Patents

Literature

35results about How to "Increase stall margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centrifugal compressor having vane jet orifice

InactiveCN101012838AIncrease stall marginInhibition of flow separationPump componentsPumpsAviationJet flow

A centrifugal compressor with a jet orifice belonged to the turbo-machine field relates to the improvement of the booster centrifugal compressor used for vehicle and ships and aviation centrifugal compressor all the like turbo-machine box. It is characterized that a jet orifice set on the principal flow direction maximal curvature of the blade. Said jet orifice can be a narrow slit or two series-wound narrow slits along blade-high direction or a line of through-hole. The invention makes the suction surface of the impeller blade injected high energy jet flow when the centrifugal compressor operates via setting jet orifice on the blades, to activate the liquid in the boundary layer of the suction surface, thereby improving the ability for opposing adverse pressure gradient, to avoid impeller blade suction surface flow breakaway and improve the stalling allowance of the centrifugal compressor.

Owner:TSINGHUA UNIV

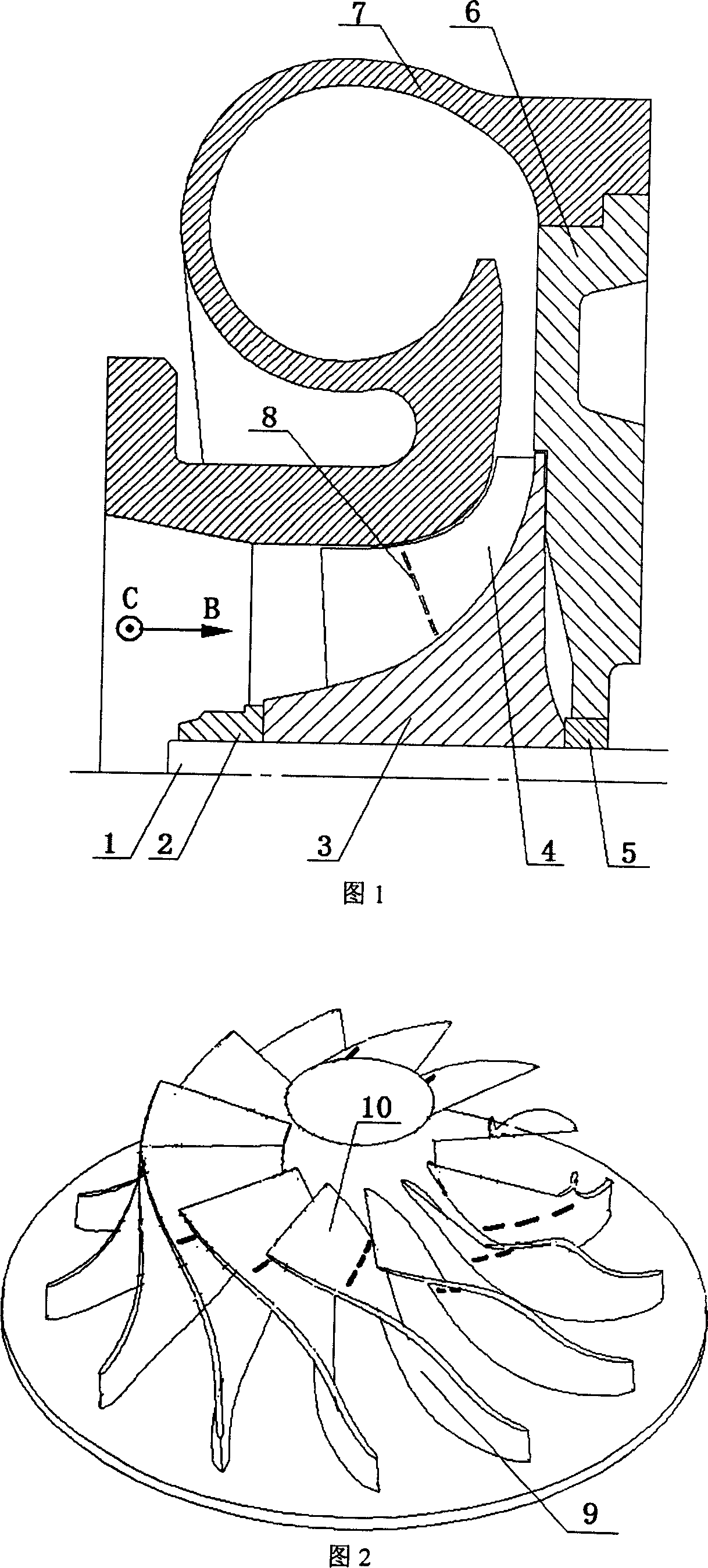

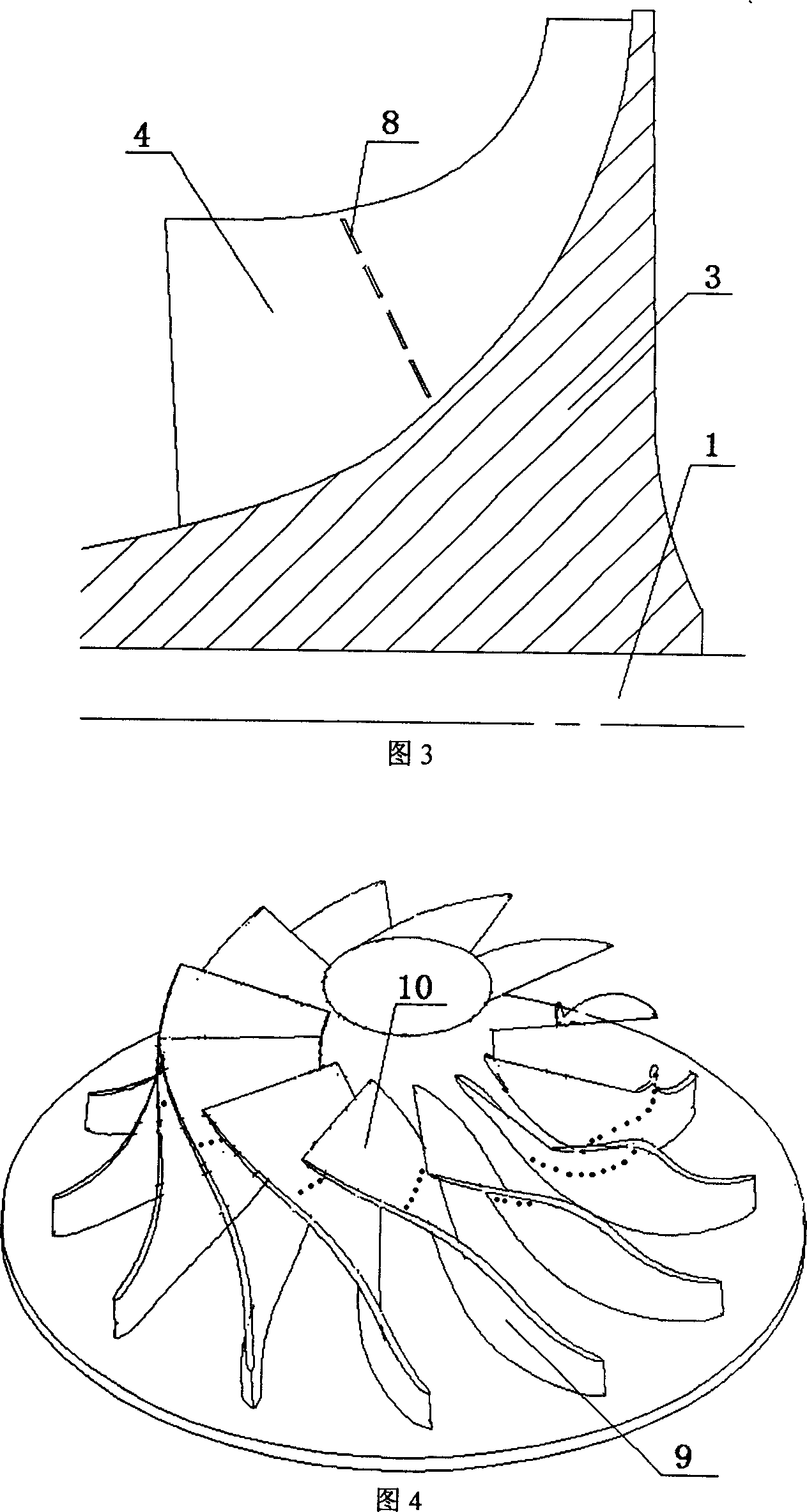

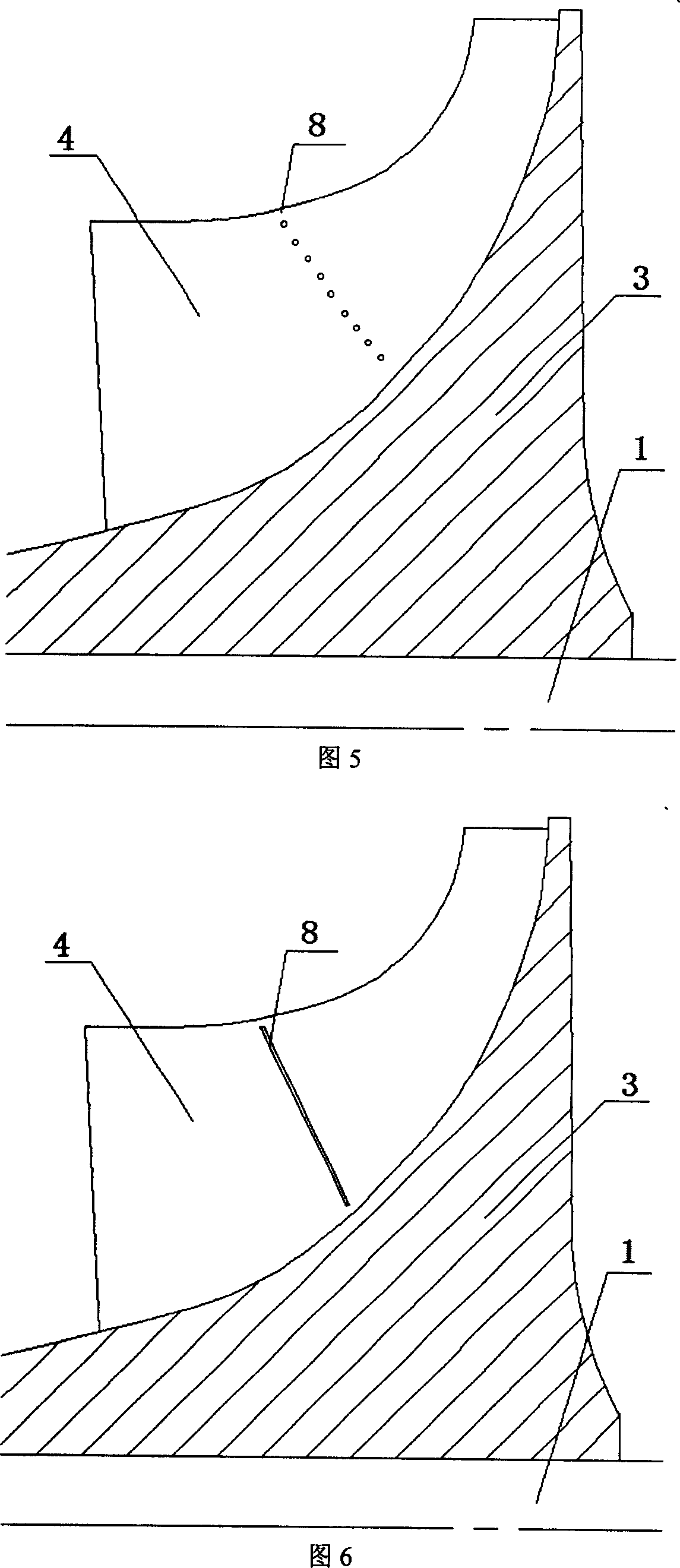

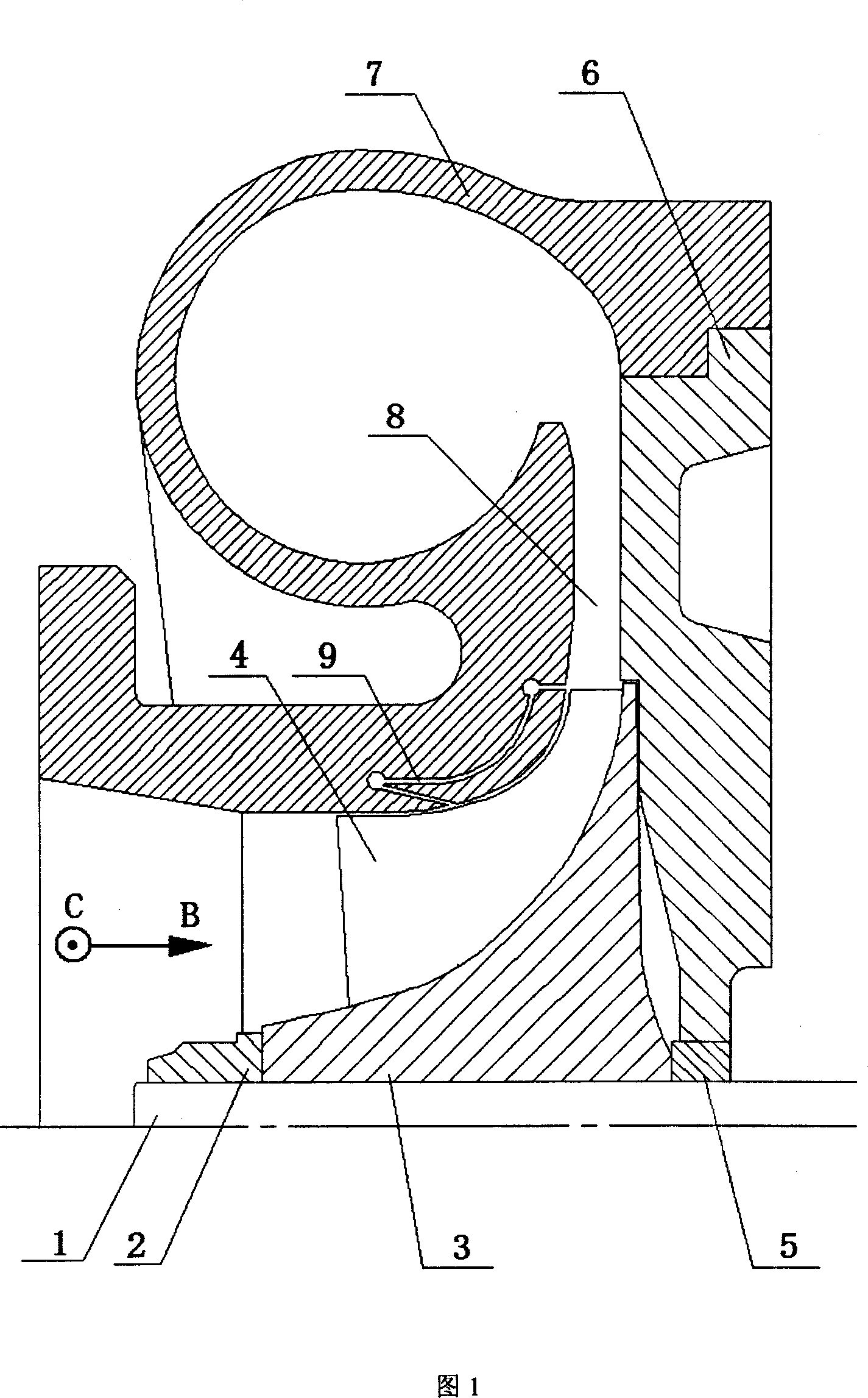

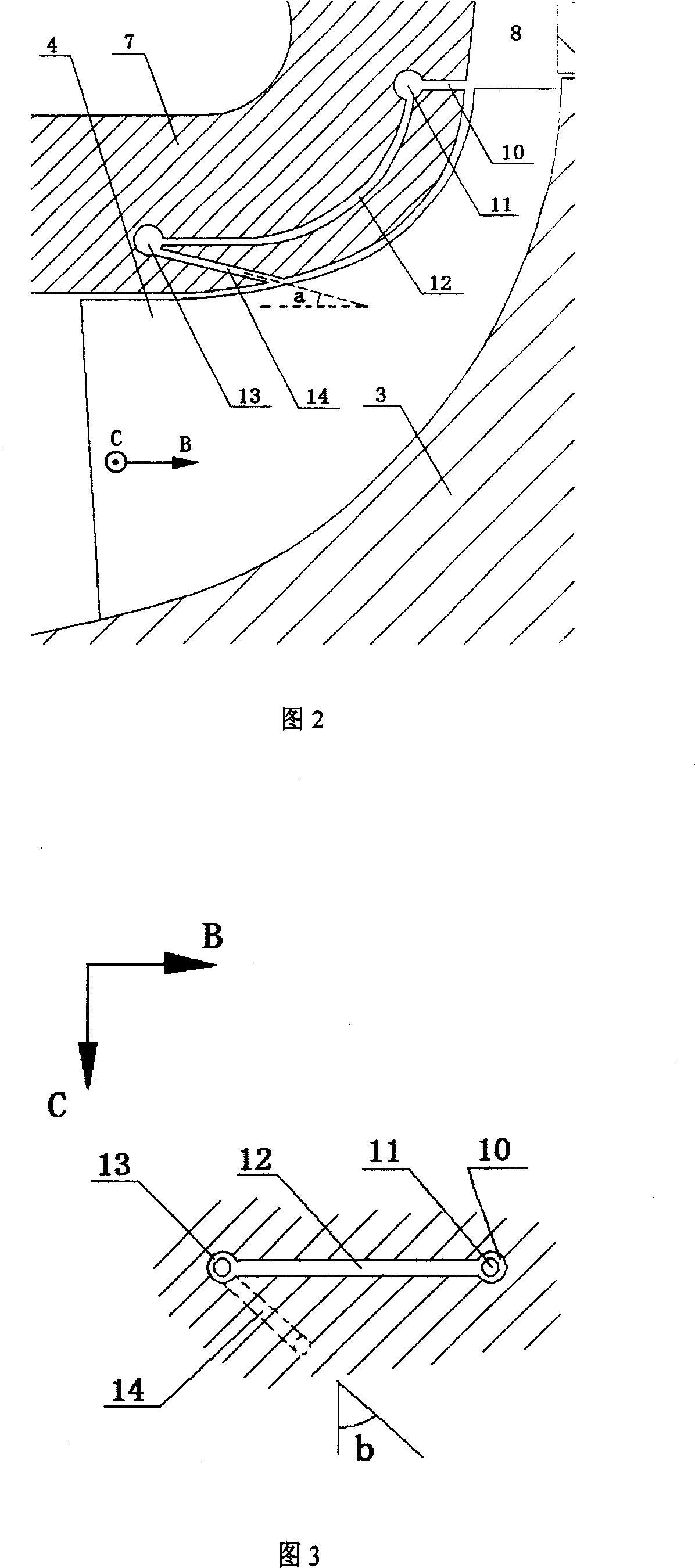

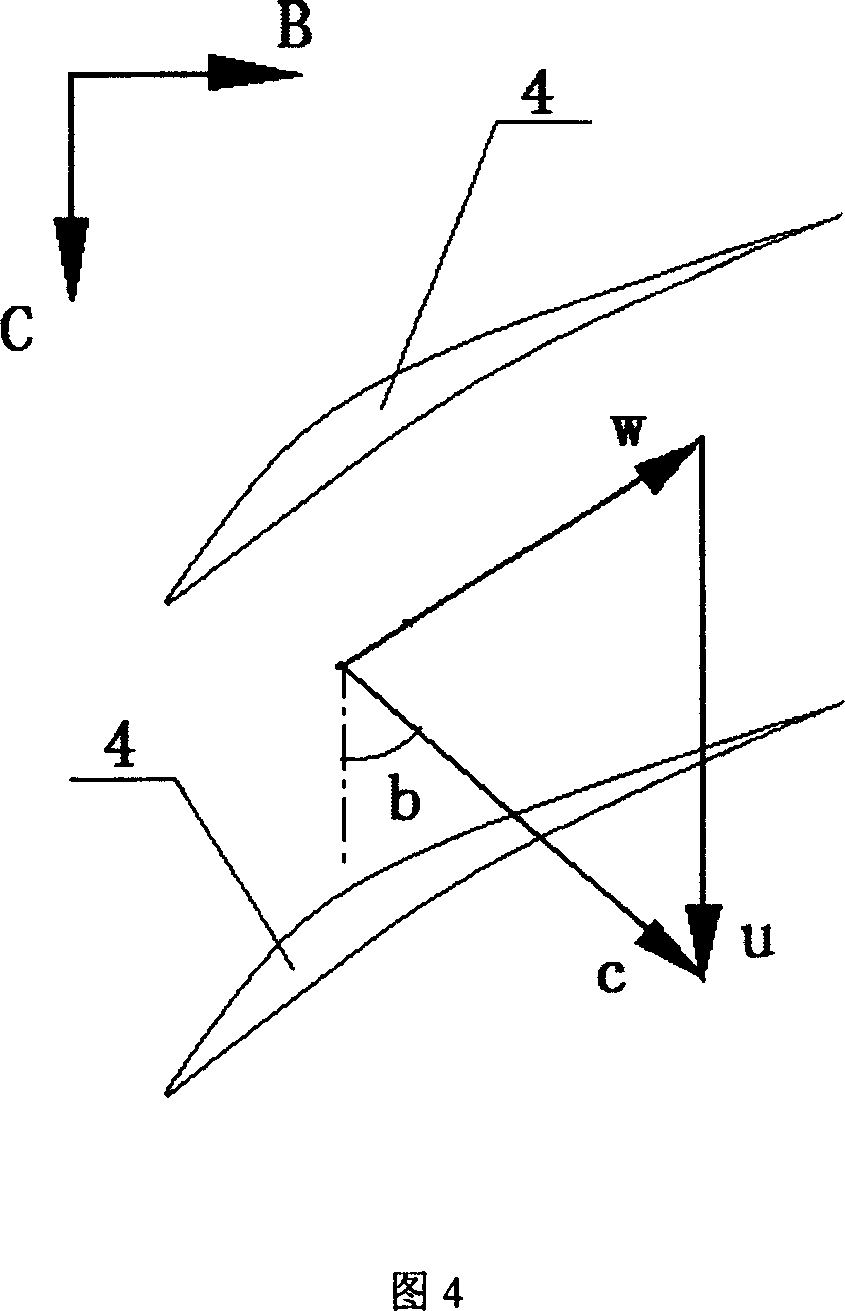

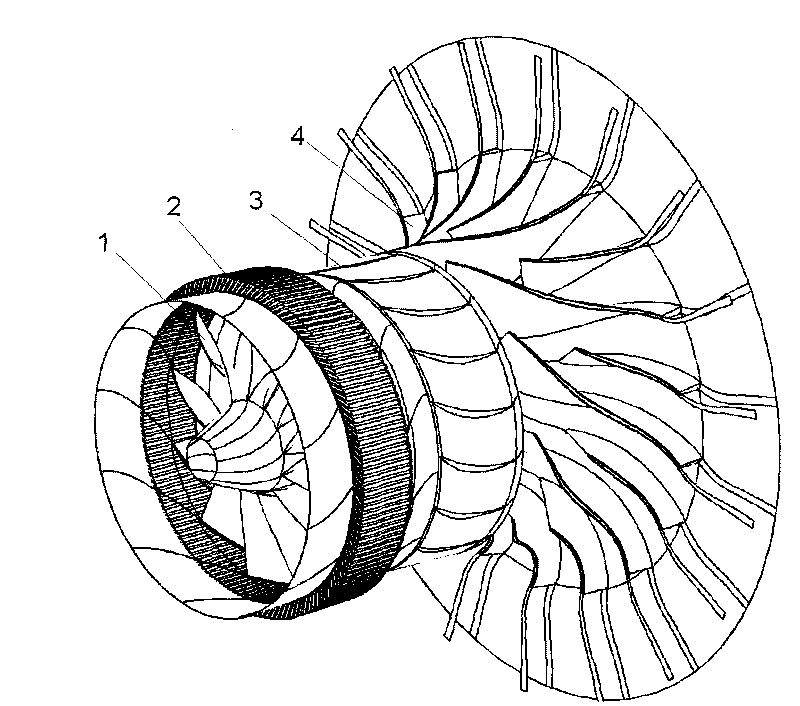

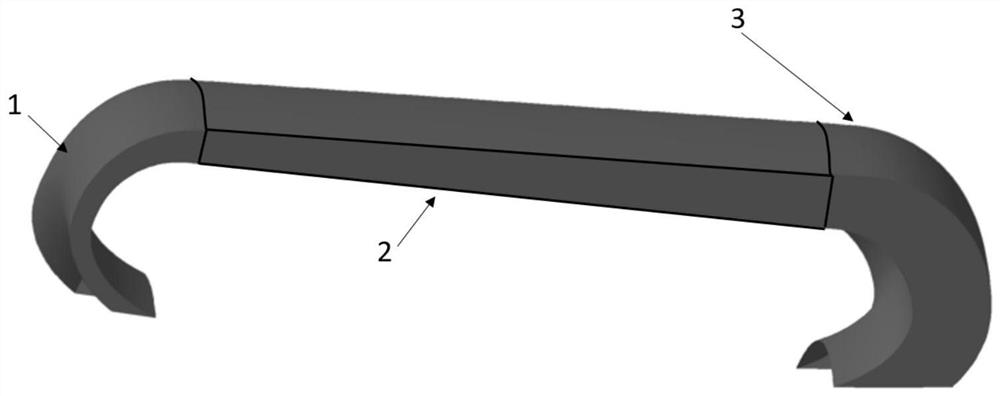

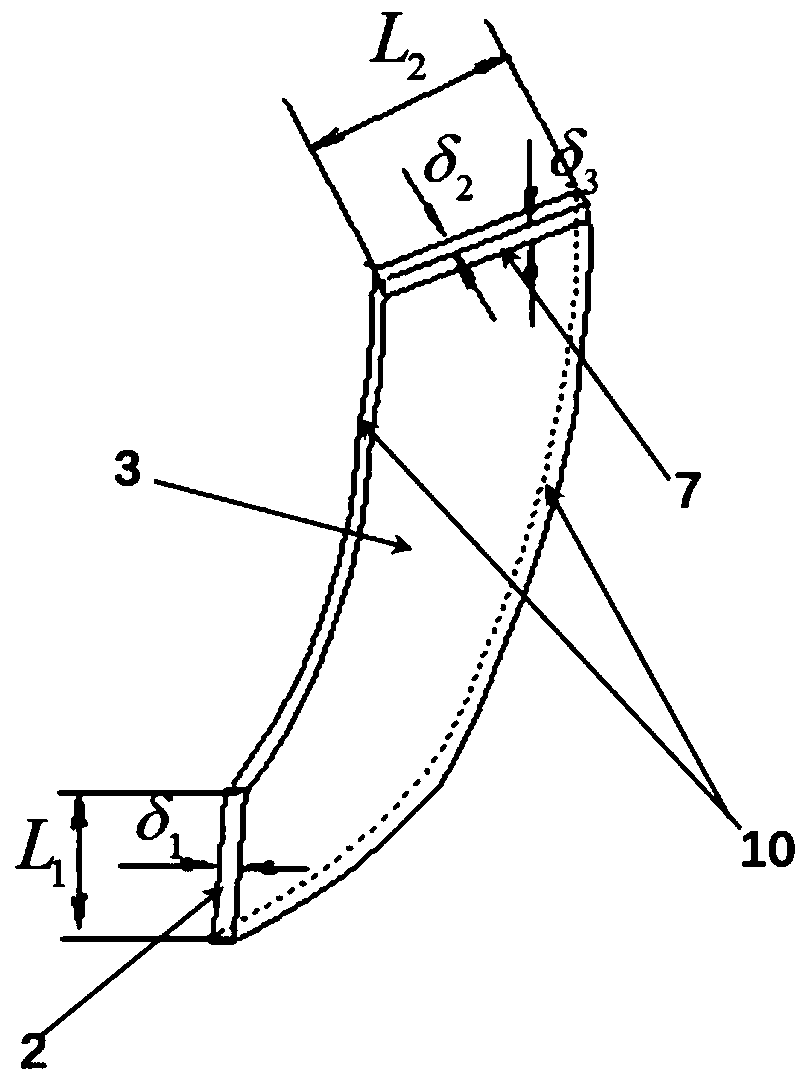

Centrifugal compressor having air removal jet box structure

InactiveCN101012837AIncrease stall marginImprove efficiencyPump componentsRadial flow pumpsHigh energyEngineering

A centrifugal compressor with an air-bleed and a jetting box construction belongs to the turbo-machine field. The invention is characterized in that the wall of the box of worm frame is arranged with at least three exhaust-injection guide channels uniformly arranged around the rotary axle of compressor, while it contains exhaust channels and injection channels. The opening of the exhaust channels is arranged at the wall at the inlet of the non-blade expander channel, and vertical to the wall of inlet box. The opening of the injection channel is at the most torsion of the channel formed by the worm frame and blade, while it is at same direction of main absolute speed of most torsion. The exhaust channel and the injection channel are connected via the guide channel. The inventive exhaust-injection guide channel can exhaust the adhere layer at the wall of expander, restrain the flow separation of expander, and fill high-energy injection into the channel of blade wheel, to restrain the flow separation of adsorption face and restrain the flow separation at small flux, to improve the speed-lost allowance and efficiency.

