Sharpened front edge structure and front edge design method of transonic speed fan blade top primitive blade profile

A design method and fan blade technology, applied to pump components, mechanical equipment, components of pumping devices for elastic fluids, etc., can solve problems affecting blade stiffness, local flutter of fan blades, etc., to improve efficiency and reduce Effects of Mach number and increased stall margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

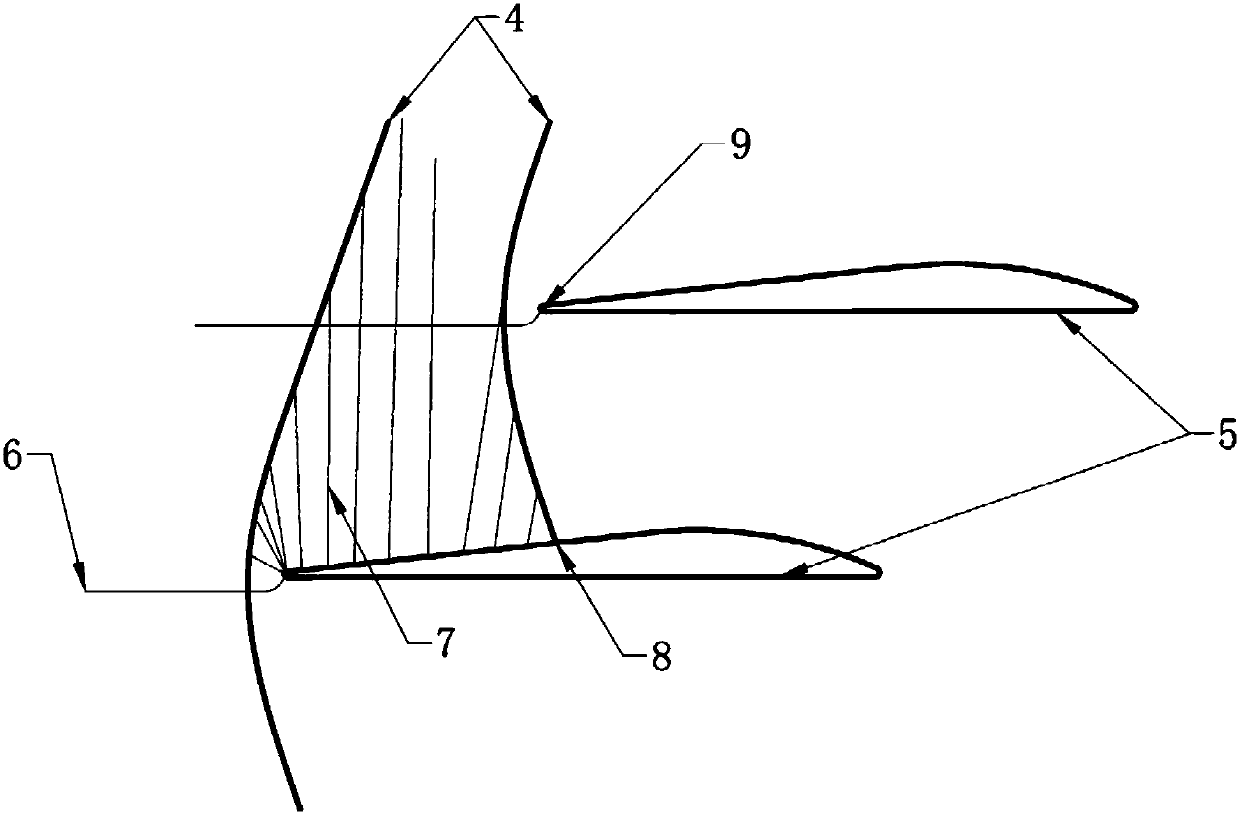

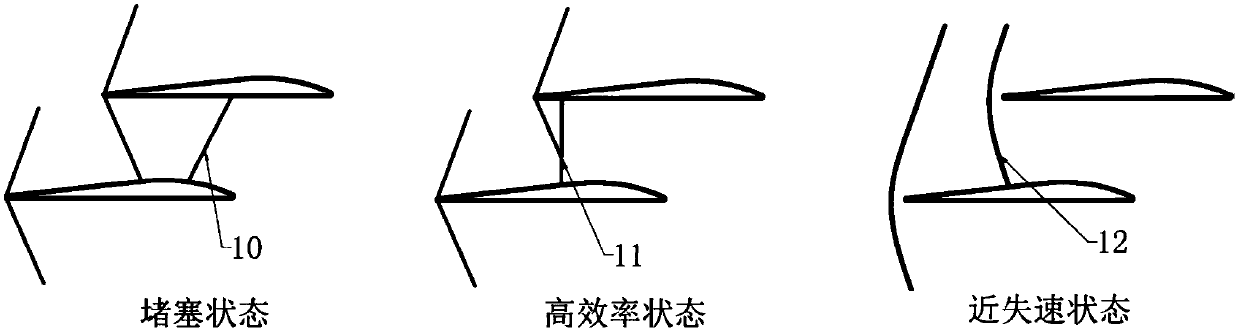

[0030] Such as Figure 4 As shown, the sharpened leading edge structure of the blade top primitive blade shape of the transonic fan of the present invention is obtained according to the following method: firstly, on the suction surface of the original primitive blade shape of the blade top, a distance of a certain length 17 from the original leading edge is obtained. Afterwards, pass this reference point to make a straight line segment 19 with a certain angle 13 with the original suction surface; then, use a circular arc segment with a radius 14 less than the original leading edge radius between the straight line segment 19 and the original pressure surface The other end of the straight line section 19 and the original suction surface are ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com