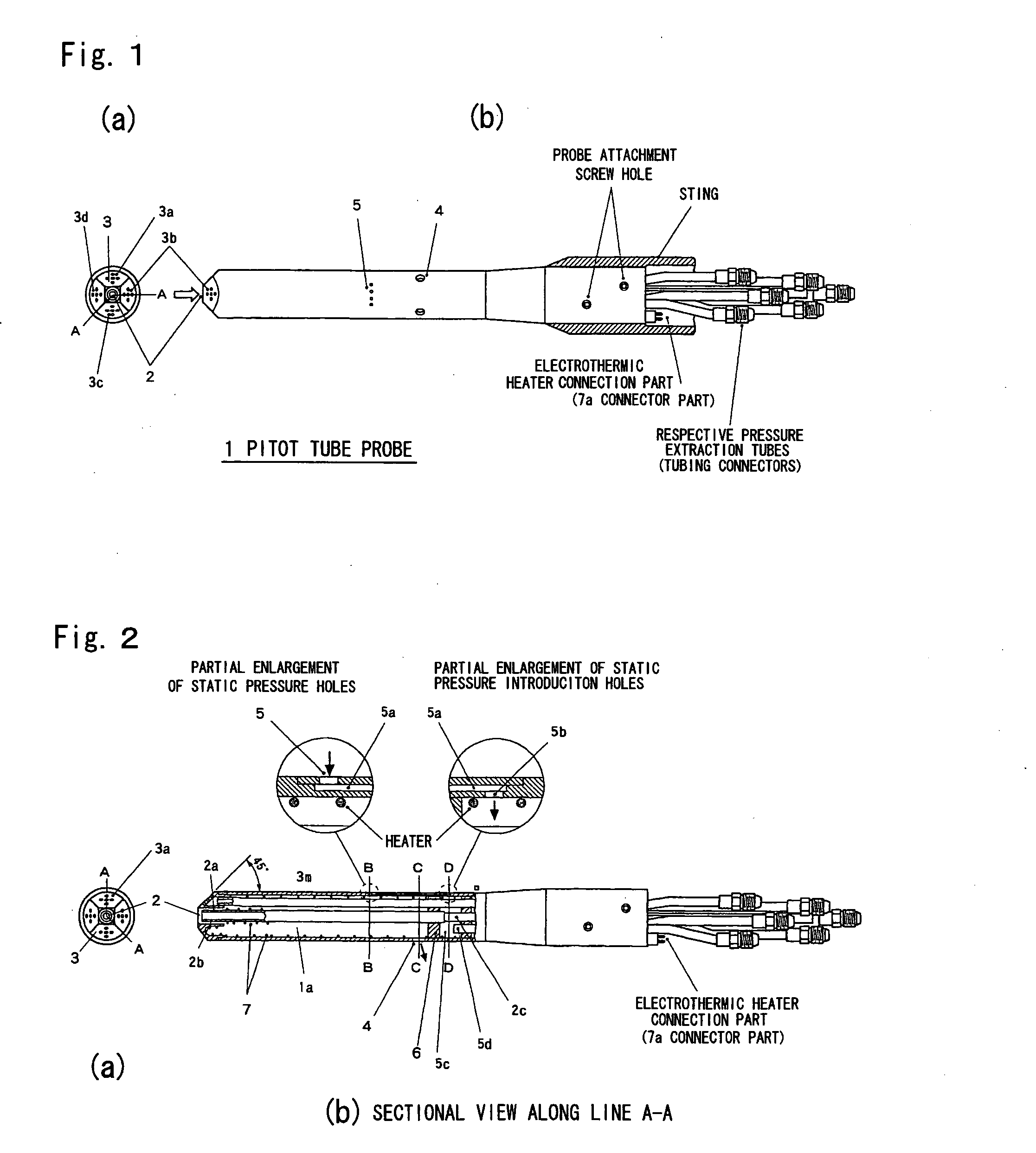

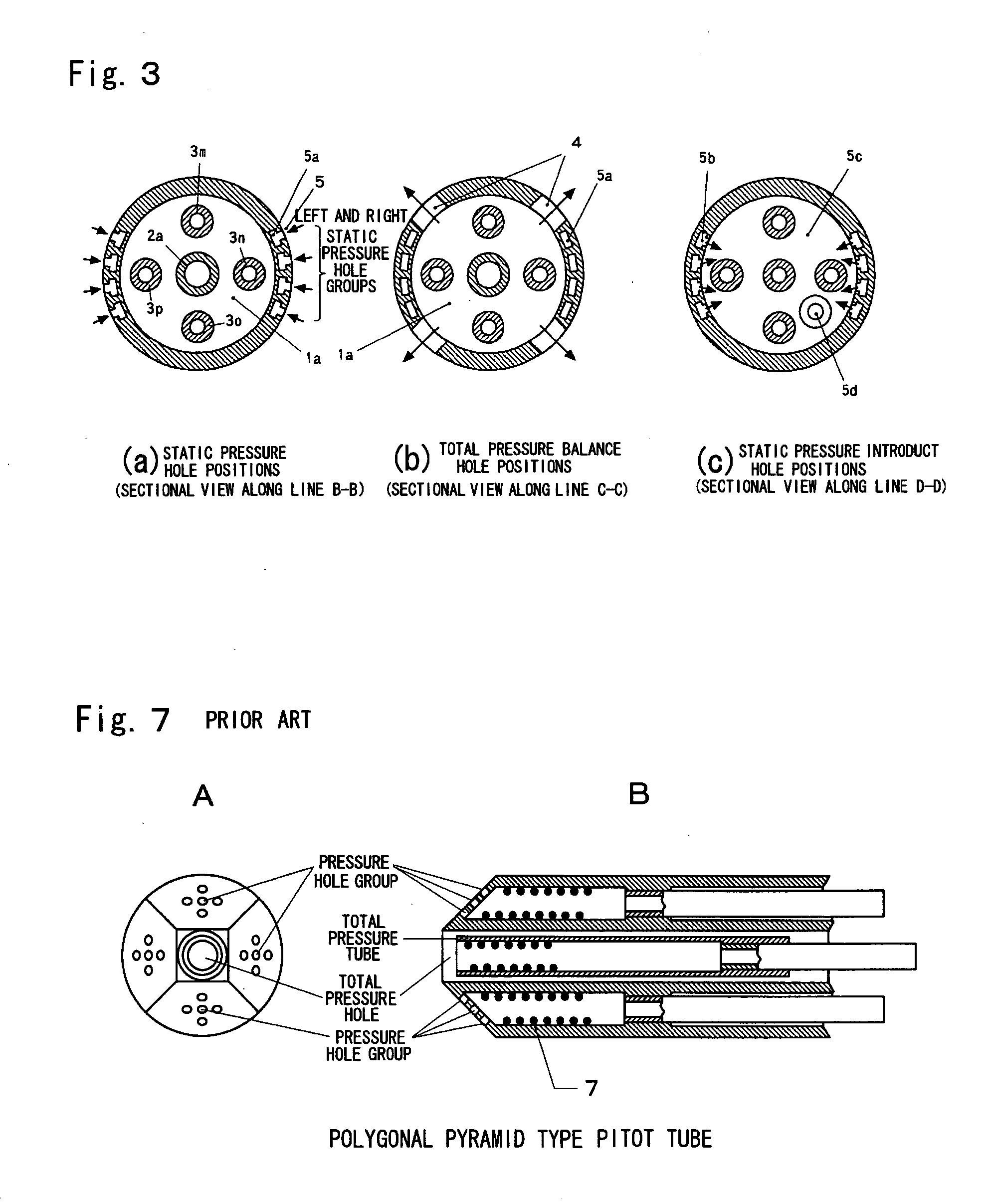

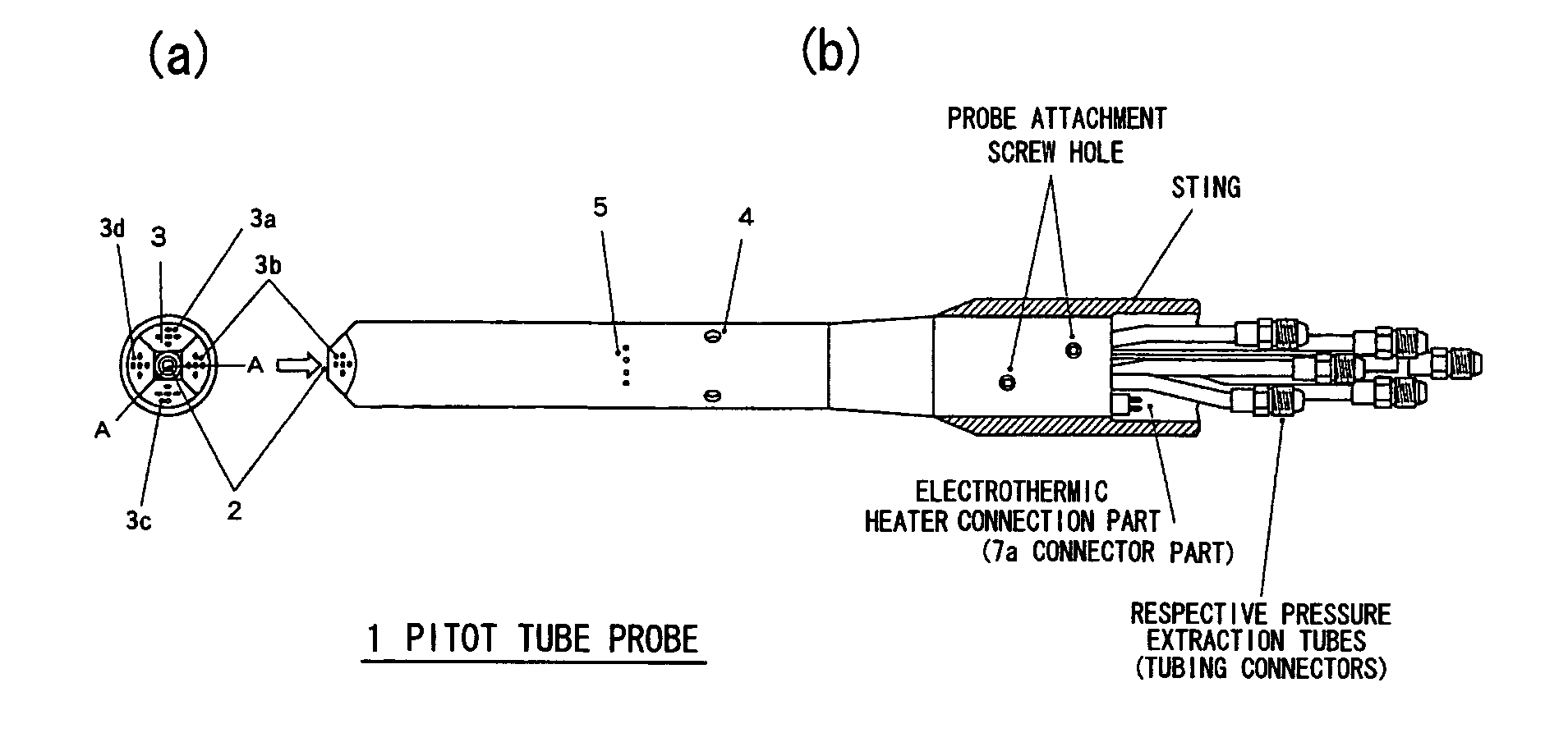

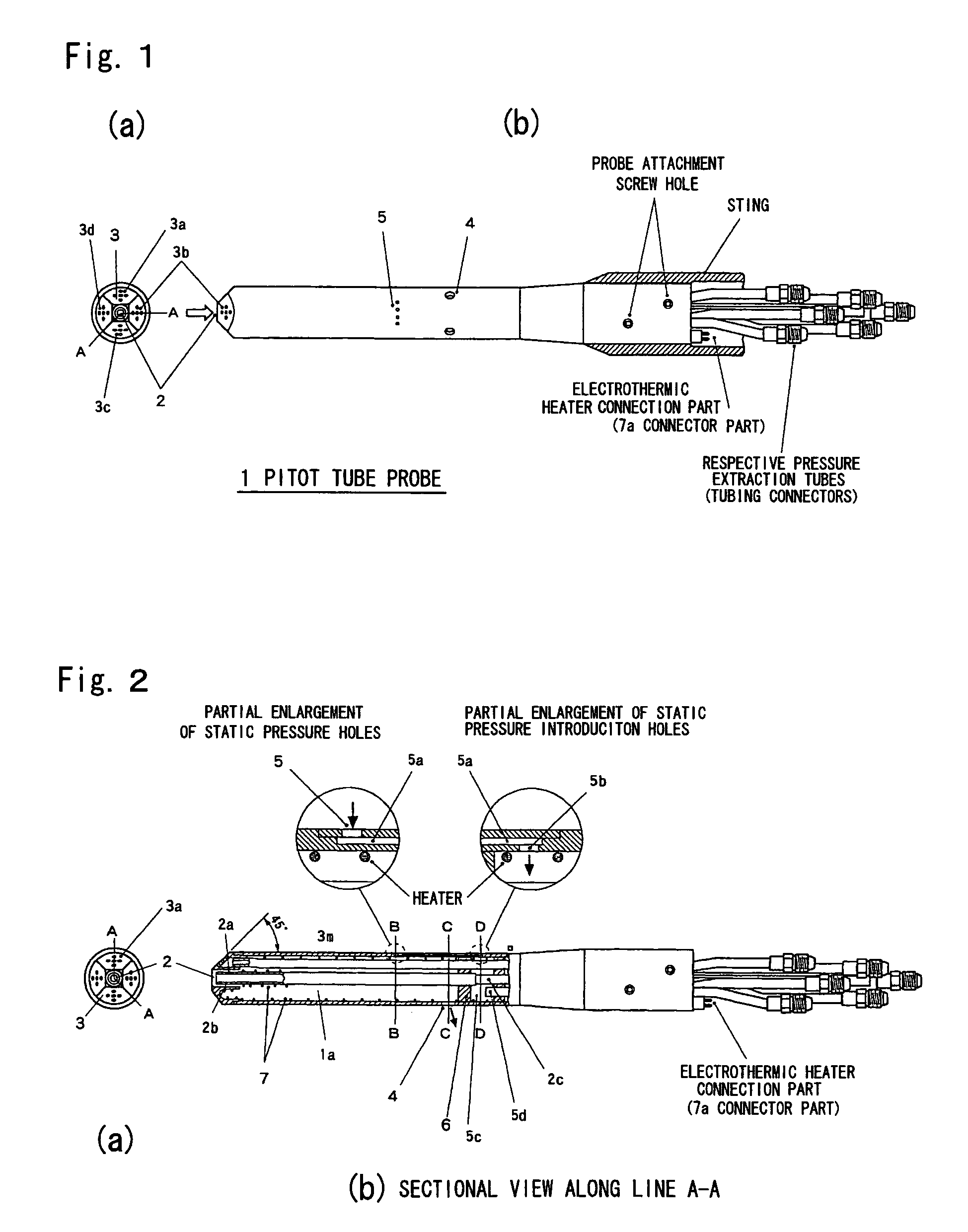

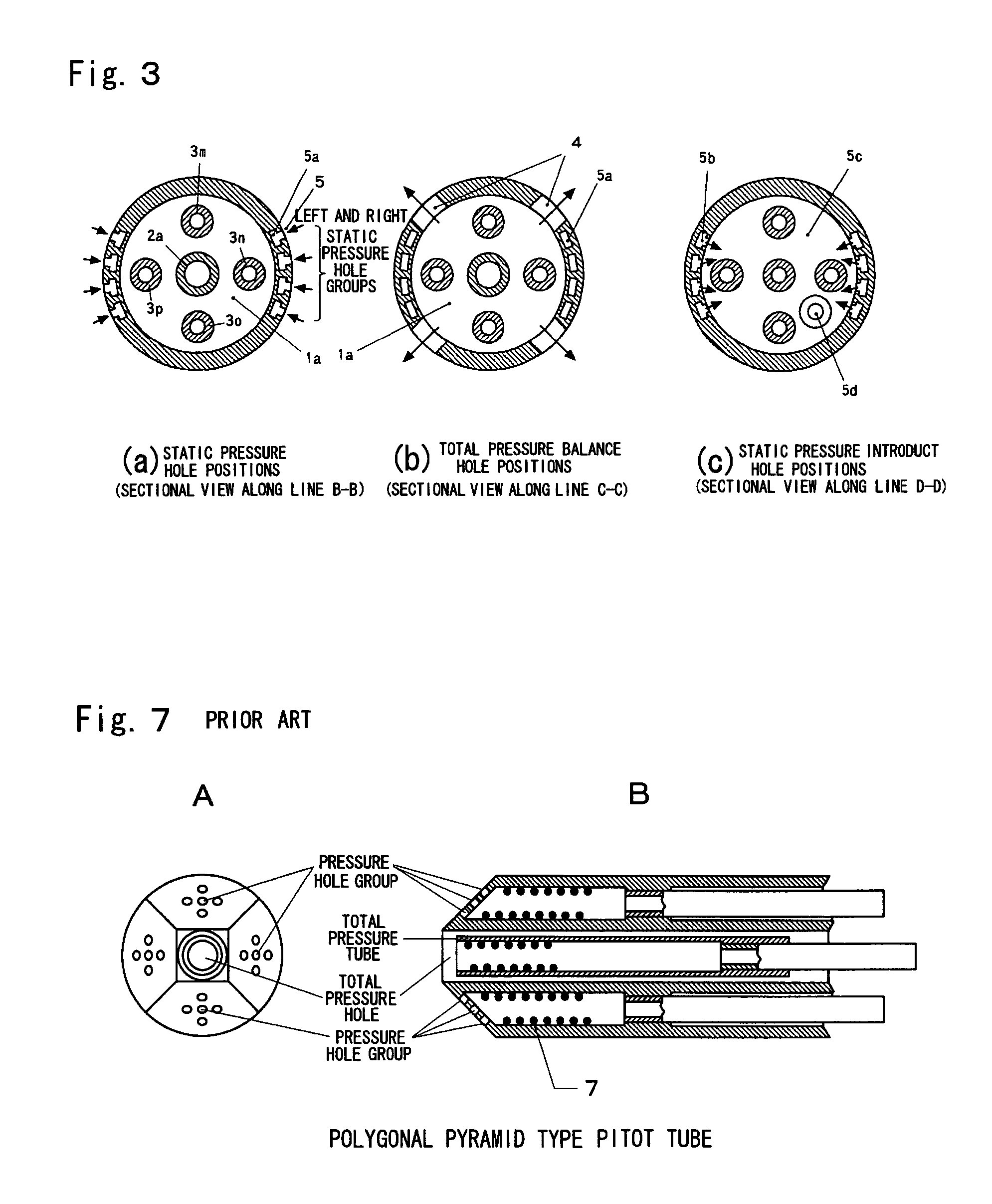

High-altitude capable wide velocity range flight velocity vector measurement probe and measurement system

InactiveUS20060178790A1Erroneous detectionPrevent fallingDigital data processing detailsFluid speed measurement using pressure differenceAnomaly detectionFlight velocity

It is an object of the present invention to solve the problem of a drop in precision in conventional systems using a square pyramid type five-hole probe due to the drop in atmospheric pressure in high altitude ranges, and to provide a wide velocity range flight velocity vector measurement system that can prevent a drop in measurement precision. Furthermore, it is also an object of the present invention to provide a method for eliminating the effects of detection fluctuations caused by adhering water droplets, ice particles or dust in a wide velocity range flight velocity vector measurement system. The flight velocity vector measurement probe of the present invention comprises means in which a static pressure hole is formed in the tube wall surface of the probe, so that a static pressure value is obtained from the pressure detected by this static pressure hole, the Mach number M is calculated on the basis of an equation approximated by a fourth-order polynomial of the static pressure / total pressure signal and the angle of attack, and in cases where an abnormal detection value is detected, this is replaced by the preceding detection value.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