Owner:TSINGHUA UNIV

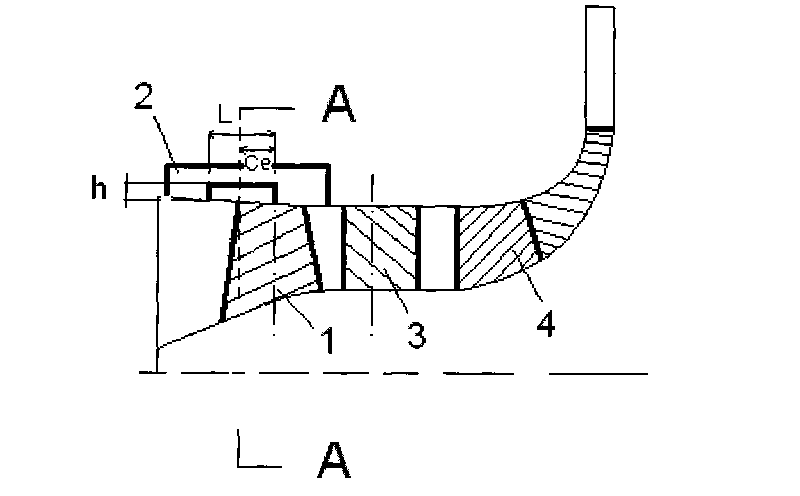

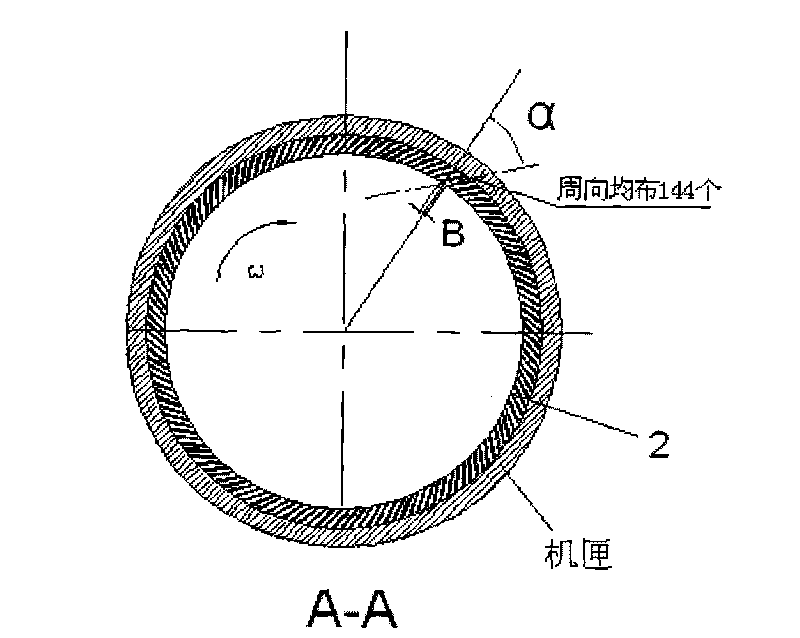

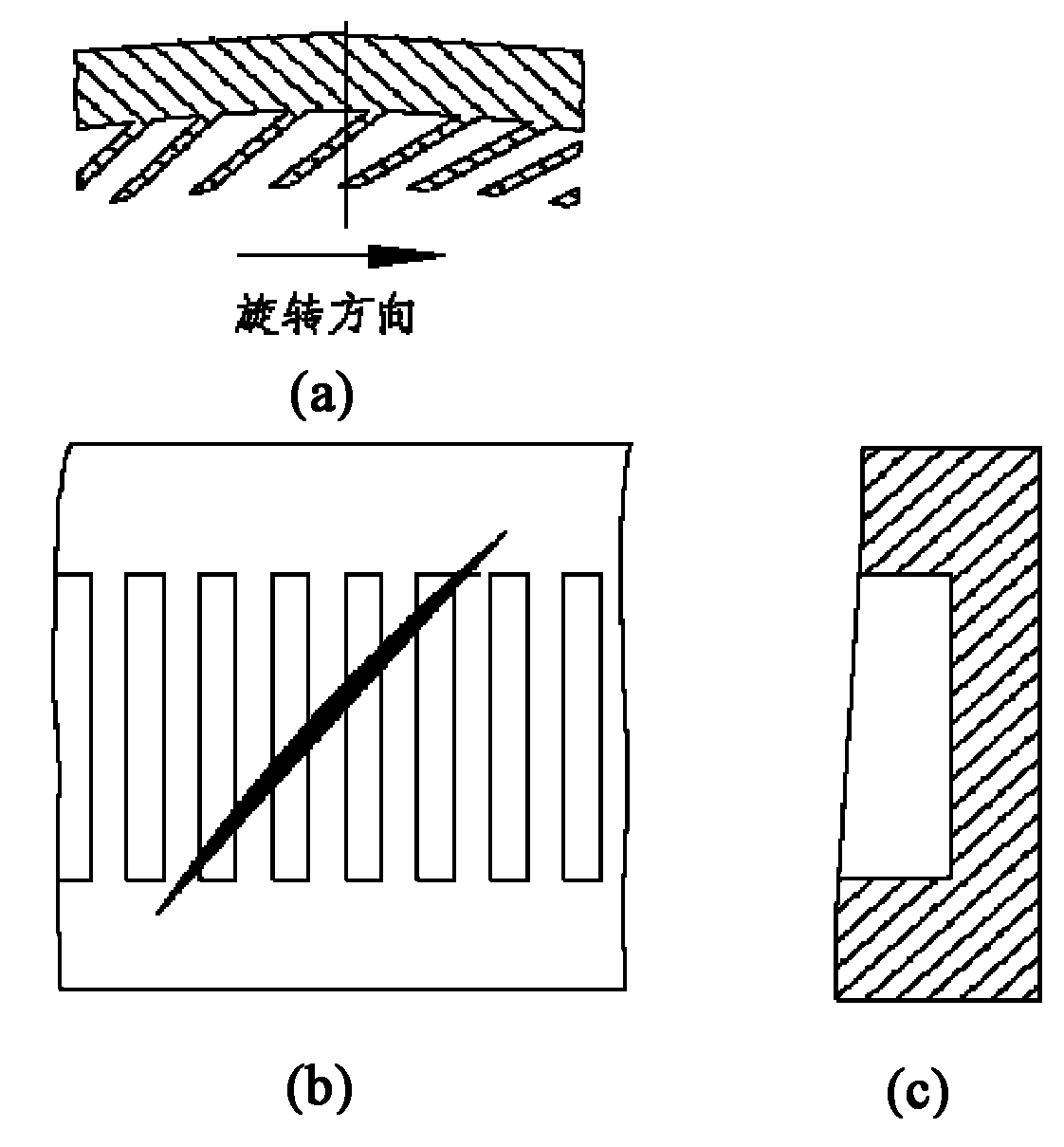

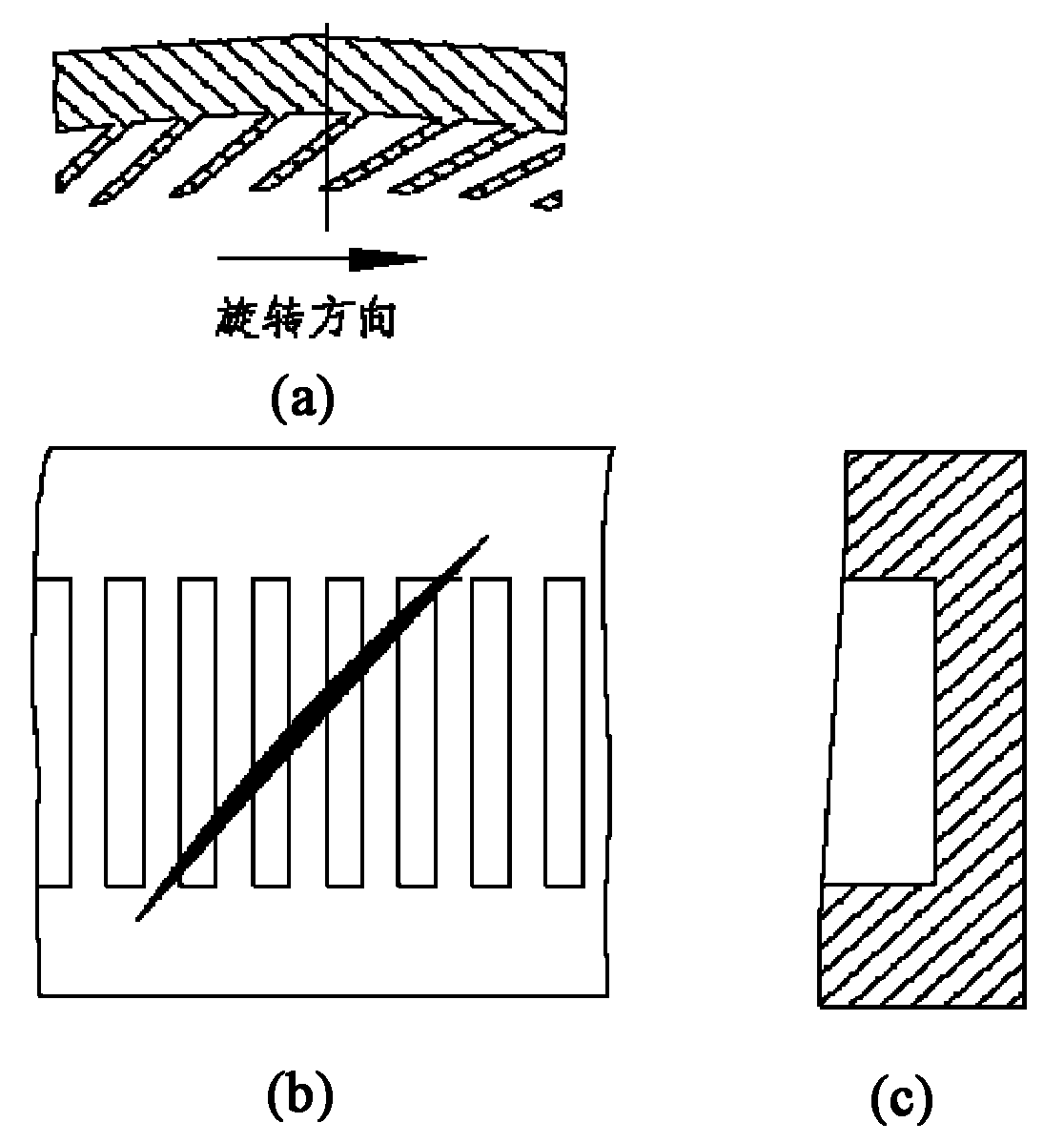

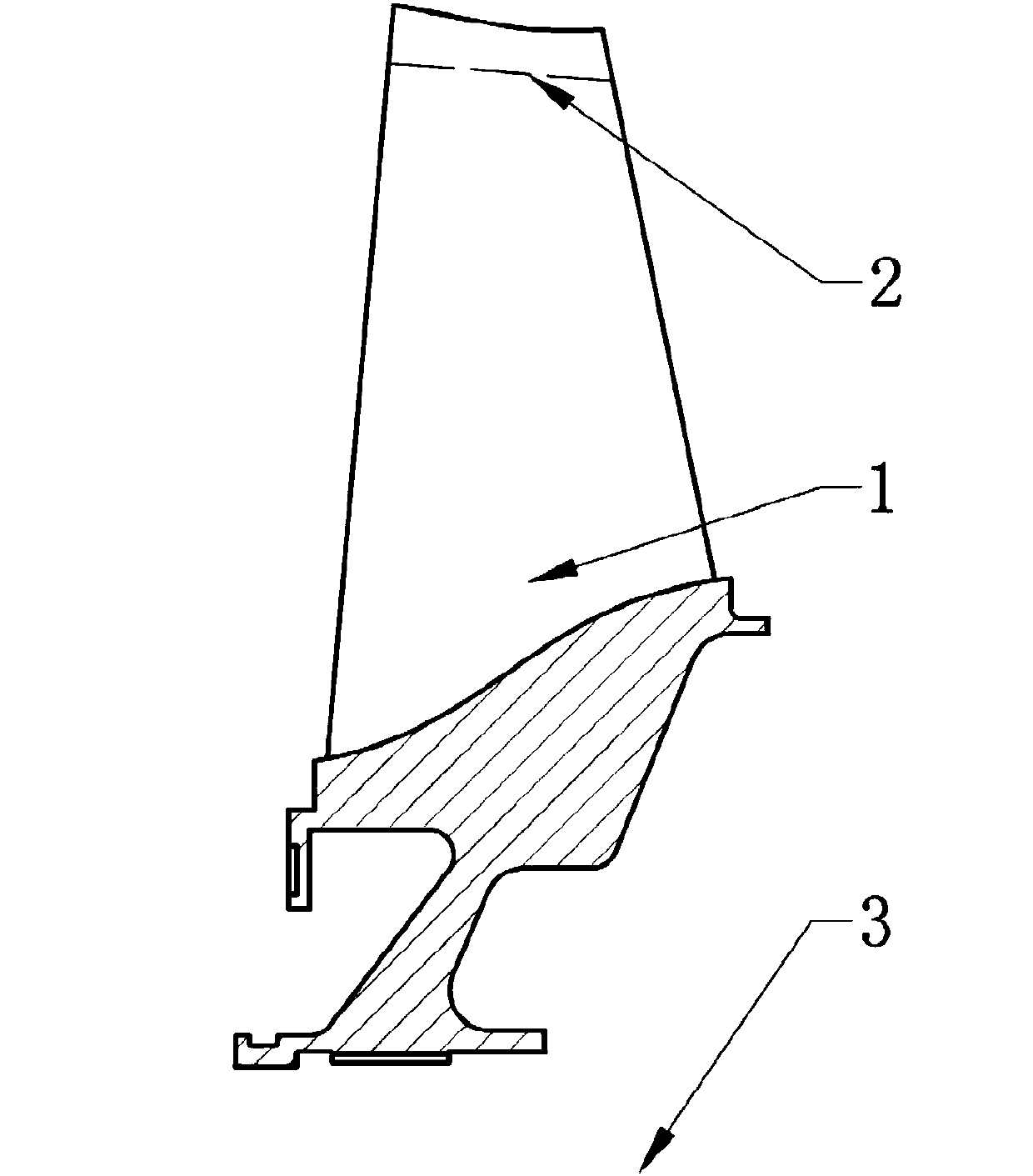

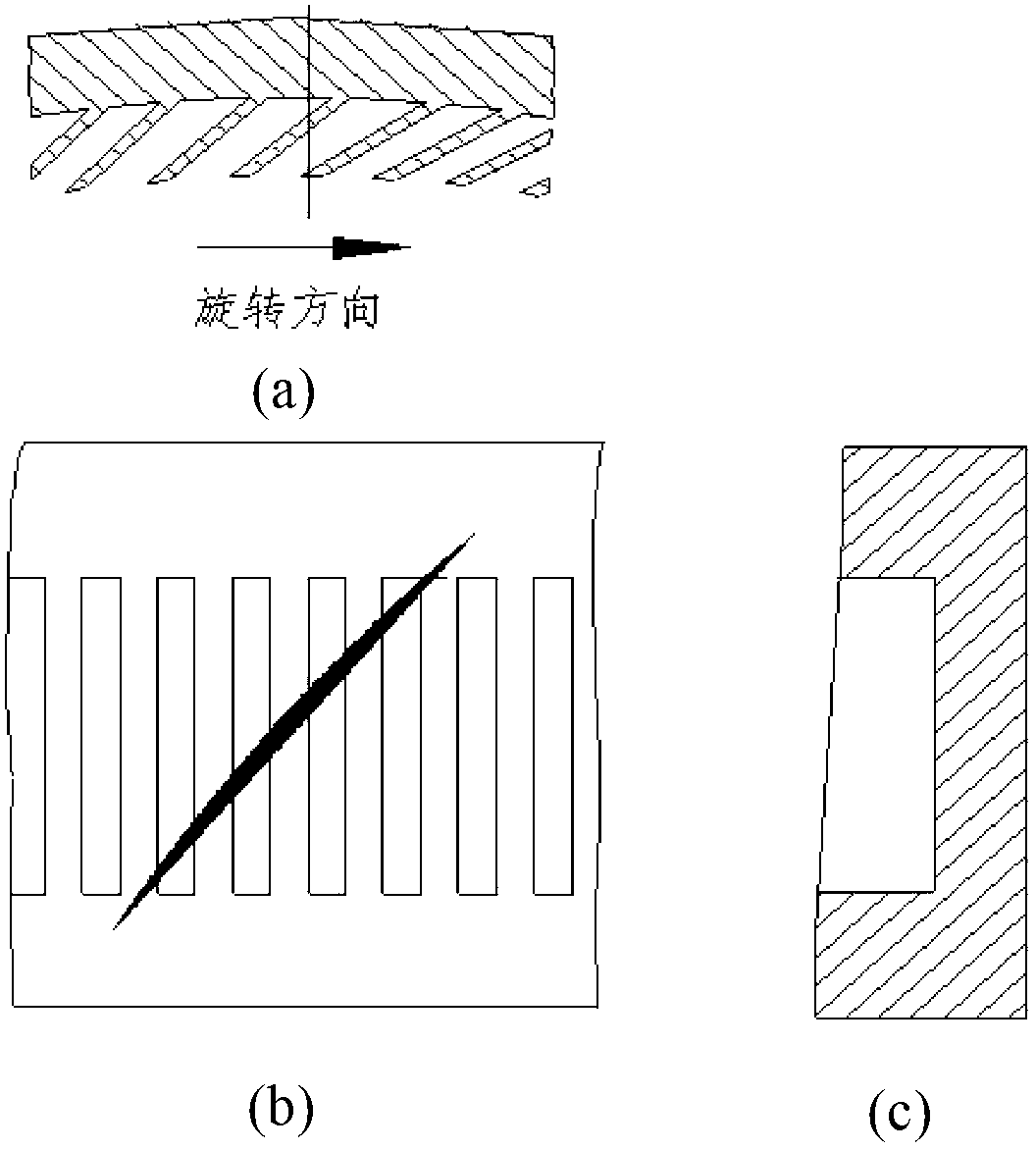

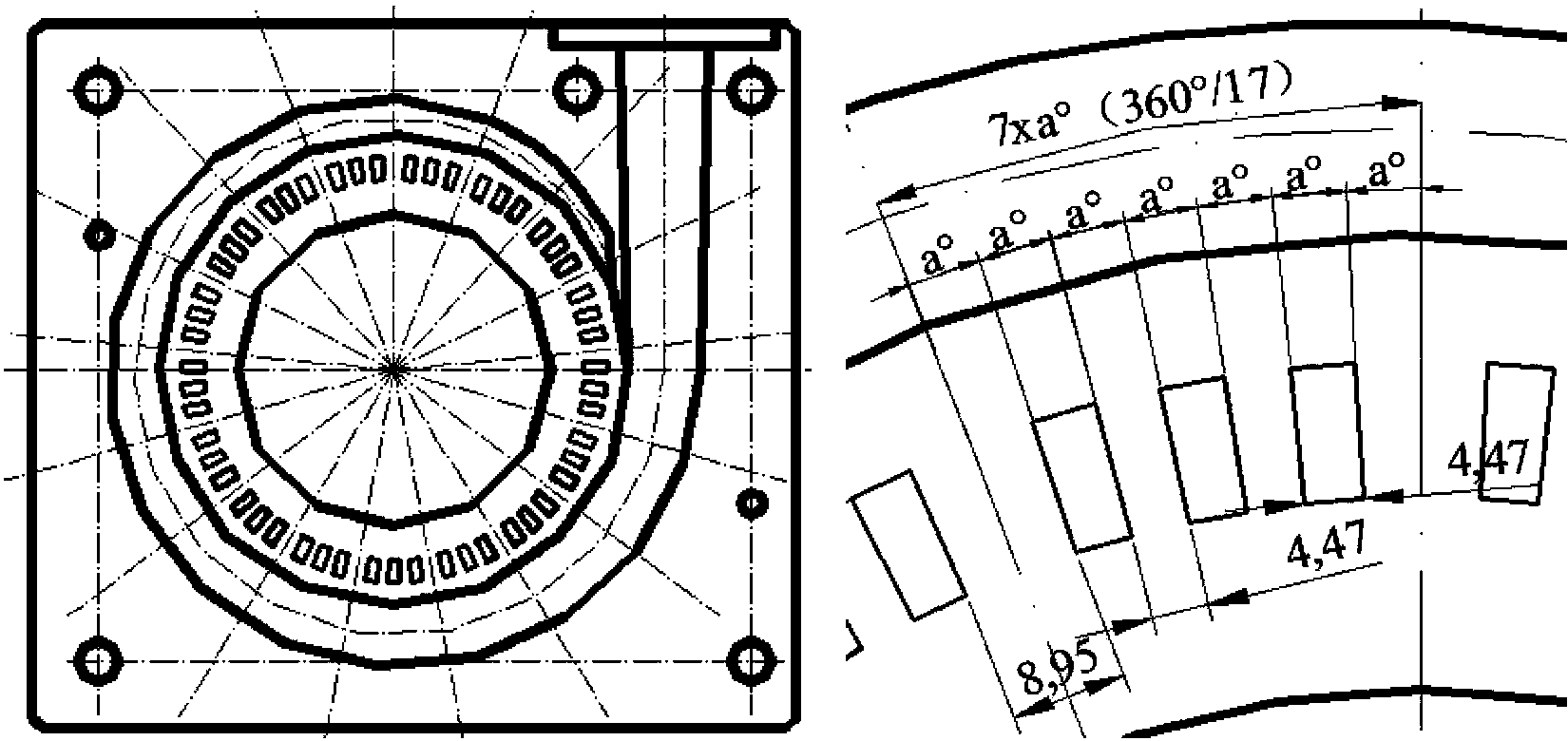

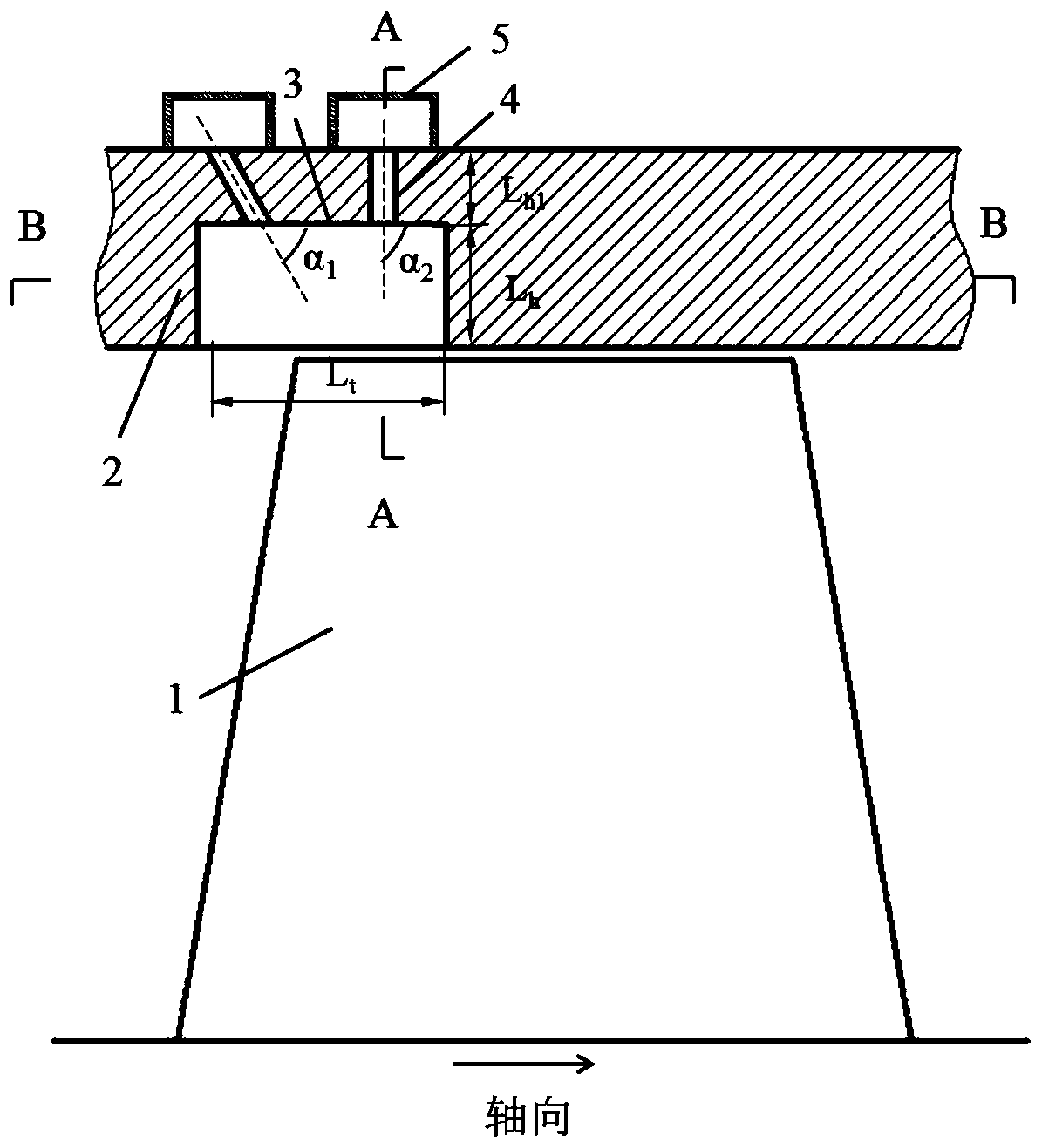

Axial and radial flowing compressor with axial chute processor casing structure

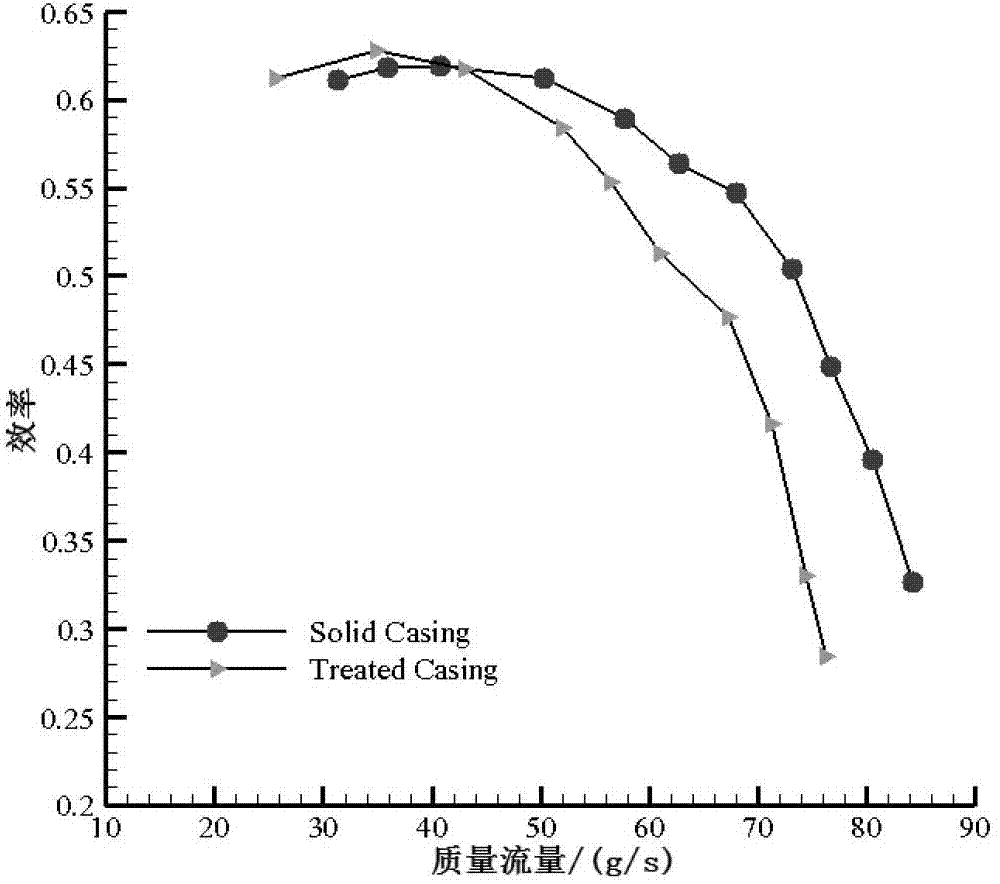

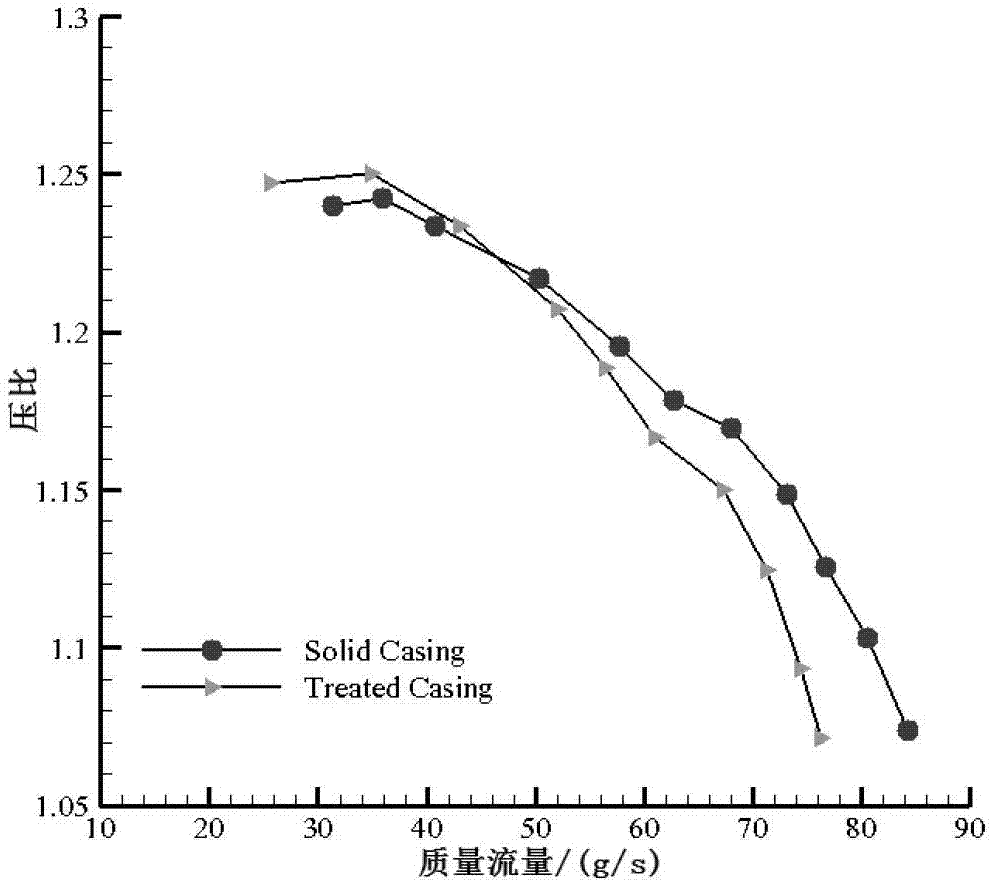

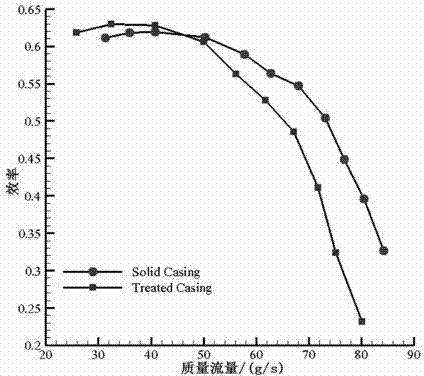

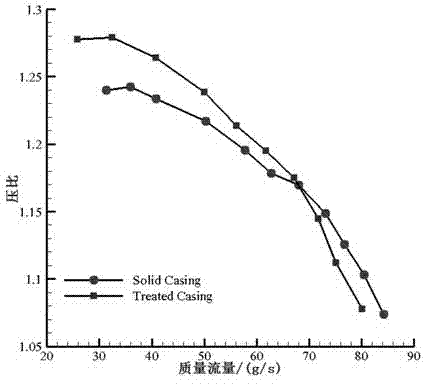

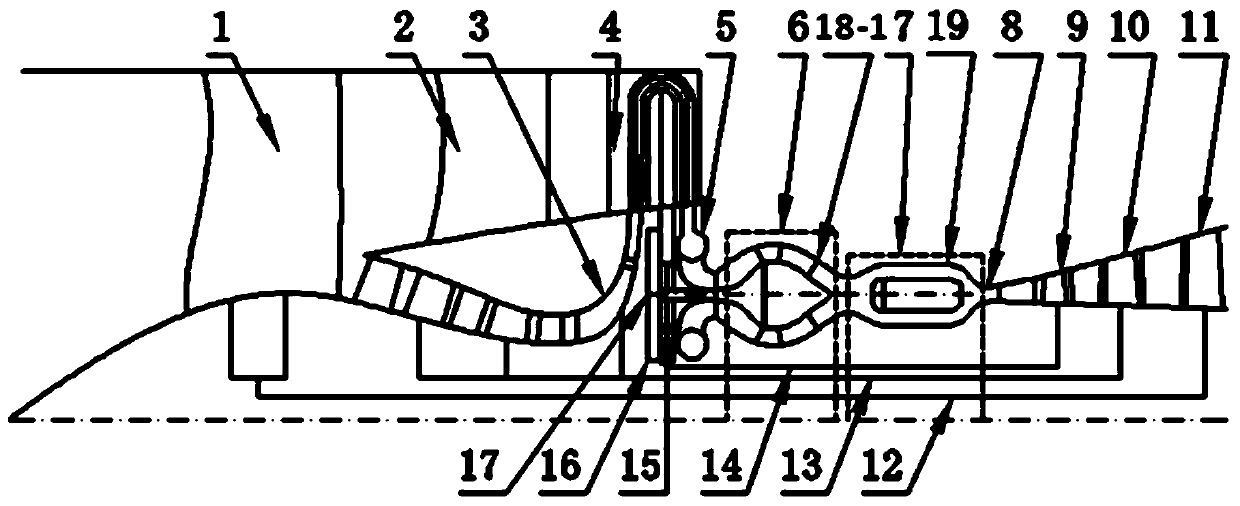

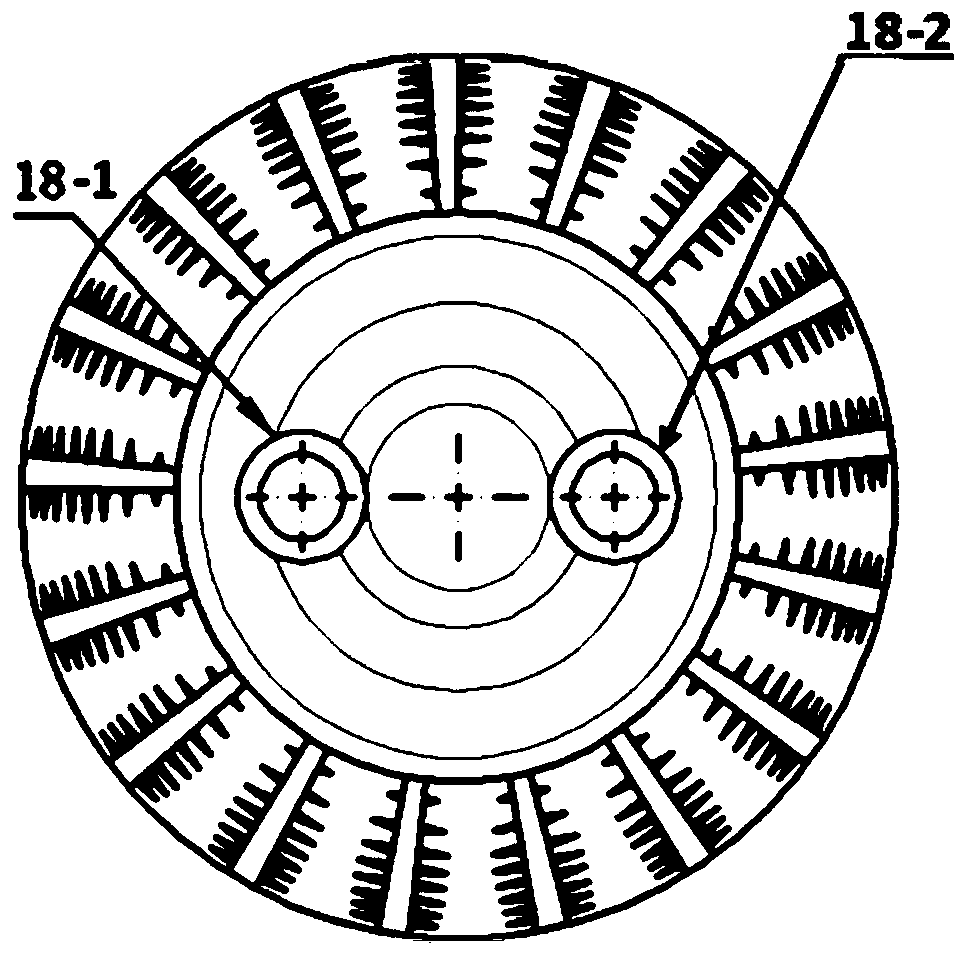

InactiveCN101691869AIncrease stall marginControl of low energy gap vorticesPump componentsPump installationsImpellerEngineering

The invention relates to an axial and radial flowing compressor with an axial chute processor casing structure, belonging to the technical field of impeller machinery; the axial and radial flowing compressor comprises an axial flowing rotor, an axial flowing stator and a radial-flowing compressor which are coaxially connected sequentially; axial chutes which are circumferentially distributed uniformly are processed on a casing wall surface of the axial flowing rotor of the axial and radial flowing compressor, the axial chute is radially inclined with 30-60 degrees along the rotating direction of the rotor. In the axial and radial flowing compressor with the axial chute processor casing structure, the low-energy tip clearance vortex of axial-flowing grade blade tip can be effectively controlled under the pumping action of the axial chute processor casing on the axial flowing rotor, flow separation is inhibited under a low flow-rate condition, the entrance condition of the radial flowing compressor is improved, so as to improve surge-to-stall margin of the axial and radial flowing compressor greatly on the premise of ensuring the little change of pressure ratio and efficiency.

