A transient jet test device for pulse wind tunnel

A test device and jet flow technology, which is applied in the field of hypersonic pulsed wind tunnel test equipment, can solve the problems of local high heat flow, complex thermal environment in the interference area, difficulties in thermal environment prediction and heat protection design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

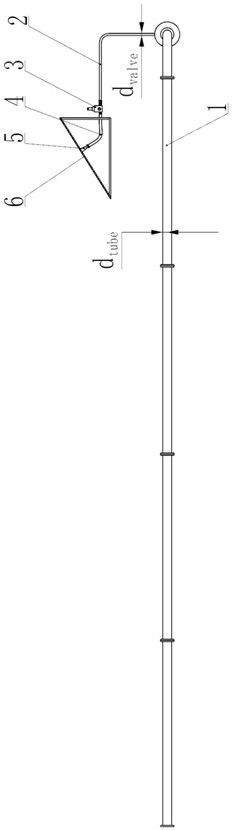

[0054] In this embodiment, the gas cylinders supplied by the gas source are 4 bottles of 13MPa, 40L bottled nitrogen, and 2 bottles of 13MPa, 40L bottled helium; the gas cylinders are connected to the gas storage pipe 1 through a stainless steel high-pressure pipe, and an integrated control is set between the two Each gas cylinder is equipped with a pressure reducing valve, and the connecting pipeline between the gas cylinders is equipped with a safety pressure relief valve. At the same time, a bottle of high-pressure gas is used alone in the gas cylinder group to provide a pilot gas source for the fast solenoid valve 3 .

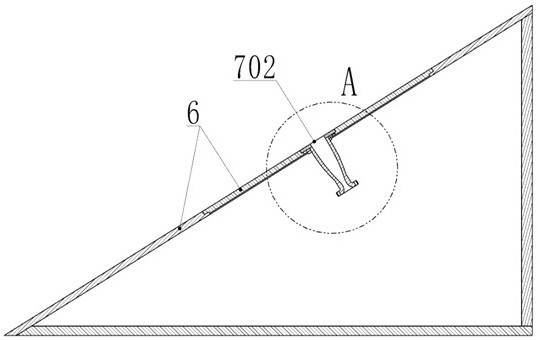

[0055] The gas storage pipe 1 is made of 304 stainless steel, with an inner diameter of 90 mm and a length of 10 m. The stable gas supply time is about 60 ms when using nitrogen gas. The air pipe 2 is connected; the other end of the small-diameter air pipe 2 is connected to the fast solenoid valve 3 . The fast electromagnetic valve 3 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com