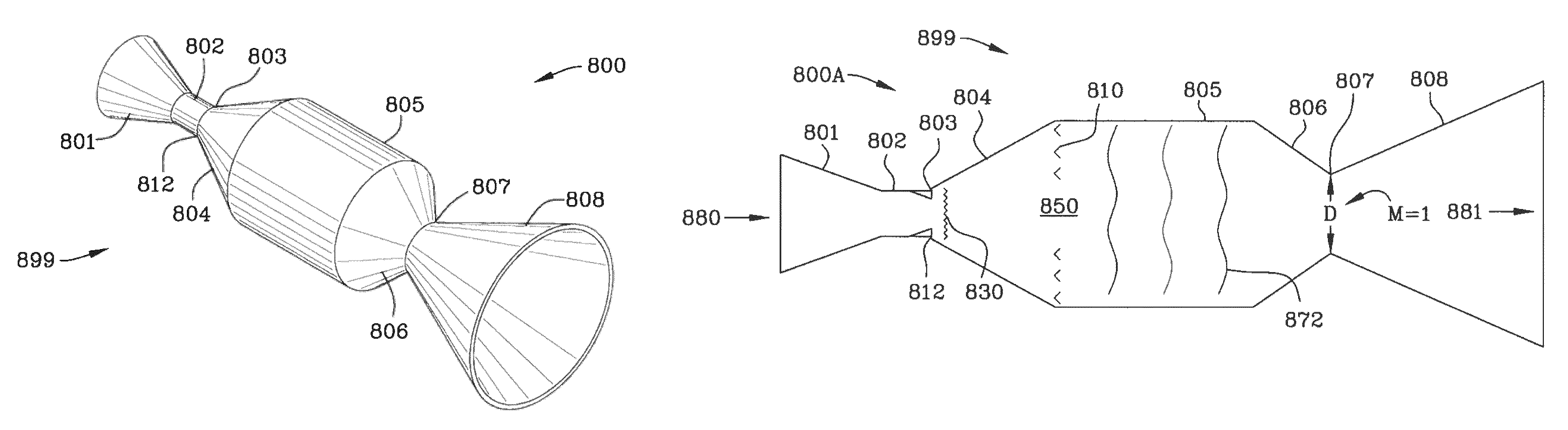

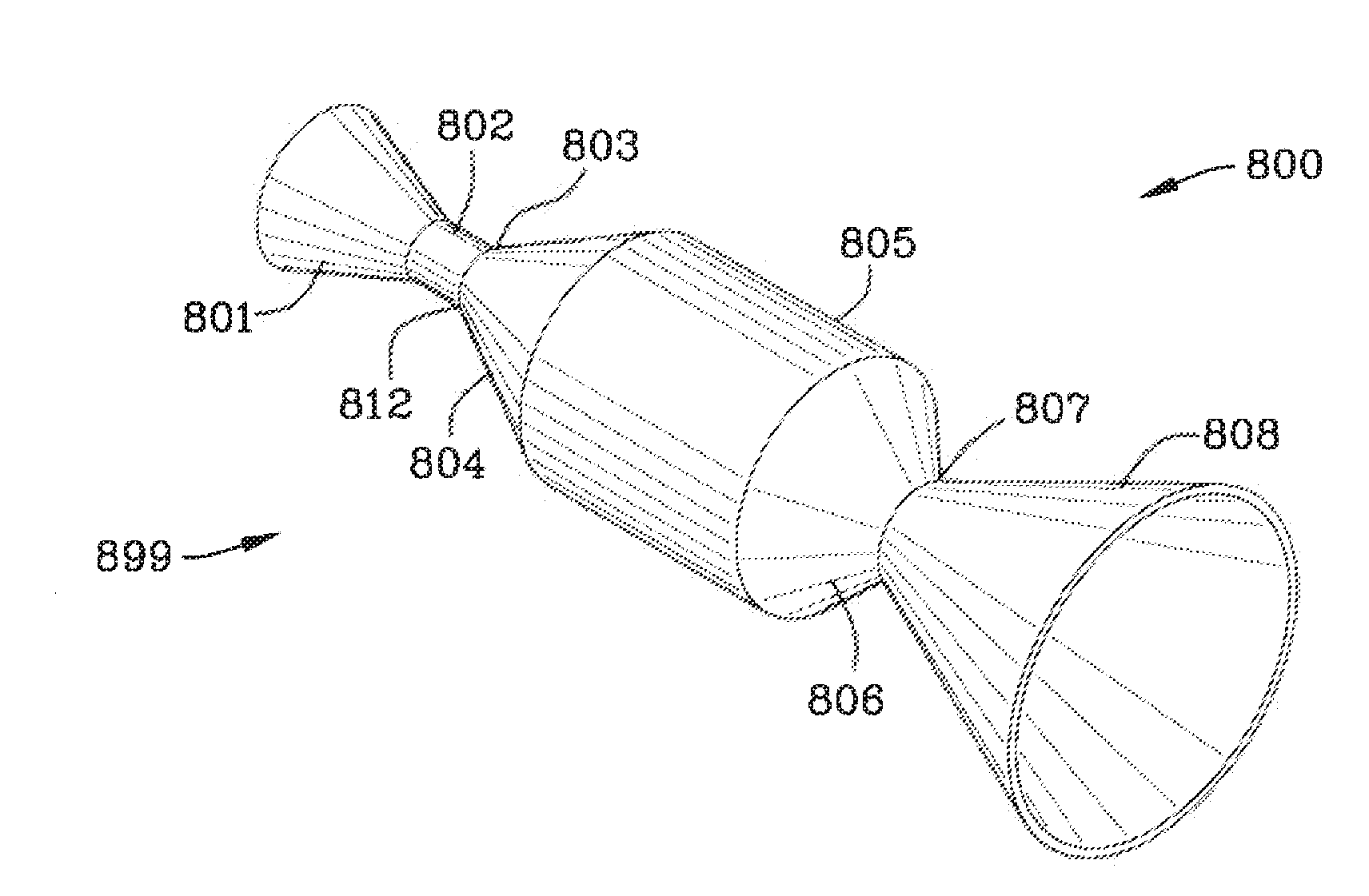

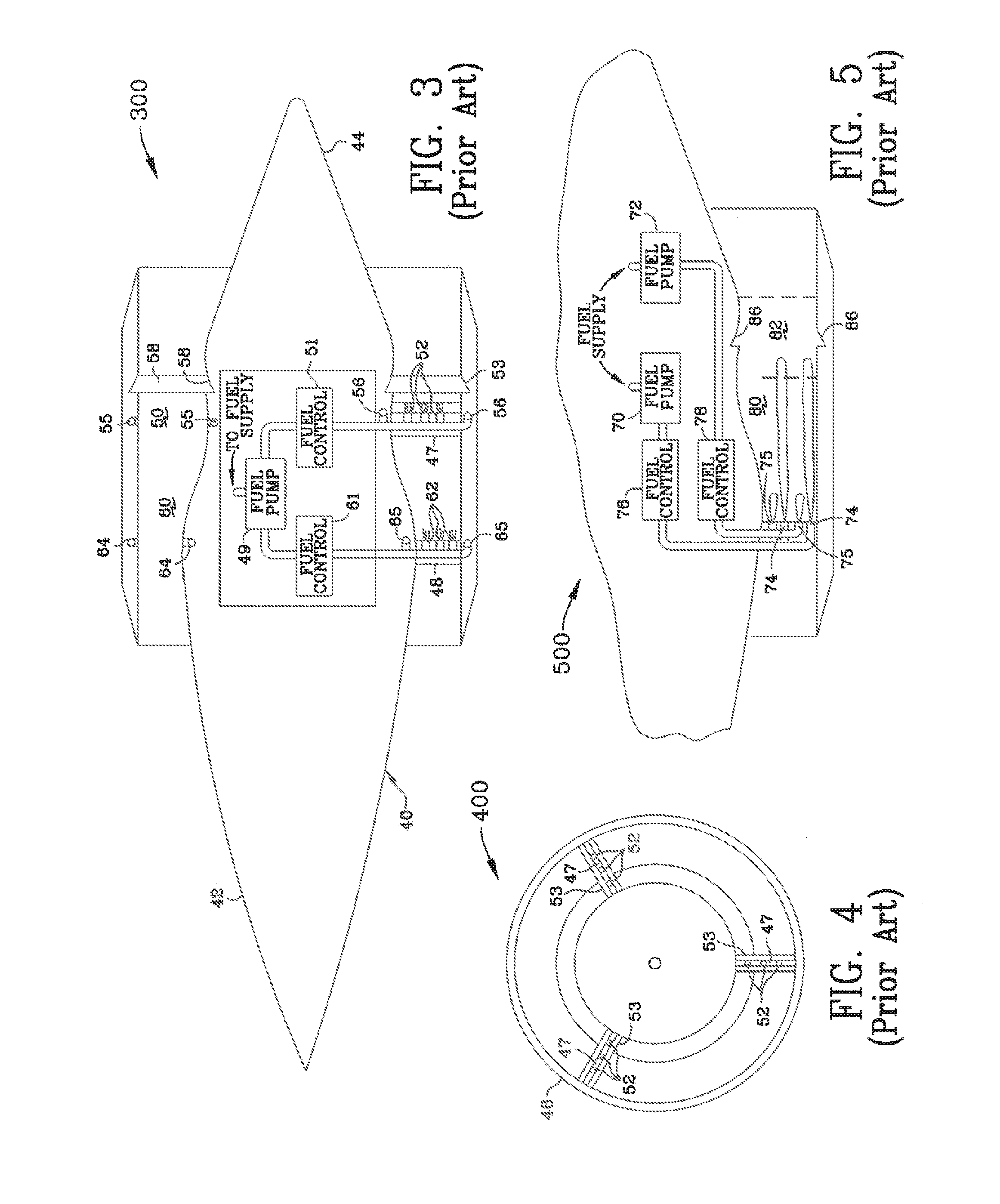

Dual-mode combustor

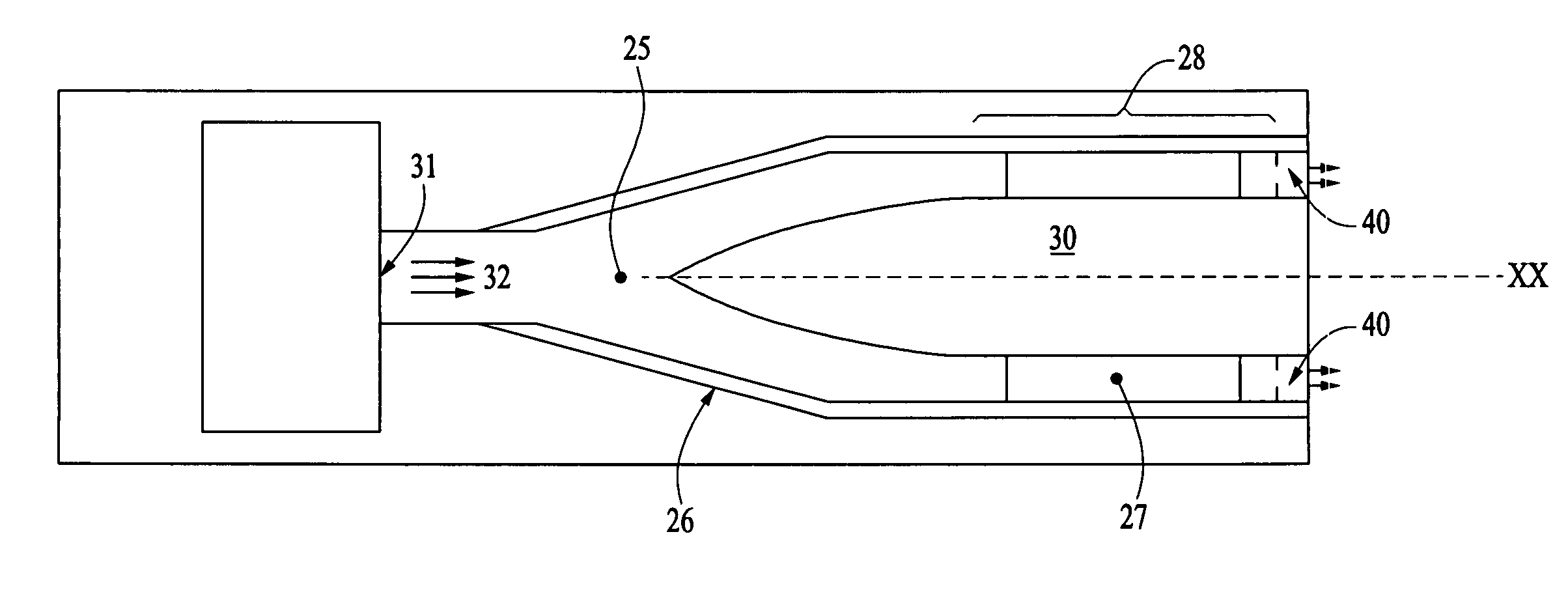

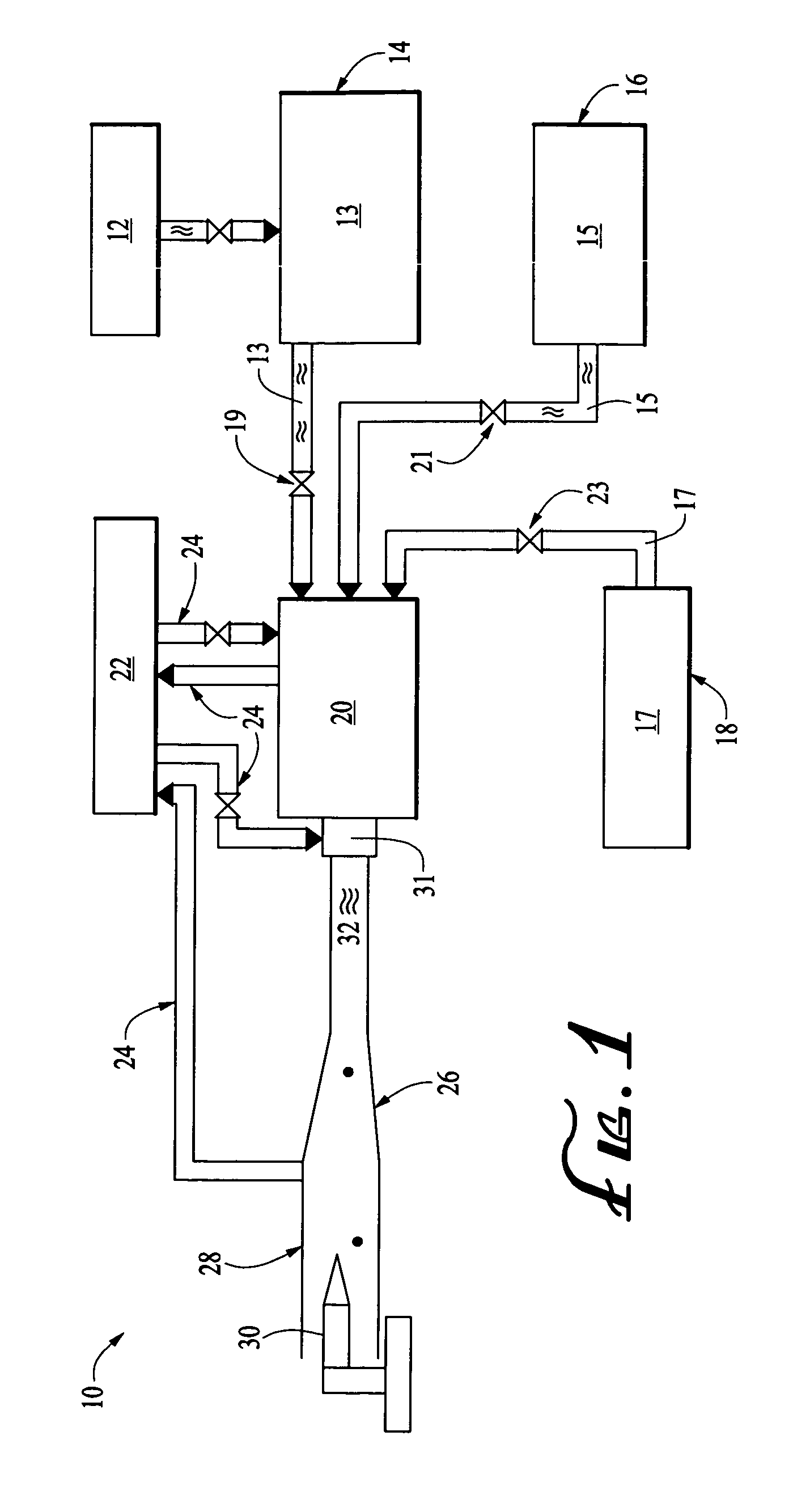

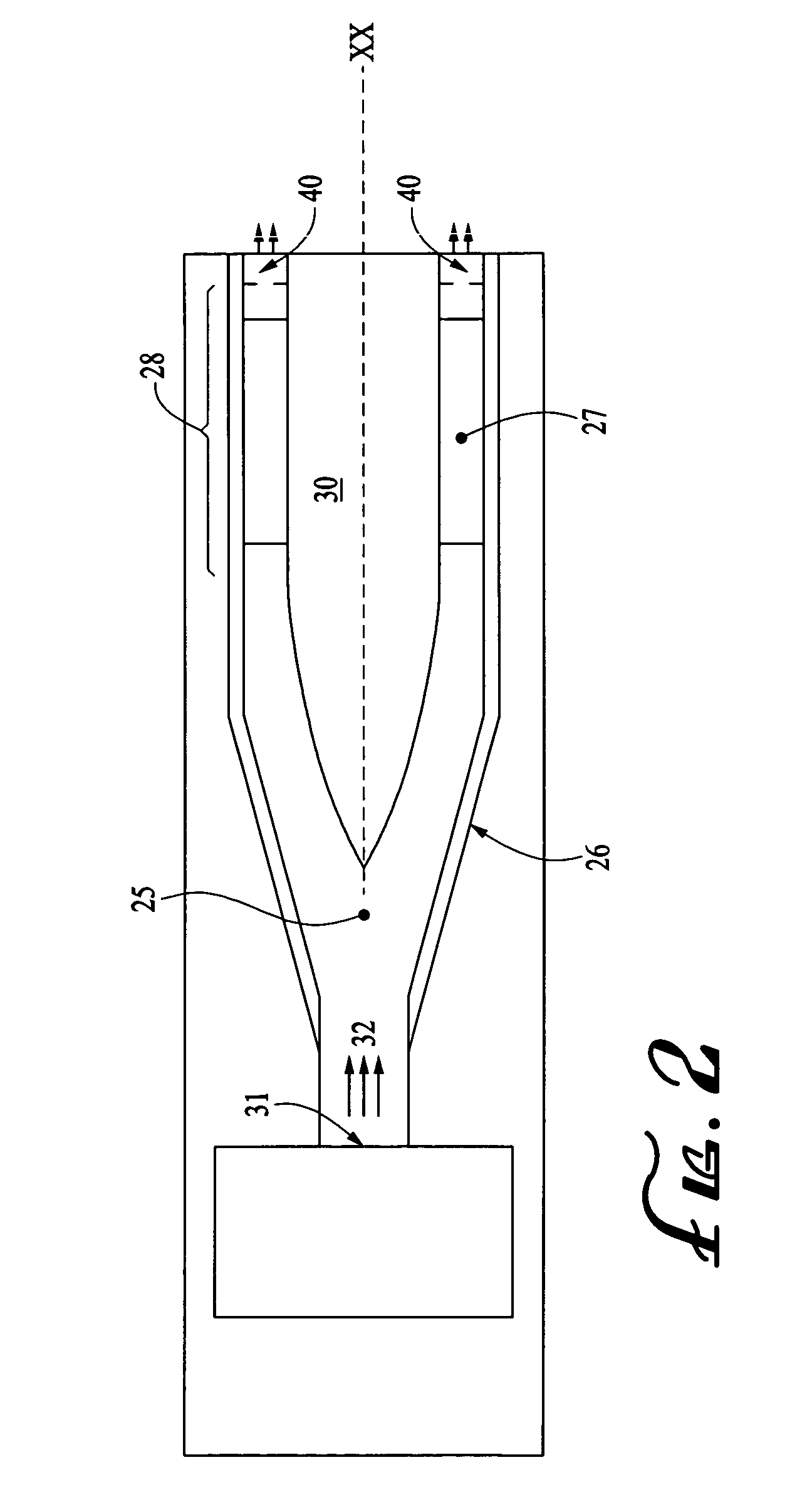

InactiveUS8484980B1Reduce the Mach numberContinuous combustion chamberPower plant arrangements/mountingRamjetCombustion chamber

A new dual-mode ramjet combustor used for operation over a wide flight Mach number range is described. Subsonic combustion mode is usable to lower flight Mach numbers than current dual-mode scramjets. High speed mode is characterized by supersonic combustion in a free-jet that traverses the subsonic combustion chamber to a variable nozzle throat. Although a variable combustor exit aperture is required, the need for fuel staging to accommodate the combustion process is eliminated. Local heating from shock-boundary-layer interactions on combustor walls is also eliminated.

Owner:NASA

Dual-Mode Combustor

InactiveUS20150013305A1Reduce the Mach numberContinuous combustion chamberPower plant arrangements/mountingRamjetCombustion chamber

A new dual-mode ramjet combustor used for operation over a wide flight Mach number range is described. Subsonic combustion mode is usable to lower flight Mach numbers than current dual-mode scramjets. High speed mode is characterized by supersonic combustion in a free-jet that traverses the subsonic combustion chamber to a variable nozzle throat. Although a variable combustor exit aperture is required, the need for fuel staging to accommodate the combustion process is eliminated. Local heating from shock-boundary-layer interactions on combustor walls is also eliminated.

Owner:US GOVT ADMINISTATOR OF NASA

High-altitude capable wide velocity range flight velocity vector measurement probe and measurement system

InactiveUS7480548B2Prevent fallingEliminate the effects ofDigital data processing detailsFluid speed measurement using pressure differenceAnomaly detectionFlight velocity

It is an object of the present invention to solve the problem of a drop in precision in conventional systems using a square pyramid type five-hole probe due to the drop in atmospheric pressure in high altitude ranges, and to provide a wide velocity range flight velocity vector measurement system that can prevent a drop in measurement precision. Furthermore, it is also an object of the present invention to provide a method for eliminating the effects of detection fluctuations caused by adhering water droplets, ice particles or dust in a wide velocity range flight velocity vector measurement system. The flight velocity vector measurement probe of the present invention comprises means in which a static pressure hole is formed in the tube wall surface of the probe, so that a static pressure value is obtained from the pressure detected by this static pressure hole, the Mach number M is calculated on the basis of an equation approximated by a fourth-order polynomial of the static pressure / total pressure signal and the angle of attack, and in cases where an abnormal detection value is detected, this is replaced by the preceding detection value.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