Owner:TSINGHUA UNIV

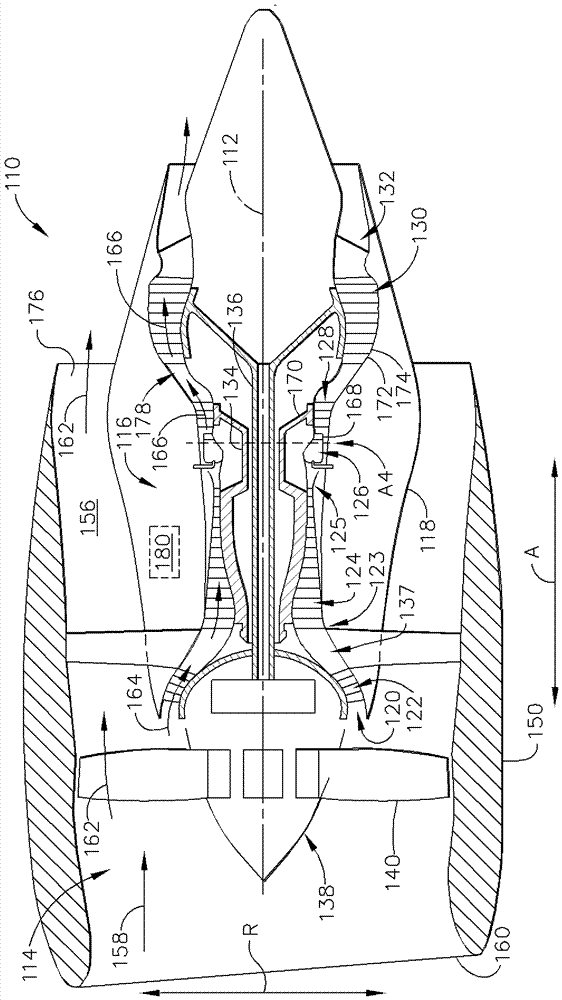

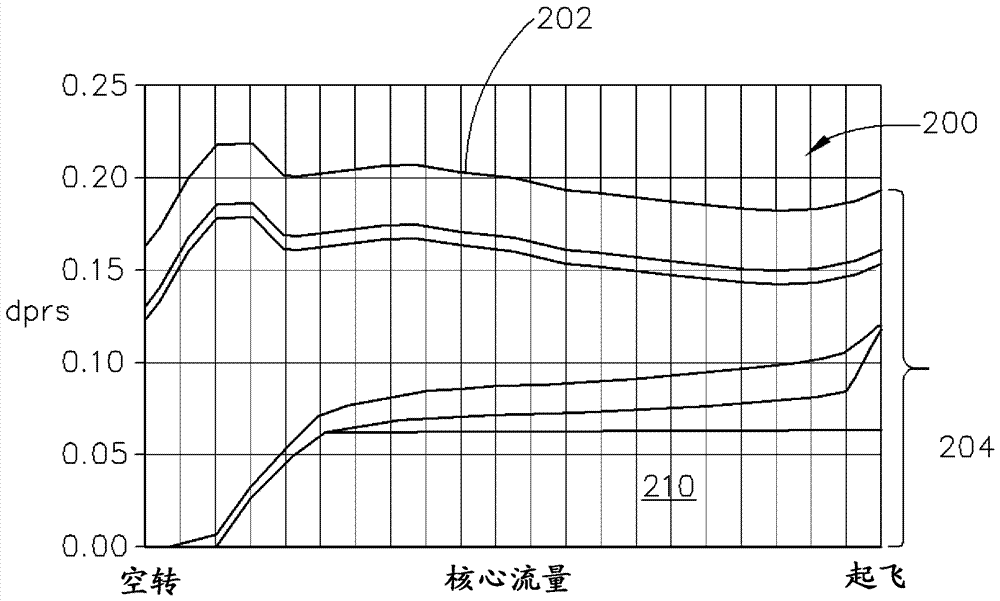

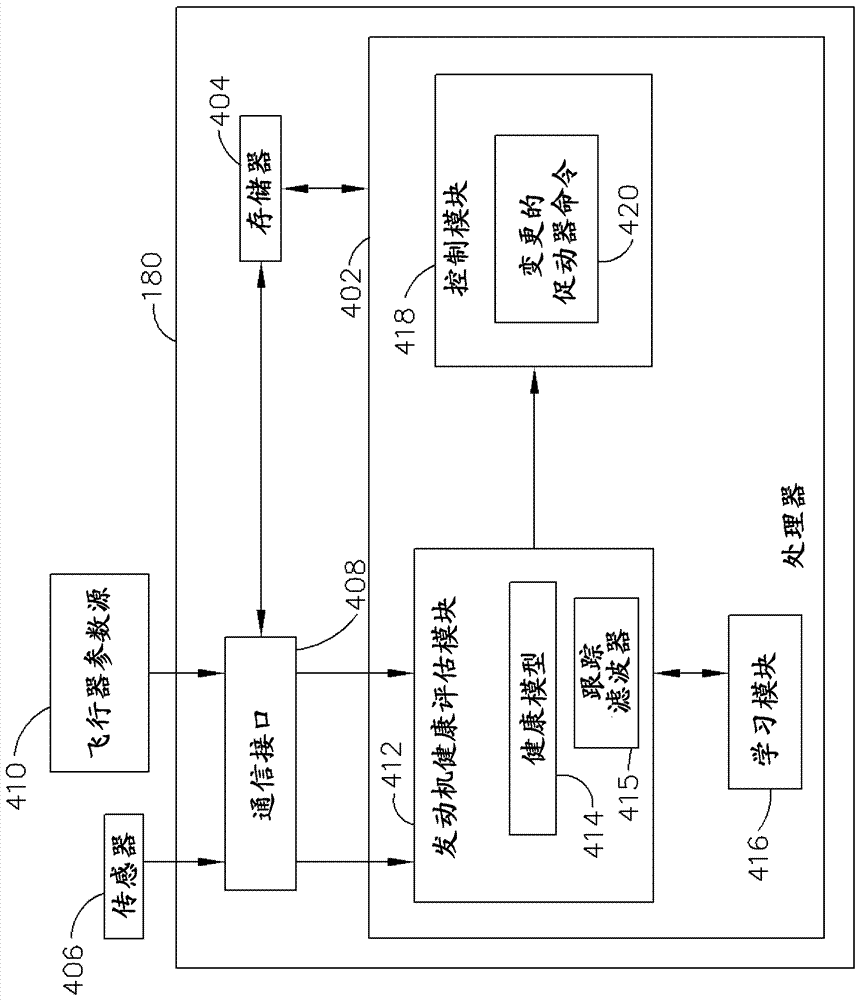

Method and system for stall margin modulation as a function of engine health

InactiveCN106907345AIncrease stall marginTurbine/propulsion engine coolingEngine fuctionsControl systemEngineering

The invention relates to a method and a system for stall margin modulation as a function of engine health. A gas turbine engine 100 is provided, including a core engine including a multistage compressor 124, and a stall margin modulation (SMM) control system 180 in communication with the core engine. The processor is programmed to determine the stall margin 304 of the compressor124, and operate the compressor under the stall margin. The processor is further programmed to assess a health of the compressor 124, and modify the stall margin 304 based on the assessed health of the compressor 124.

Owner:GENERAL ELECTRIC CO

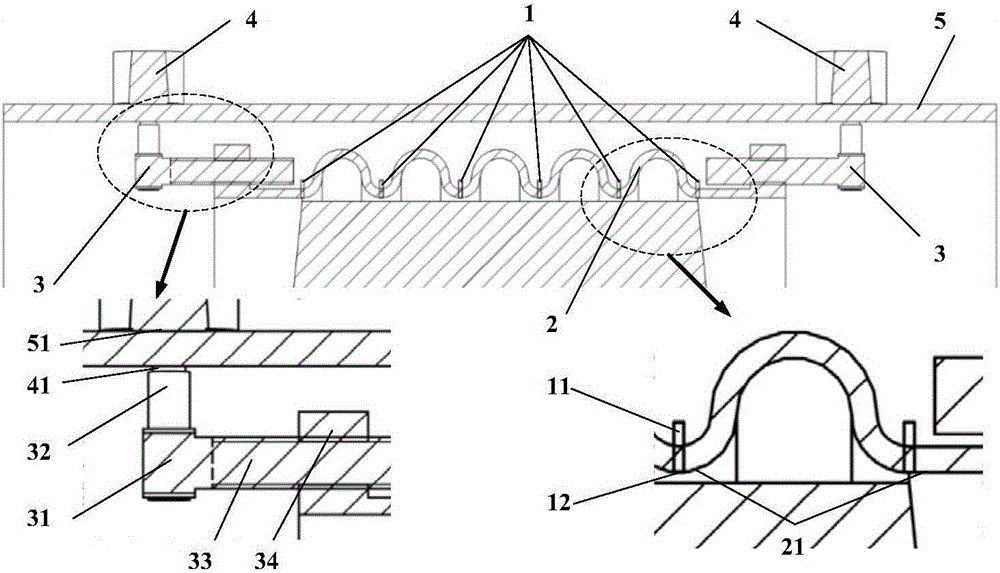

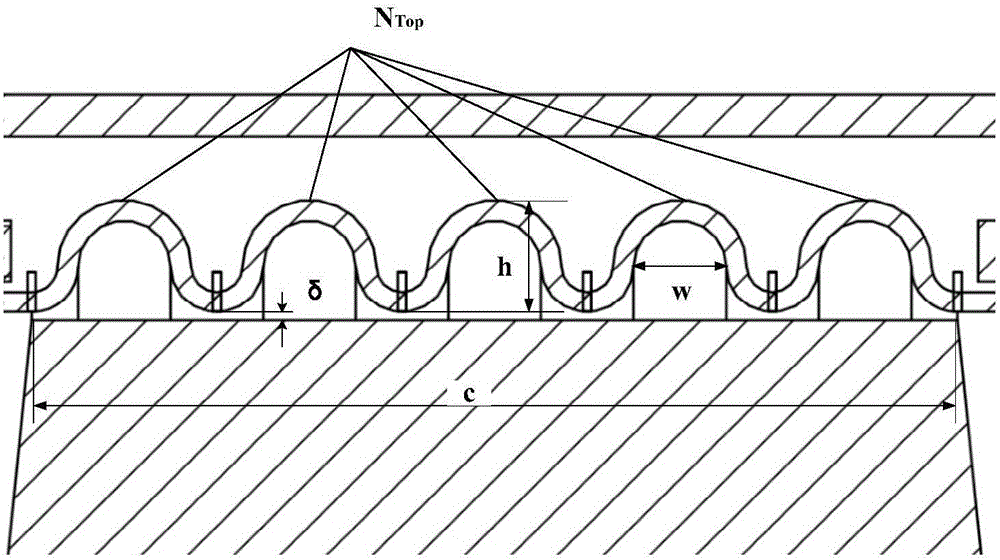

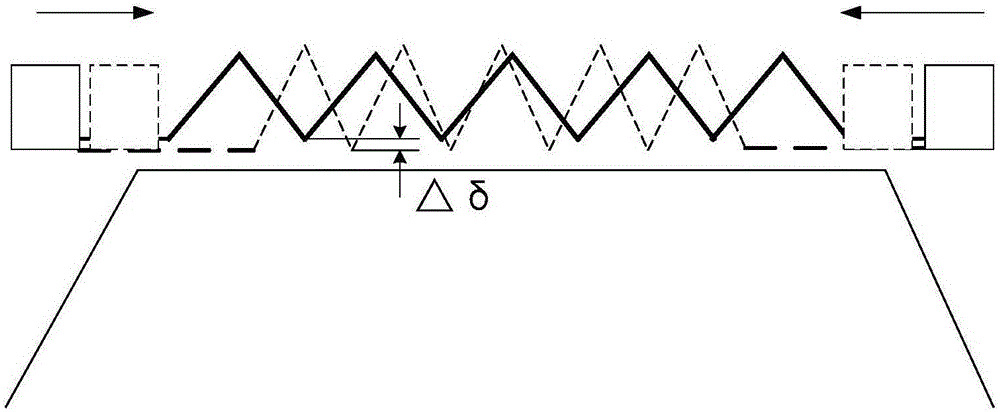

Mechanism for active control over blade top gap and case shape of air compressor within full working condition range

ActiveCN105840549AIncrease stall marginApplicable to active control requirementsPump componentsEngine controlImpellerGas compressor

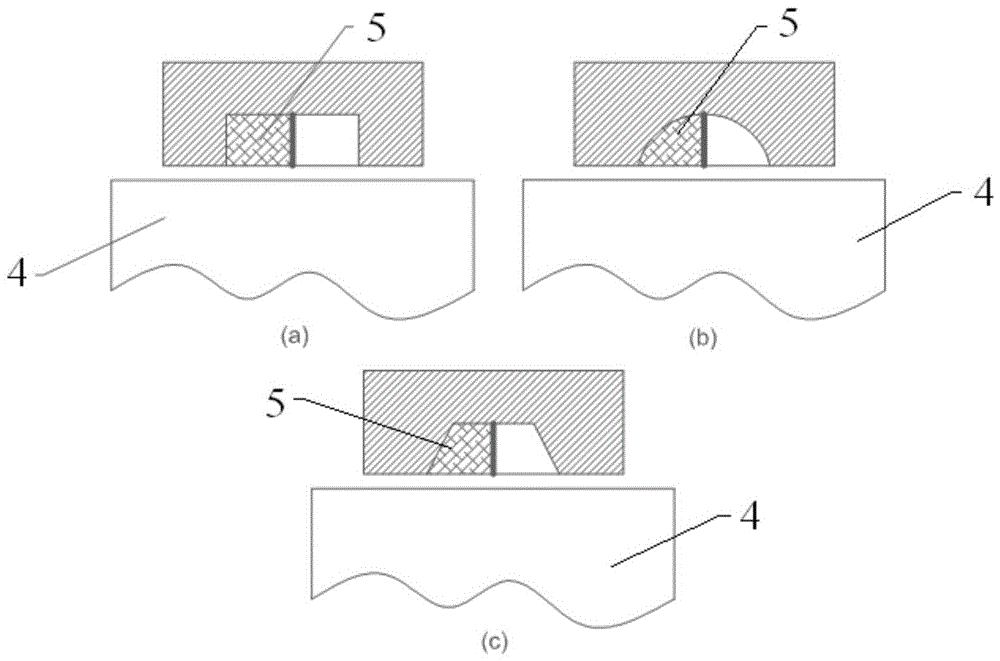

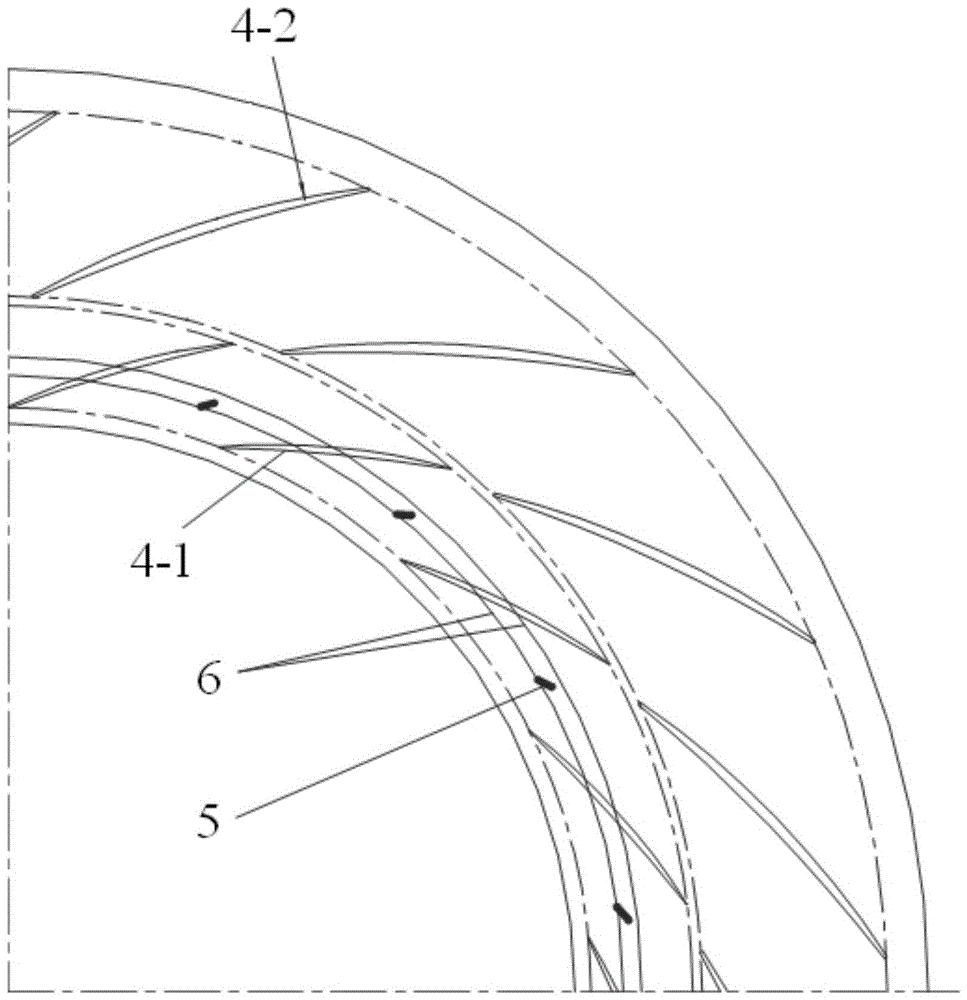

The invention relates to a mechanism for active control over the blade top gap and the case shape of an air compressor within the full working condition range. Under the condition that the working condition of the air compressor changes, the blade top gap size and the case shape of the air compressor are controlled in a closed-loop mode by monitoring the pneumatic performance and the blade top gap, and the mechanism aims to improve the pneumatic stability and structural stability of the air compressor within the full working condition range. According to the mechanism for active control over the blade top gap and the case shape of the air compressor within the full working condition range, a main structure comprises a blade top gap measurement system, a corrugated inner case, a worm gear and worm transmission mechanism, a stepping motor and an outer case, wherein the blade top gap measurement system is used for monitoring the blade top gap delta; the corrugated inner case is used for adjusting the size of the blade top gap and the case shape; the worm gear and worm transmission mechanism is used for stretching or compressing the corrugated inner case; the stepping motor is used for driving the worm gear and worm transmission mechanism; the outer case is used for isolated sealing of a flow channel of the air compressor and safety protection of a rotating piece; the diameter DINmin of the inner wall surface of a trough of the corrugated inner case, the blade top gap delta and the diameter DBTop of the blade top of an impeller meet the relational expression of DINmin=DBTop+2delta; the wave number NTop of the corrugated inner case within the range of the axial chord length C of the blade top ranges from 5 to 6; the ripple depth h of the corrugated inner case and the axial chord length C of the blade top meet the relational expression of h=A.c / 100, wherein A=10-50; and the ripple opening width w of the corrugated inner case and the axial chord length C of the blade top meet the relational expression of w=B.c / 100, wherein B=10-15. The mechanism is suitable for active adjustment of the blade top gap and the case shape of the air compressor within the full working condition range, and the pneumatic stability and the structural stability of the air compressor are improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

