Wide-speed-range air inlet channel design method based on double-incidence bending shock waves

A bending shock wave and design method technology, applied in the direction of mechanical equipment, jet propulsion devices, gas turbine devices, etc., can solve the lack of wide-speed range inlet design methods, narrow the scope of inlet geometric structure, and limit the choice of reference flow field range and other issues to achieve the effect of reducing the Mach number of the throat, reducing losses and increasing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

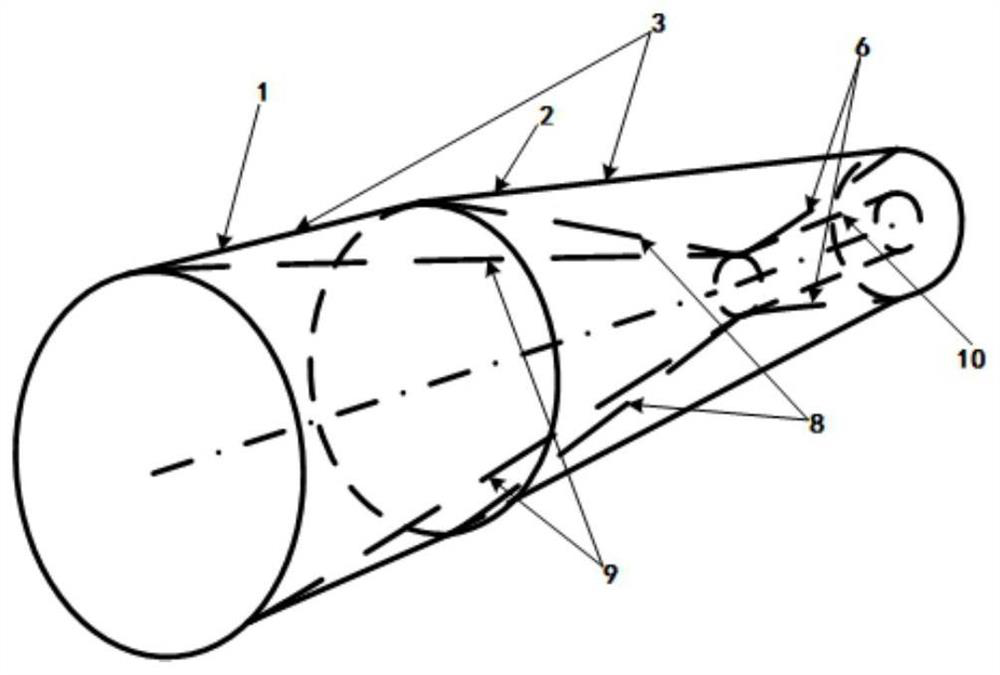

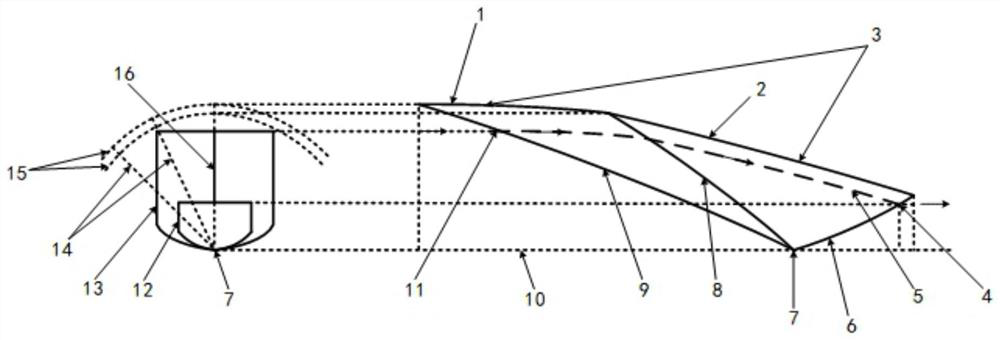

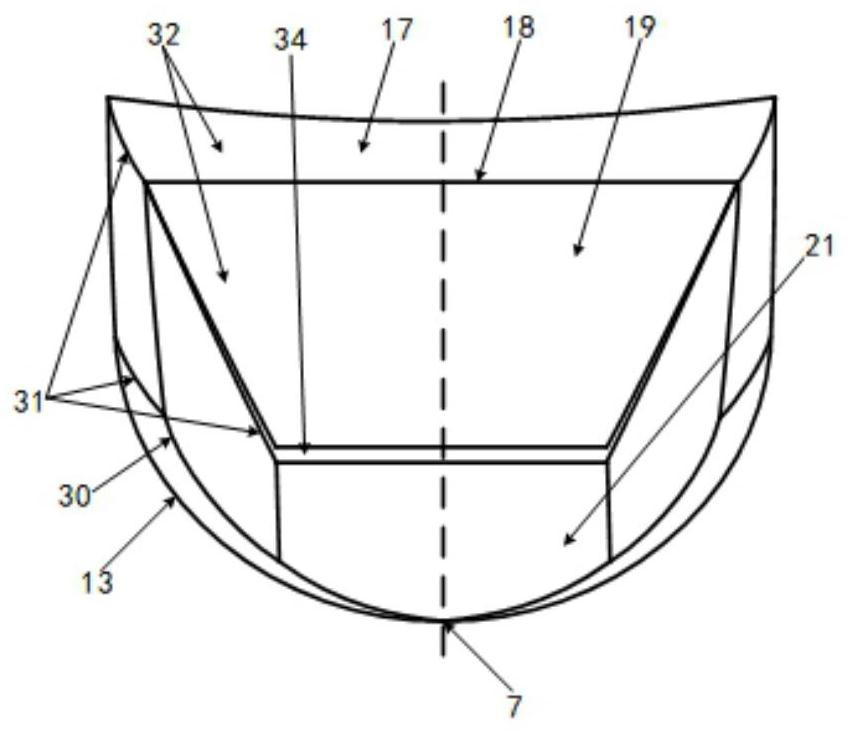

[0032] Such as Figure 1-7 As shown, the wide-velocity domain inlet design method based on double-incident curved shock waves includes the following steps:

[0033] 1) Designate the reference flow field 15 of the double-incident bending shock wave according to the design requirements, the first three-dimensional bending incident shock wave 9 and the second three-dimensional bending incident shock wave 8, wherein, due to the axial symmetry of the double-incident bending shock wave reference flow field 15 In different reference planes 14, the first three-dimensional curved incident shock wave 9-shaped line has the same shape, and the second three-dimensional curved incident shock wave 8-shaped line has th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com