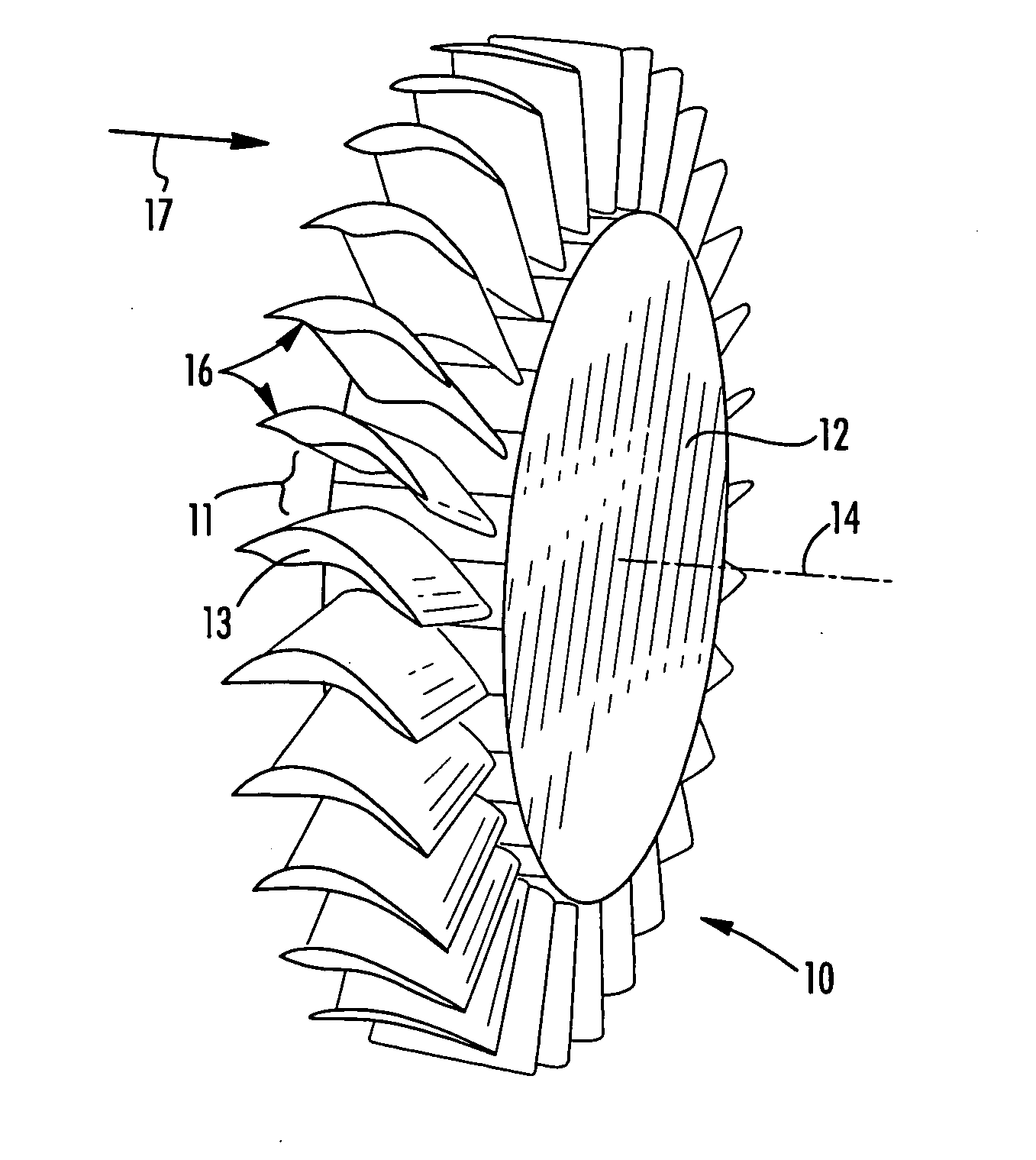

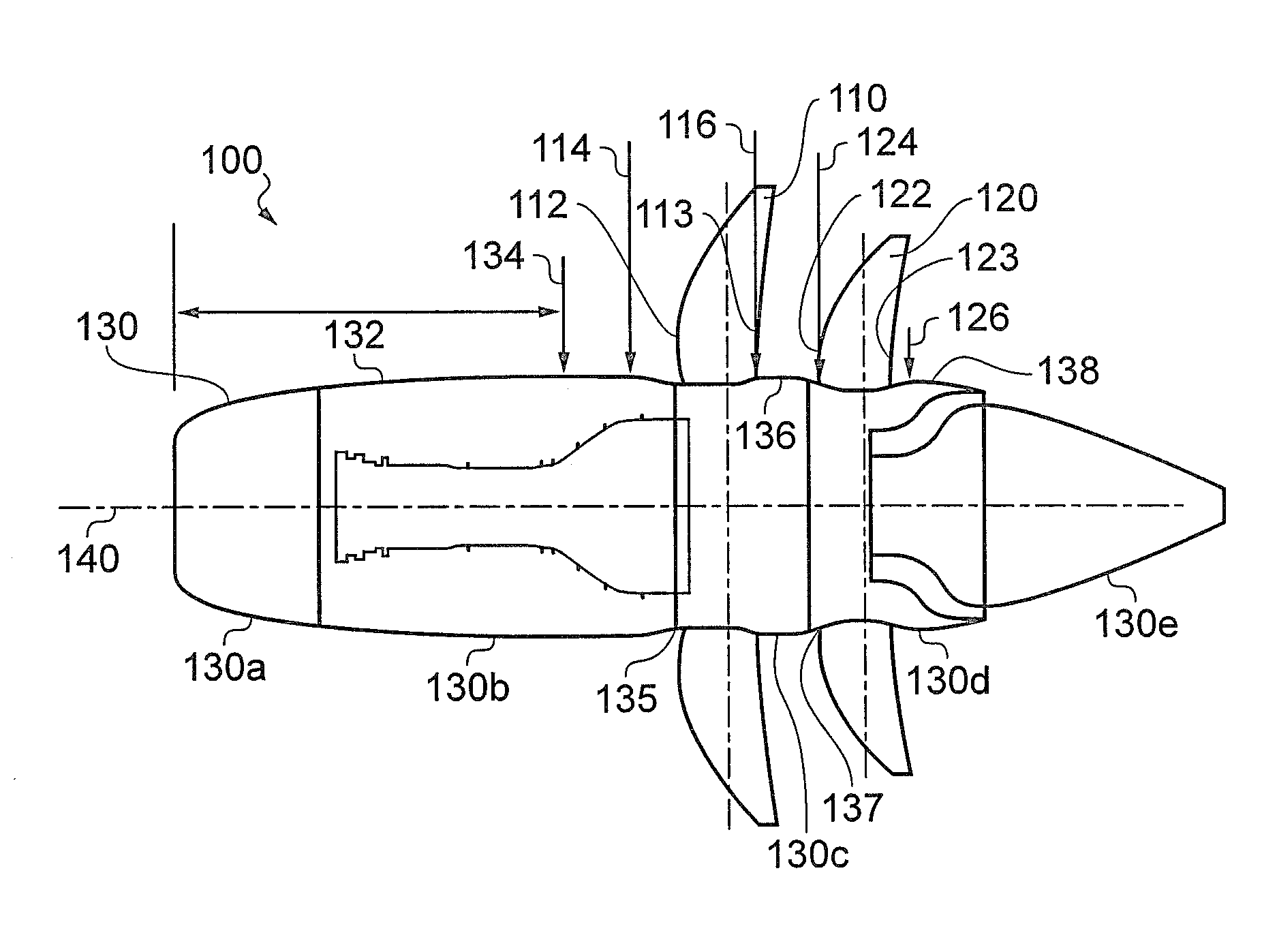

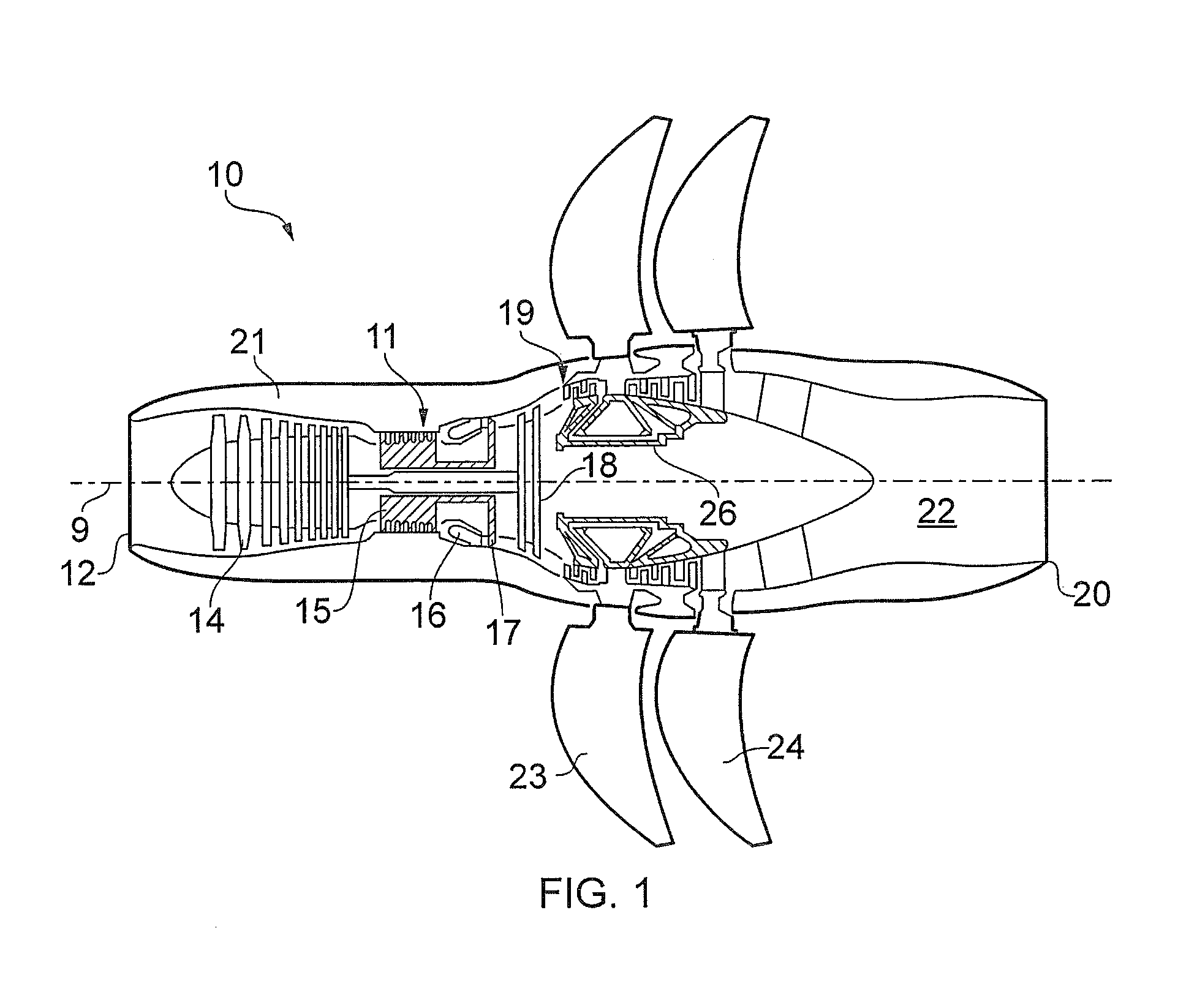

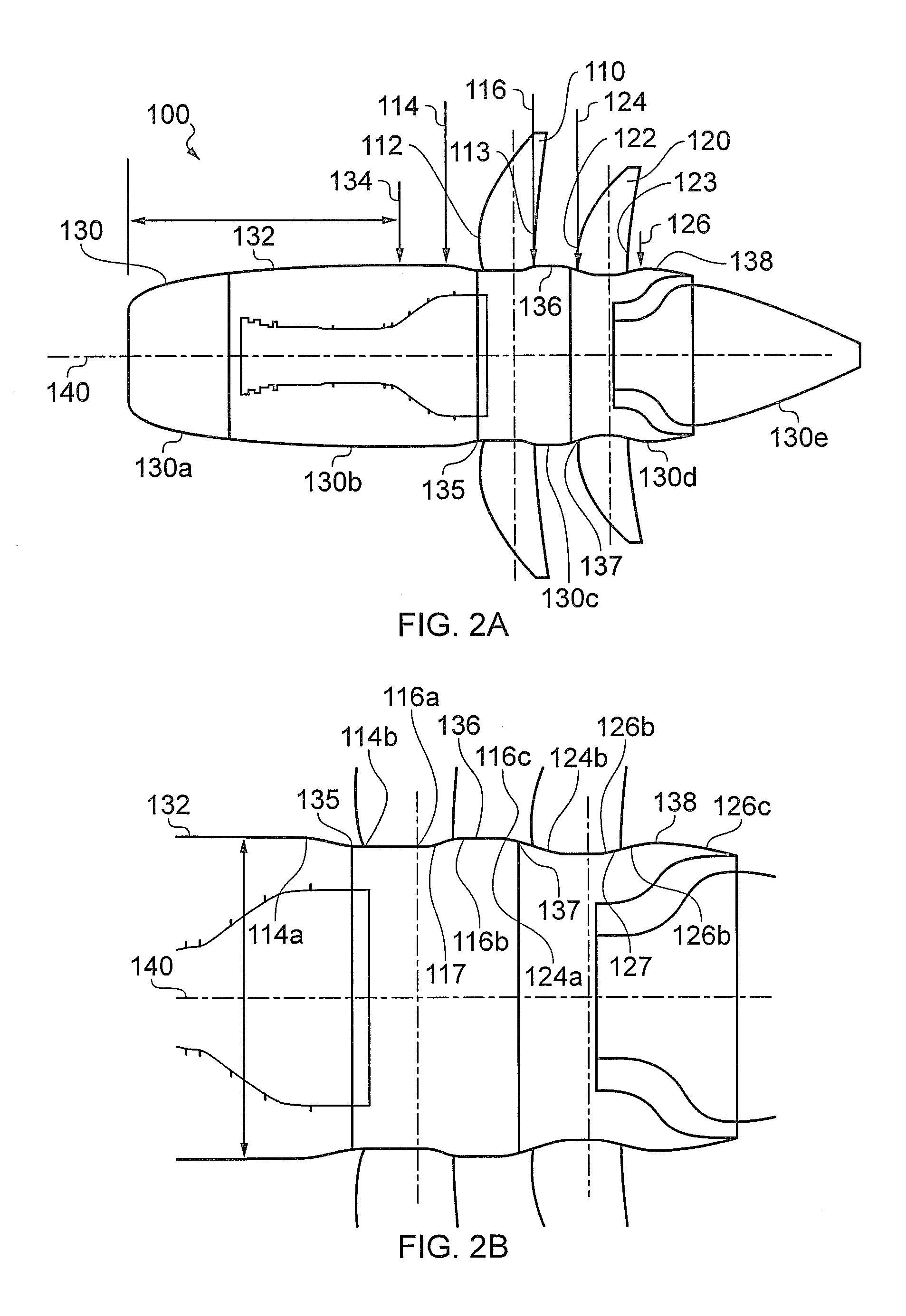

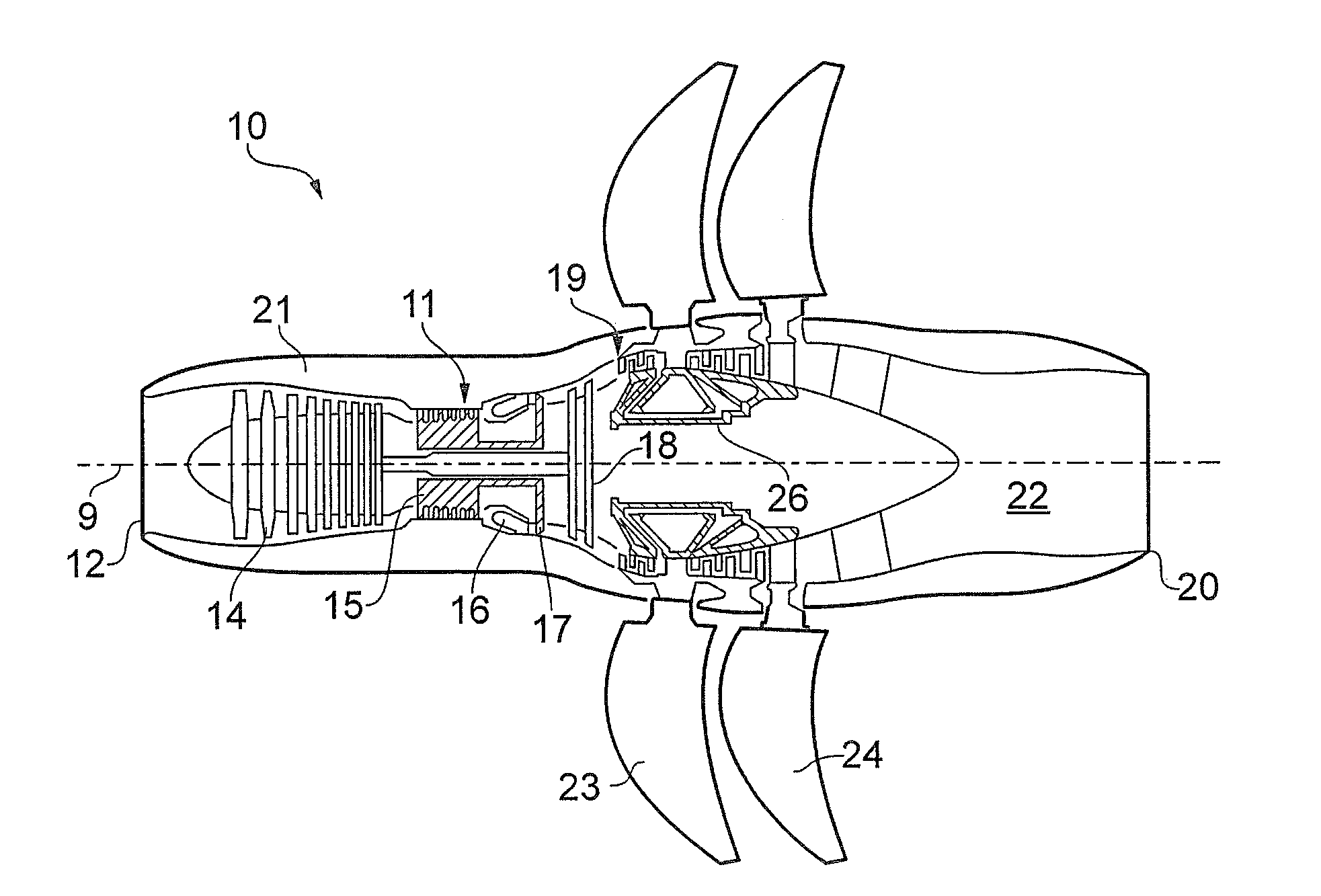

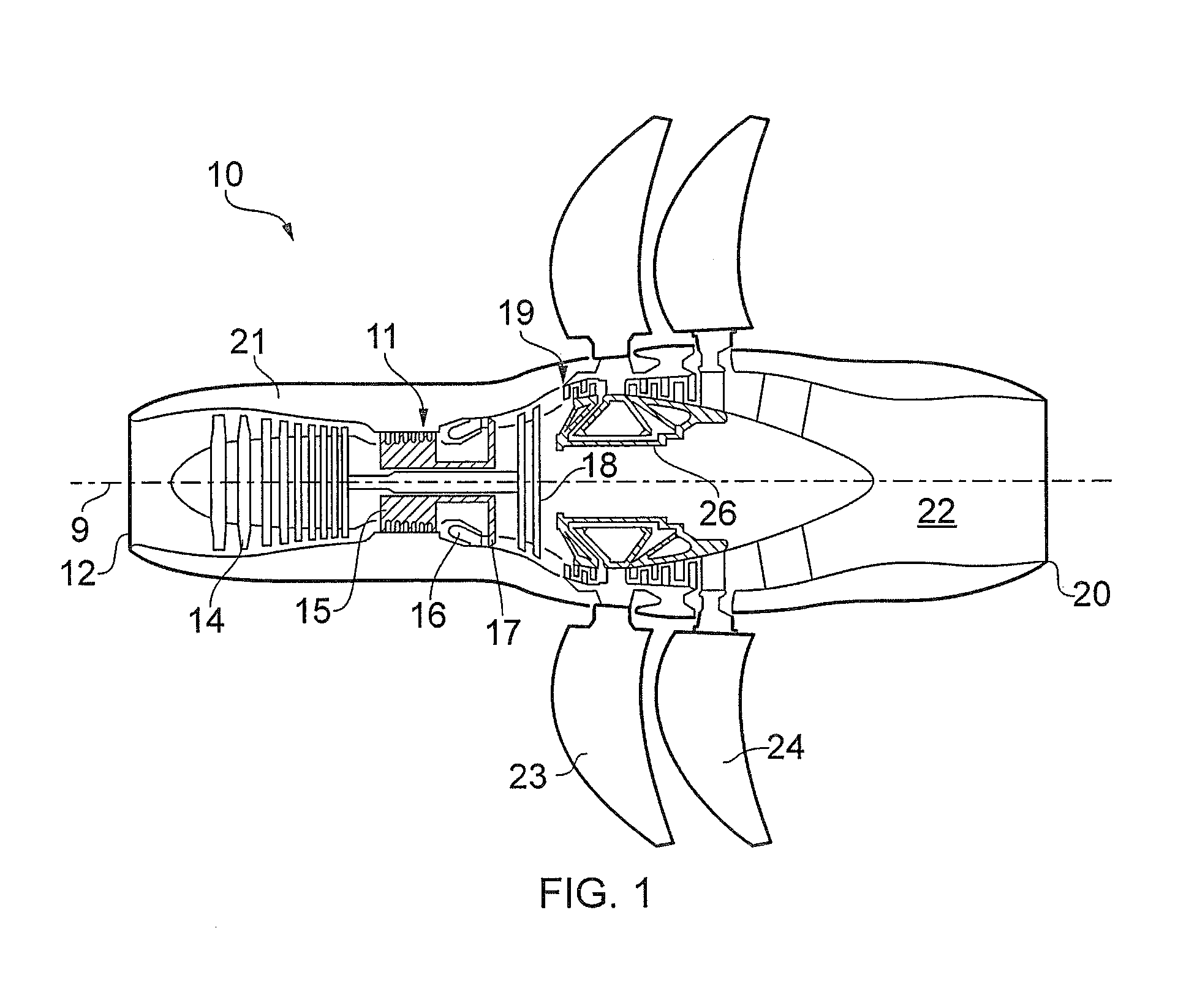

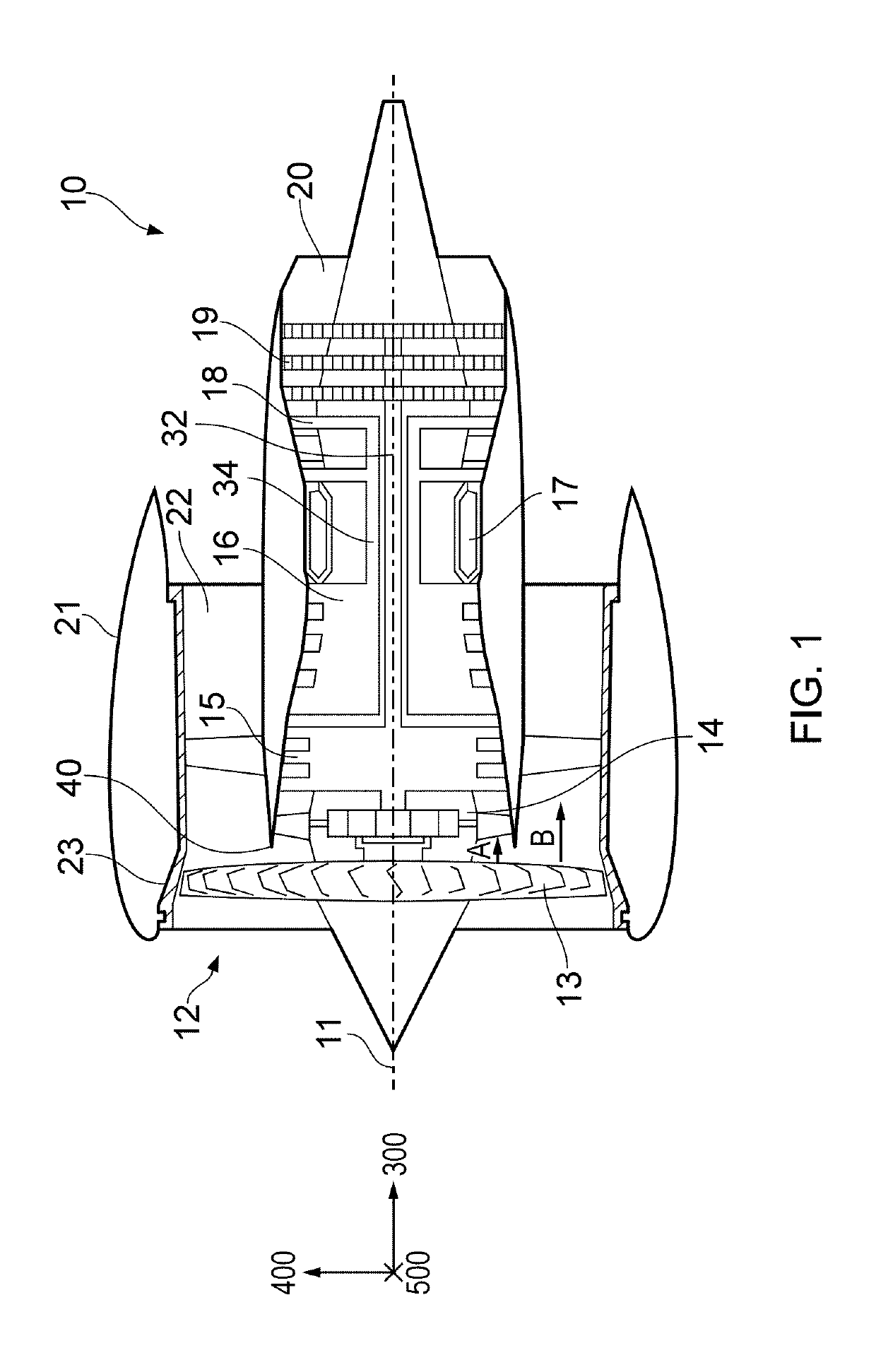

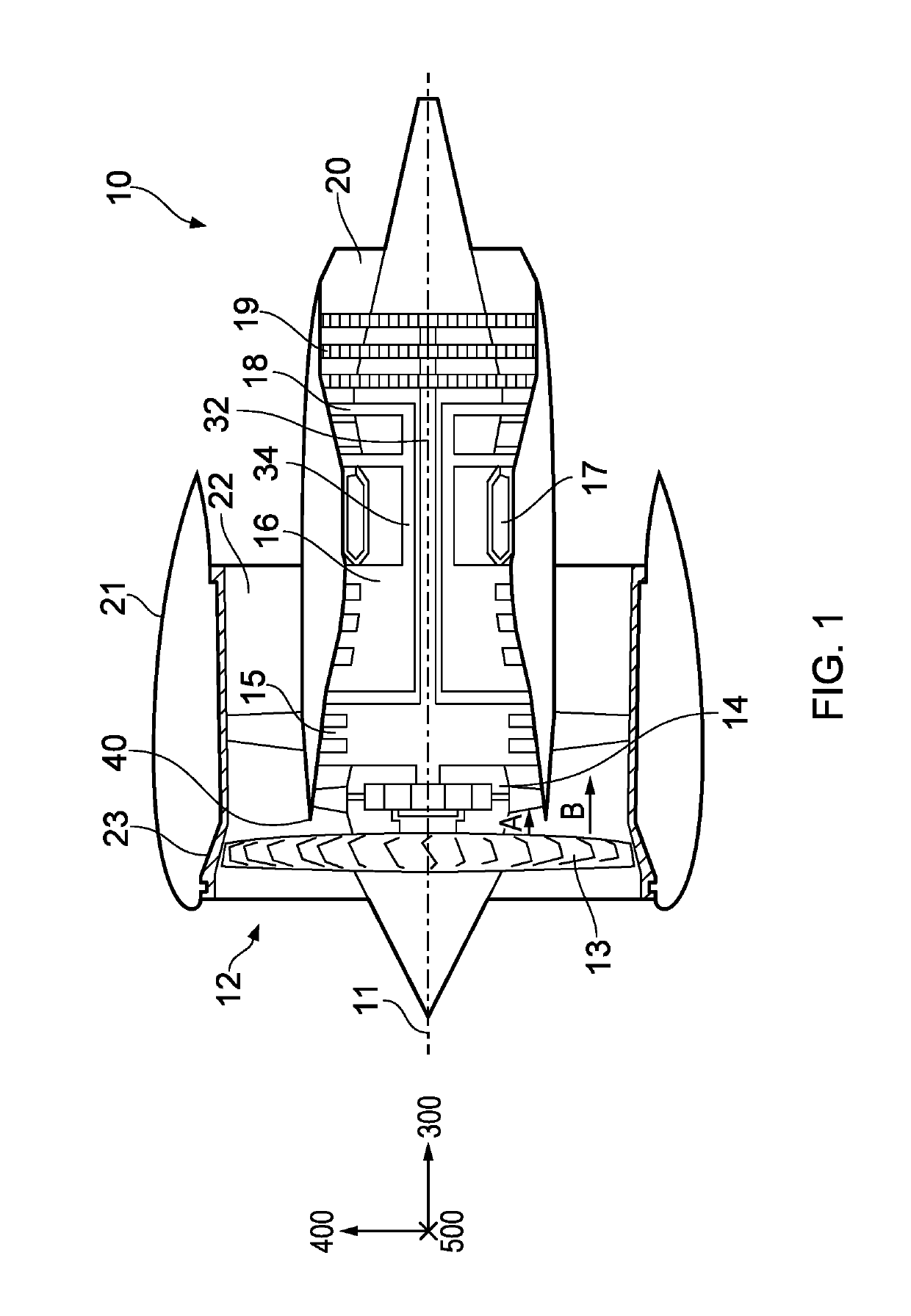

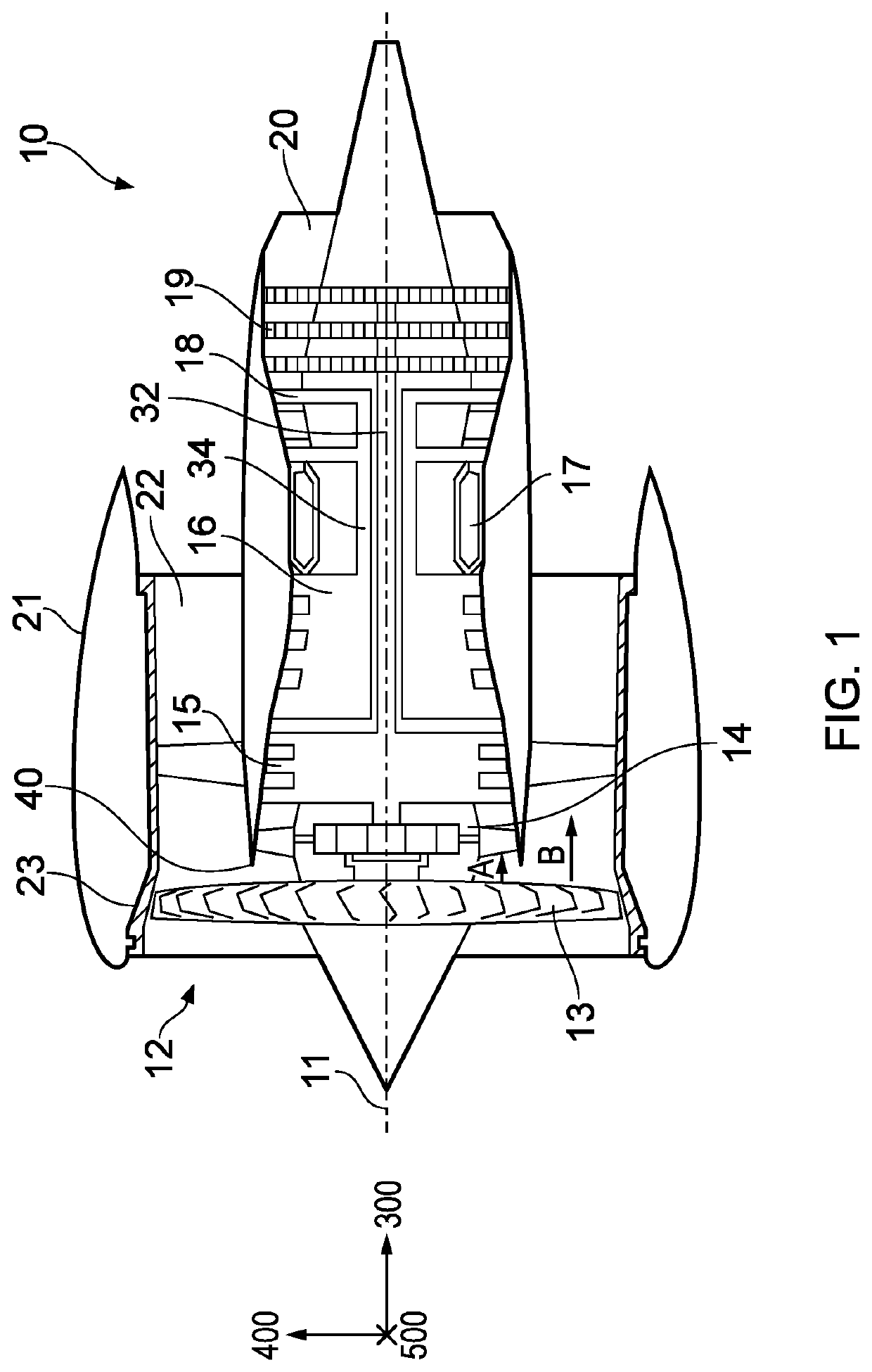

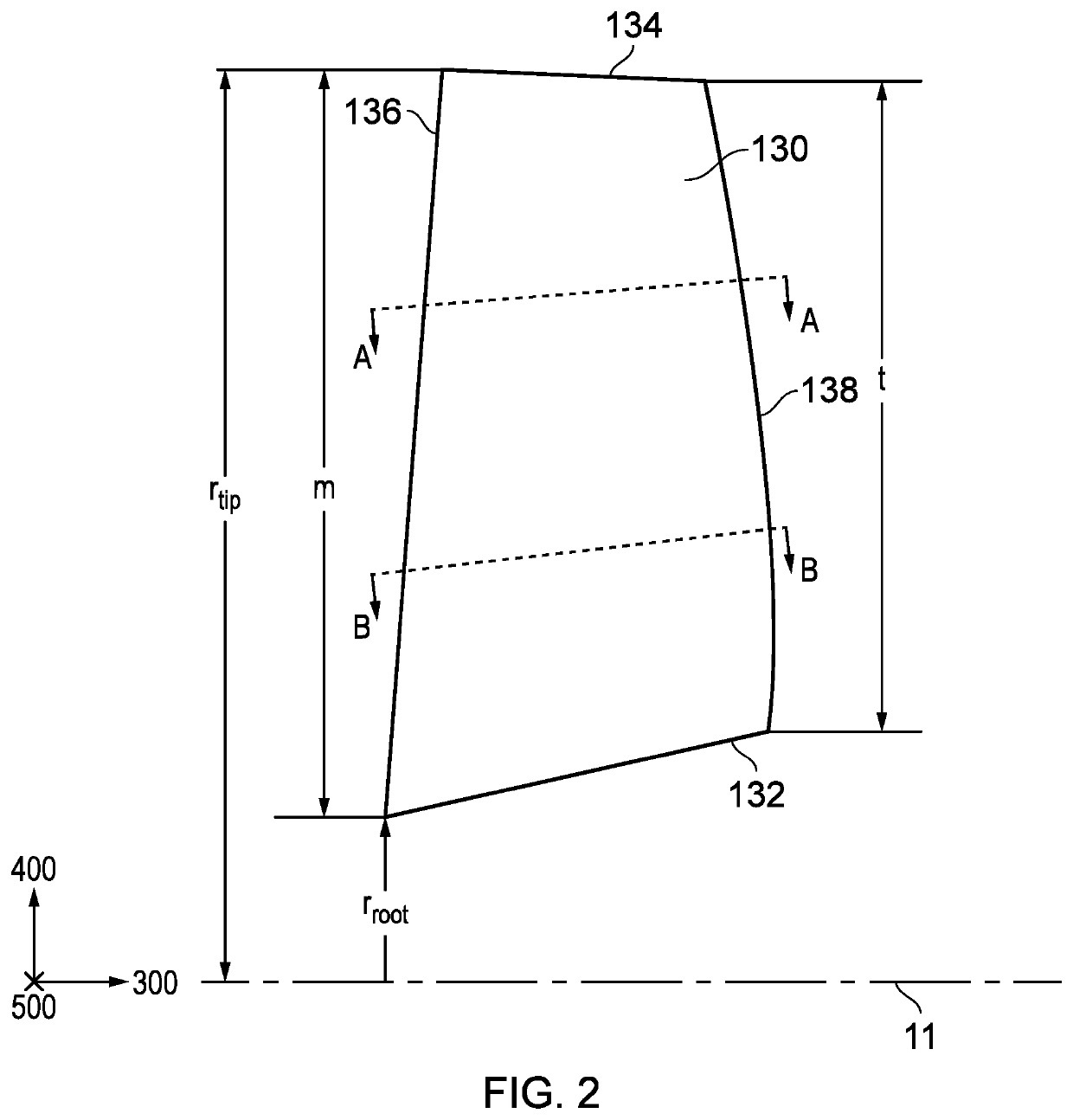

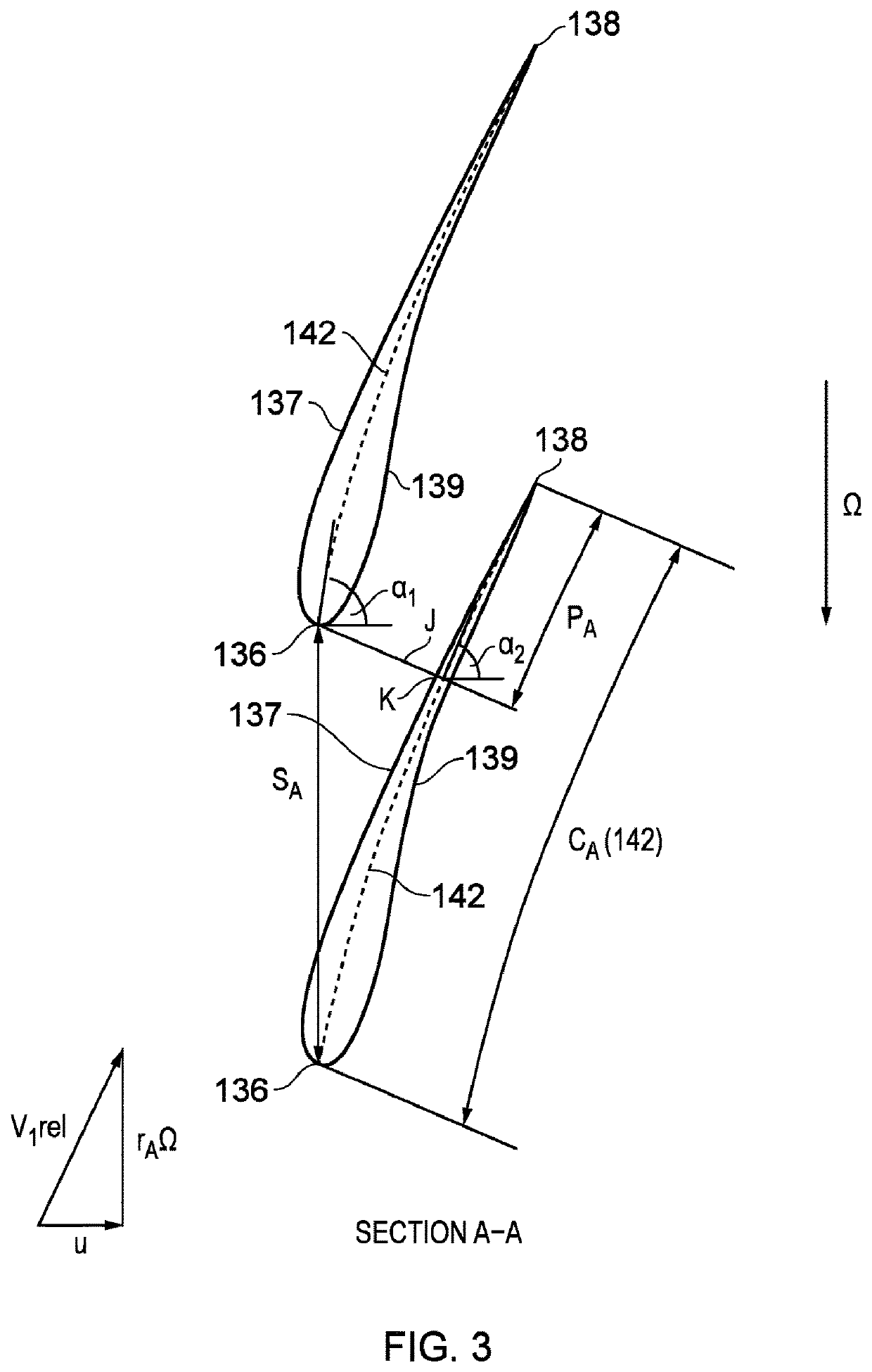

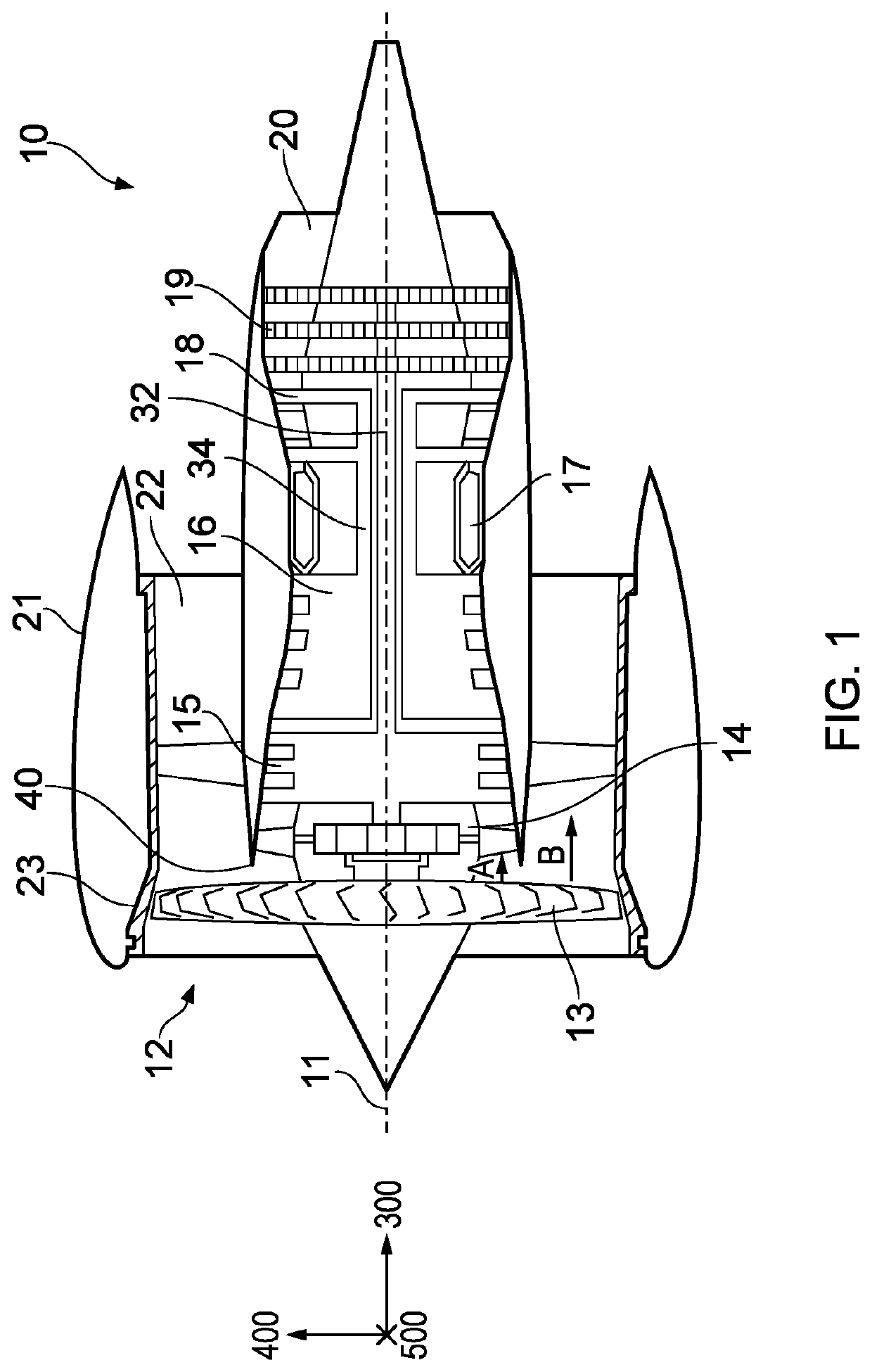

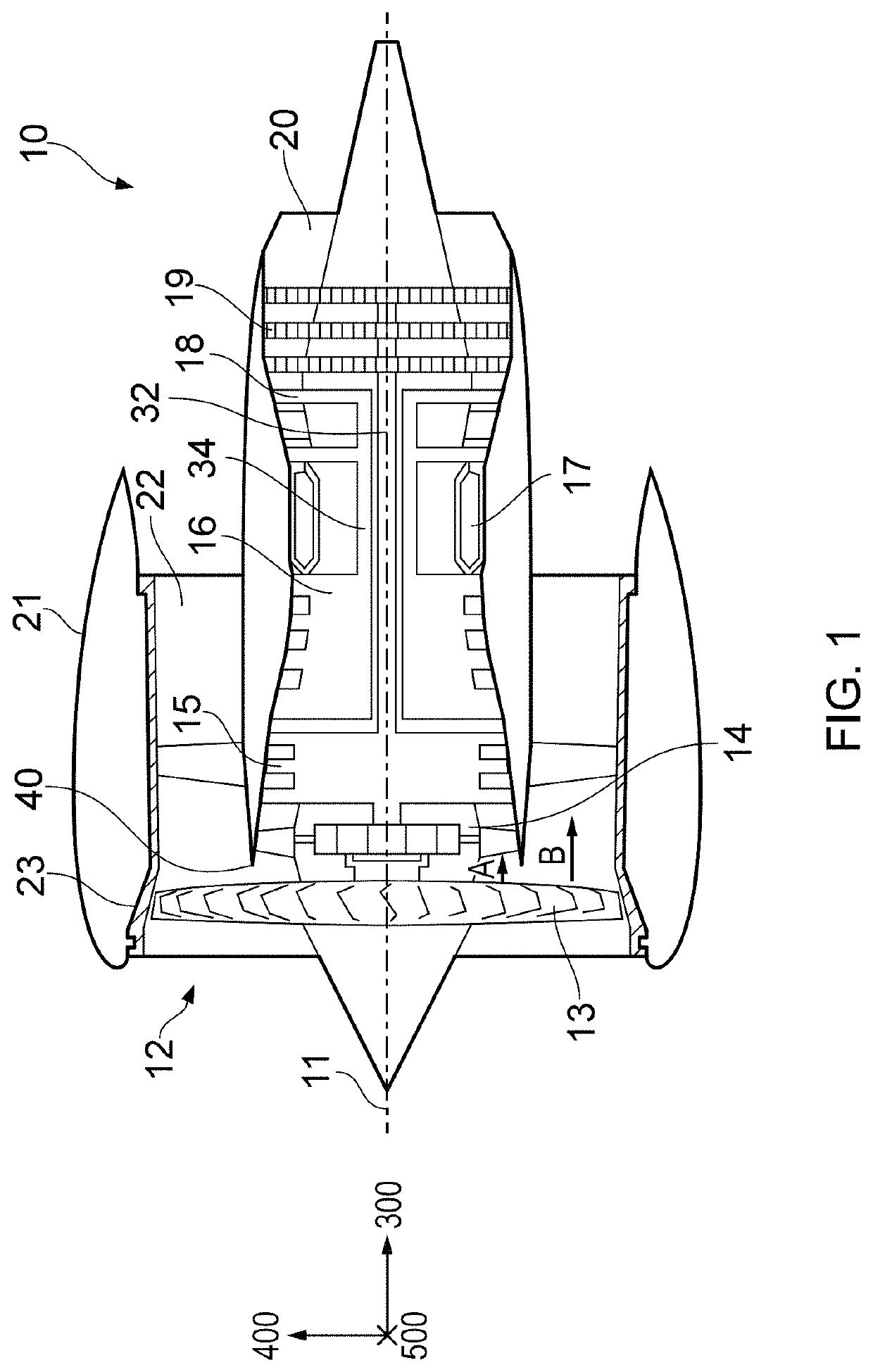

Propfan engine

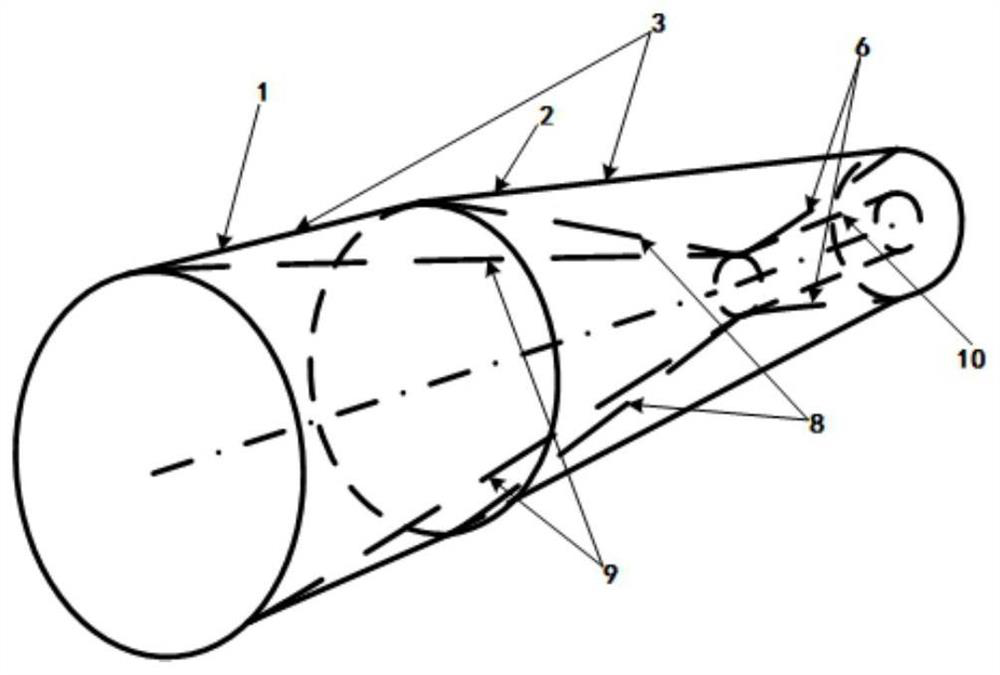

ActiveUS8967967B2Great reduction in hub Mach numberAlleviate root choke concernsPropellersPower plant arrangements/mountingLeading edgeEngineering

The present disclosure relates to a propfan engine comprising: one or more rotor stages comprising a plurality of rotors; and an outer wall comprising an outer profile, at least a portion of the outer profile defining a substantially circular cross-section, wherein the diameter of the substantially circular cross-section increases in the direction of flow over the outer wall and downstream of a leading edge of the rotors, and the diameter increases at substantially all points defining the circumference of the substantially circular cross-section.

Owner:ROLLS ROYCE PLC

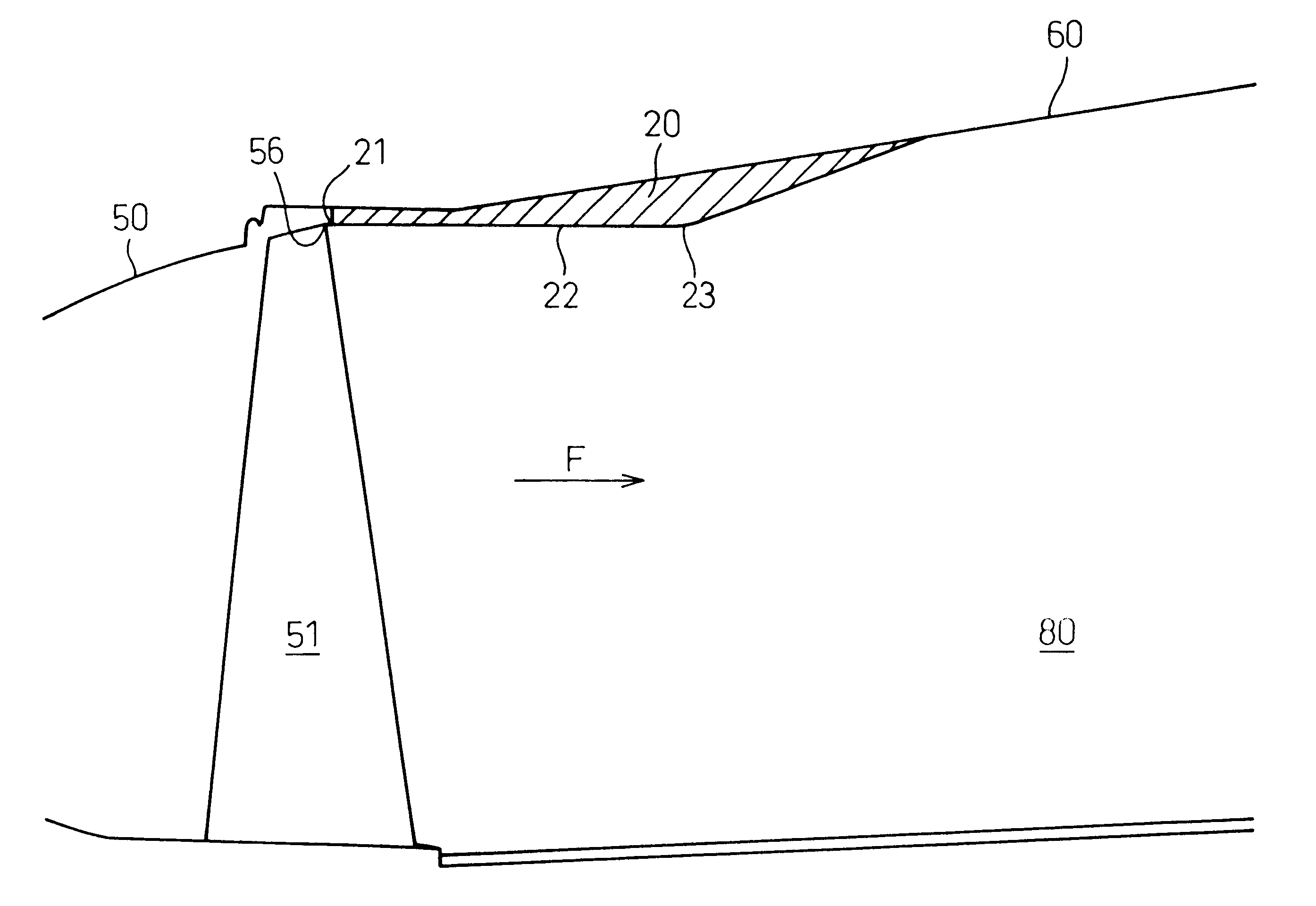

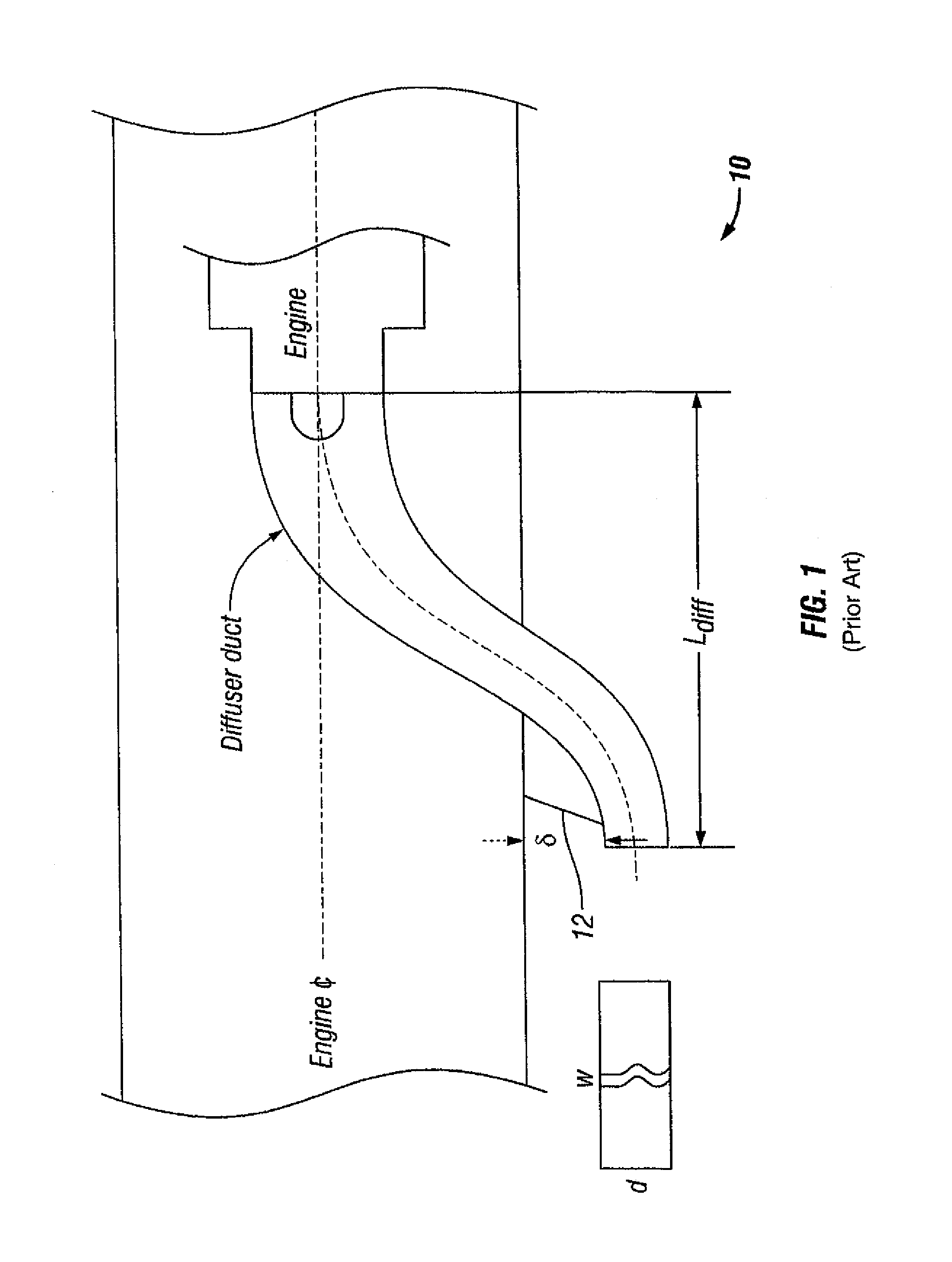

Axial-flow turbine having stepped portion formed in axial-flow turbine passage

InactiveUS6733238B2Improve efficiencyReduce total pressure lossPump componentsGas turbine plantsTrailing edgeTurbine

There is provided an axial-flow turbine comprising an exhaust chamber; a turbine including multiple stage rotor blades, said multiple stage rotor blade including terminal stage rotor blades; an annular diffuser located between the turbine and the exhaust chamber; and an annular axial-flow turbine passage defined by the turbine, the diffuser and the exhaust