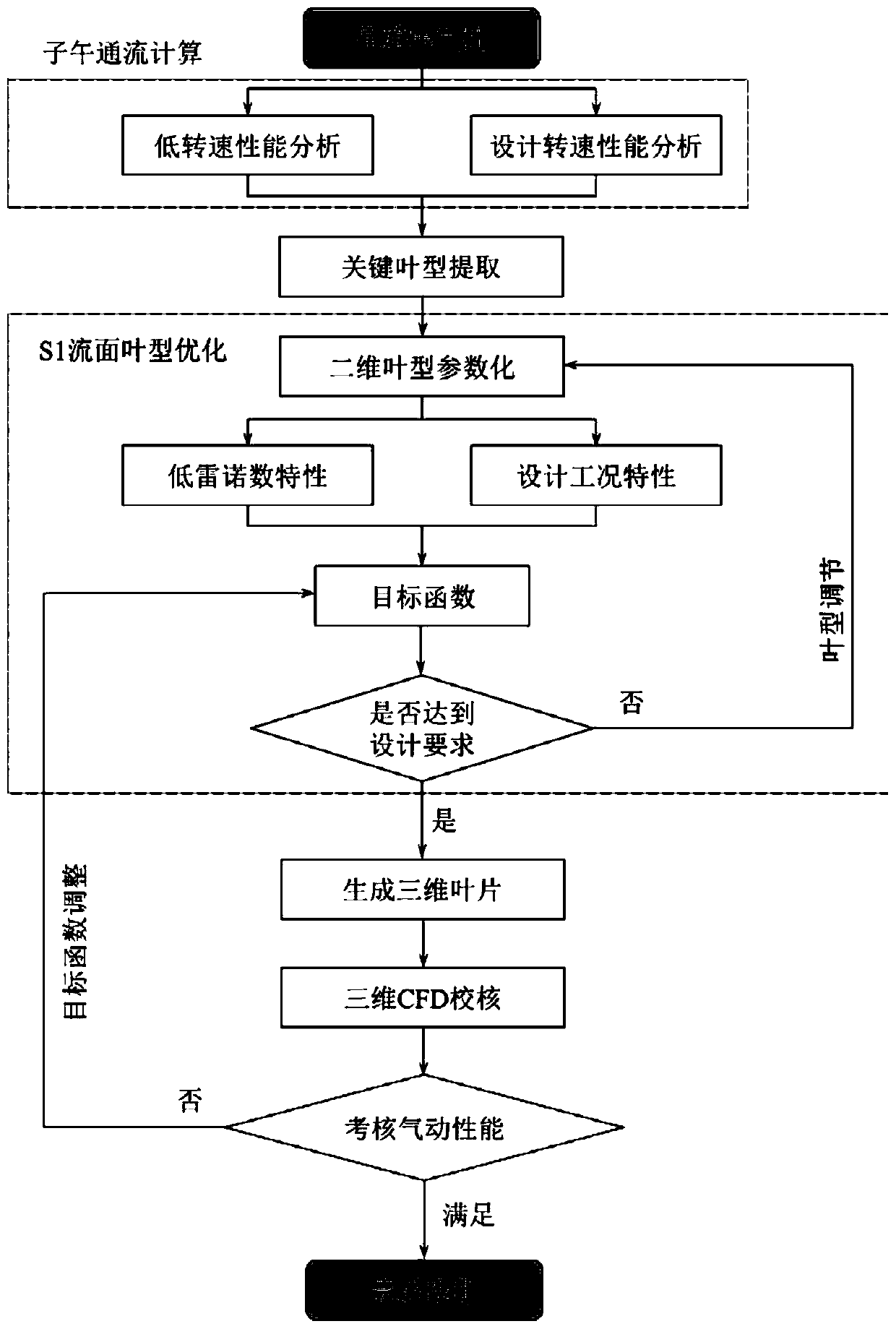

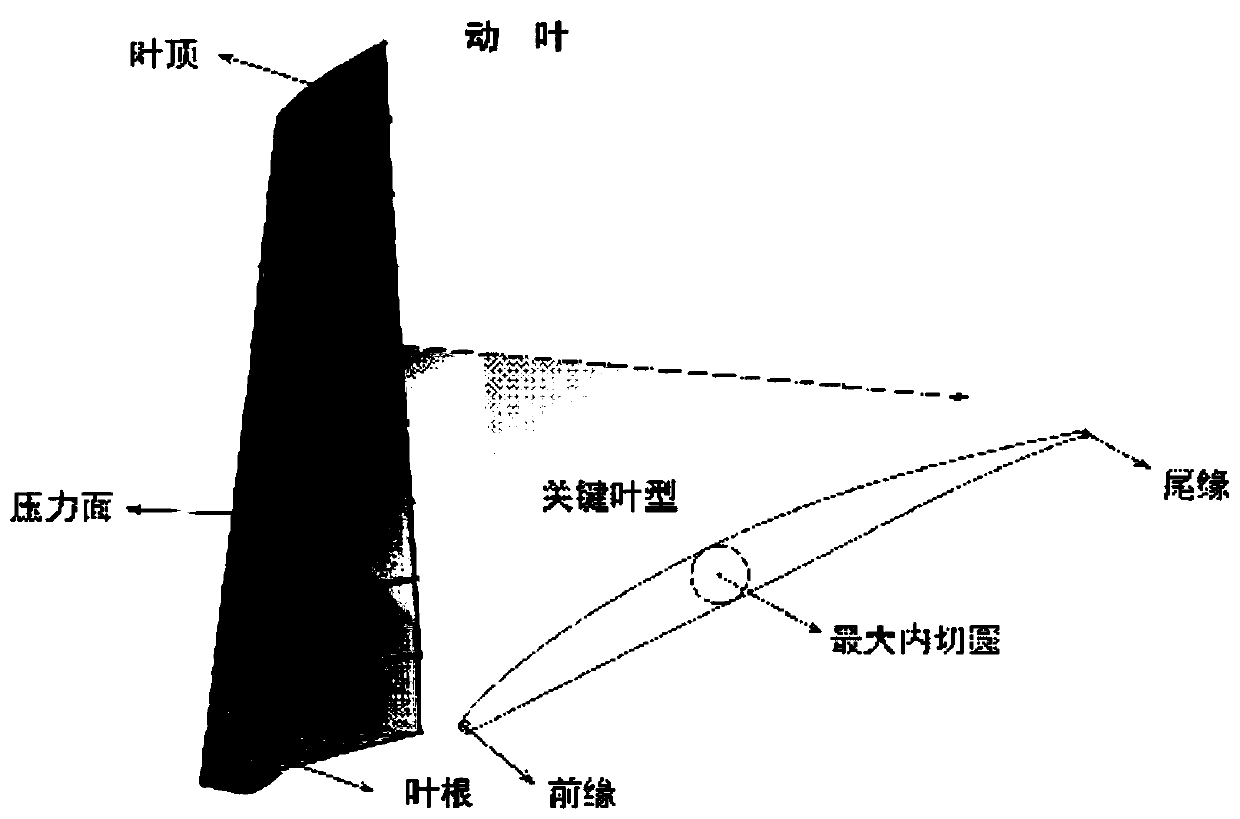

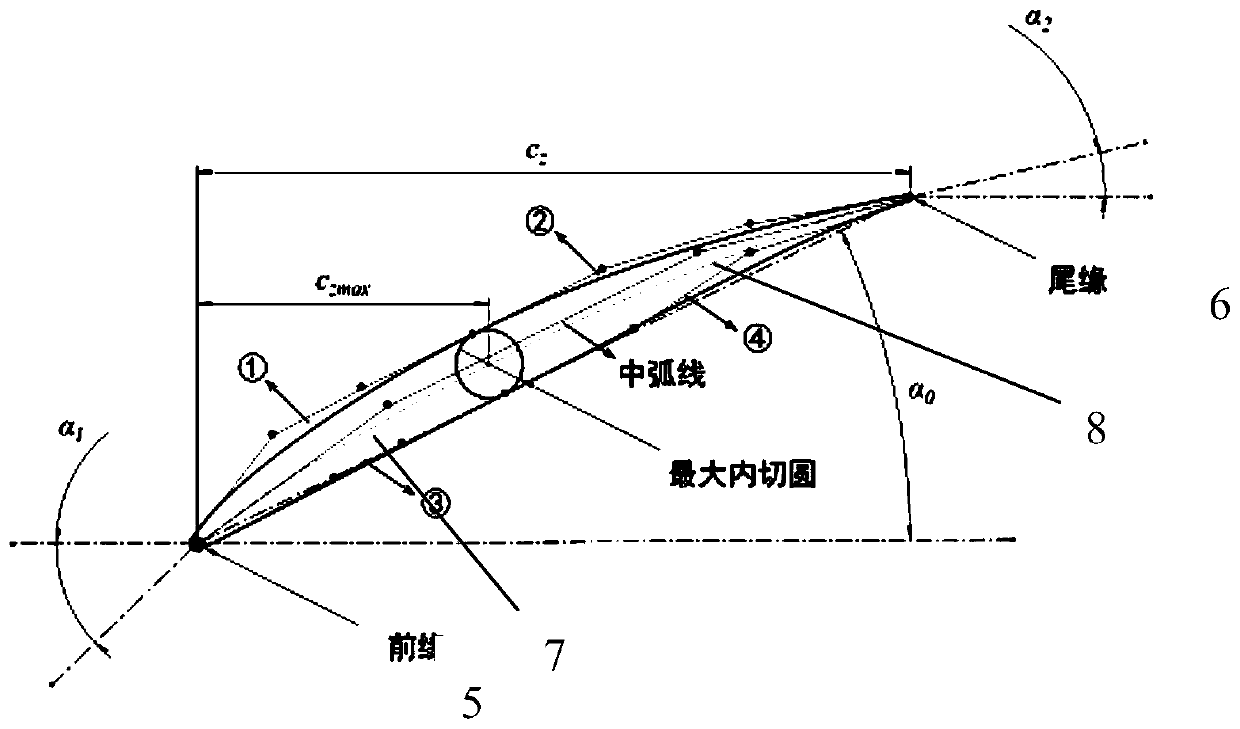

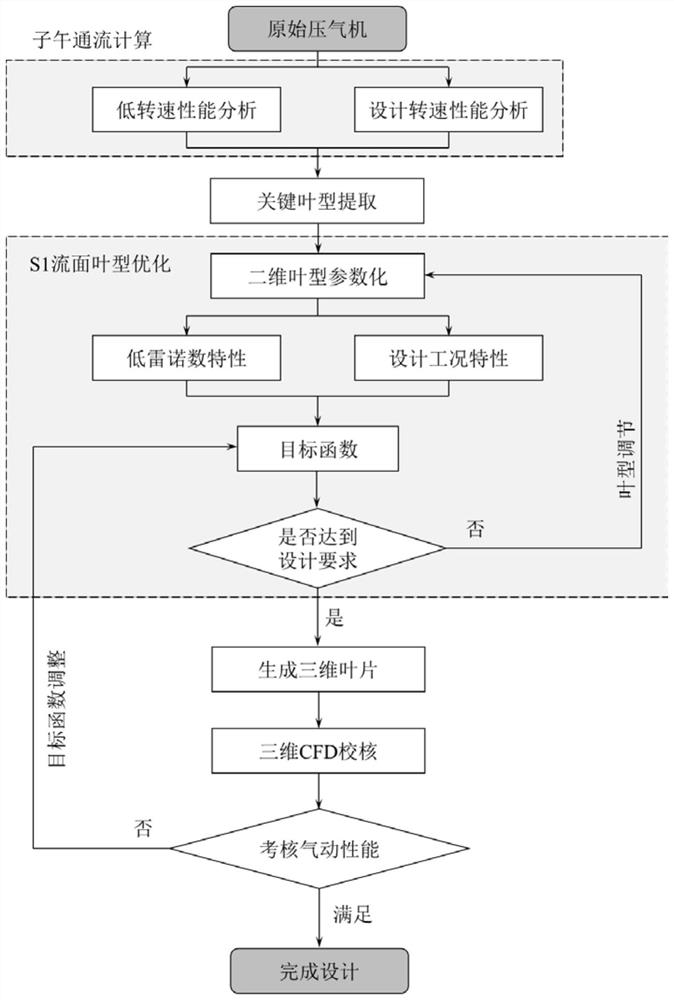

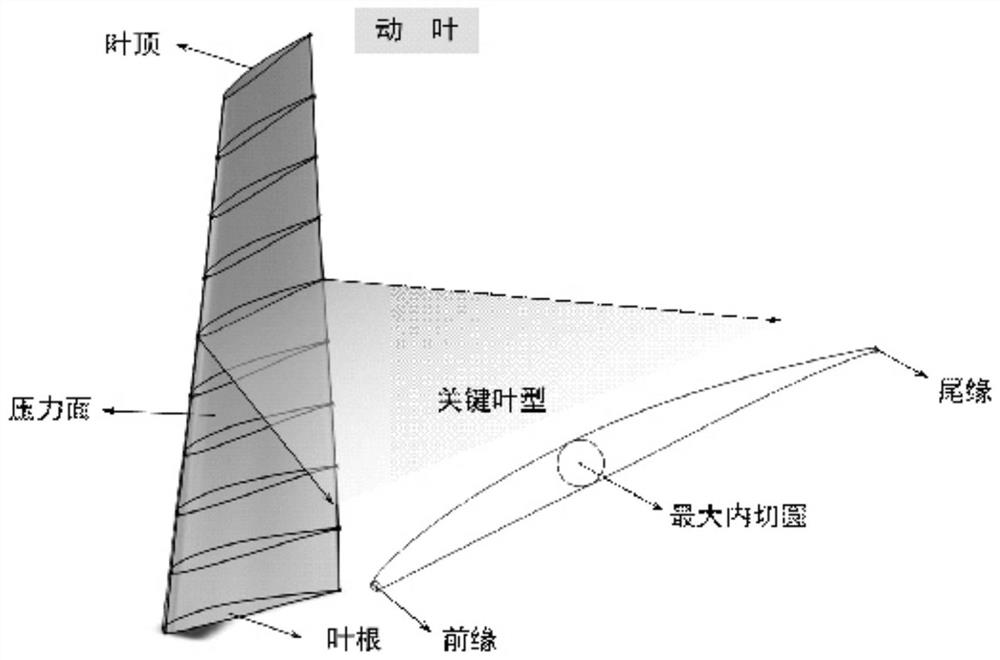

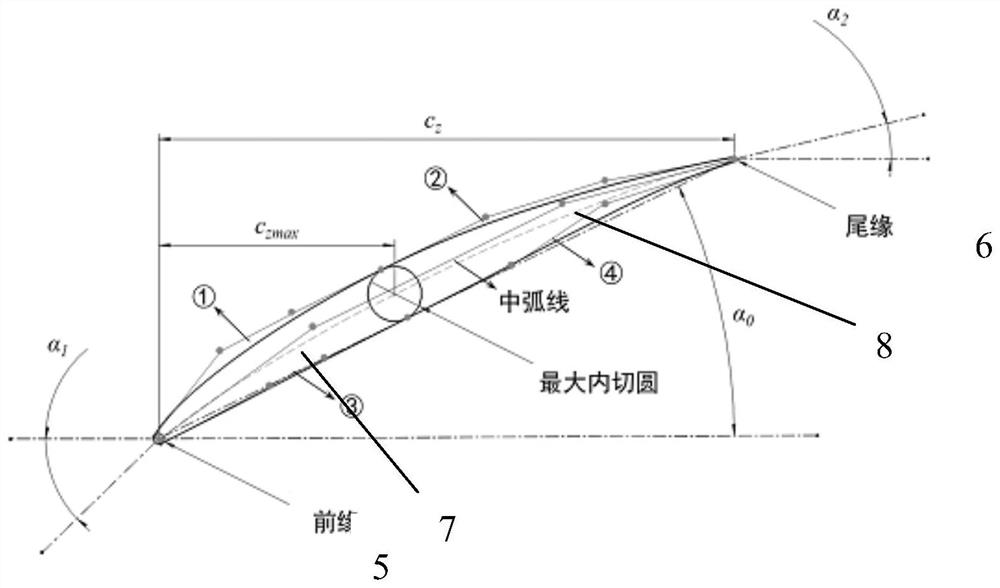

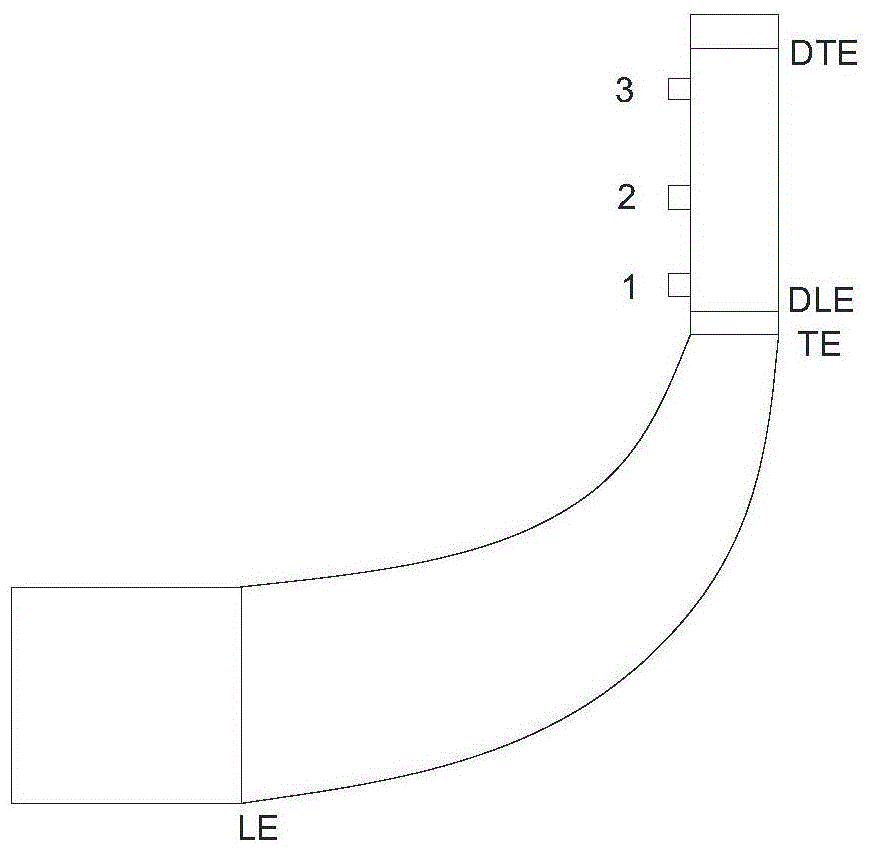

Two-dimensional blade profile optimization method for compressor considering low Reynolds number working performance

ActiveCN109779972AImprove aerodynamic performanceIncrease stall marginPump componentsPumpsGenetic algorithmEngineering

The invention relates to a two-dimensional blade profile optimization method for a compressor considering a low Reynolds number working performance; the optimization method is characterized by comprising the following steps of: step 1: analyzing the meridional flow performance of a prototype multistage axial flow compressor at different rotating speeds; step 2: determining a key two-dimensional blade profile section to be optimized; step 3: performing parametric fitting to the key two-dimensional blade profile in step 2; step 4: analyzing the aerodynamic performance of the two-dimensional blade profile, and analyzing the aerodynamic performance of the parameterized two-dimensional blade profile to obtain the variable attack angle performance of the blade profile under a low Reynolds numberworking condition and the variable attack angle performance under a high Reynolds number working condition; and step 5: optimizing the modeling parameters of the two-dimensional blade profile, adjusting the two-dimensional modeling parameters according to the variable attack angle performance parameters of the two-dimensional blade profile obtained in step 4 at different Reynolds numbers, using agenetic algorithm to circularly iterate steps 3 and 4 until a two-dimensional blade profile design reducing loss and increasing stall margin is obtained, and then obtaining a new two-dimensional blade profile. According to the invention, the performance optimization of the two-dimensional blade profile of the axial flow compressor at different Reynolds numbers and different attack angles is realized; the designed working performance of the compressor is improved while the aerodynamic performance of the compressor at the low rotation speed working condition is improved; and the flow efficiencyis improved while the normal starting and stable working of the compressor are ensured.

Owner:HANGZHOU TURBINE POWER GRP

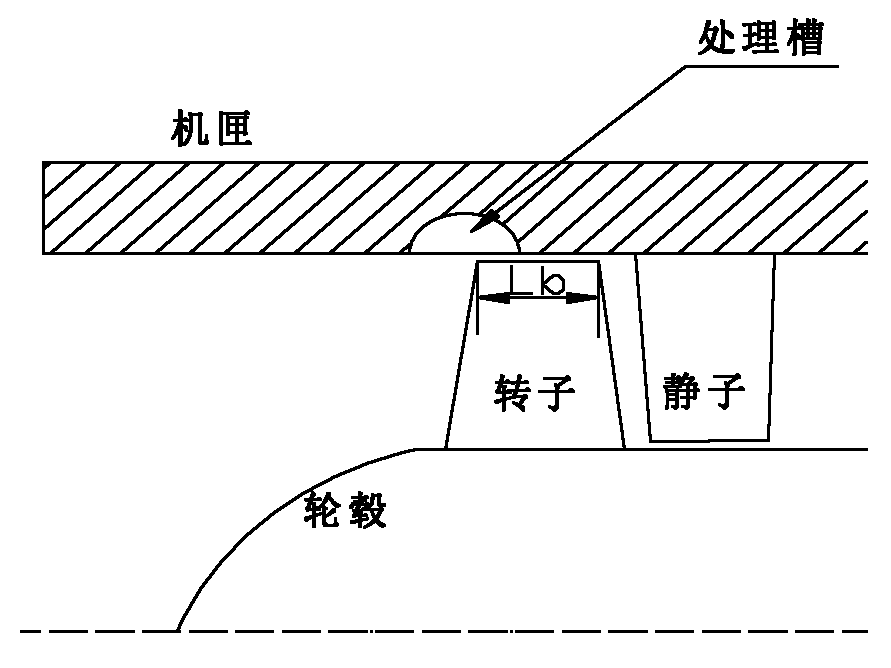

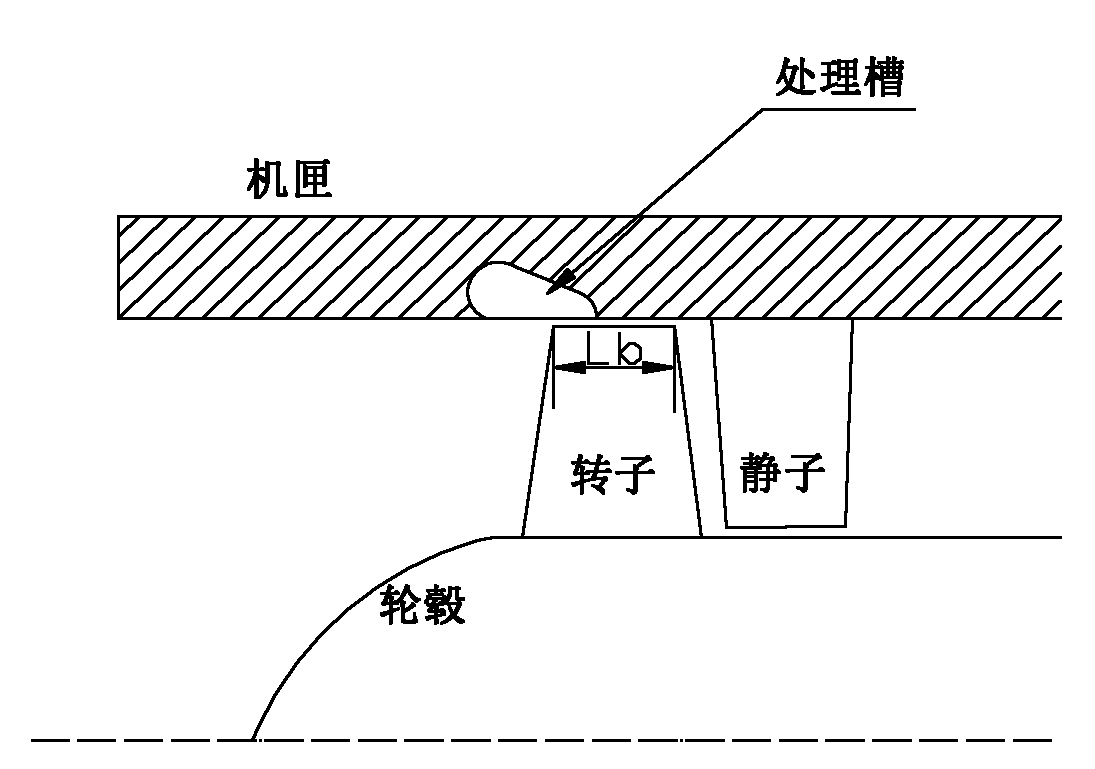

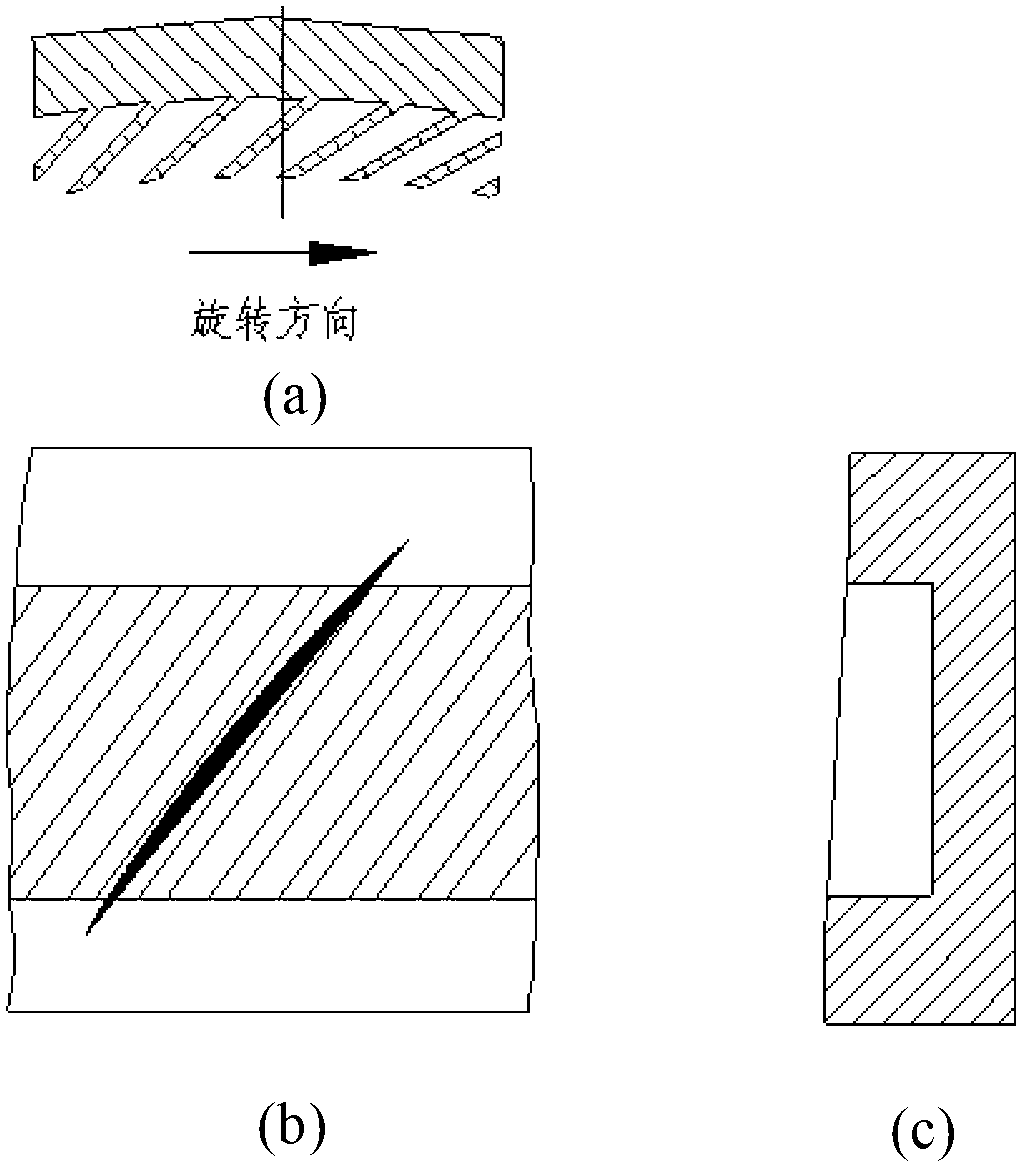

Ellipse/circular arc chute processing machine box

The invention relates to an ellipse / circular arc chute processing machine box applying to a rotor blade tip end region of an axial flow compressor. For the design of the ellipse or circular arc chute processing machine box, the greater flow loss of the processing chute caused by the rectangular and trapezoid design of the traditional processing machine box is taken into account. Through the reasonable design of a geometric construction type of the processing chute, namely the combination design that an ellipse shape is adopted at the R direction (radial) and a circular arc shape is adopted at the Z direction (axial), the greater low loss caused by the rectangular and trapezoid design is avoided, thus the efficiency is not reduced, meanwhile the stall margin of the compressor is improved greatly for the ellipse or circular arc chute processing machine box.

Owner:BEIHANG UNIV

Multi-arc chute processing machine box

The invention relates to a multi-arc chute processing machine box applying to a rotor blade tip end region of an axial flow compressor. For the design of the multi-arc chute processing machine box, the greater flow loss of the processing chute caused by the rectangular and trapezoid design of the traditional processing machine box is taken into account. Through the reasonable design of a geometric construction type of the processing chute, namely the combination design that a double-arc shape is adopted at the direction of the R direction and a circular arc shape is adopted for theta (circumference), the greater low loss caused by the rectangular and trapezoid design is avoided, thus the peak value efficiency is improved slightly, meanwhile the stall margin of the compressor is improved greatly for the multi-arc chute processing machine box.