chamber, wherein fluid flows through the axial-flow turbine passage toward the exhaust chamber, and an annular stepped portion which inwardly projects in a radial direction is formed on the portion of an inner wall of the axial-flow turbine passage that is located on the downstream side of a trailing edge of a tip portion of the terminal stage rotor blades provided in the flow direction of the fluid. In the stepped portion, a projecting portion which inwardly projects in a radial direction may be provided.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Propfan engine

ActiveUS20130343892A1Reduce diameterGreat reduction in hub Mach numberPropellersEngine manufactureEngineeringMechanical engineering

The present disclosure relates to a propfan engine comprising: one or more rotor stages comprising a plurality of rotors; and an outer wall comprising an outer profile, at least a portion of the outer profile defining a substantially circular cross-section, wherein the diameter of the substantially circular cross-section increases in the direction of flow over the outer wall and downstream of a leading edge of the rotors, and the diameter increases at substantially all points defining the circumference of the substantially circular cross-section.

Owner:ROLLS ROYCE PLC

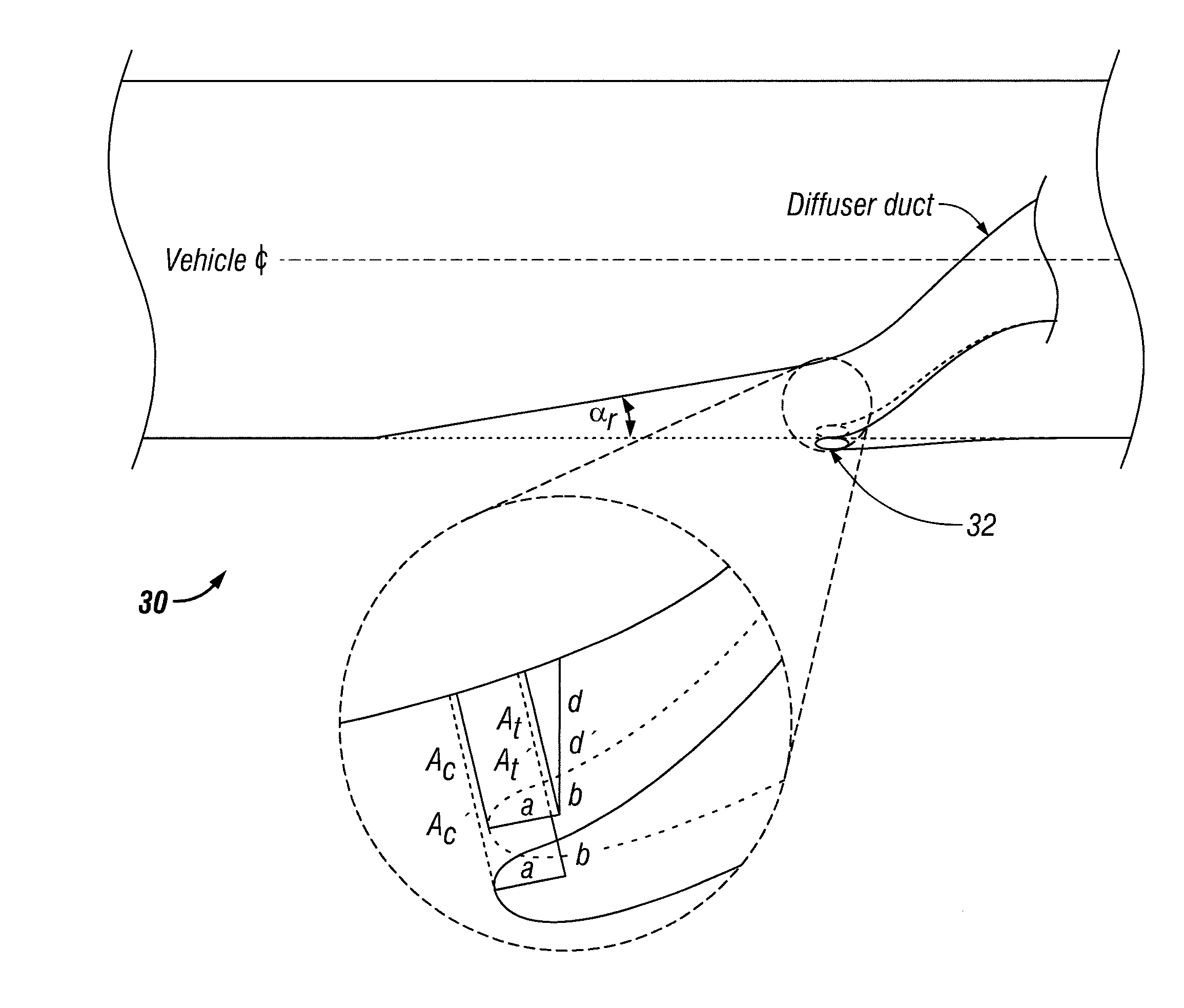

Hybrid (pitot-flush) air intake system for air-breathing missiles and aircraft

ActiveUS9056670B1Low distortion levelHigh pressure recoveryAir-flow influencersPower plant air intake arrangementsFuselageAirplane

A hybrid air intake system and method for air-breathing missiles and aircraft comprising providing to an airborne vehicle fuselage an air intake opening comprising at least a pair of side walls and at least an upper wall and a lower wall extending between the side walls, wherein the lower wall extends below a plane defined by the vehicle fuselage, and not employing a boundary layer diverter between the fuselage and the upper wall.