Owner:BEIHANG UNIV

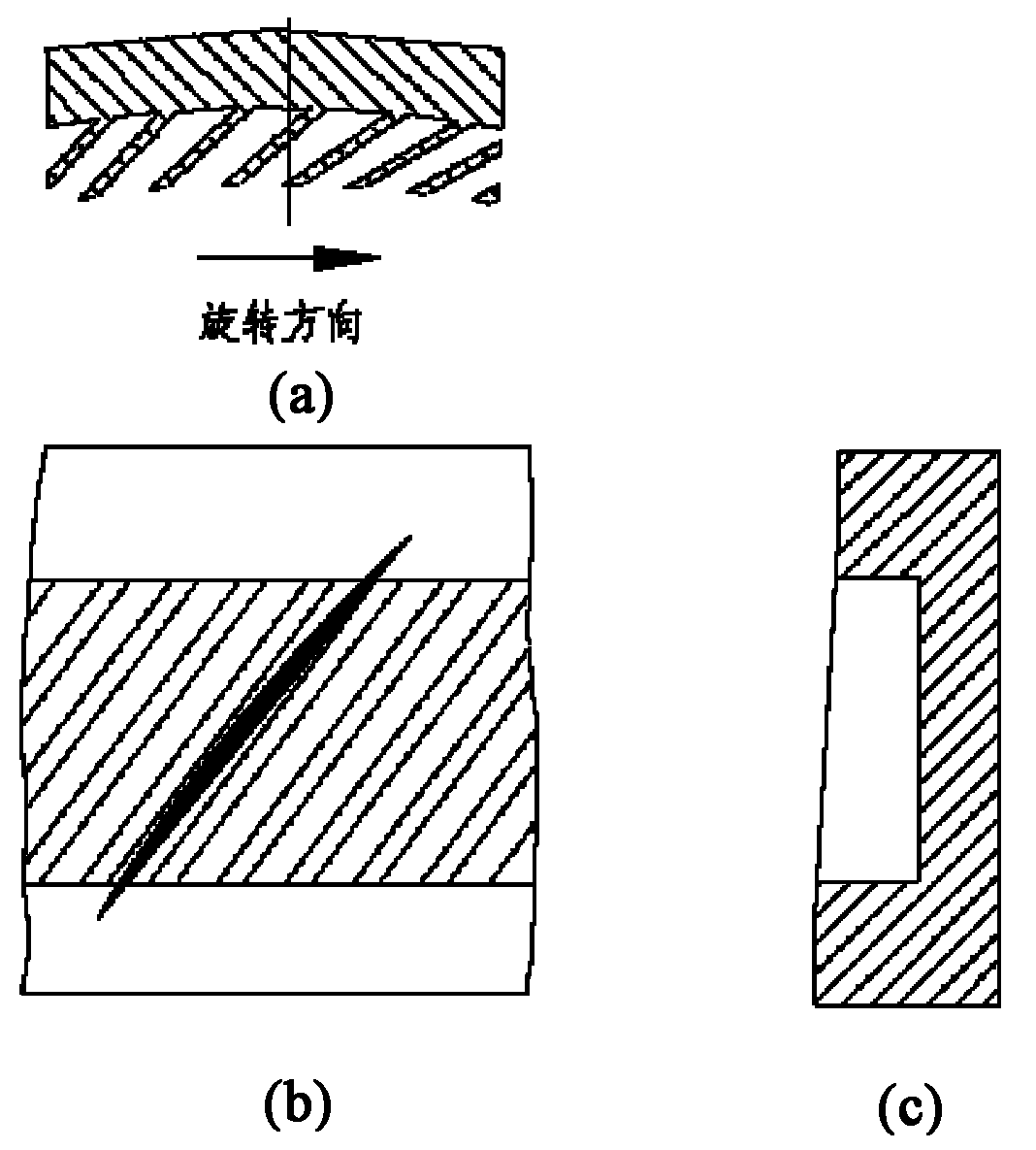

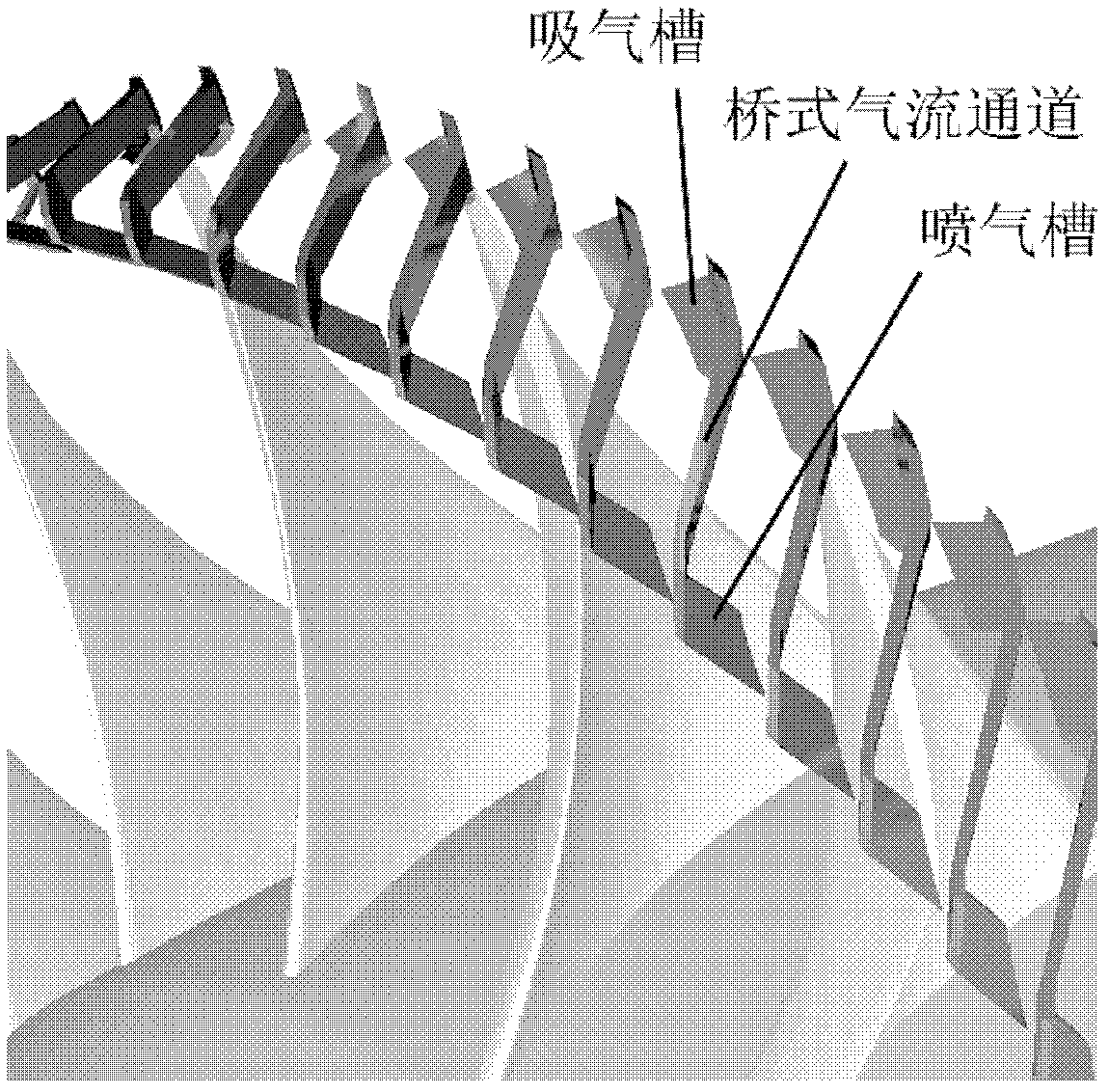

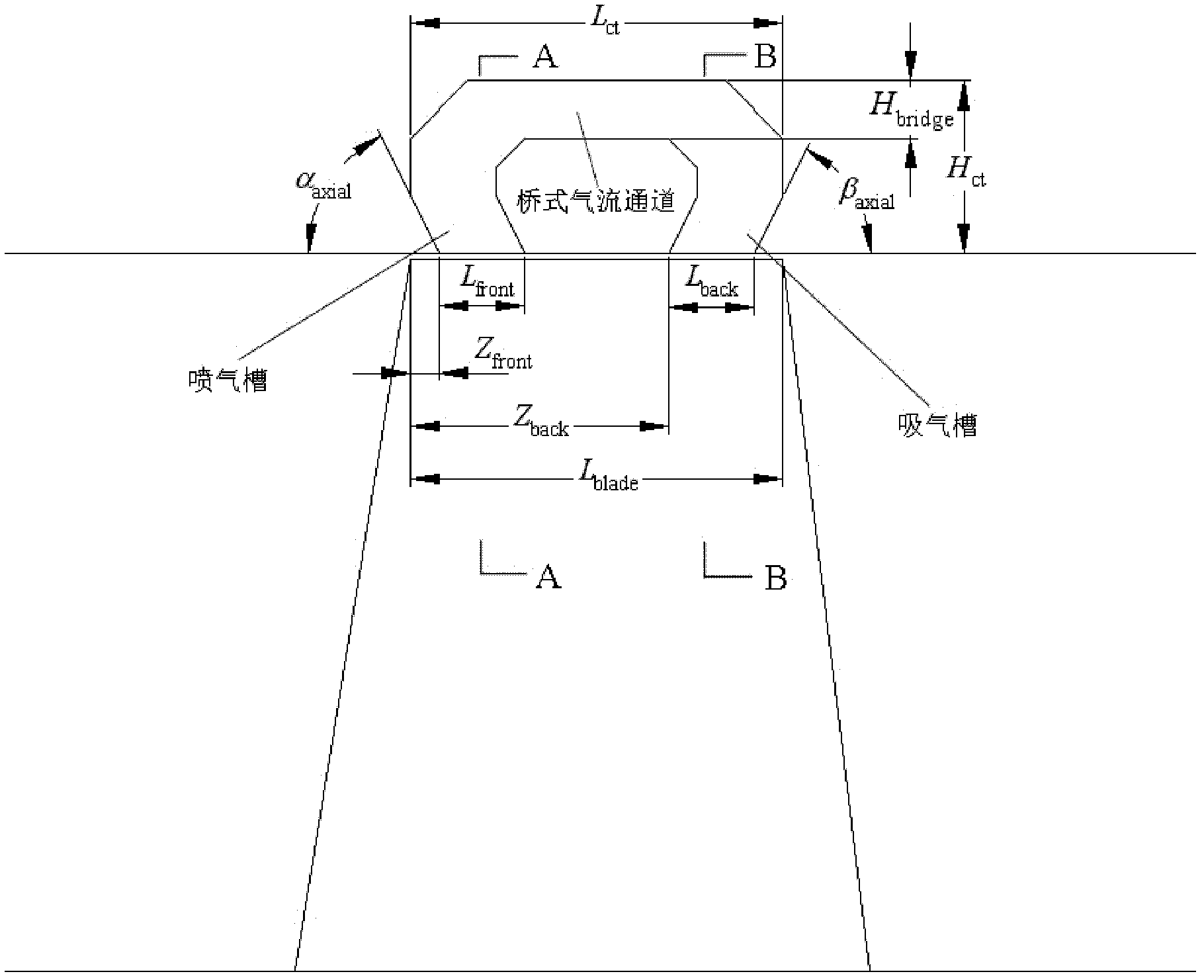

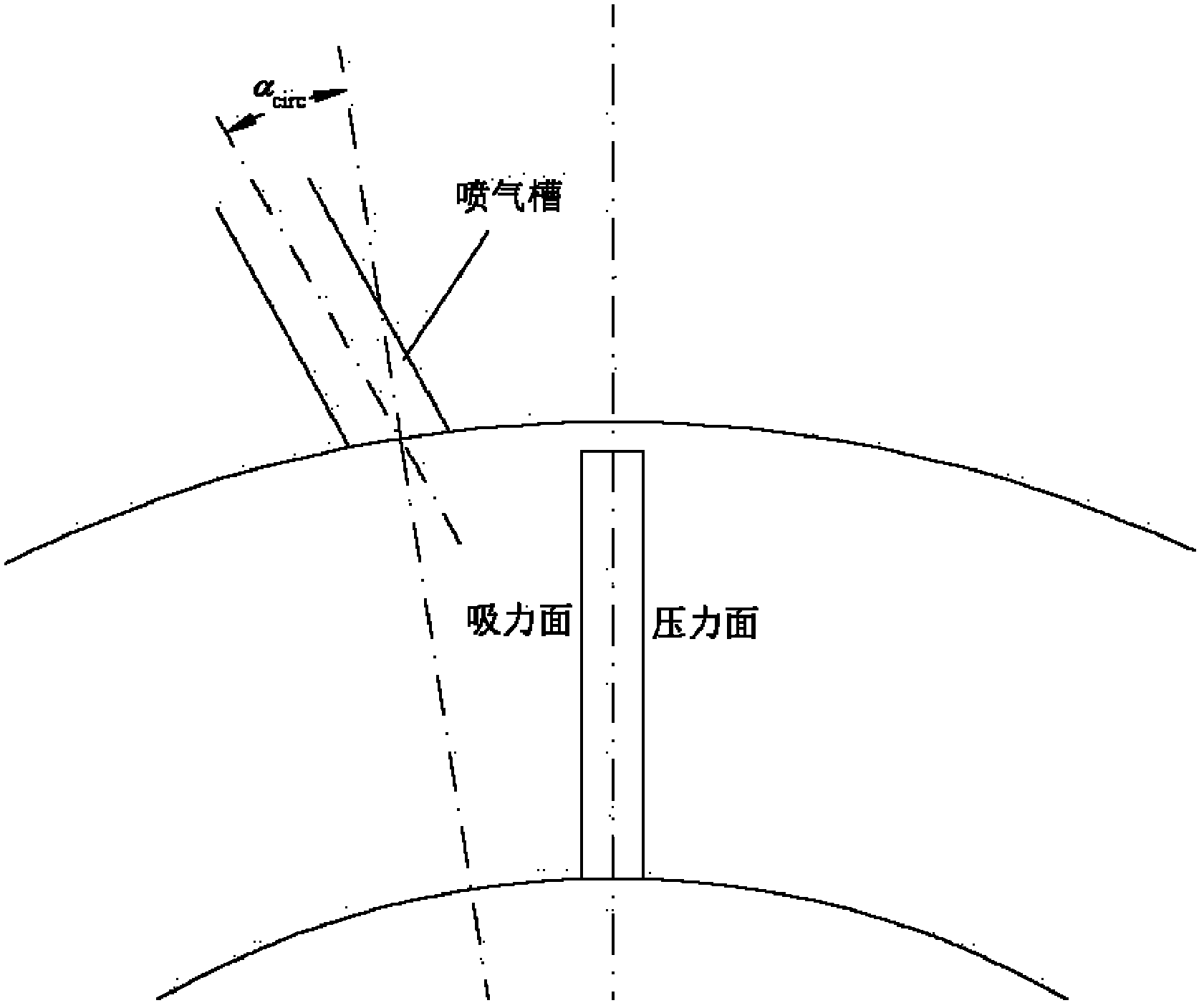

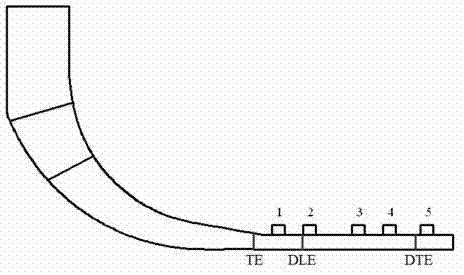

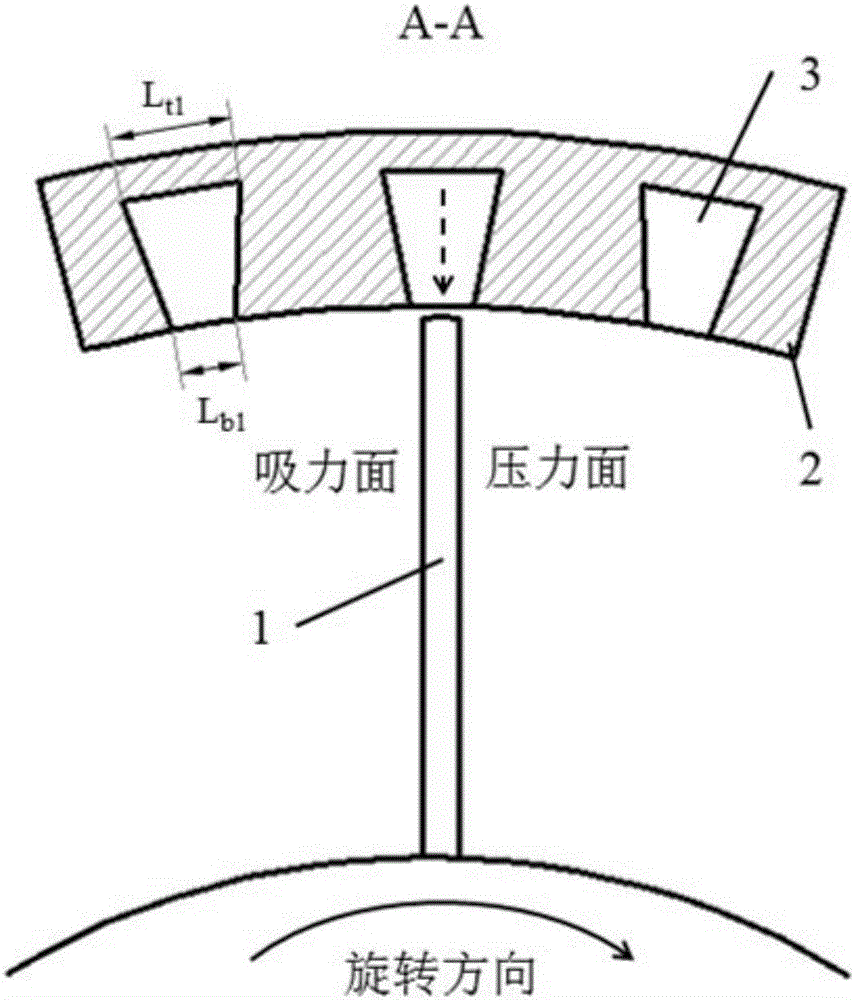

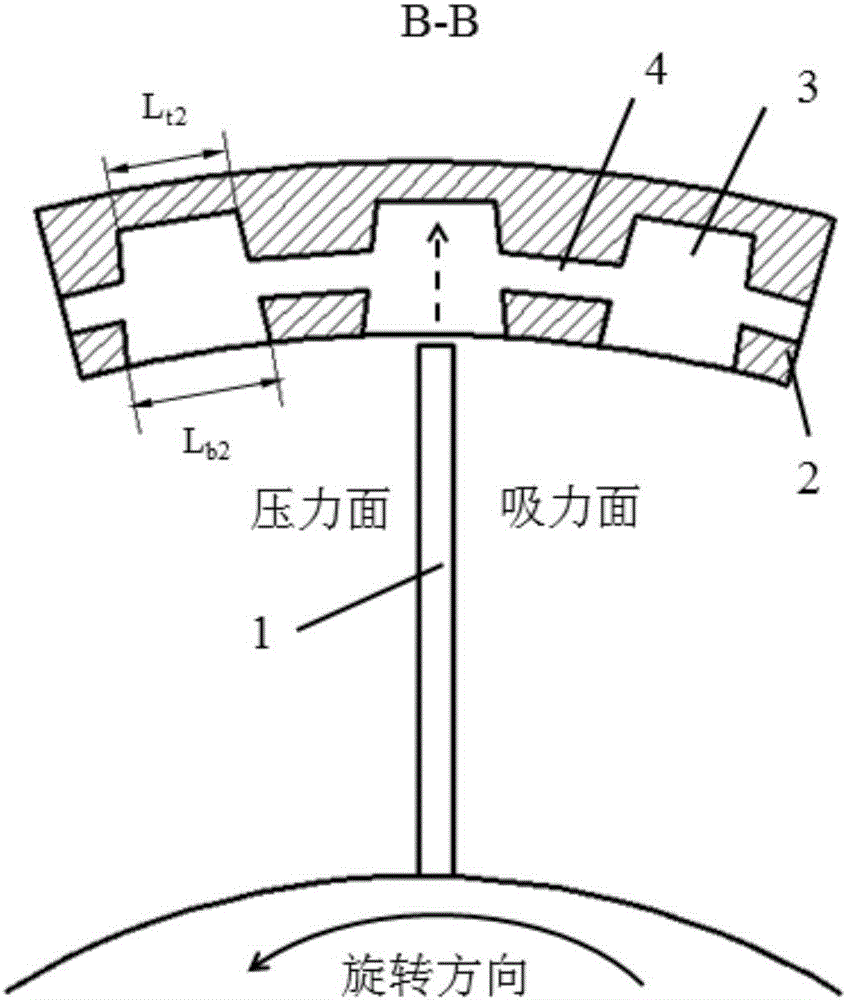

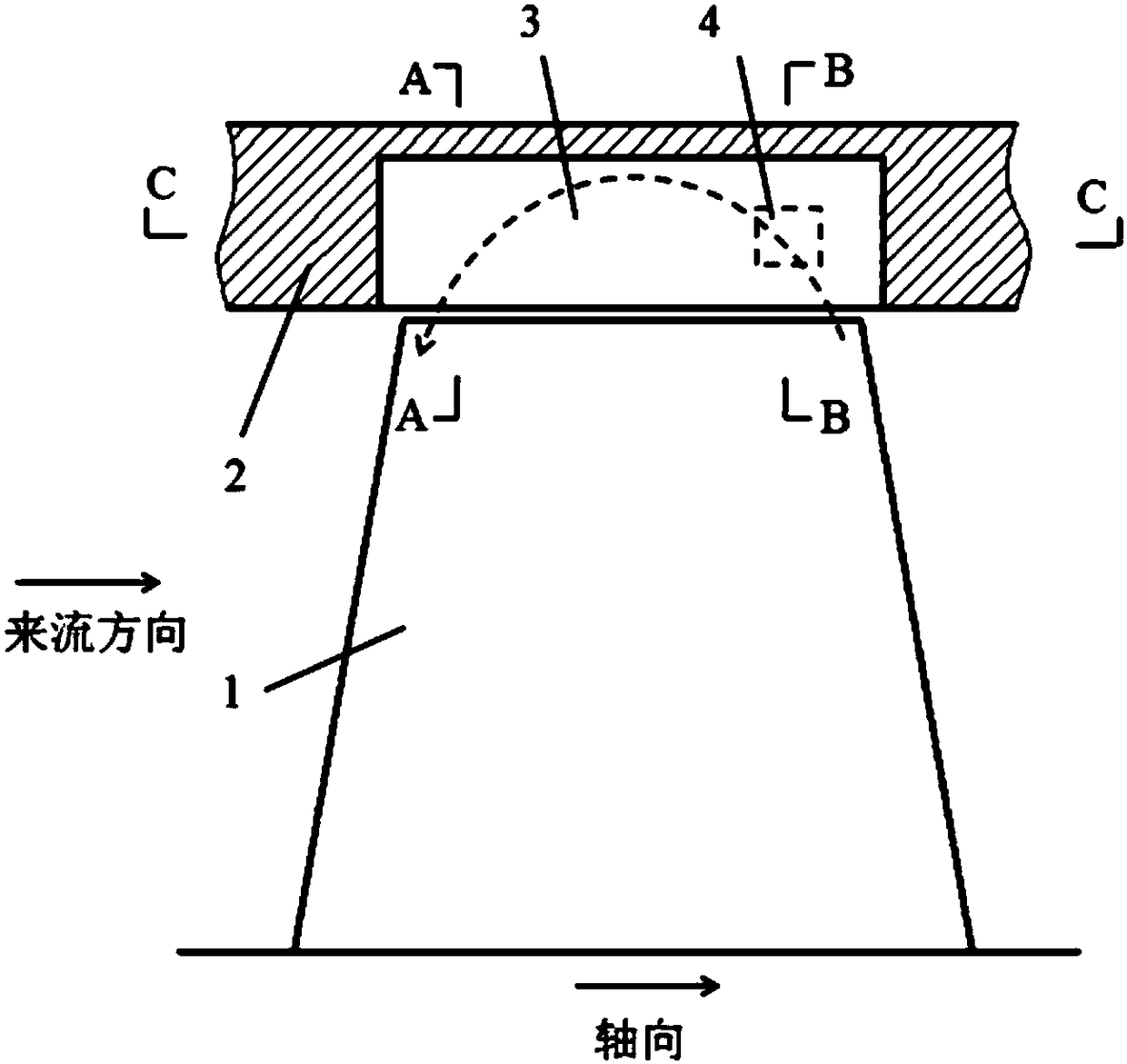

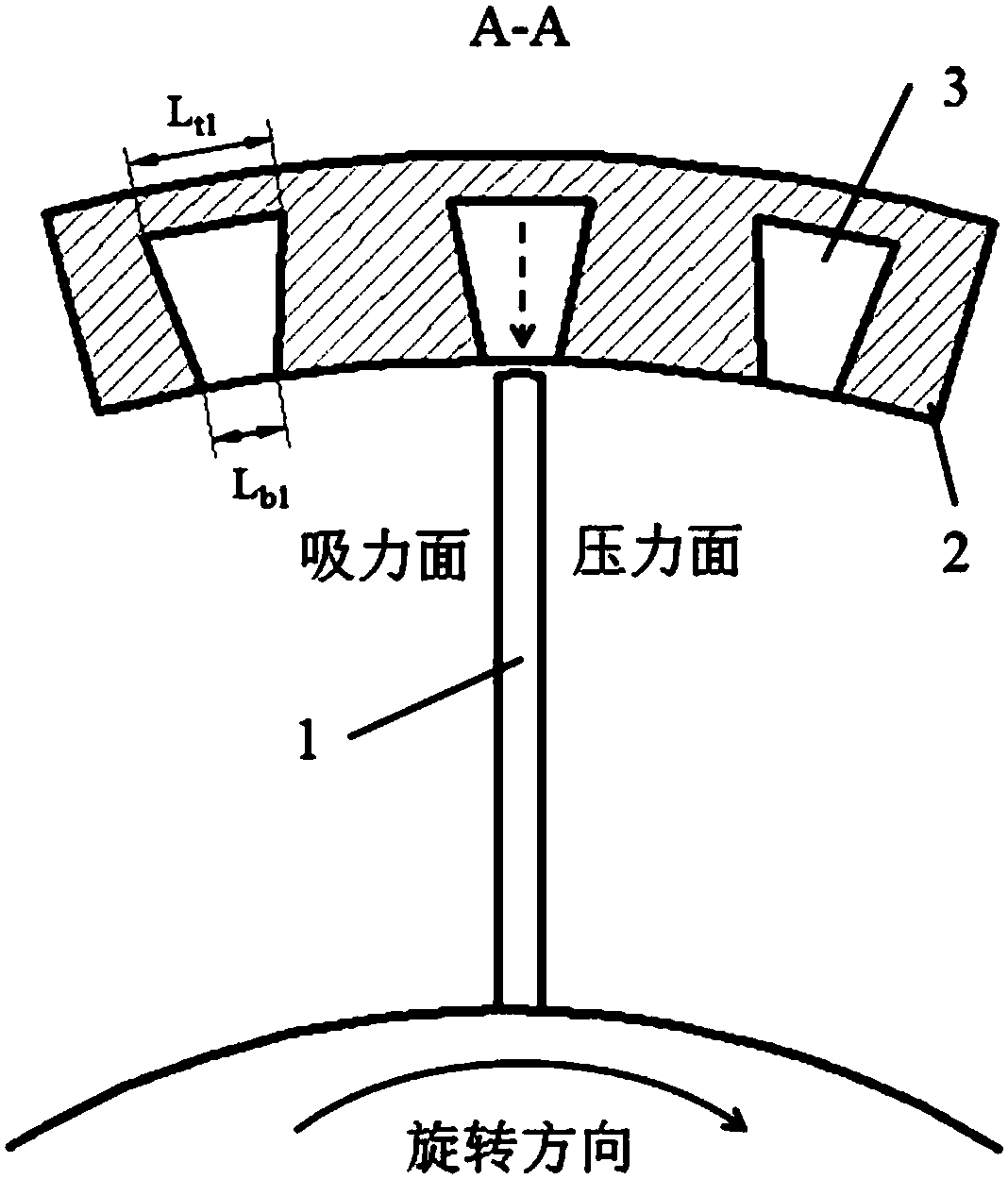

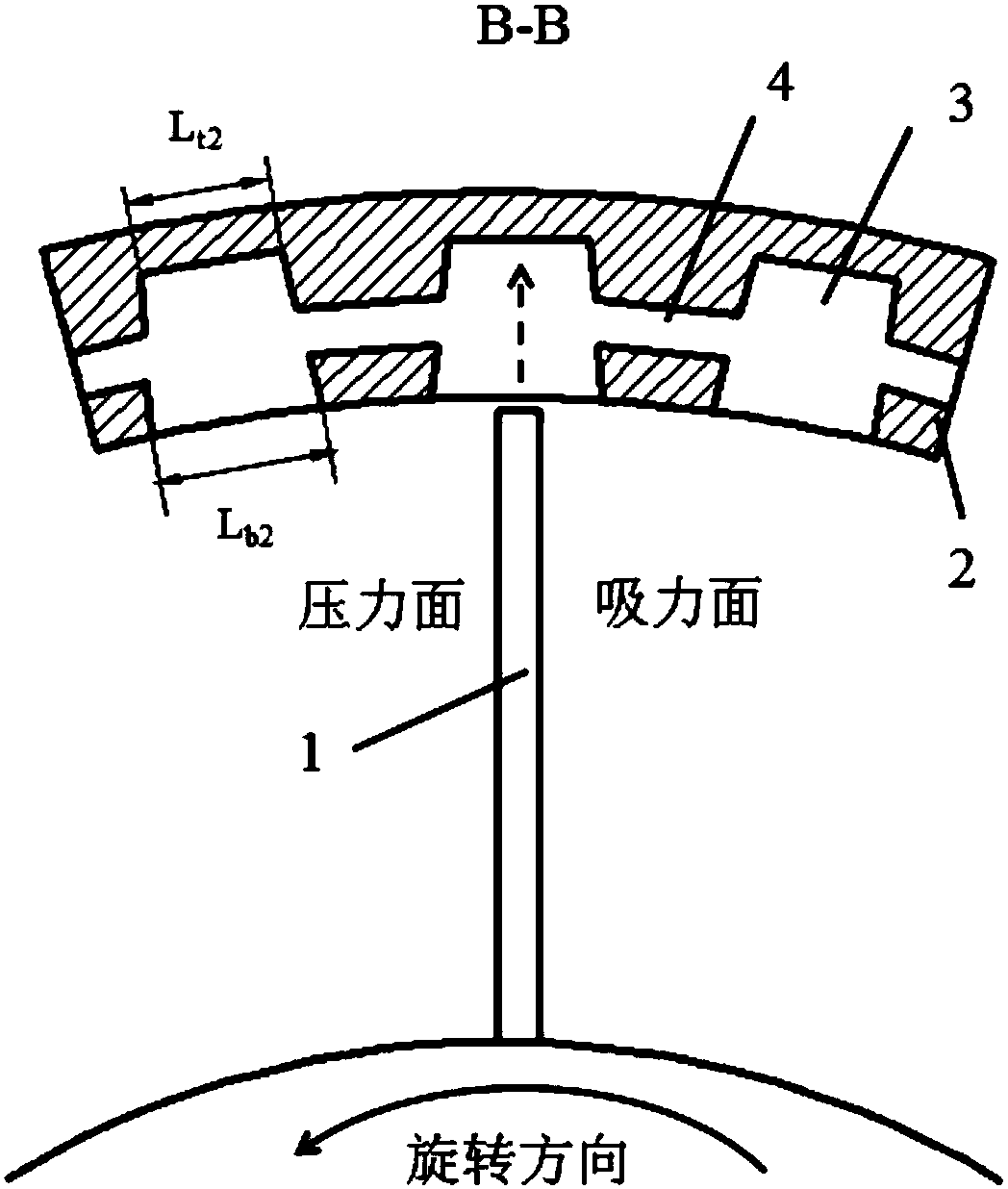

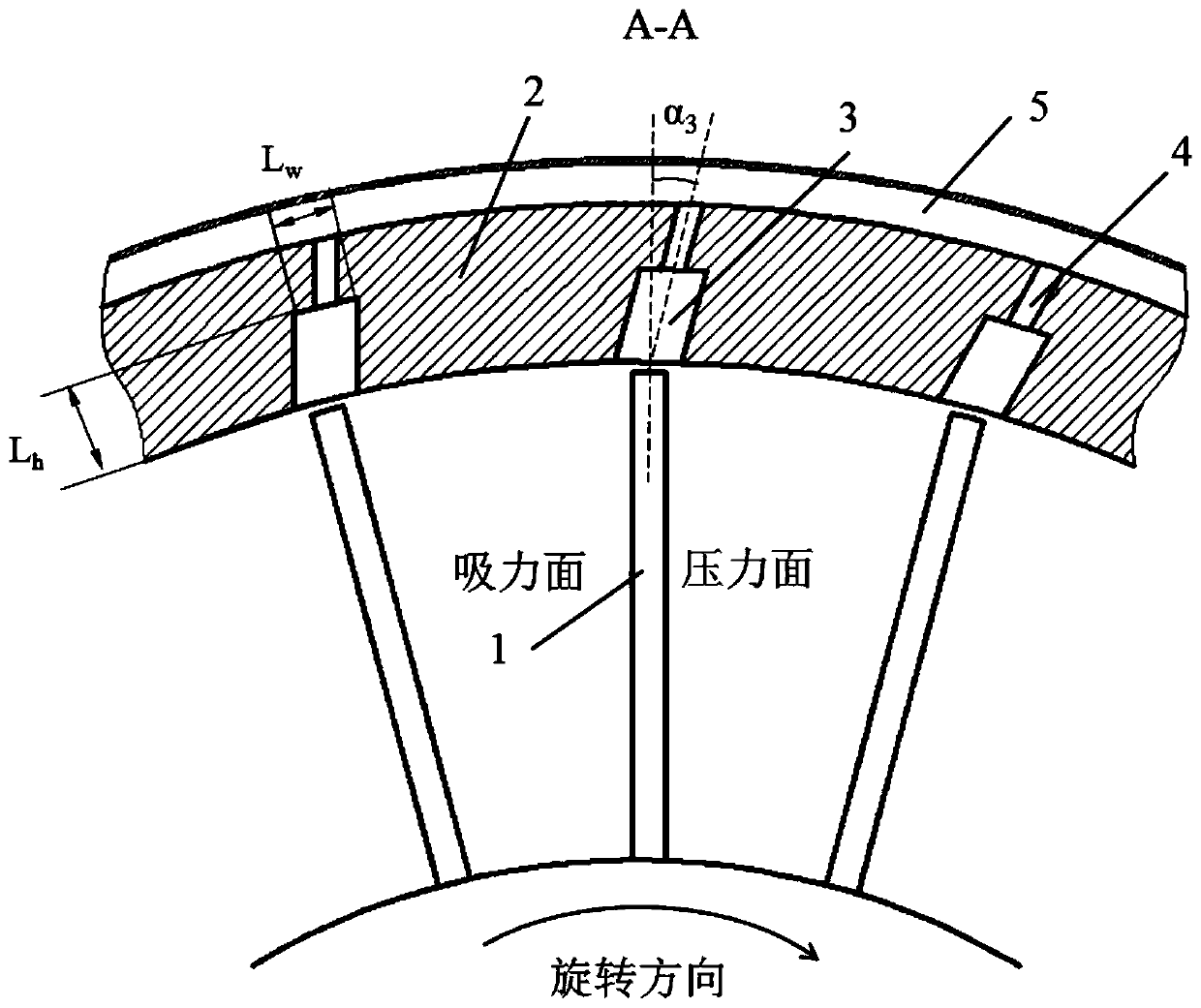

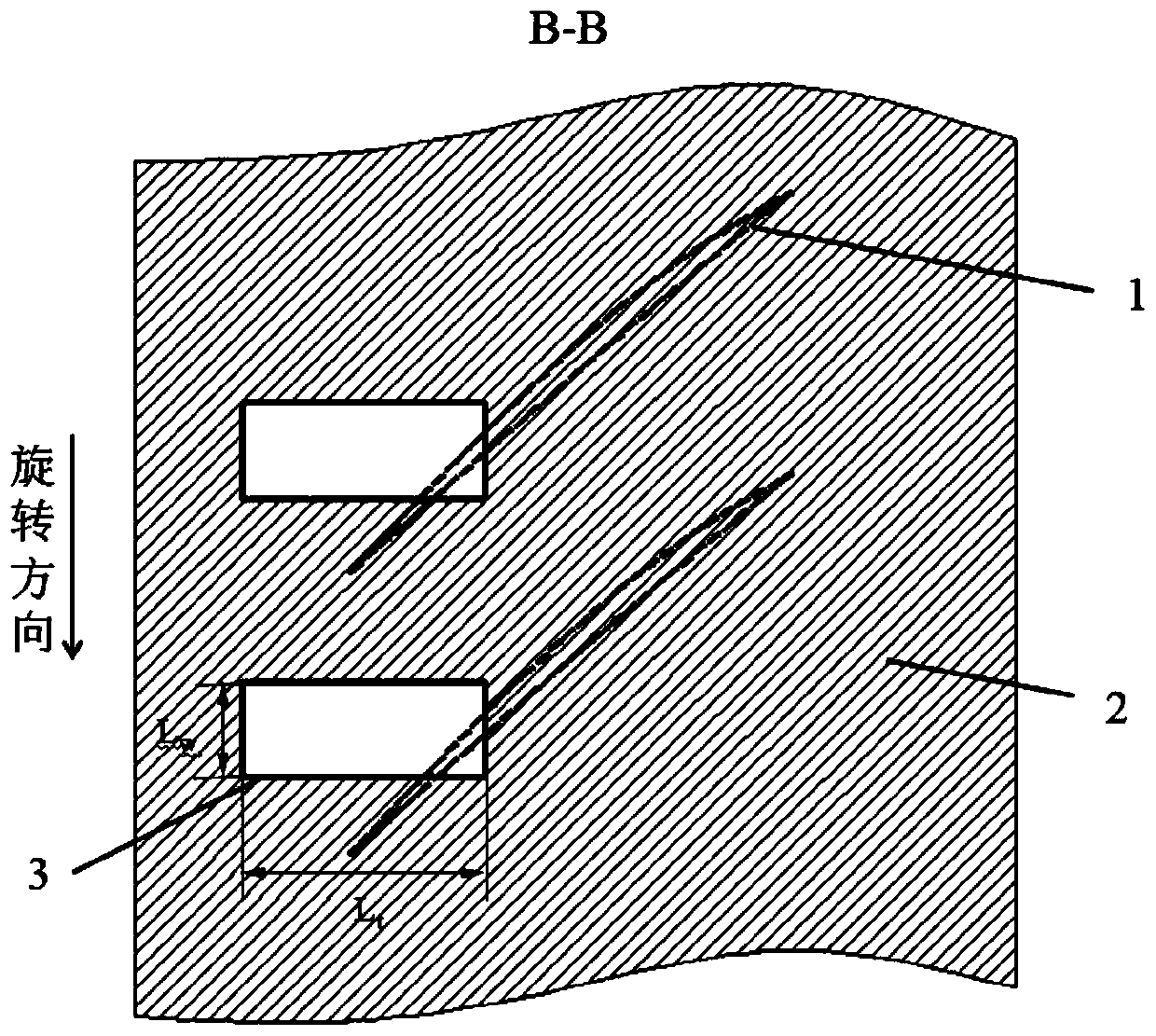

Unsteady standing vortex type treatment casing

The invention relates to a treatment casing applied to an axial-flow air compressor in the field of impeller machinery, in particular to an unsteady standing vortex type treatment casing, which can be used for improving the stability margin of the axial-flow air compressor without reducing efficiency. The unsteady standing vortex type treatment casing comprises an air jet groove, a bridge-type air flow channel and an air suction groove, wherein the air jet groove is arranged at the position of a suction surface of a blade, and the air suction groove is arranged at the position of a pressure surface of the blade. The treatment casing is designed to suppress leakage flow generated on the suction surface of a front edge of the blade, the air suction groove is exactly close to the pressure surface in the rear middle of the blade when the blade sweeps over, and the air jet groove is close to the suction surface of the front edge of the blade. Therefore, differential pressure is formed between the air suction groove and the air jet groove to drive fluids to spray from the downstream of the blade to the upstream of the blade, and the air jet groove is positioned close to the suction surface of the front edge of the blade and exactly aligned to a leakage vortex generating area of the blade, so that leakage flow can be suppressed, and further the stall margin of the air compressor is increased. Moreover, as an air jet direction is consistent with a main flow direction, mixing loss of an air jet area and a main flow area is decreased, the momentum of a boundary layer of the wall surface of the casing is increased, and positive effects are achieved for the efficiency of the air compressor.

Owner:BEIHANG UNIV

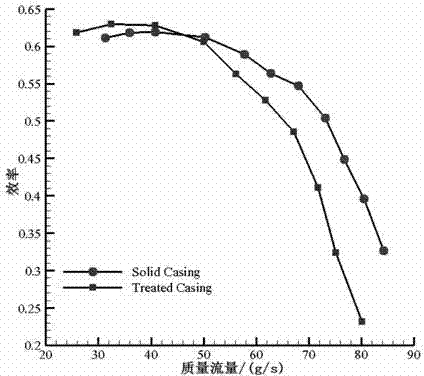

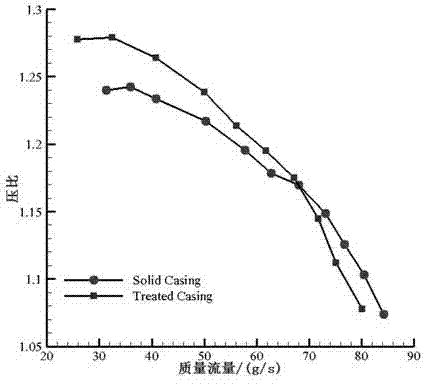

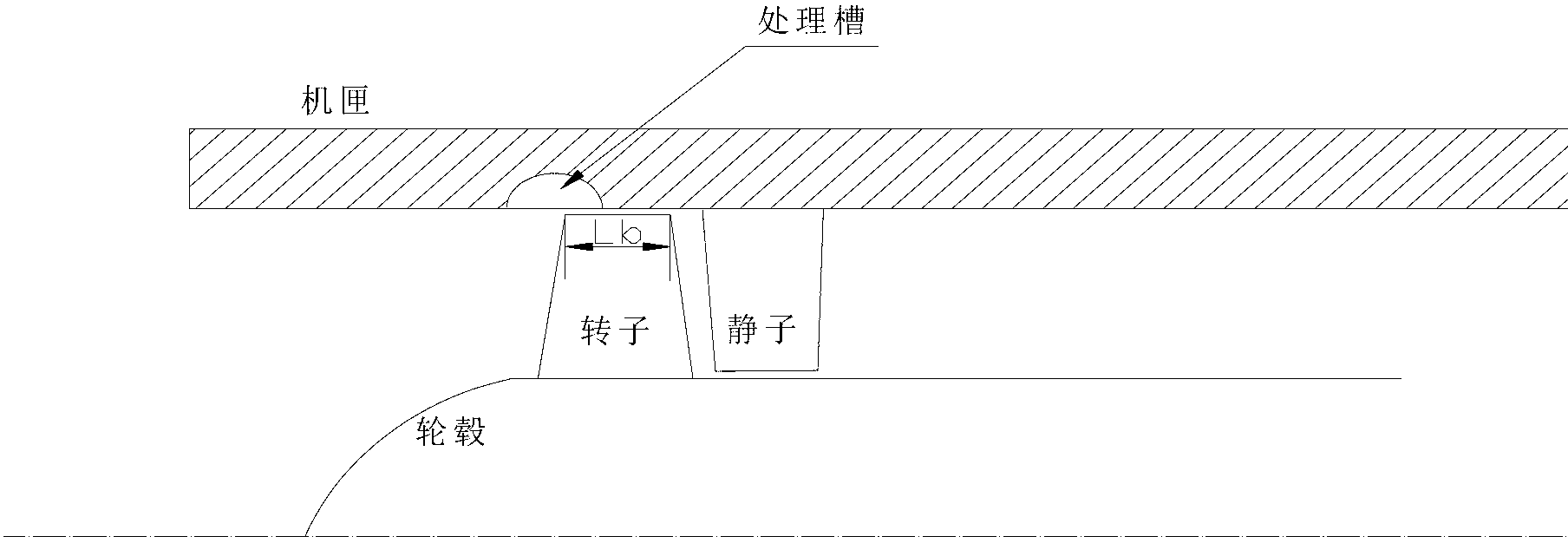

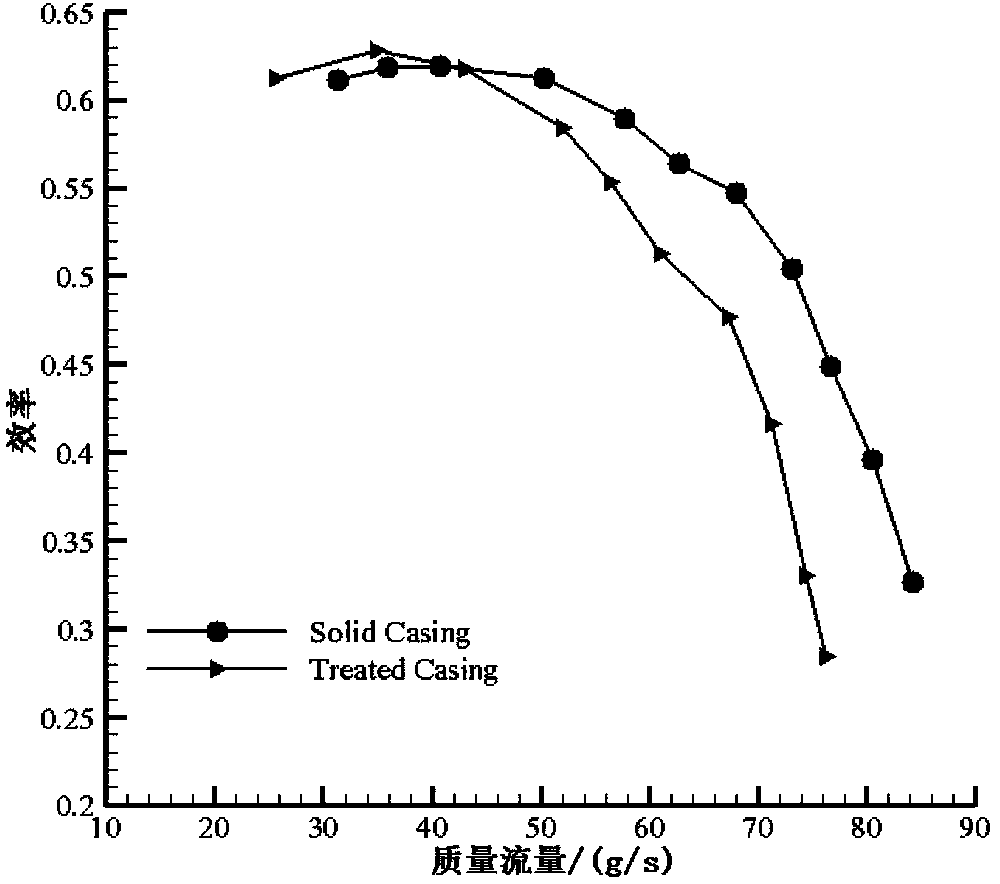

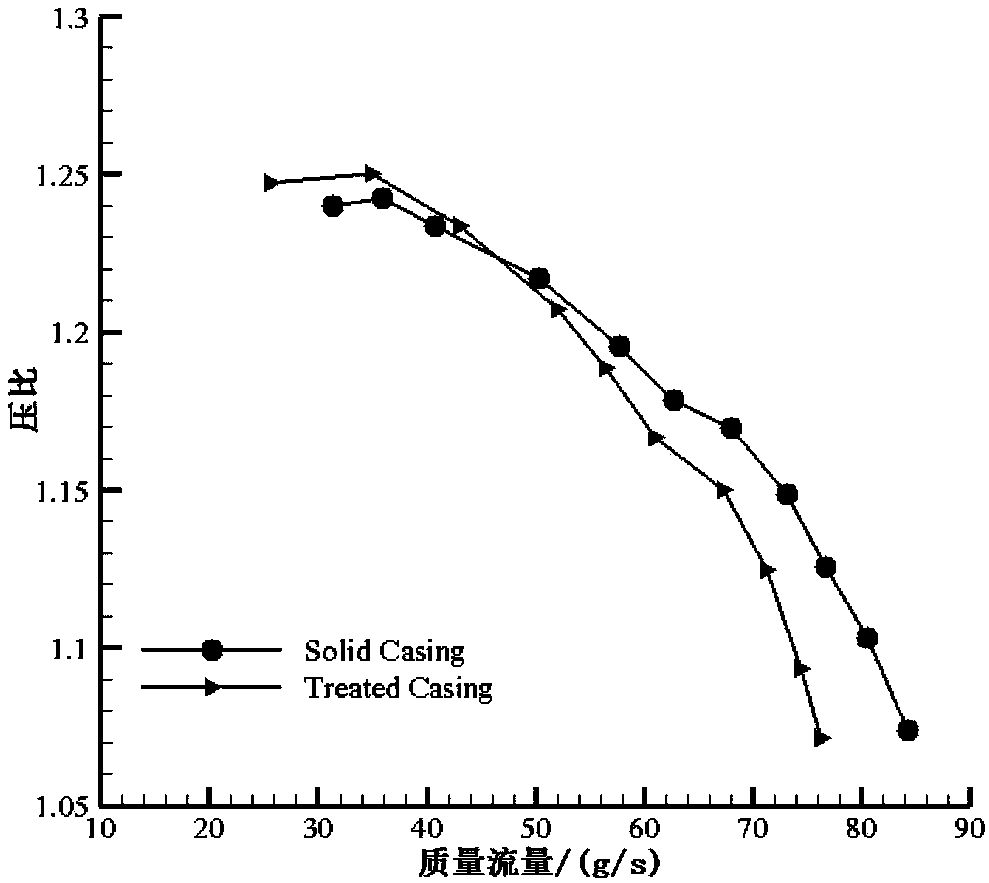

Circumferential groove casing treatment method