Owner:LOCKHEED MARTIN CORP

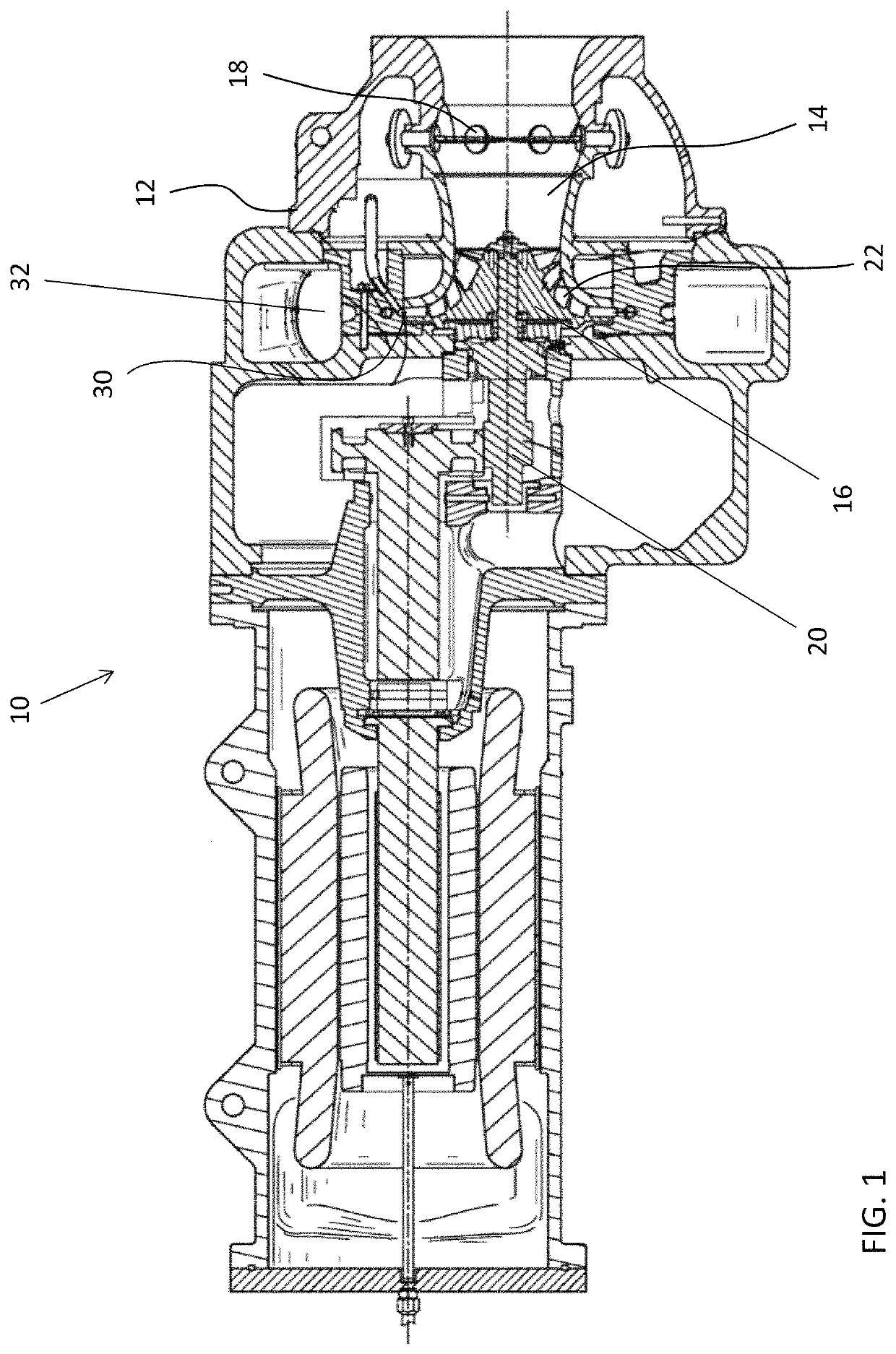

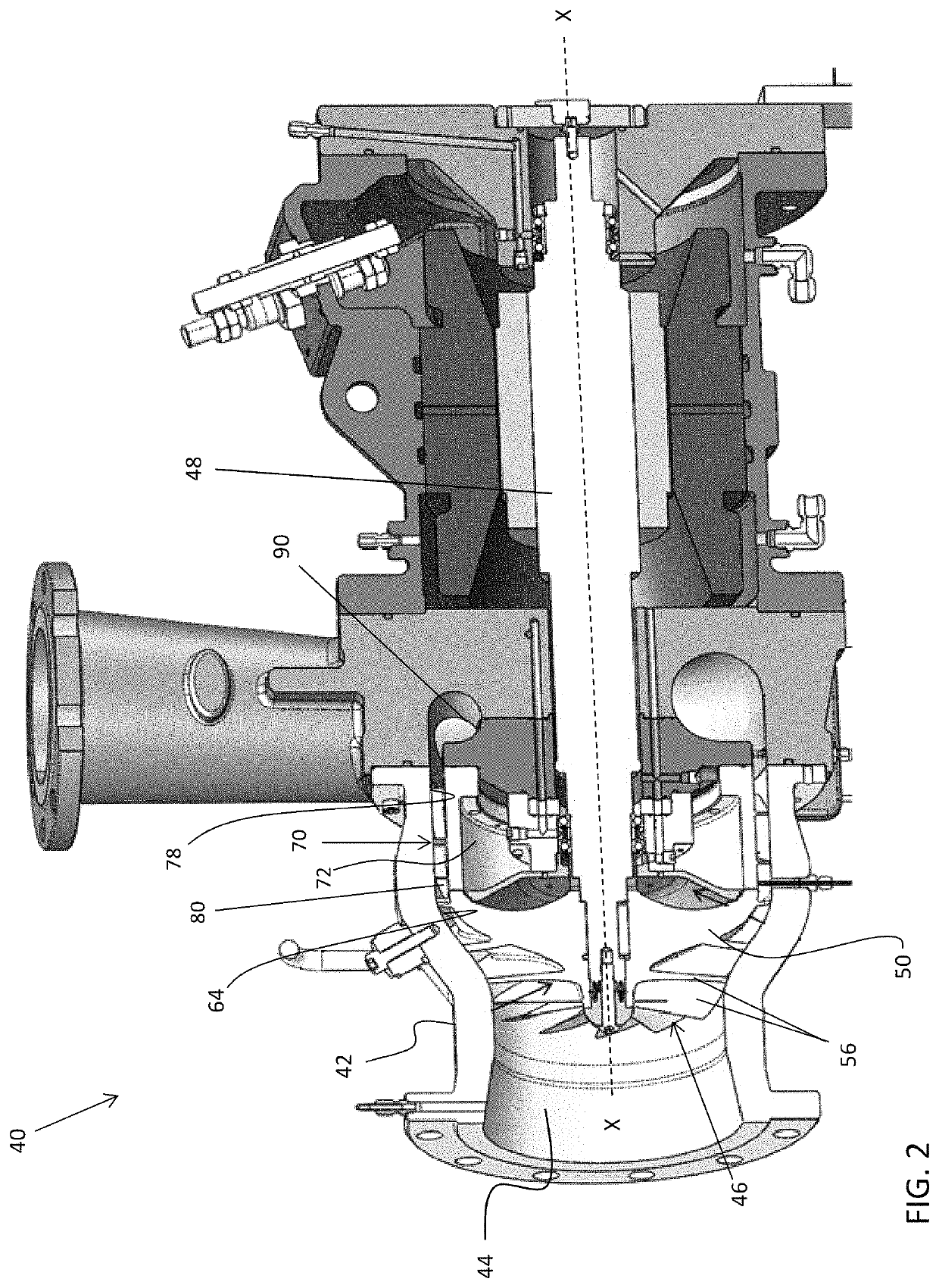

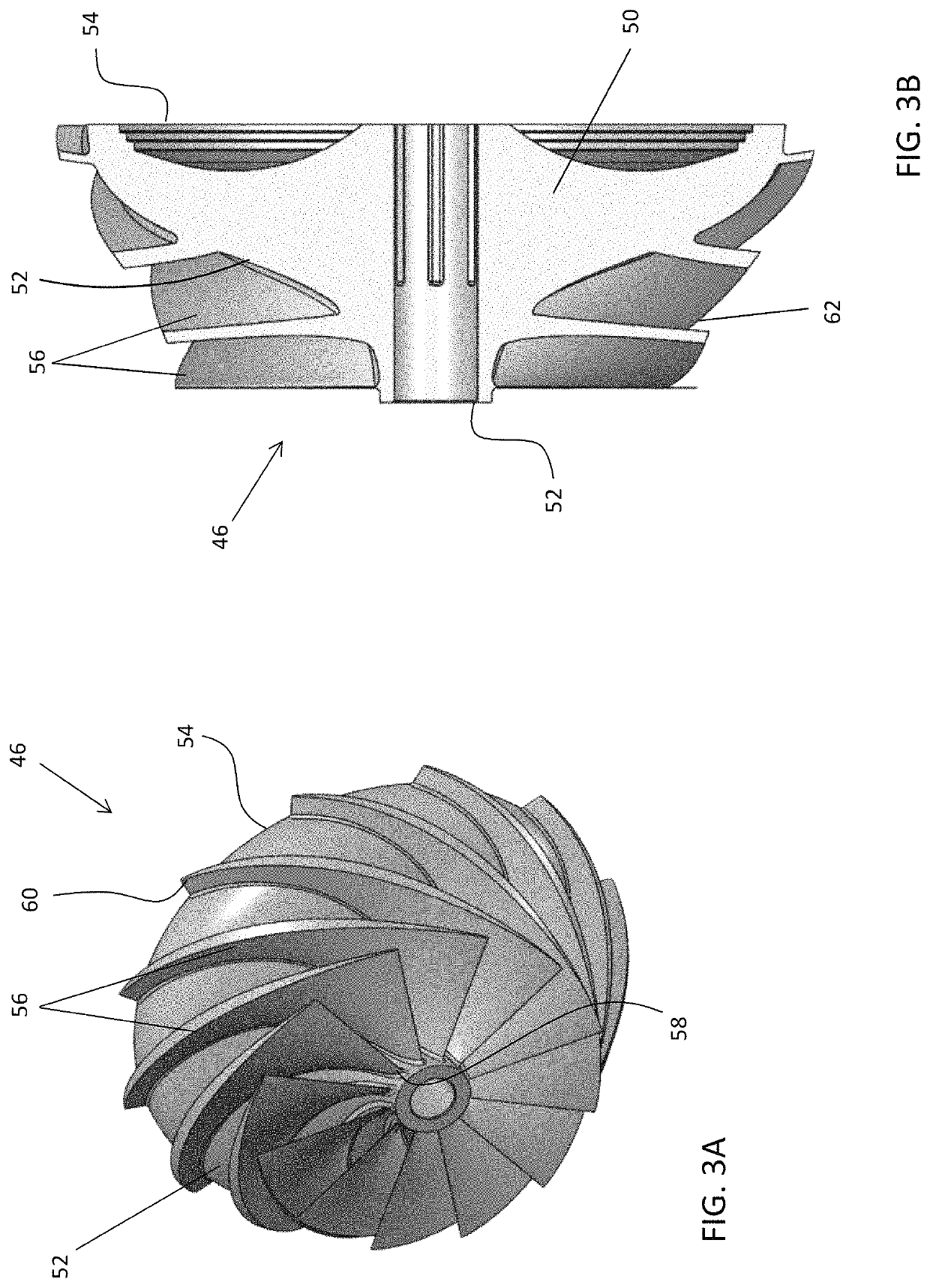

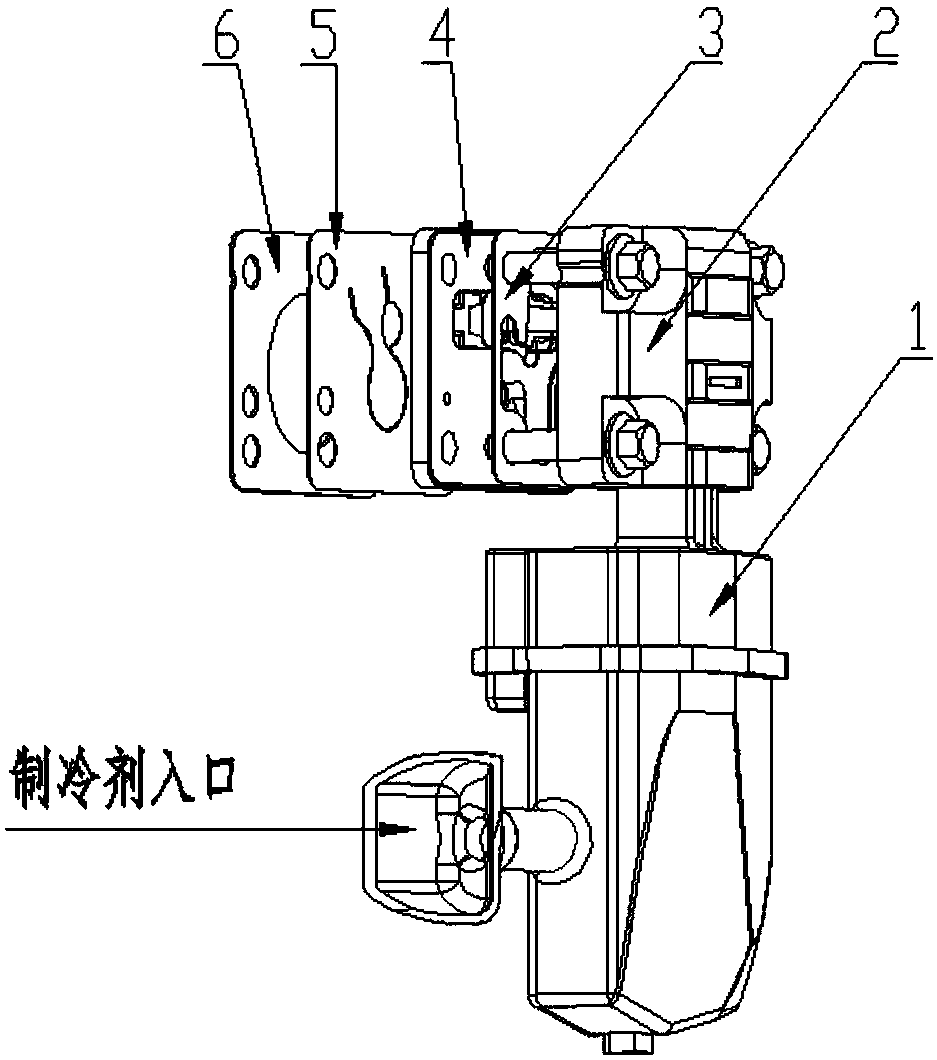

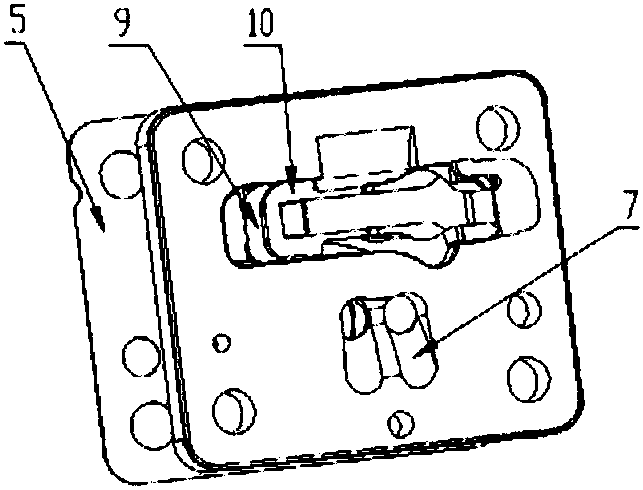

Refrigeration system mixed-flow compressor

An impeller mountable within a centrifugal compressor includes a hub having a front side and a back side, the hub being rotatable about an axis of rotation and a plurality of vanes extending outwardly from the front side of the hub such that a plurality of passages is defined between adjacent vanes. The plurality of vanes is oriented such that a flow output from the plurality of passages adjacent the back side of the impeller is arranged at an angle to the axis of rotation of less than 20 degrees.

Owner:CARRIER CORP

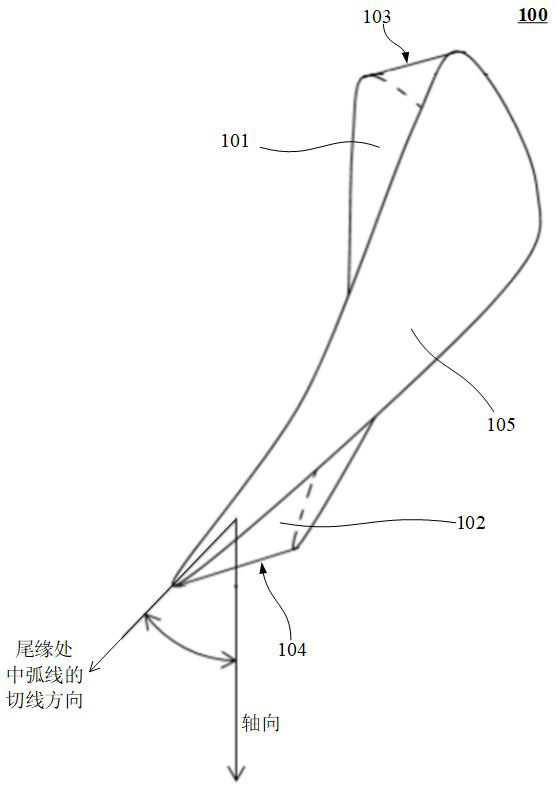

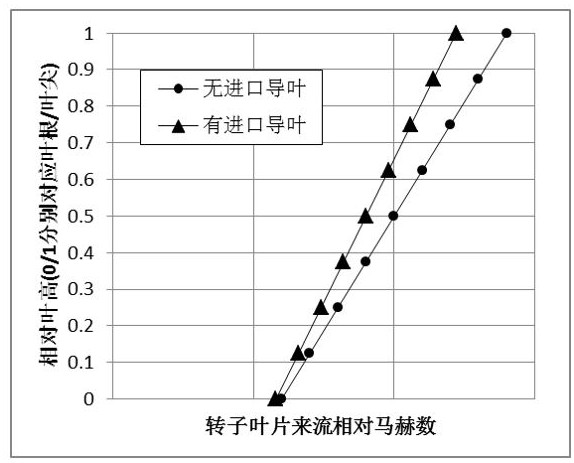

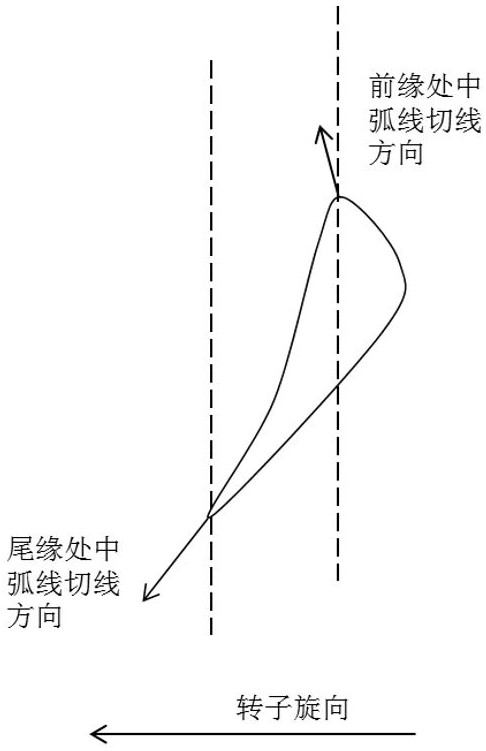

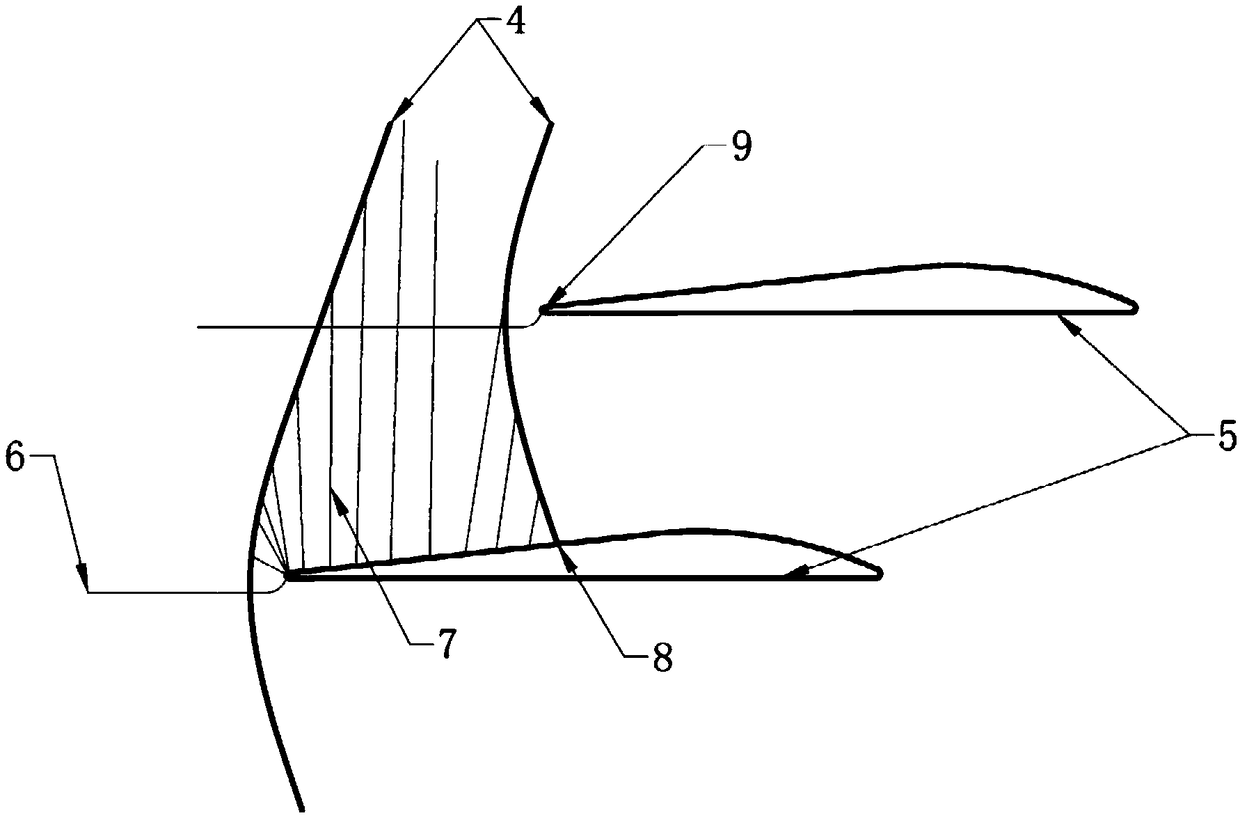

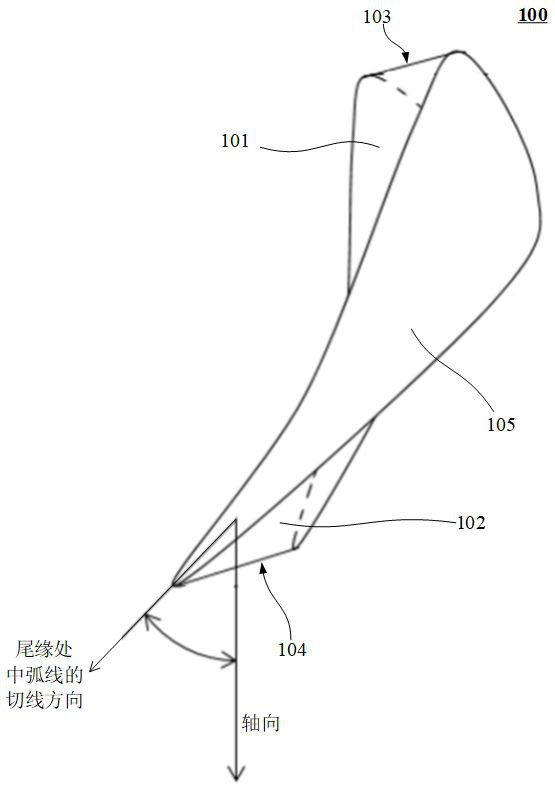

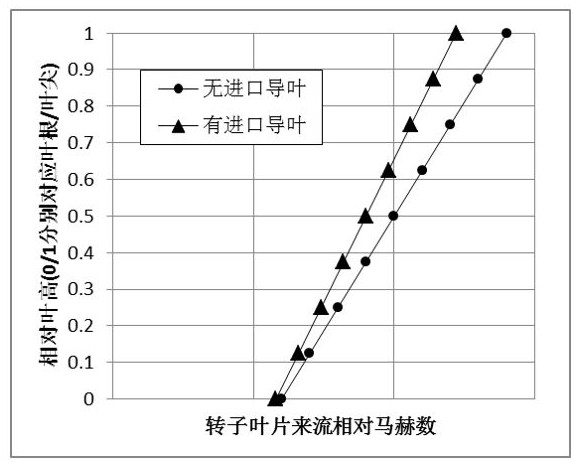

Inlet stage blade assembly for gas compressor and axial flow gas compressor comprising same

ActiveCN113339325AIncrease reactionImprove working abilityPump componentsPumpsMechanicsRadial deformation

The invention discloses an inlet stage blade assembly for a gas compressor and an axial flow gas compressor comprising the same. The inlet stage blade assembly comprises an inlet guide blade and a first stage moving blade, wherein the position of the inlet guide blade with the largest trailing edge metal angle is a first position, and the relative blade height T at the first position is larger than or equal to 0.8 and smaller than or equal to 0.9; the blade-shaped section of the first-stage moving blade at the blade tip has a first chord length, the blade-shaped section of the first-stage moving blade at the second position with the relative blade height being T has a second chord length, and the first chord length is 3%-10% larger than the second chord length; and between the second position and the blade tip of the first-stage moving blade, the sweepforward or sweepback degree of the stacking shaft of the first-stage moving blade does not exceed 1% of the absolute blade height of the first-stage moving blade. By the adoption of the structure, the stall margin of the blade tip of the first-stage movable blade can be improved, and radial deformation of the front edge and the tail edge of the first-stage movable blade from the static state to the running state is more coordinated.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

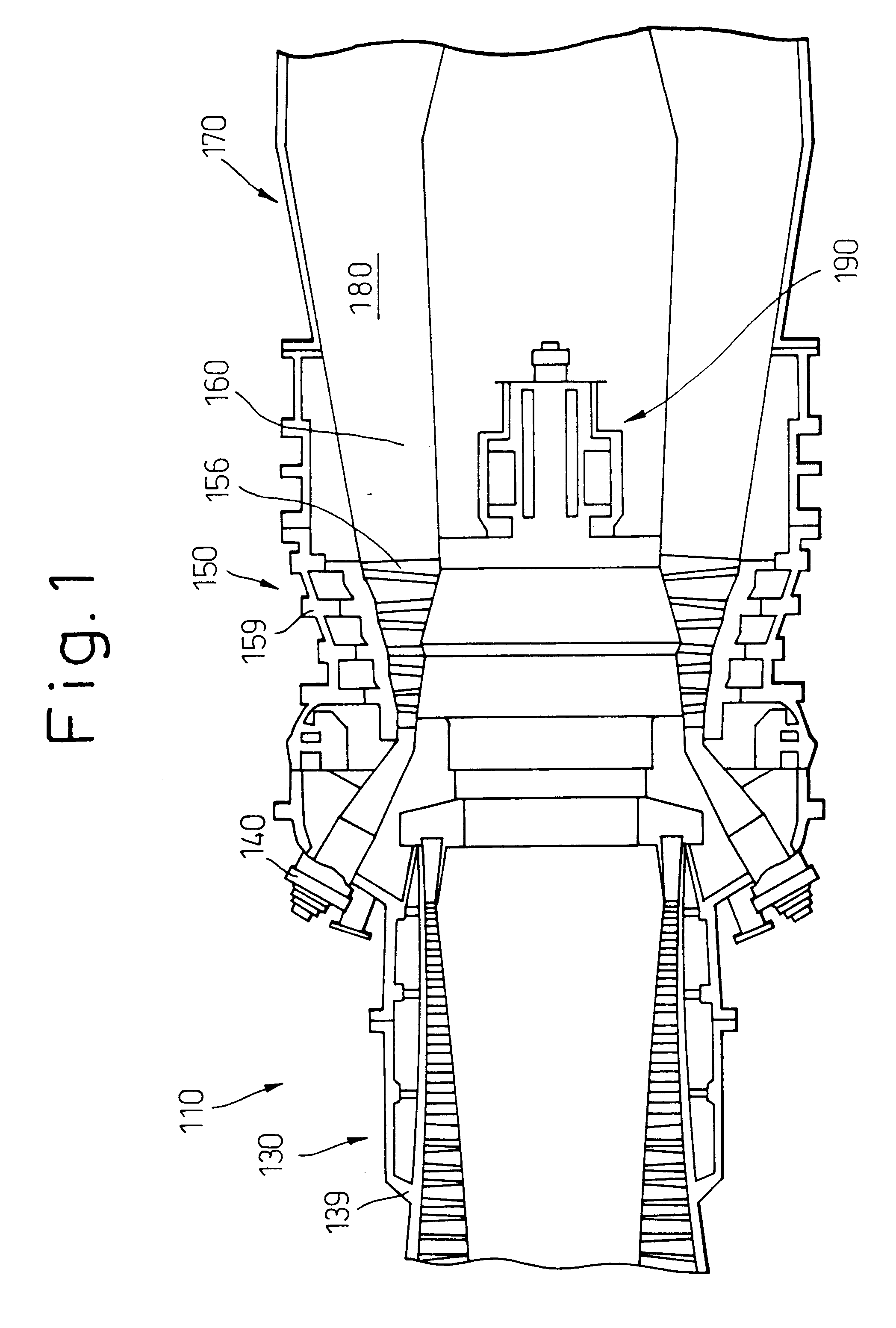

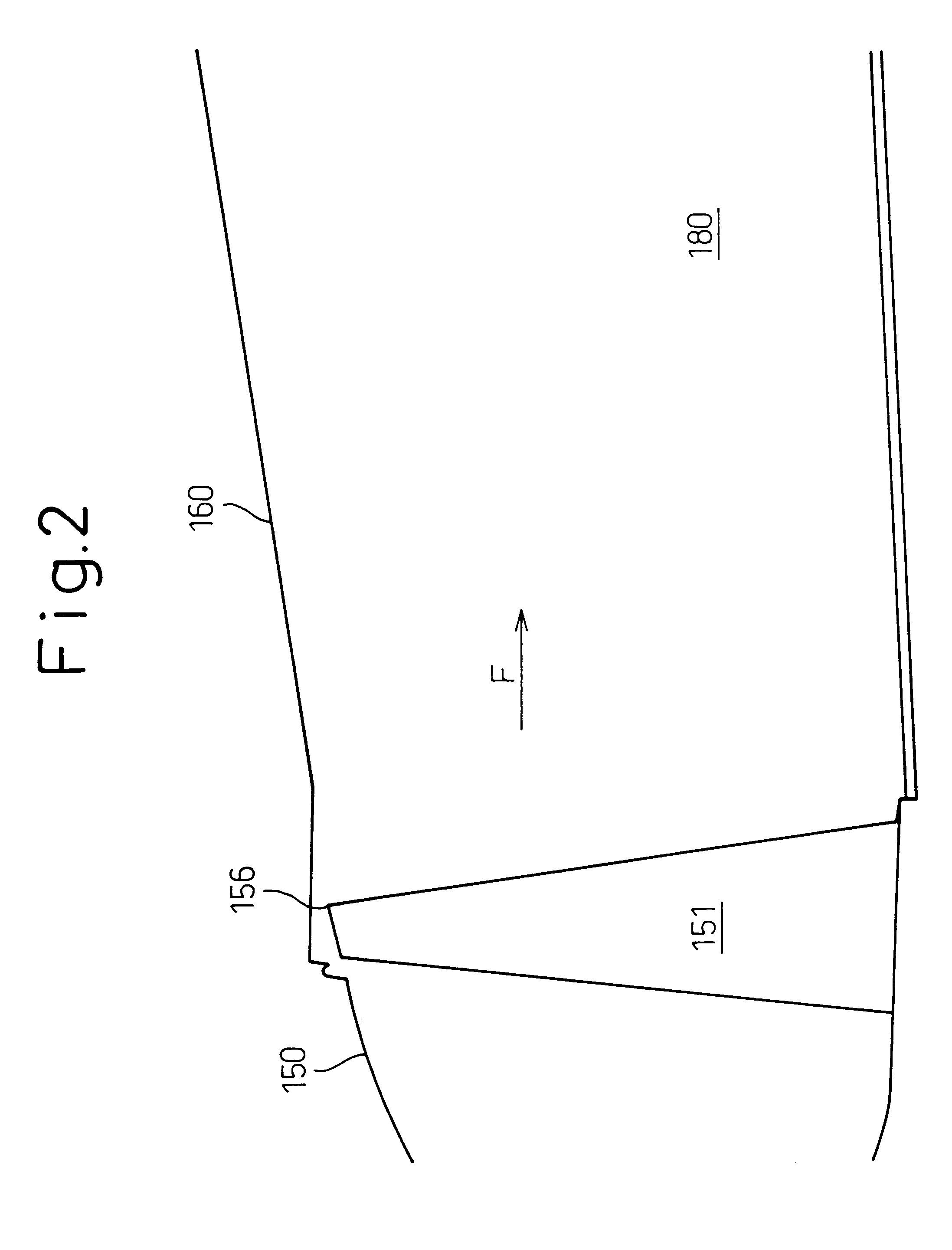

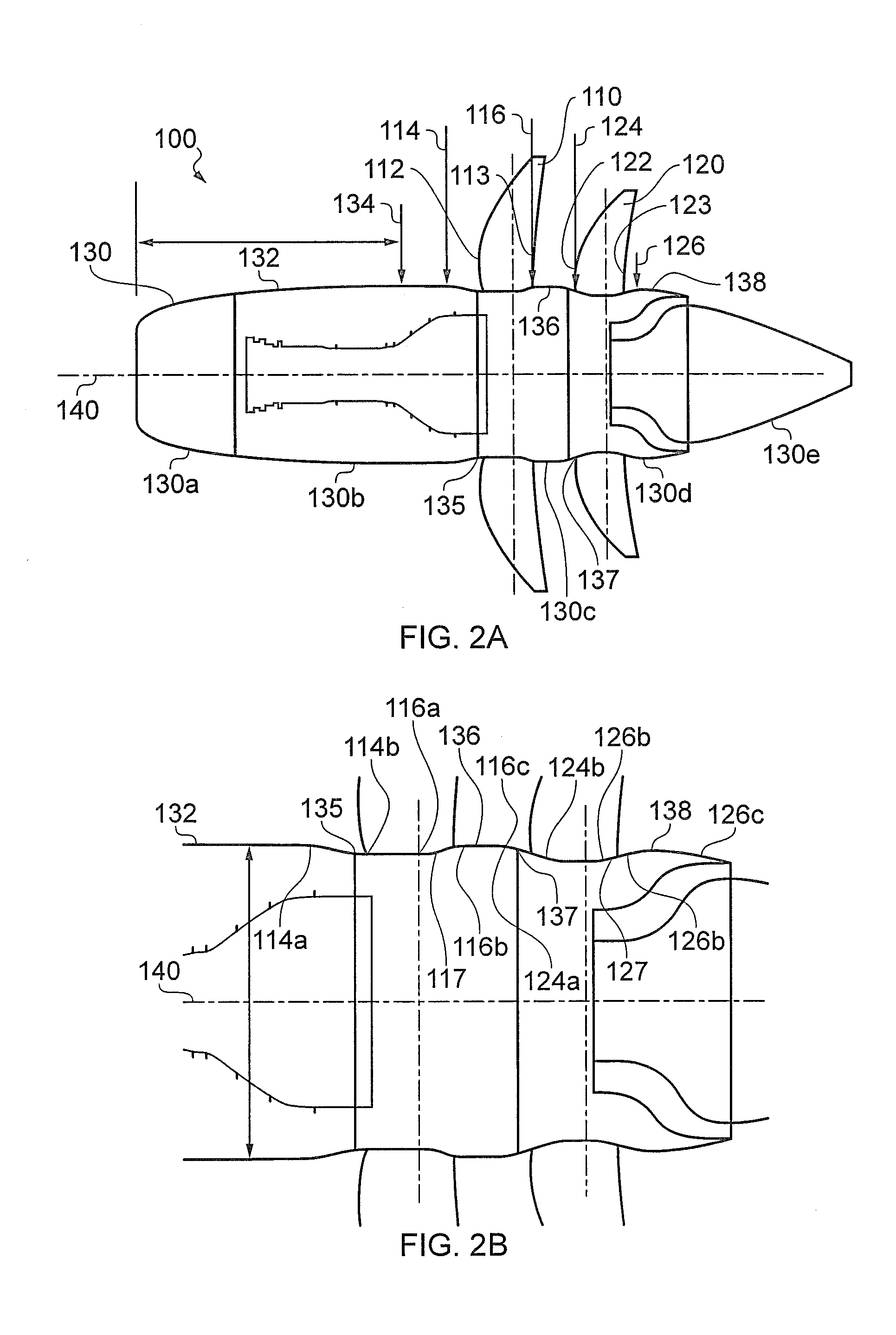

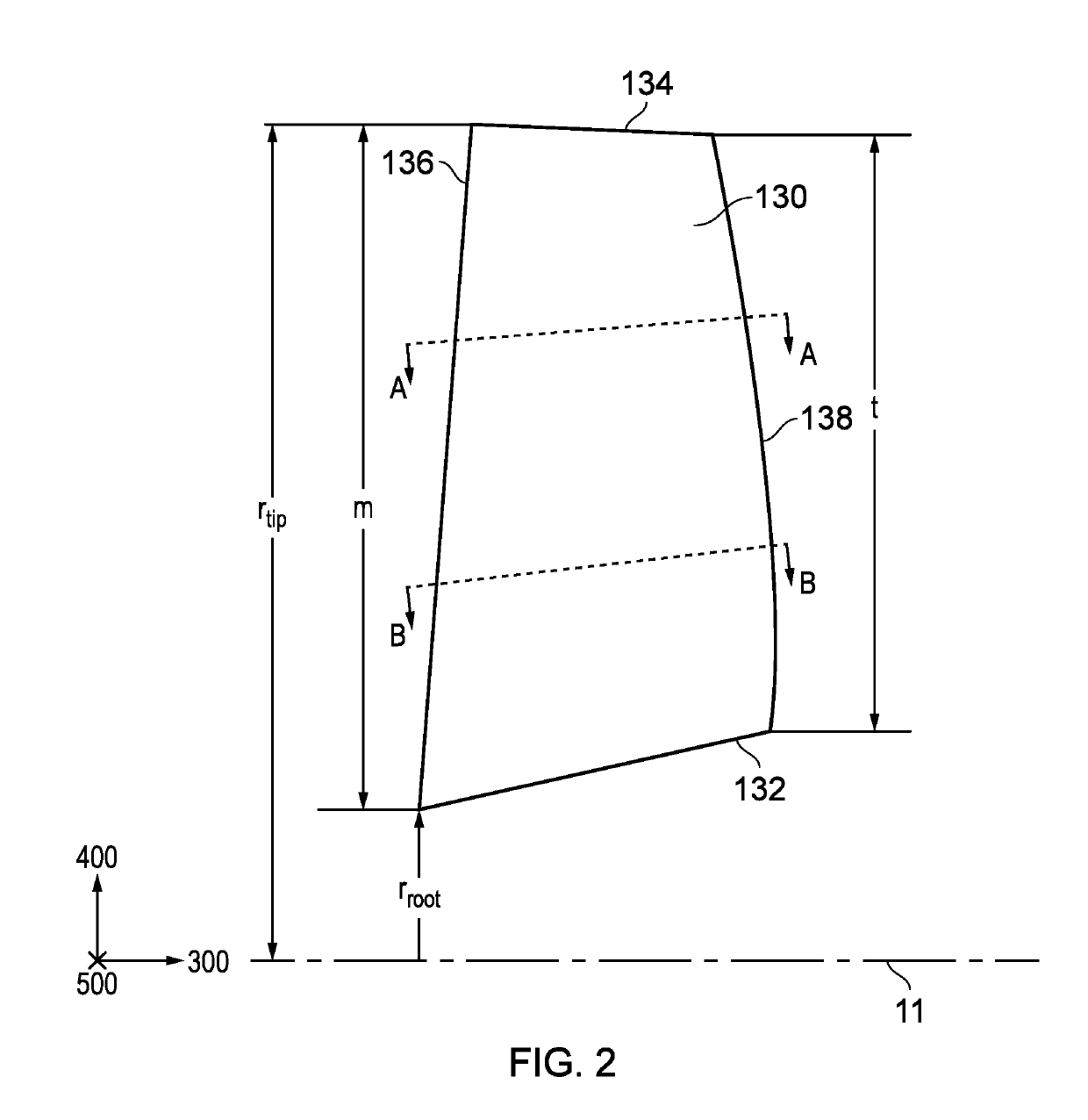

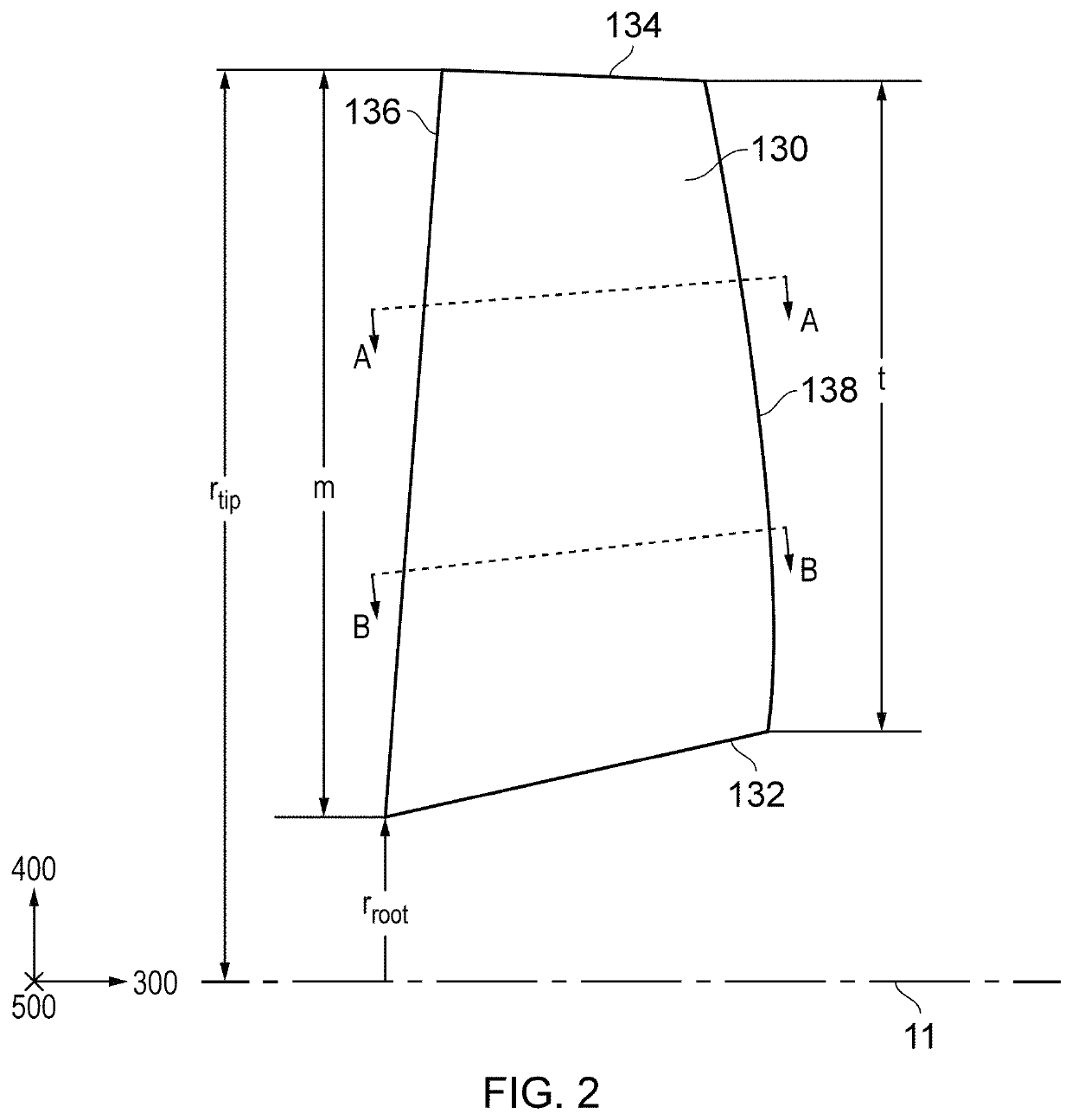

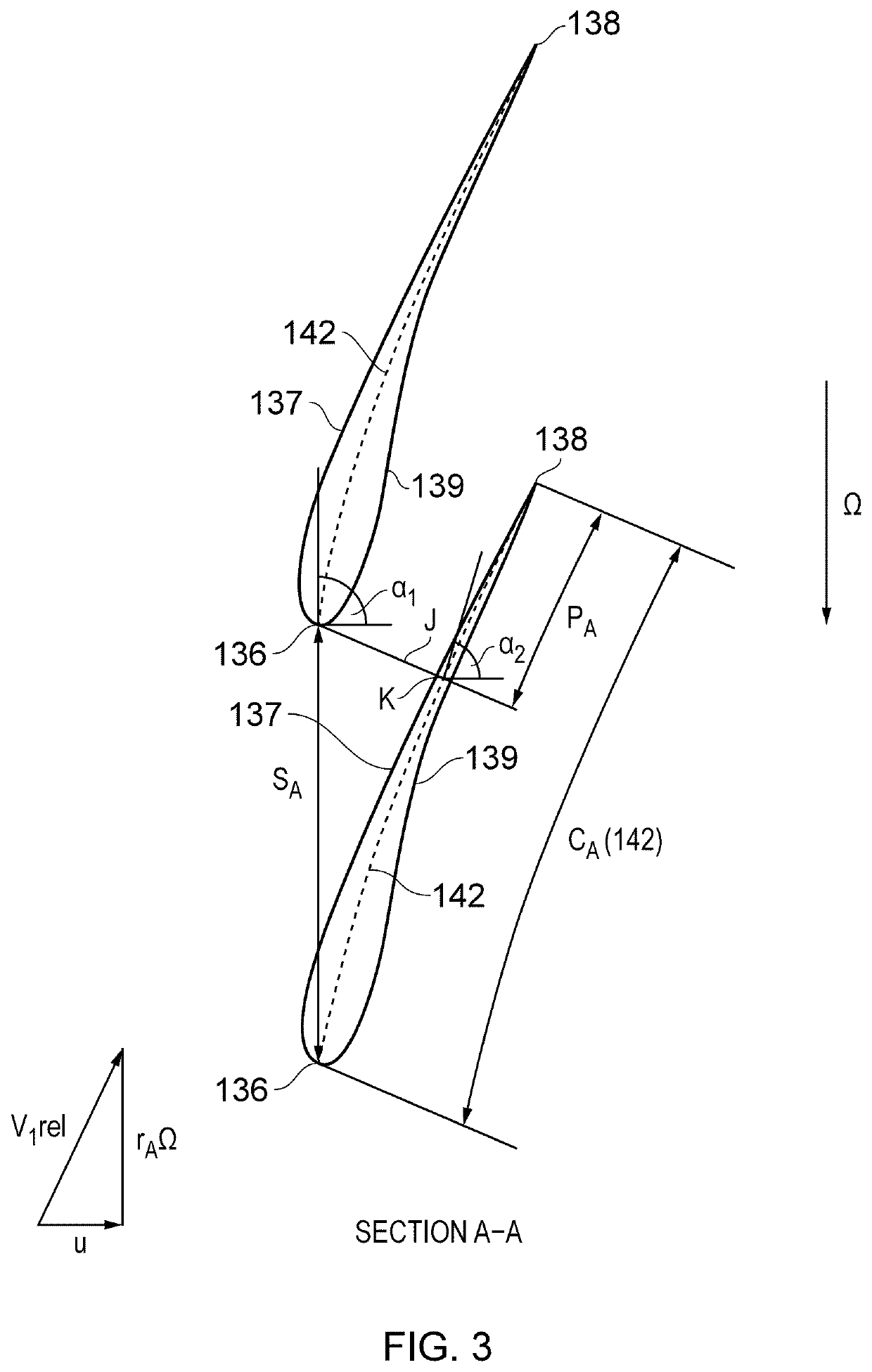

Gas turbine engine

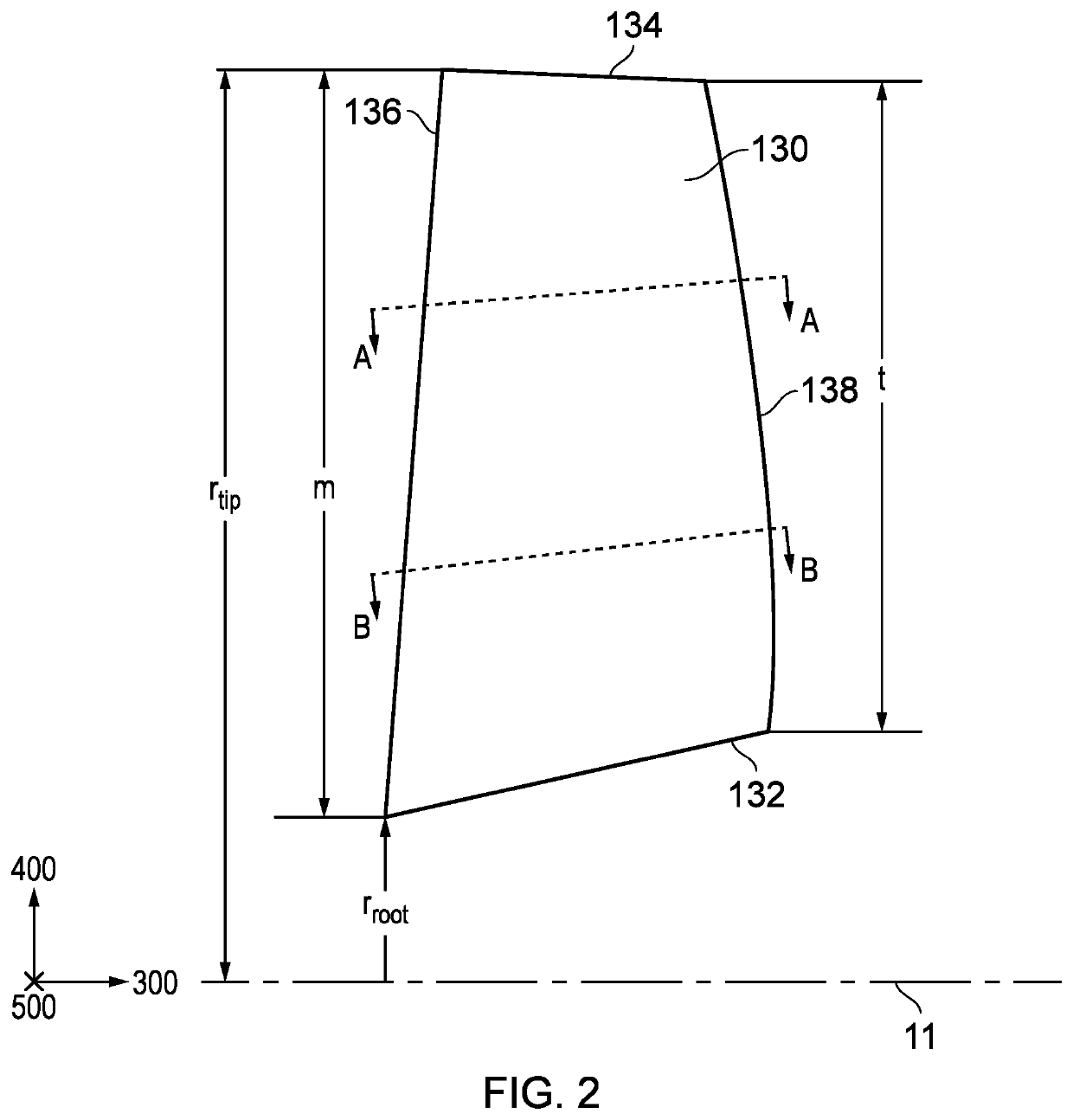

ActiveUS20190162070A1Easy to operateIncrease arcEngine manufactureEngine fuctionsFan bladeGas turbines

A gas turbine engine 10 is provided in which a fan having fan blades 139 in which the camber distribution relative to covered passage of the fan 13 allows the gas turbine engine to operate with improved efficiency when compared with conventional engines, whilst retaining an acceptable flutter margin.

Owner:ROLLS ROYCE PLC

Gas turbine engine

ActiveUS20190162071A1Easy to operateIncrease arcEngine manufactureEngine fuctionsCamber angleFan blade

A gas turbine engine 10 is provided in which a fan having fan blades 139 in which the camber distribution relative to covered passage of the fan 13 allows the gas turbine engine to operate with improved efficiency when compared with conventional engines, whilst retaining an acceptable flutter margin.

Owner:ROLLS ROYCE PLC

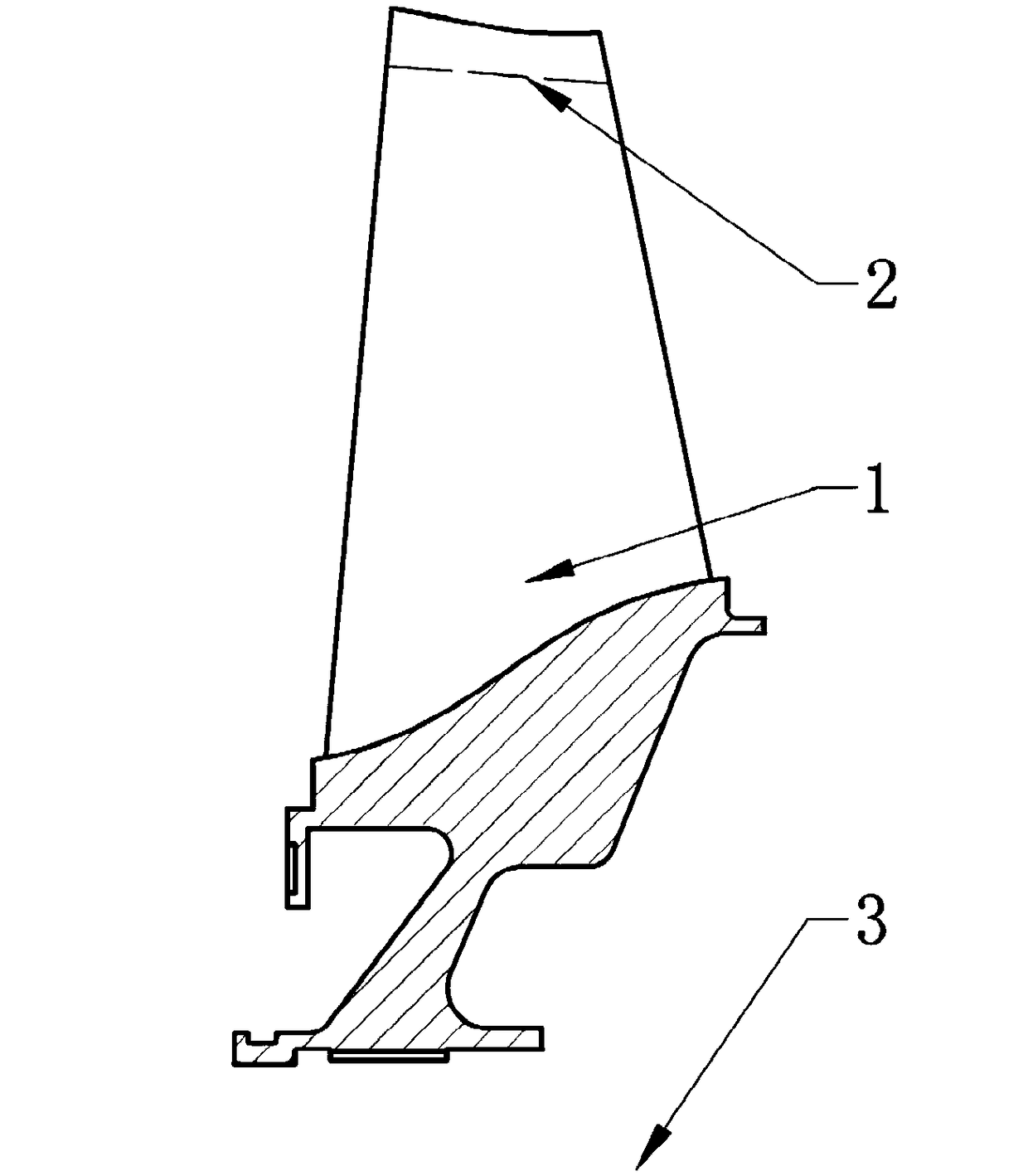

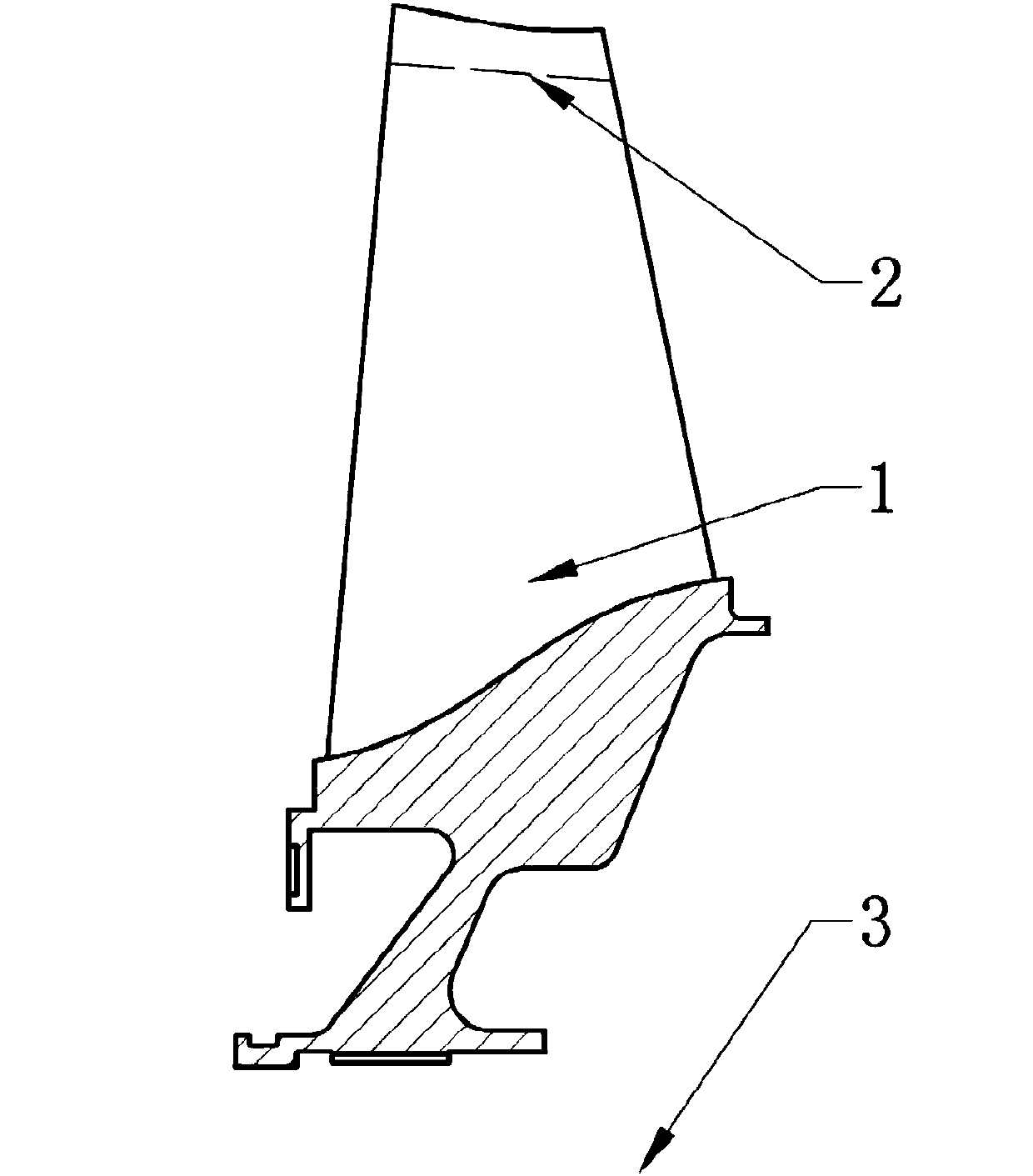

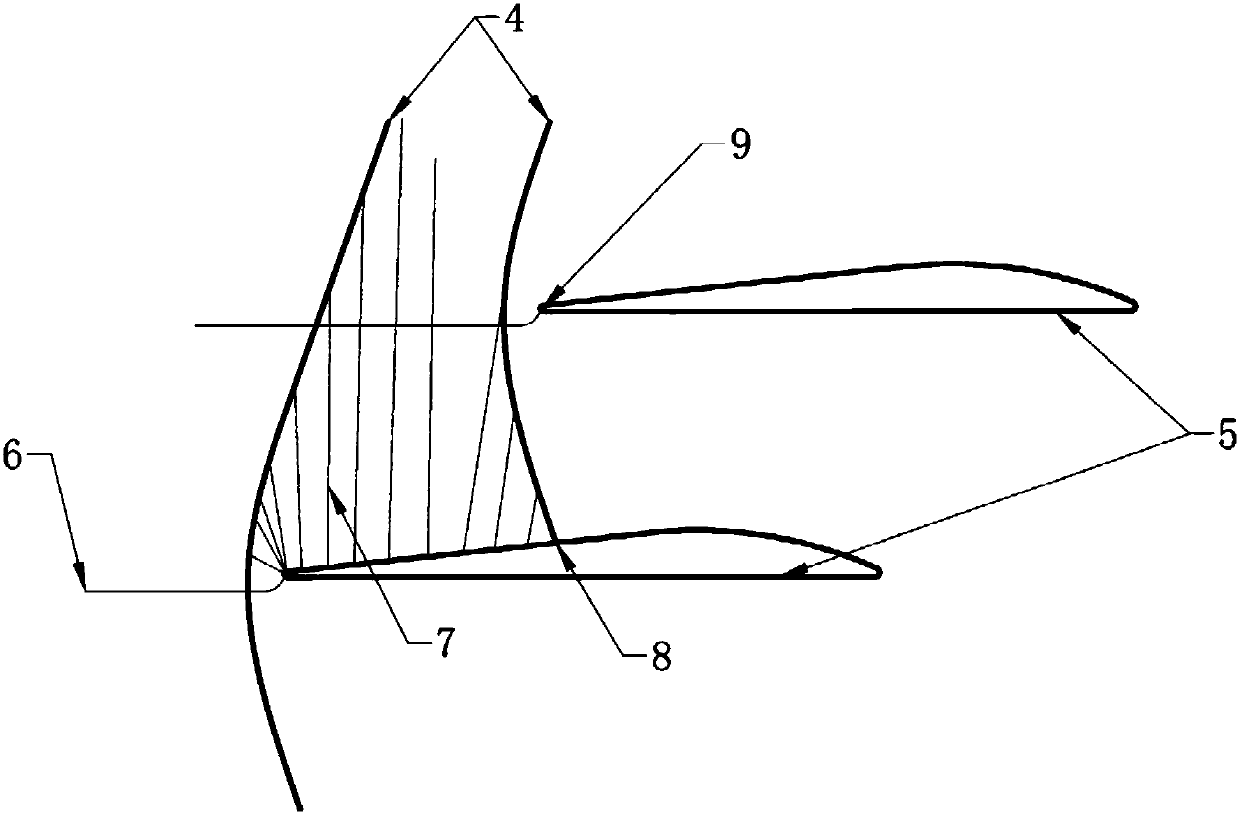

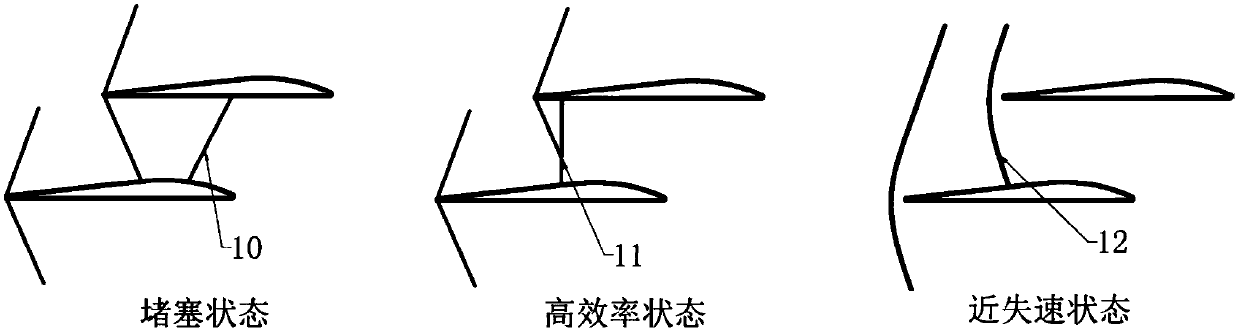

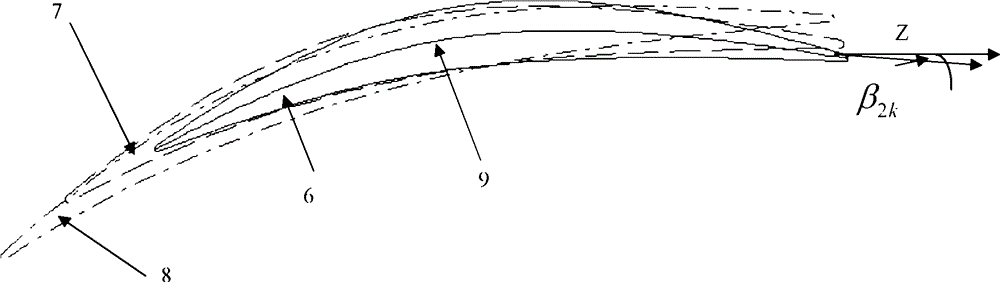

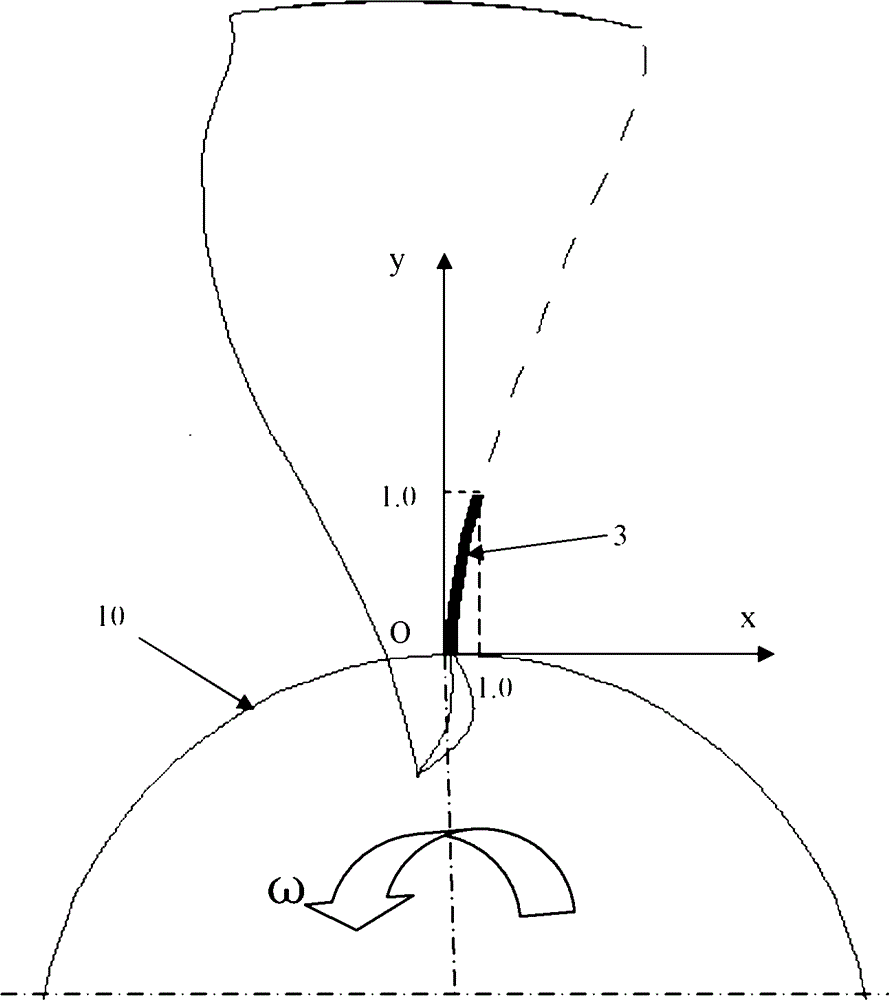

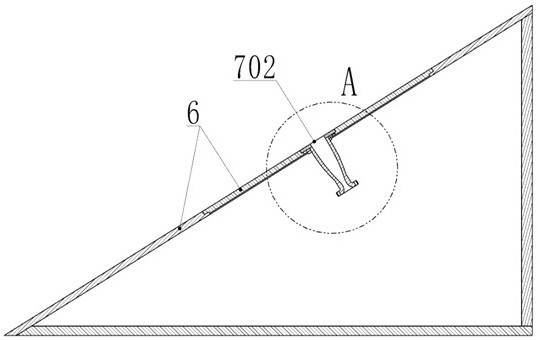

A sharpened leading edge structure and design method of a transonic fan blade top primitive blade profile

ActiveCN107869482BIncrease stall marginImprove efficiencyPump componentsPumpsEffective radiusFan blade

The invention relates to a front edge design method of a transonic speed fan blade top primitive blade profile. The front edge design method comprises the steps that a reference point distant from anoriginal front edge by a certain length is obtained on a suction surface of a blade top original primitive blade profile; a linear section is made by passing the reference point, wherein a certain included angle is formed between the original suction surface and the linear section; and the linear section is connected with an original pressure surface by an arc section with a small radius, the other end of the linear section is in smooth transition with the original suction surface by a chamfer, and the axial positions of a new blade front edge and an old blade front edge are kept unchanged. Since the front edge of the blade top original primitive blade profile is subjected to sharpening treatment and the effective radius of the front edge is reduced, shock wave detachment may be delayed, and the surge-to-stall margin of a fan can be improved advantageously. In addition, with the introduction of a sharpening structure, an expansion wave at the blade front edge is split into two parts, wherein one part is an expansion wave triggered by the front edge radius and the other part is an expansion wave triggered by the transition part of the linear section and the suction surface, so thatthe mach number before a channel shock wave can be lowered advantageously, and the efficiency of the blade top original primitive blade profile is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Wide-speed-range air inlet channel design method based on double-incidence bending shock waves

ActiveCN113153529AFeature length shortenedGuaranteed performanceSustainable transportationGas turbine plantsInlet channelEngineering

The invention discloses a wide-speed-range air inlet channel design method based on double-incidence bending shock waves. The method comprises the following steps of designing a double-incidence bending shock wave reference flow field based on the bending shock wave theory; designing an air inlet channel initial throat section molded line, and performing reverse flow streamline tracking in the reference flow field to obtain an initial air inlet channel compression molded surface; designing an air inlet channel isolation section outlet section, expanding an air inlet channel initial throat section in a double-S-bend form, and stretching in an equal-straight manner to obtain a three-dimensional inward-turning wide-speed-range air inlet channel isolation section; carrying out wall surface fairing and viscosity correction; taking the tail end of a first-stage compression molded surface of an air inlet channel as the rotating shaft position of a first-stage splitter plate, and taking the length of a second-stage compression molded surface as the length of the first-stage splitter plate; taking the position where the second derivative of an upper wall curve of the air inlet isolation section is zero, taking the position as the position of a second-stage splitter plate rotating shaft, and taking the length from the second-stage splitter plate rotating shaft to the air inlet channel initial throat section as the length of the second-stage splitter plate; and designing a discharge port area under the Mach number and a throat area under the Mach number. Expansion waves at the position of the rotating shaft can be eliminated; and performance requirements are met.

Owner:XIAMEN UNIV

Sharpened front edge structure and front edge design method of transonic speed fan blade top primitive blade profile

ActiveCN107869482AIncrease stall marginReduce the Mach numberPump componentsPumpsEffective radiusEngineering

The invention relates to a front edge design method of a transonic speed fan blade top primitive blade profile. The front edge design method comprises the steps that a reference point distant from anoriginal front edge by a certain length is obtained on a suction surface of a blade top original primitive blade profile; a linear section is made by passing the reference point, wherein a certain included angle is formed between the original suction surface and the linear section; and the linear section is connected with an original pressure surface by an arc section with a small radius, the other end of the linear section is in smooth transition with the original suction surface by a chamfer, and the axial positions of a new blade front edge and an old blade front edge are kept unchanged. Since the front edge of the blade top original primitive blade profile is subjected to sharpening treatment and the effective radius of the front edge is reduced, shock wave detachment may be delayed, and the surge-to-stall margin of a fan can be improved advantageously. In addition, with the introduction of a sharpening structure, an expansion wave at the blade front edge is split into two parts, wherein one part is an expansion wave triggered by the front edge radius and the other part is an expansion wave triggered by the transition part of the linear section and the suction surface, so thatthe mach number before a channel shock wave can be lowered advantageously, and the efficiency of the blade top original primitive blade profile is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

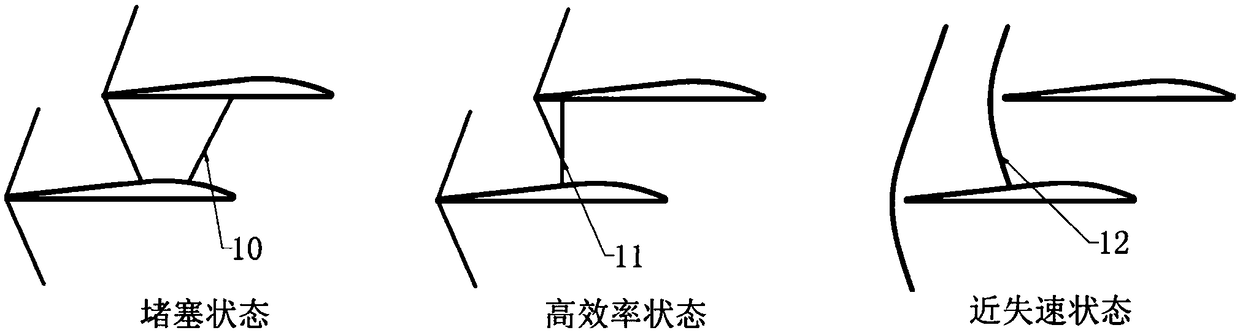

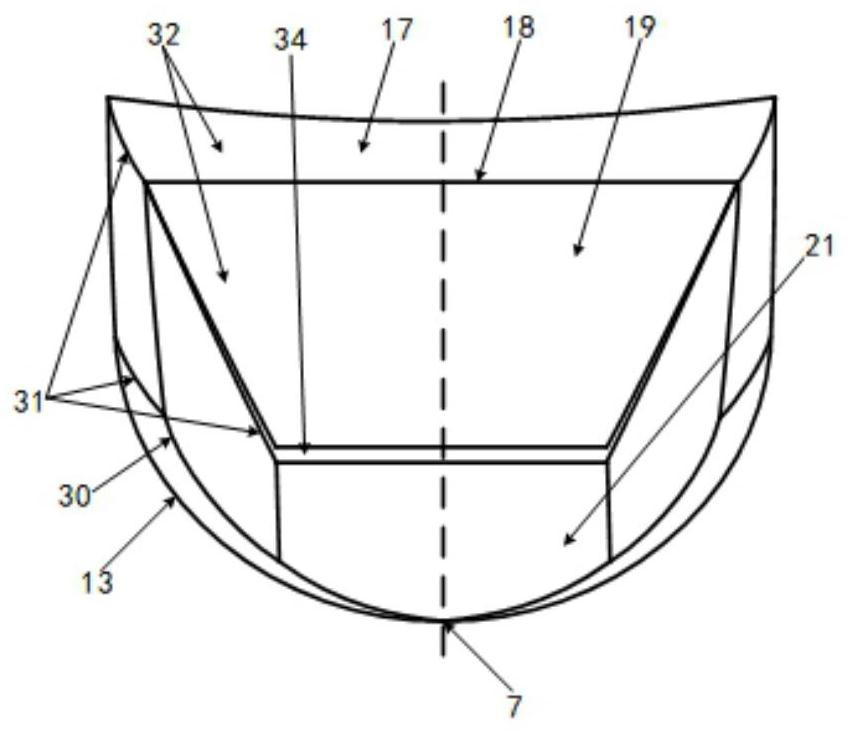

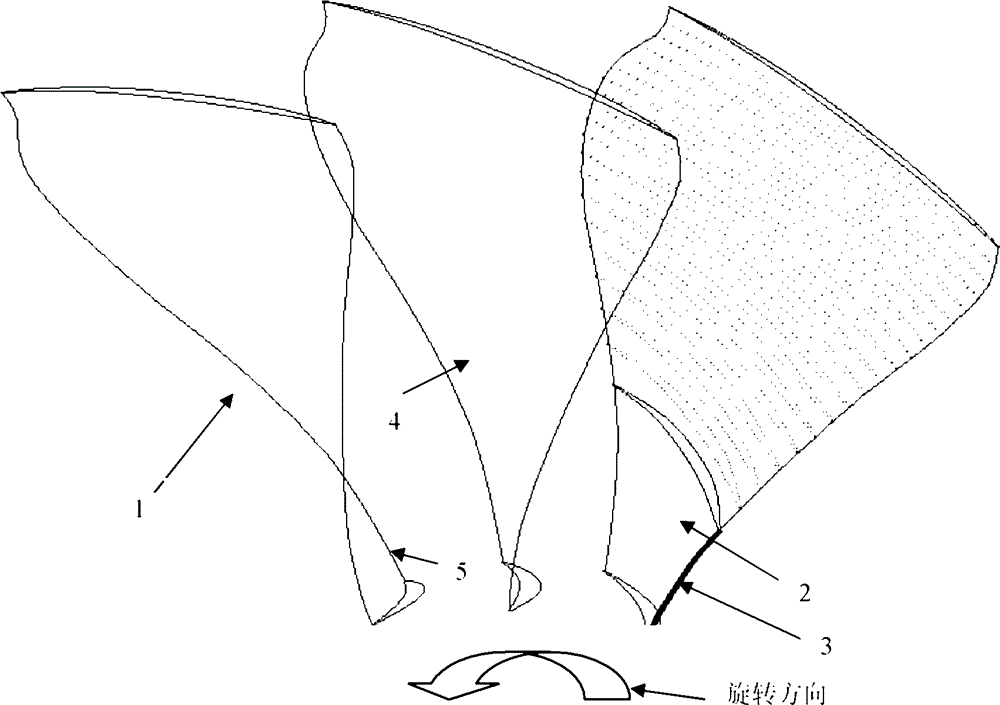

Pneumatic and structural feature considered three-dimensional geometric structure of fan blade of aircraft engine

InactiveCN102536327BImprove efficiencyReduce the Mach numberBlade accessoriesMachines/enginesAviationAcute angle

The invention discloses a pneumatic and structural feature considered three-dimensional geometric structure of a large fan connotative blade of a civil aircraft engine. The rear section of a blade profile at the root part of the large fan which is designed traditionally has a larger bent corner, a smaller acute angle is formed by a trailing edge suction surface and a hub, low-energy gas is accumulated in the acute-angle area, the flow loss is great, and the smaller acute angle between the suction surface and the hub is not beneficial to the structure modeling of the root stretching section of the blade. According to the invention, the change of an outlet metal corner of an element blade profile of the large fan connotative blade (which is the part within 20% of a blade height of the large fan blade) along the blade height is mainly optimized and a distribution curve of the outlet metal corner of a connotative blade and a projection curve of a trailing edge line in a plane vertical to the axial direction are fit. Through the verification of three-dimensional CFD (Computational Fluid Dynamics), the pneumatic and structural feature considered three-dimensional geometric structure disclosed by the invention has the advantages that the flow separation in the acute-angle area formed by the trailing edge suction surface of the fan and the hub can be effectively reduced, the fan connotative efficiency can be increased, a good entrance condition is provided for a pressure boosting grade, and the blade at the root part and the hub are relatively almost vertical, so that convenience is provided for the installation of the blade on a wheel disc.

Owner:BEIHANG UNIV

Gas turbine engine

Owner:ROLLS ROYCE PLC

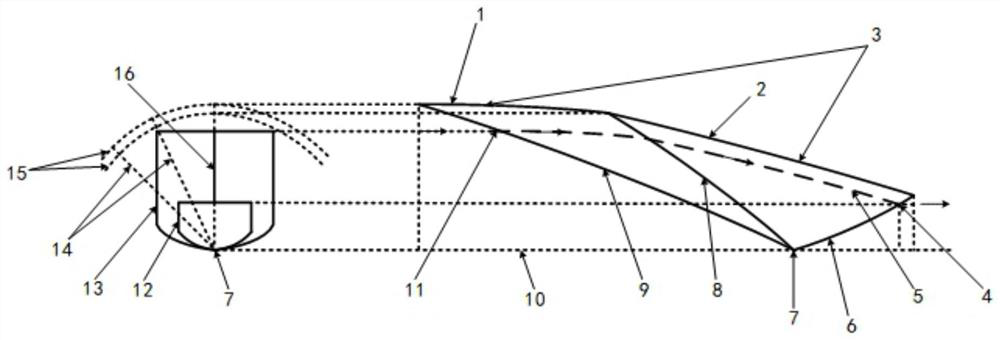

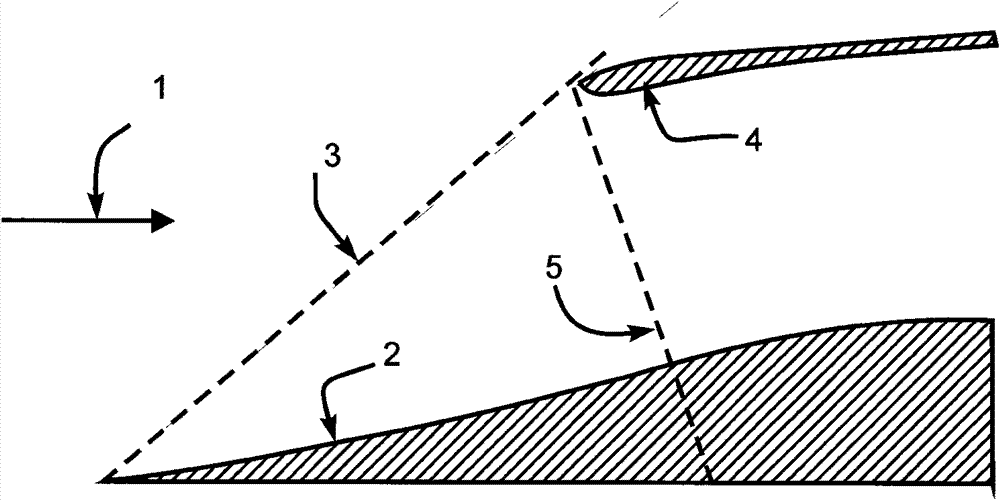

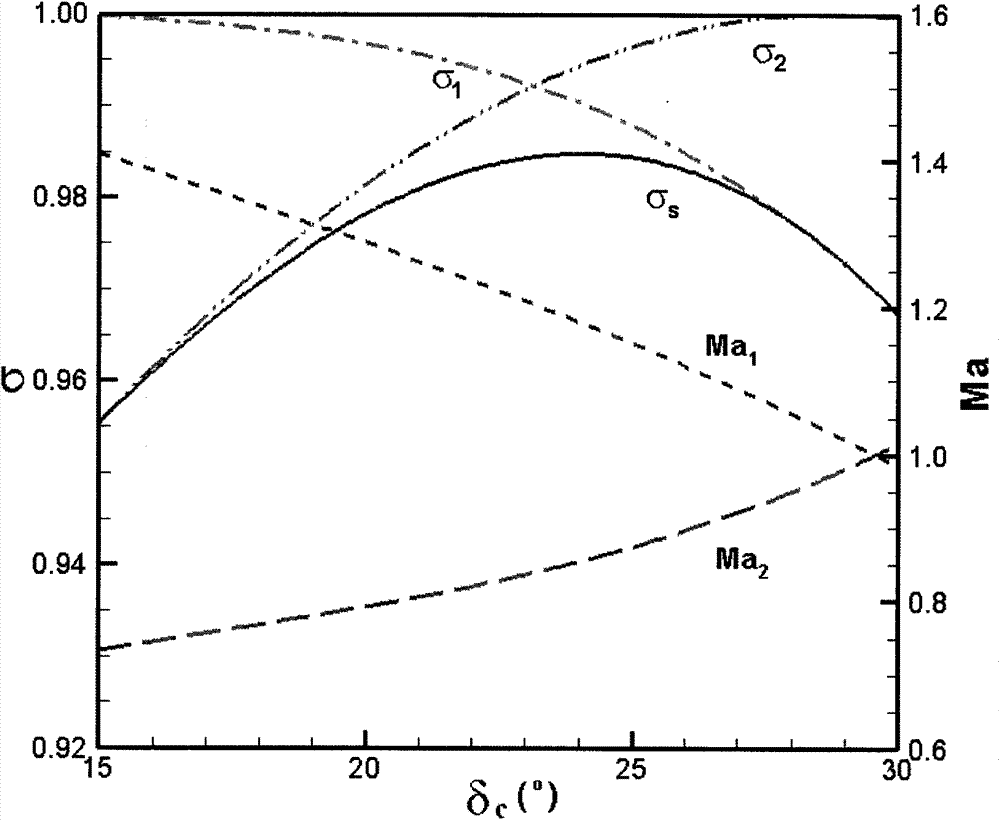

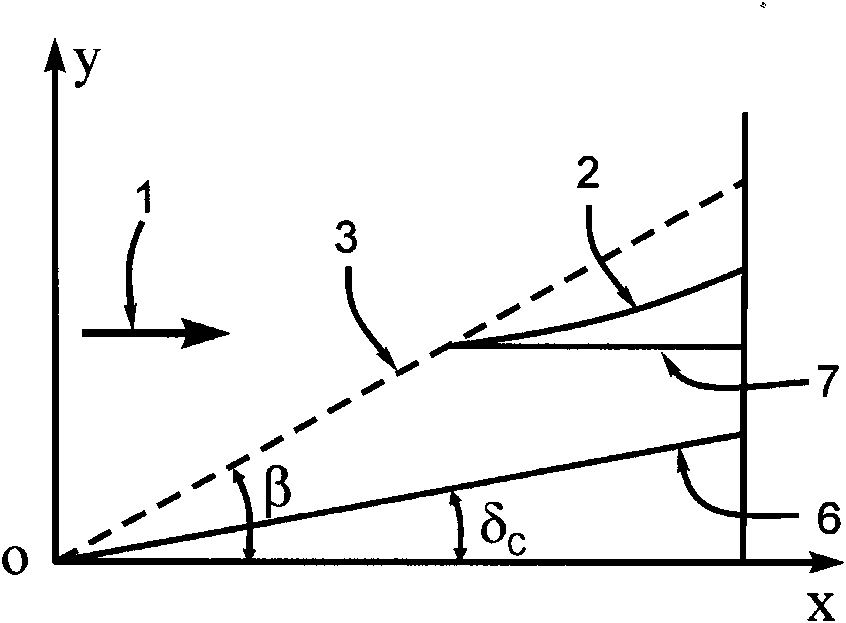

Bump air inlet method for realizing integration of unequal-strength wave system with forebody

InactiveCN101813027BReduce the Mach numberImprove performanceTurbine/propulsion air intakesShock waveEngineering

The invention provides a bump air inlet method for realizing integration of an unequal-strength wave system with a forebody, relating to the technical field of ultrasonic air inlet. The method comprises the following steps that: 1, an air inlet wave system adopts an external-compression double wave system structure based on an unequal-strength system, and the total pressure recovery coefficient sigma=sigma1*sigma2, wherein the sigma1 and the sigma2 are total pressure recovery coefficients of a conical shock wave and a normal shock wave; 2, a cone with a semi-cone angle delta c formed by the conical shock wave generates a second conical shock wave with second semi-cone angle beta in ultrasonic flow; 3, the bump height of the air inlet is h, the h / delta is 2-2.5 when the local boundary layer thickness is delta, the bump compressive plane generated in the step 2 is scaled to meet the requirement of an actual size; and 4, the lip of the air inlet adopts a conformal and sweepback lip design. The method realizes reduction of throat Mach number of the air inlet, improves the air inlet performance to ensure that the lip sweepback angle of the air inlet, the maximum turning angle of the bump compressive plane and the inlet normal shock wave angle are consistent, can increase the curve of the total pressure recovery coefficient, and reduces resistance coefficient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

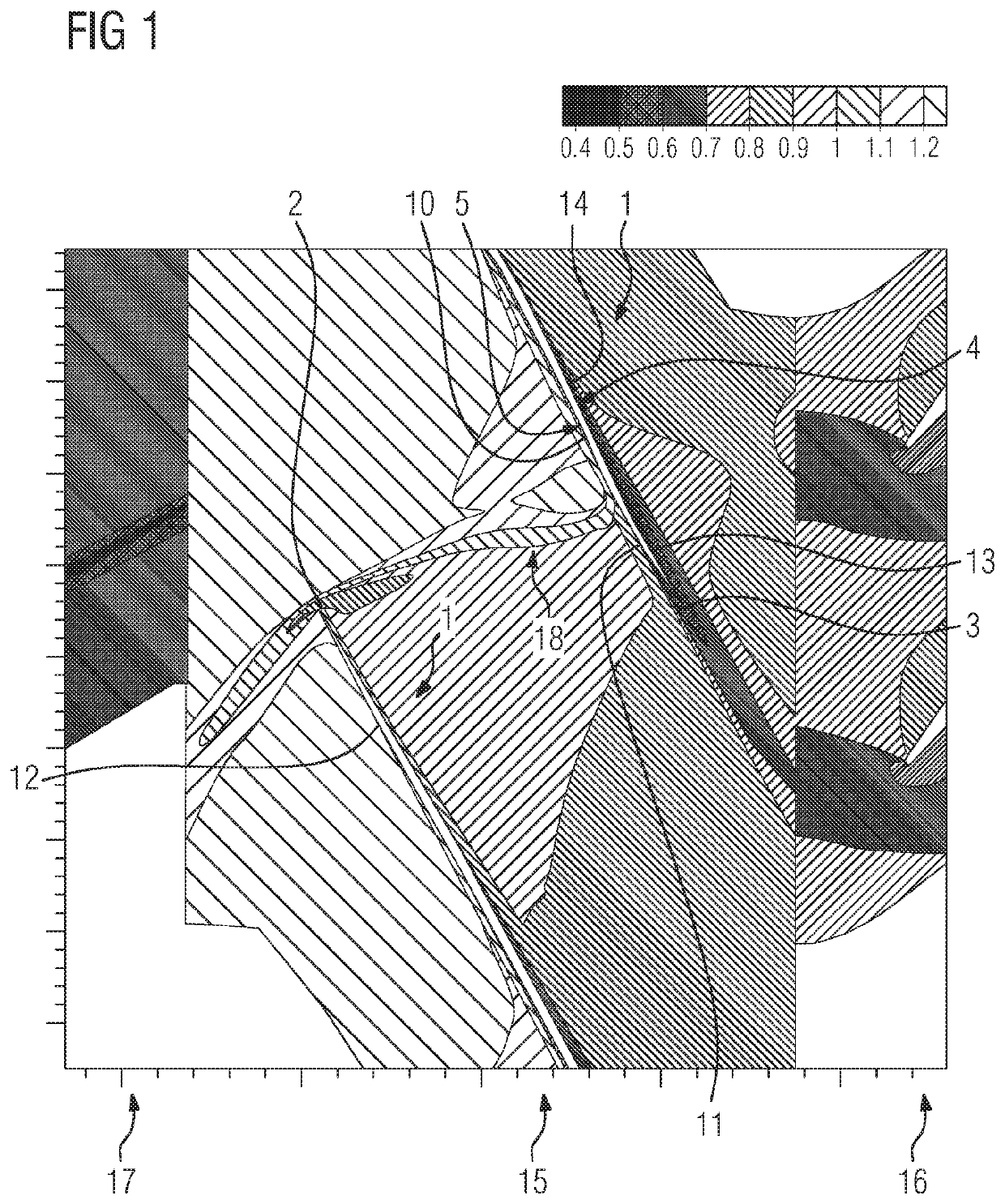

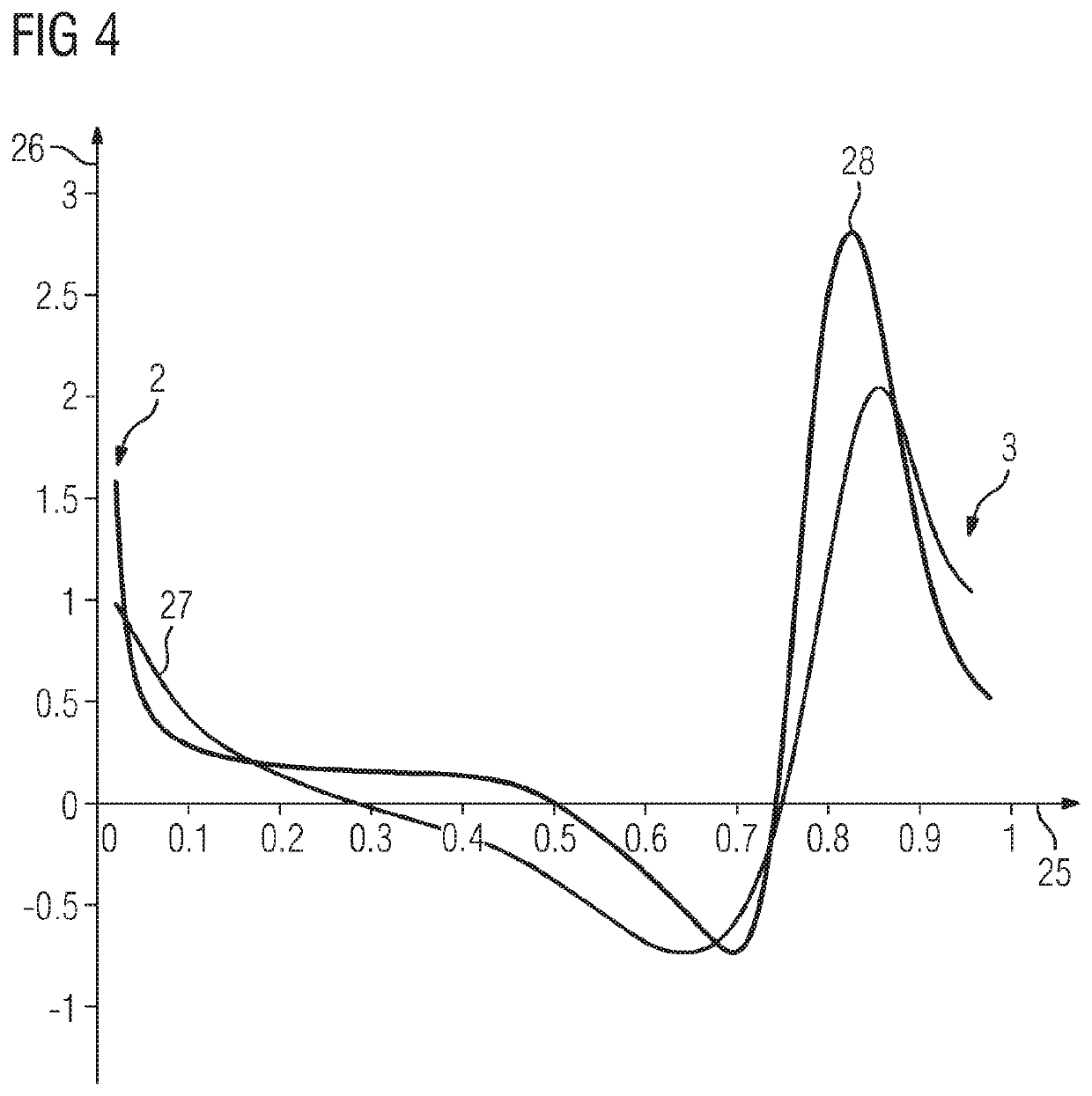

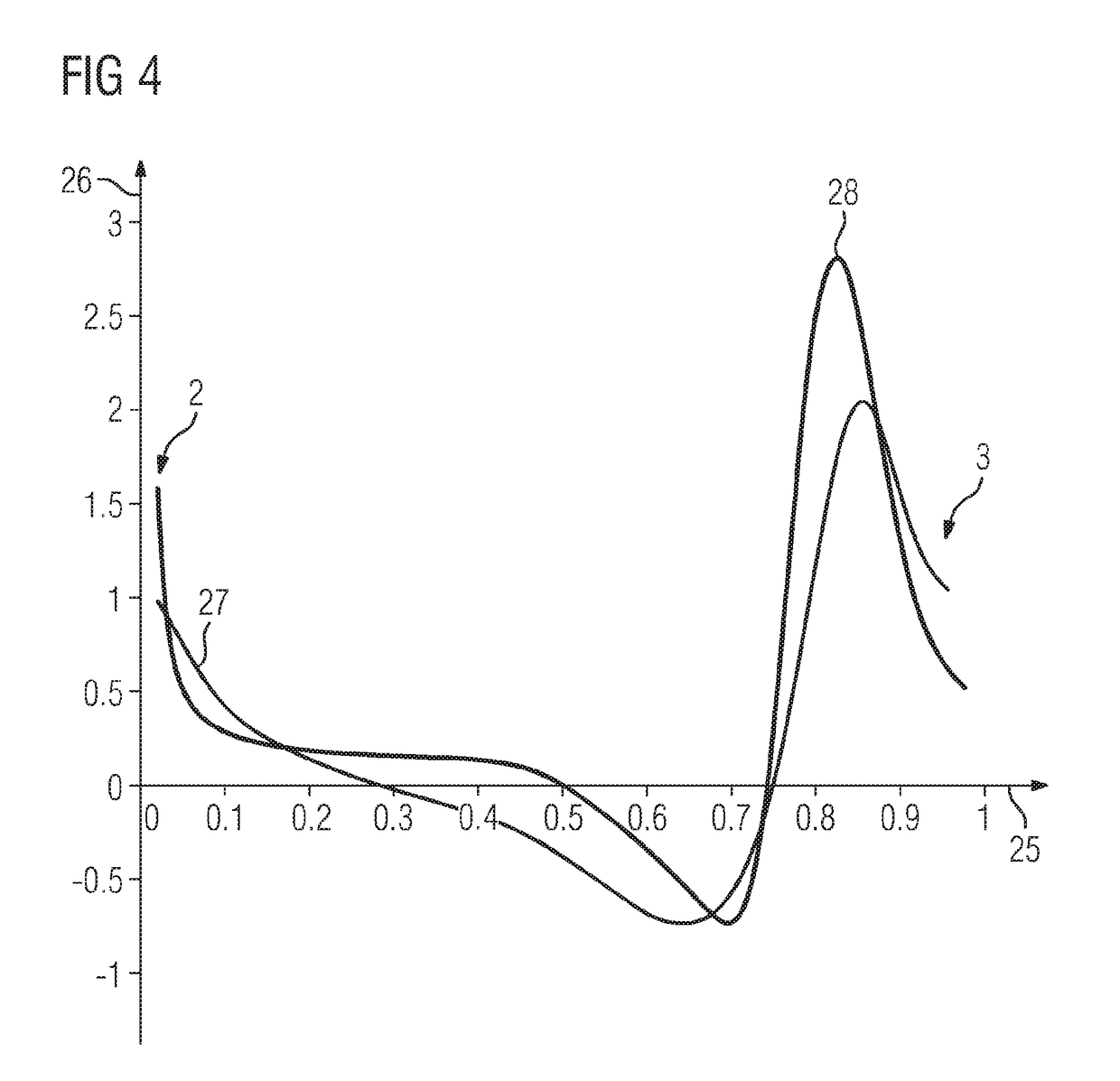

Compressor rotor blade, compressor, and method for profiling the compressor rotor blade

ActiveUS10837450B2Improve efficiencyWithout loss in degree of efficiencySupersonic fluid pumpsPump componentsSuction forceEngineering

A compressor rotor blade for an axial-type compressor has a blade profile having a transonic section and a profile section which extends in the transonic section and has concave and convex suction-side regions on the suction side, the convex suction-side region arranged downstream of the concave suction-side region, and has convex and concave pressure-side regions on the pressure side, the concave pressure-side region arranged downstream of the convex pressure-side region. Curvature progressions on the pressure side and on the suction side are both applied in a continuous manner over a profile chord of the profile section, the positions of the minimum values of the curvature progressions deviate from each other by not more than 10% of the length of the profile chord, and the positions of the maximum values of the curvature progressions deviate from each other by not more than 10% of the length of the profile chord.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

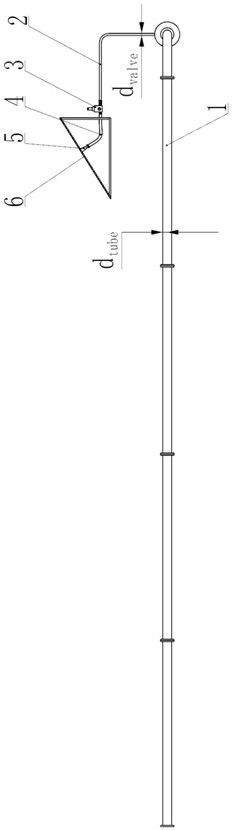

A transient jet test device for pulse wind tunnel

ActiveCN113884267BReduce deviationReduce the Mach numberAerodynamic testingJet flowSynchronous control

The invention discloses a transient jet flow test device used in a pulse wind tunnel. The transient jet flow test device includes a jet flow test model, an air source supply system, a fast synchronous control system and a jet flow parameter measurement device; the jet flow test model ejects a stable jet flow; the air source supply system provides the required Stable air source, fast synchronous control system to ensure that the formation time of the stable jet flow is synchronized with the formation time of the main flow of the pulse wind tunnel; at the same time, the air source supply system ensures that the duration of the stable jet flow exceeds the effective test time of the main flow of the pulse wind tunnel, and the fast synchronous control system is in The air source supply system is automatically turned off after the set stable jet flow time is reached; the jet flow parameter measuring device is used to measure the flow field parameters of the stable jet flow from the model before the jet flow test. The transient jet flow test device can provide jet flow with accurate parameters, good stability and repeatability to evaluate the influence of jet flow disturbance on the aerodynamic characteristics of the aircraft, and can quickly complete the jet flow preparation and accurately control the injection time.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

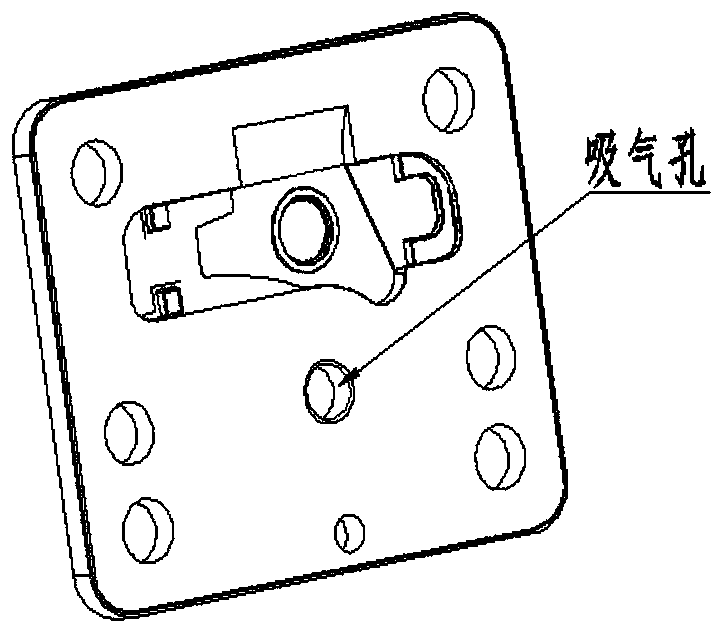

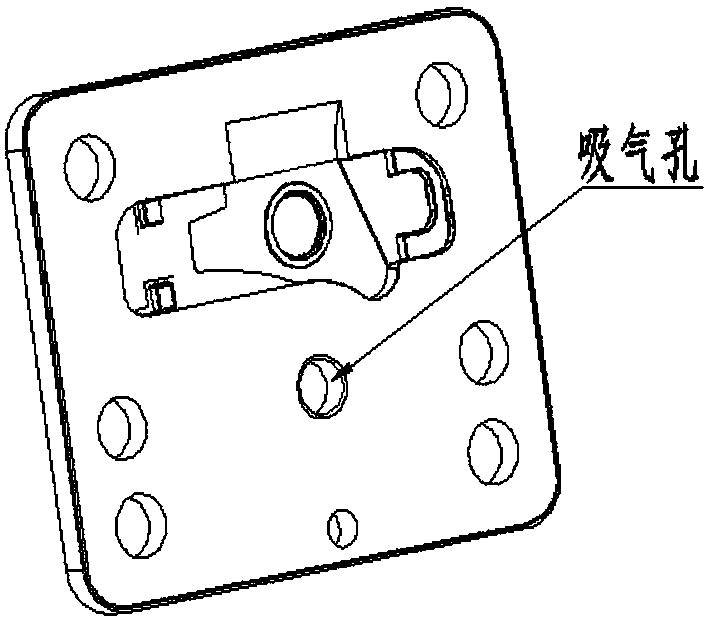

Manufacturing method of high-efficiency and low-noise piston compressor valve plate

ActiveCN108194325BReduce shockReduce noisePositive displacement pump componentsPositive-displacement liquid enginesLow noiseCompression molding

The invention discloses a method for manufacturing a valve plate of a high-efficiency and low-noise piston compressor. The compressor includes a cylinder head assembly, wherein a crescent-shaped suction port is arranged on the valve plate, and the crescent-shaped suction port is a crescent-shaped suction port. through hole. The valve plate is a powder metallurgical part; the manufacturing process of the valve plate is: mixing powder; molding with a mold; high temperature sintering; shaping; inspection; steam treatment. With the above technical solution, the pressure loss is reduced, and the energy efficiency ratio of the compressor is improved; the airflow velocity at the air inlet becomes smaller, the opening of the valve plate becomes slower, and the displacement of the valve plate becomes smaller; at the same time, the lift of the valve plate is reduced, reducing the The impact of the plate on the limit plate and the valve seat reduces the noise of the valve plate from the source; in addition, the displacement of the valve plate is reduced, the stress on the waist of the valve plate is reduced, the area of the dangerous stress area of the valve plate is reduced, and the valve plate is reliable. Enhanced performance; improved energy efficiency ratio, reduced airflow noise and improved compressor reliability.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

Gas turbine engine with optimized fan blade geometry

ActiveUS20210172323A1Easy to operateIncrease arcEngine manufactureEngine fuctionsFan bladeControl theory

A gas turbine engine 10 is provided in which a fan having fan blades 139 in which the camber distribution relative to covered passage of the fan 13 allows the gas turbine engine to operate with improved efficiency when compared with conventional engines, whilst retaining an acceptable flutter margin.

Owner:ROLLS ROYCE PLC

Manufacturing method of high-efficiency low-noise piston compressor valve plate

ActiveCN108194325AReduce shockReduce noisePositive displacement pump componentsPositive-displacement liquid enginesLow noiseCompression molding

The invention discloses a manufacturing method of a high-efficiency low-noise piston compressor valve plate. A compressor comprises an air cylinder head assembly, wherein a crescent-shaped air suctionport is formed in the valve plate and is a crescent-shaped through hole; and the valve plate is a powder metallurgical part. The technological process of the valve plate manufacturing method comprises the steps of powder mixing, compression molding through a die, high temperature sintering, shaping, inspection and steam treatment. By adopting the above technical scheme, pressure losses are reduced, and the compressor energy efficiency ratio is increased; the airflow velocity at an air inlet is decreased, a valve block is opened in a slow-down mode, and valve block displacement is reduced; meanwhile, the valve block lift is reduced, impact to a limiting plate and a valve seat is reduced, and noise of the valve block is reduced from the source; in addition, valve block displacement is reduced, stress to the waist of the valve block is reduced, thus, the critical stress zone area of the valve block is decreased, and the reliability of the valve block is improved; and the energy efficiency ratio is increased, airflow noise is reduced, and the reliability of the compressor is improved.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

Inlet stage blade assemblies for compressors and axial flow compressors incorporating same

ActiveCN113339325BIncrease stall marginReduce the Mach numberPump componentsPumpsMarine engineeringStructural engineering

The invention discloses an inlet-stage blade assembly for a compressor and an axial-flow compressor containing the same. The inlet-stage blade assembly includes an inlet guide vane and a first-stage moving blade, and the inlet guide vane has the largest trailing edge metal angle. The position is the first position, and the relative blade height T at the first position satisfies 0.8≤T≤0.9; The airfoil section at the second position of T has a second chord length, and the first chord length is 3%~10% longer than the second chord length; between the second position and the tip of the first-stage moving blade, the first chord length The forward or backward sweep of the stacking axis of the first-stage rotor blade shall not exceed 1% of the absolute blade height of the first-stage rotor blade. Adopting the above structure can improve the stall margin of the blade tip of the first-stage moving blade, and make the radial deformation of the leading edge and the trailing edge of the first-stage moving blade more coordinated when the first-stage moving blade changes from a static state to a running state.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

Gas turbine engine with optimized fan blade geometry

ActiveUS10954798B2Easy to operateIncrease arcEngine manufactureEngine fuctionsFan bladeControl theory

A gas turbine engine 10 is provided in which a fan having fan blades 139 in which the camber distribution relative to covered passage of the fan 13 allows the gas turbine engine to operate with improved efficiency when compared with conventional engines, whilst retaining an acceptable flutter margin.

Owner:ROLLS ROYCE PLC

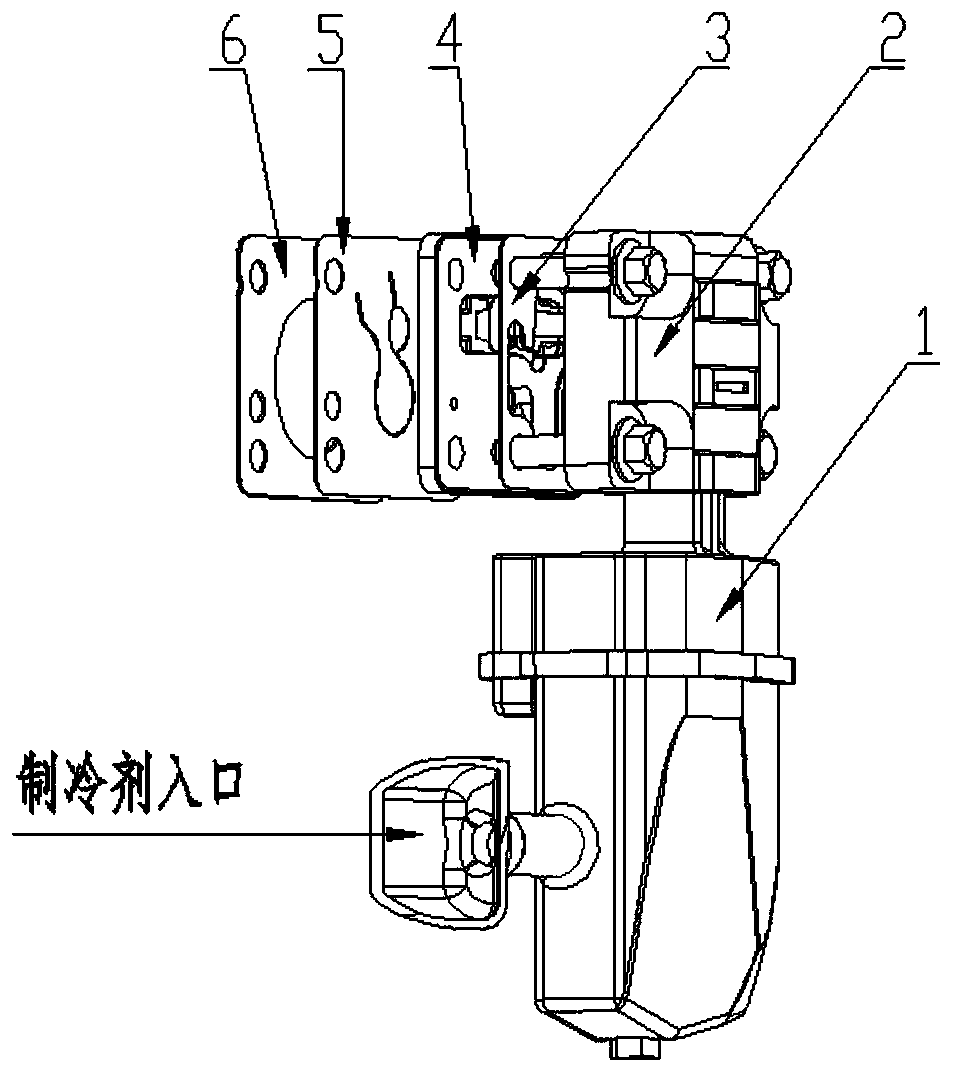

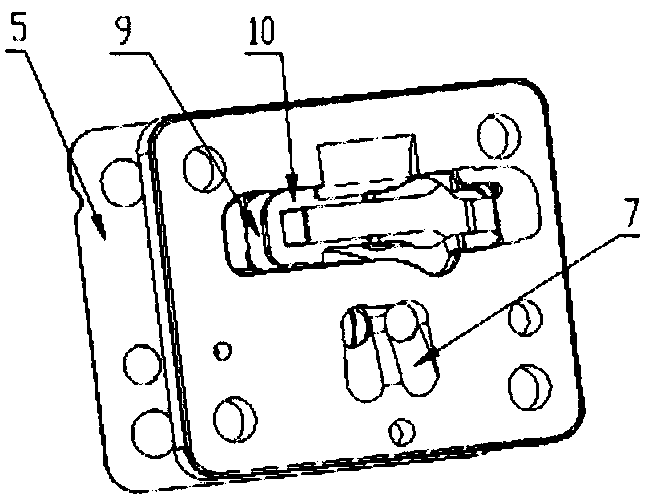

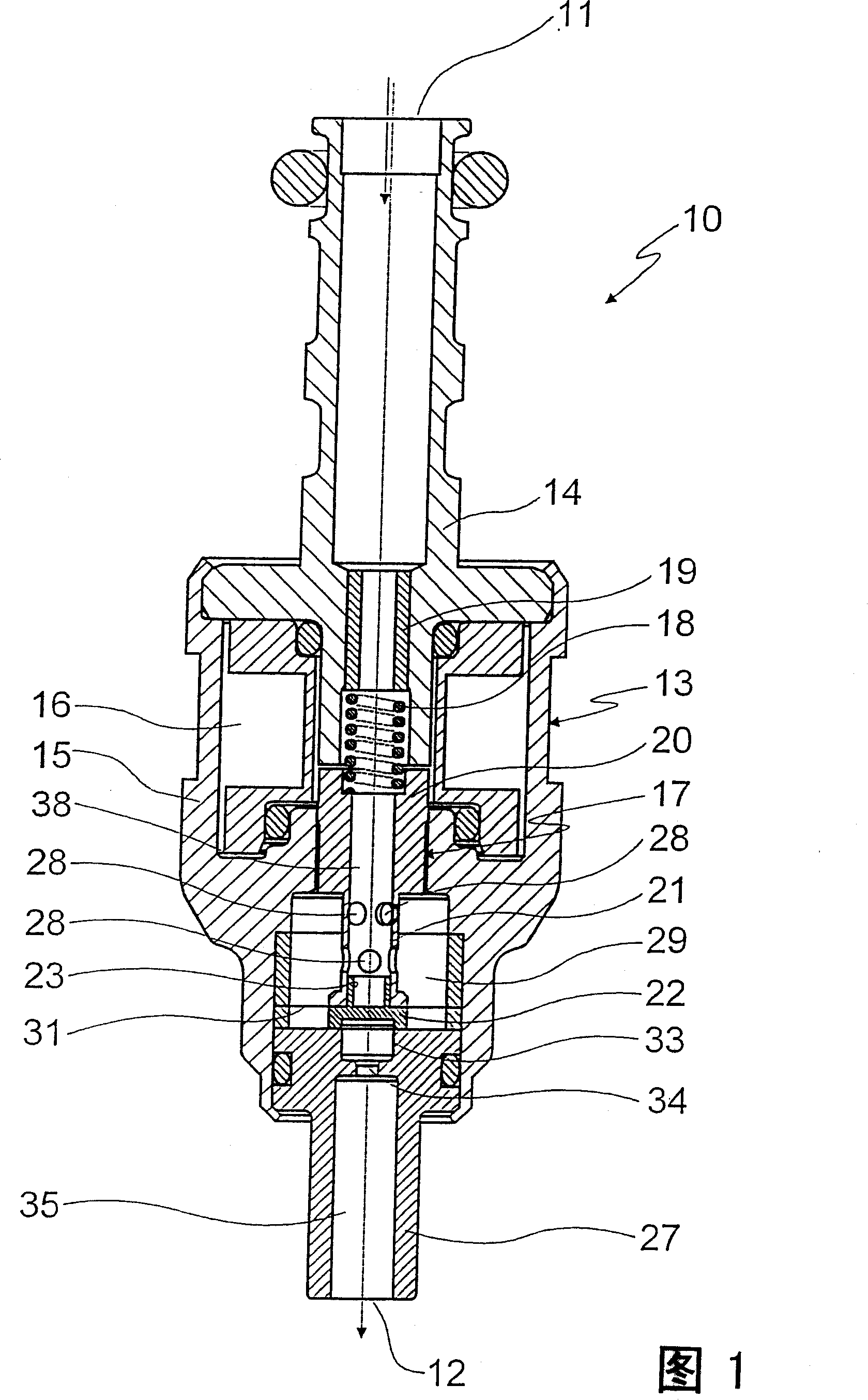

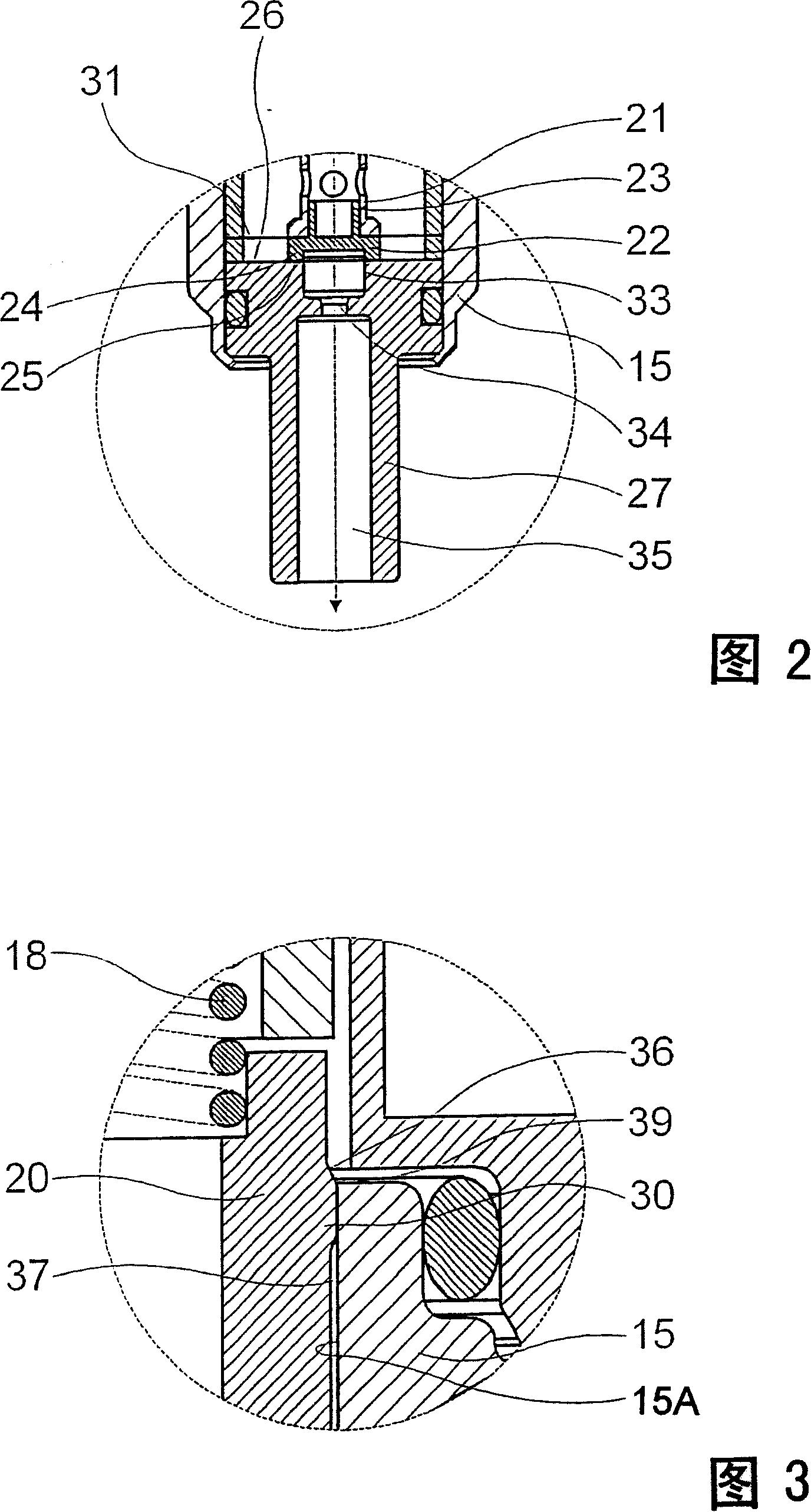

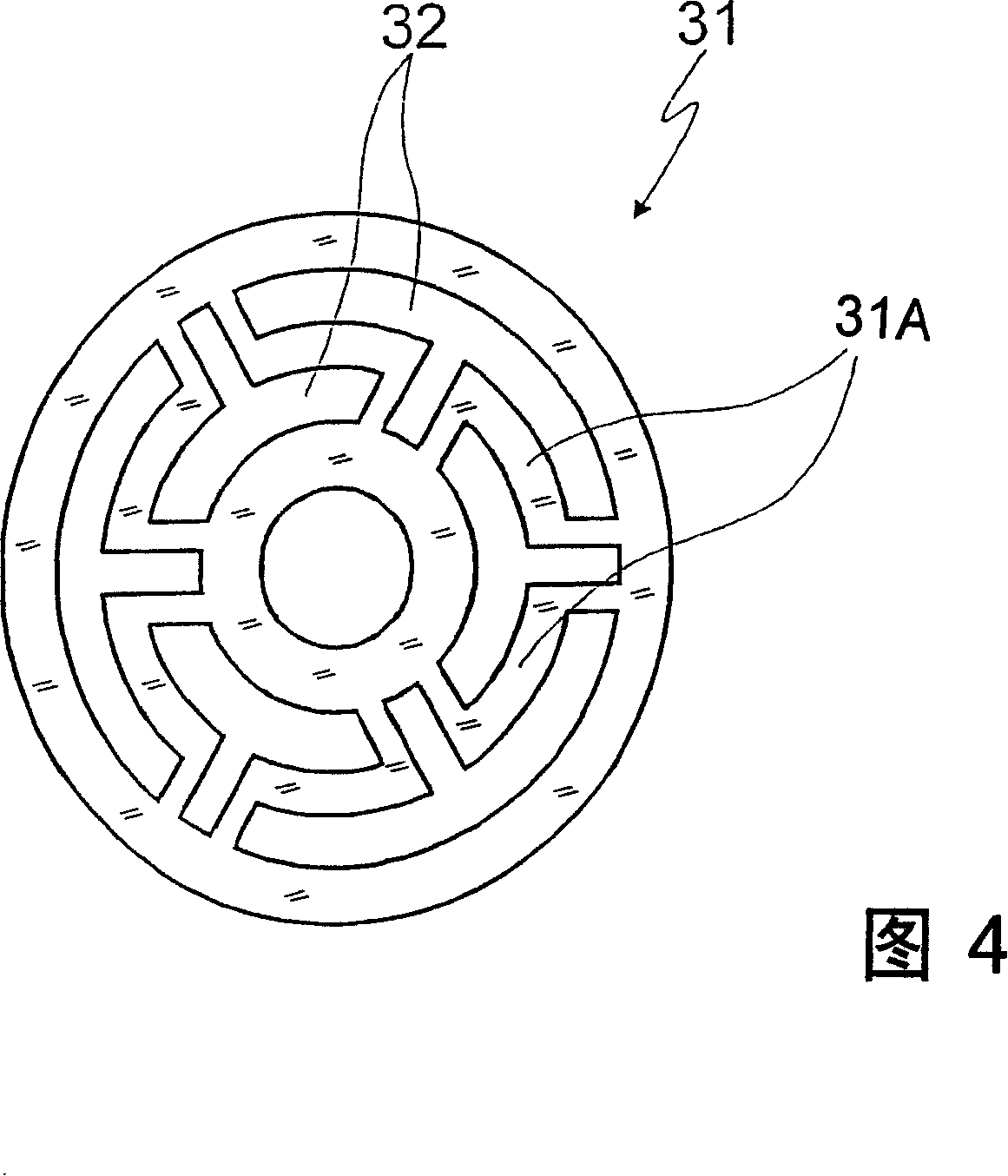

Valve for controlling a fluid

InactiveCN100365338CThe risk of failure is minimizedGuaranteed anti-tipping guidanceOperating means/releasing devices for valvesInternal combustion piston enginesFluid controlControl valves

A valve for controlling a fluid, in particular for controlling a gas, is described, encompassing a valve housing an actuation unit for an at least locally tubular valve armature which is guided axially displaceably and is equipped with a valve closure member by which a fluid flow between an inflow side and an outlet side is controllable and which coacts with a valve seat. The valve armature comprises a guidance collar in a region remote from the valve closure member, and is equipped with a second guidance in a region offset with respect to the guidance collar.

Owner:ROBERT BOSCH GMBH

Compressor rotor blade, compressor, and method for profiling the compressor rotor blade

ActiveUS20190048880A1Improve efficiencyWithout loss in degree of efficiencySupersonic fluid pumpsPump componentsMechanical engineeringEngineering

A compressor rotor blade for an axial-type compressor has a blade profile having a transonic section and a profile section which extends in the transonic section and has concave and convex suction-side regions on the suction side, the convex suction-side region arranged downstream of the concave suction-side region, and has convex and concave pressure-side regions on the pressure side, the concave pressure-side region arranged downstream of the convex pressure-side region. Curvature progressions on the pressure side and on the suction side are both applied in a continuous manner over a profile chord of the profile section, the positions of the minimum values of the curvature progressions deviate from each other by not more than 10% of the length of the profile chord, and the positions of the maximum values of the curvature progressions deviate from each other by not more than 10% of the length of the profile chord.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com