The invention provides a circumferential groove casing treatment method of a centrifugal compressor. The circumferential groove casing treatment method completely takes structure characteristics and internal flow situations of the centrifugal compressor into consideration. A groove is arranged in a position prone to speed reduction of a diffuser channel along the circumference of a wheel cap side so as to provide a backflow channel for low-speed fluid in a top area of the diffuser, and then lower-power fluid lump is pumped into a treatment groove and transported along the circumference direction and flow direction of the treatment groove. In the process, only part of the fluid refills into a main fluid, the area of lower-power fluid is reduced and flow speed is improved, flow situations of the top channel of the diffuser are improved, blocking of the top channel is weakened, steady operation range of the compressor is enlarged greatly, and meanwhile peak value efficiency and pressure ratios are improved.

Owner:XI AN JIAOTONG UNIV

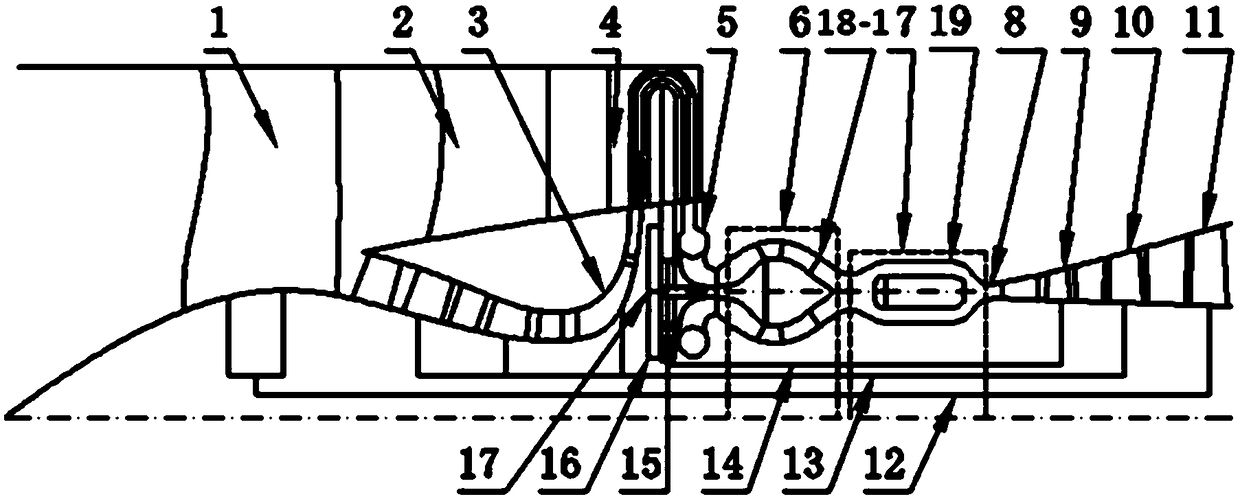

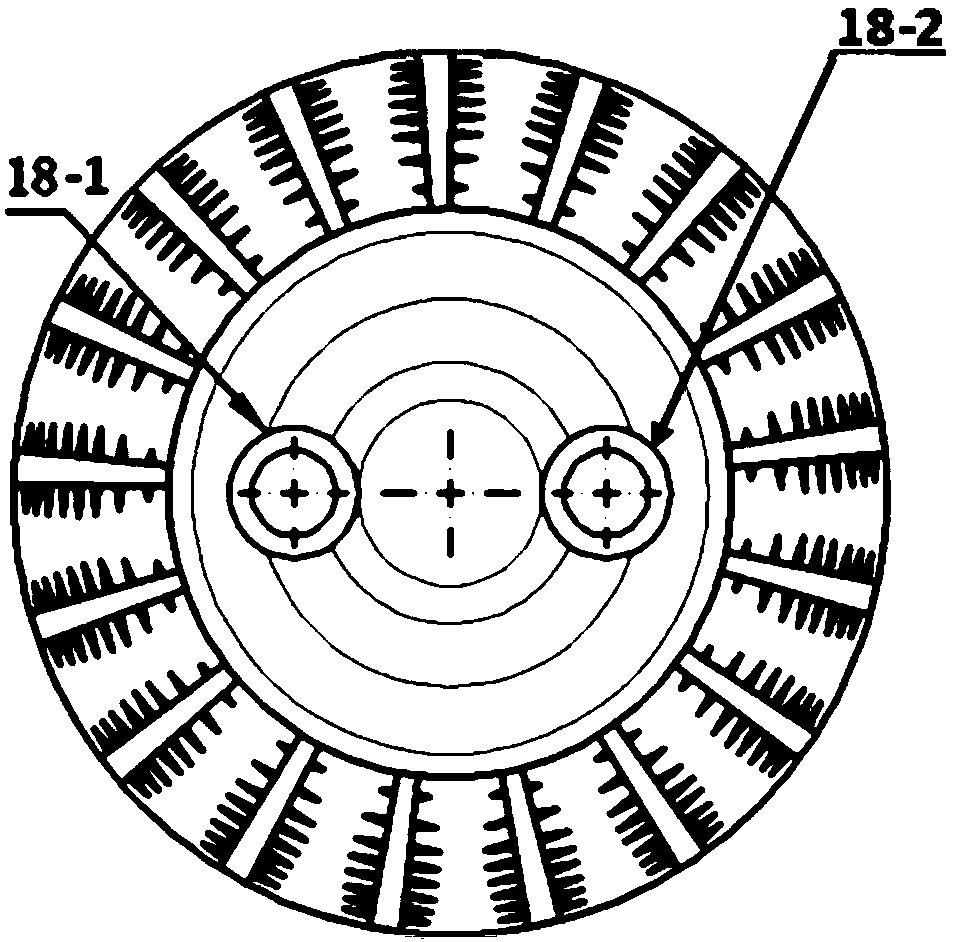

Very-high-pressure intercooling cycle turbofan engine

ActiveCN108661822ACompact structureIncrease stall marginGas turbine plantsJet propulsion plantsSingle stageCombustion chamber

The invention provides a very-high-pressure intercooling cycle turbofan engine. The engine comprises fans, a high-pressure air compressor, an intercooler, a very-high-pressure air compressor, a combustion chamber, a circular rotating fan transition section, a very-high-pressure turbine, a high-pressure turbine, a low-pressure turbine, a low-pressure shaft, a high-pressure shaft and a very-high-pressure shaft. The fans, the high-pressure air compressor, the intercooler, the very-high-pressure air compressor, the combustion chamber, the circular rotating fan transition section, the very-high-pressure turbine, the high-pressure turbine and the low-pressure turbine are connected in sequence. The very-high-pressure turbine drives the very-high-pressure air compressor to operate through the very-high-pressure shaft. The high-pressure turbine drives the high-pressure air compressor to operate through the high-pressure shaft. The low-pressure turbine drives the fans to operate through the low-pressure shaft. The rotation central axis of the very-high-pressure air compressor, and the axis of the combustion chamber are both parallel to the axis of the engine but not coincide with the axis ofthe engine. The high-pressure air compressor is composed of a multi-stage high-load axial flow air compressor and a single-stage high-through-flow centrifugal / oblique flow air compressor.

Owner:AERO ENGINE ACAD OF CHINA

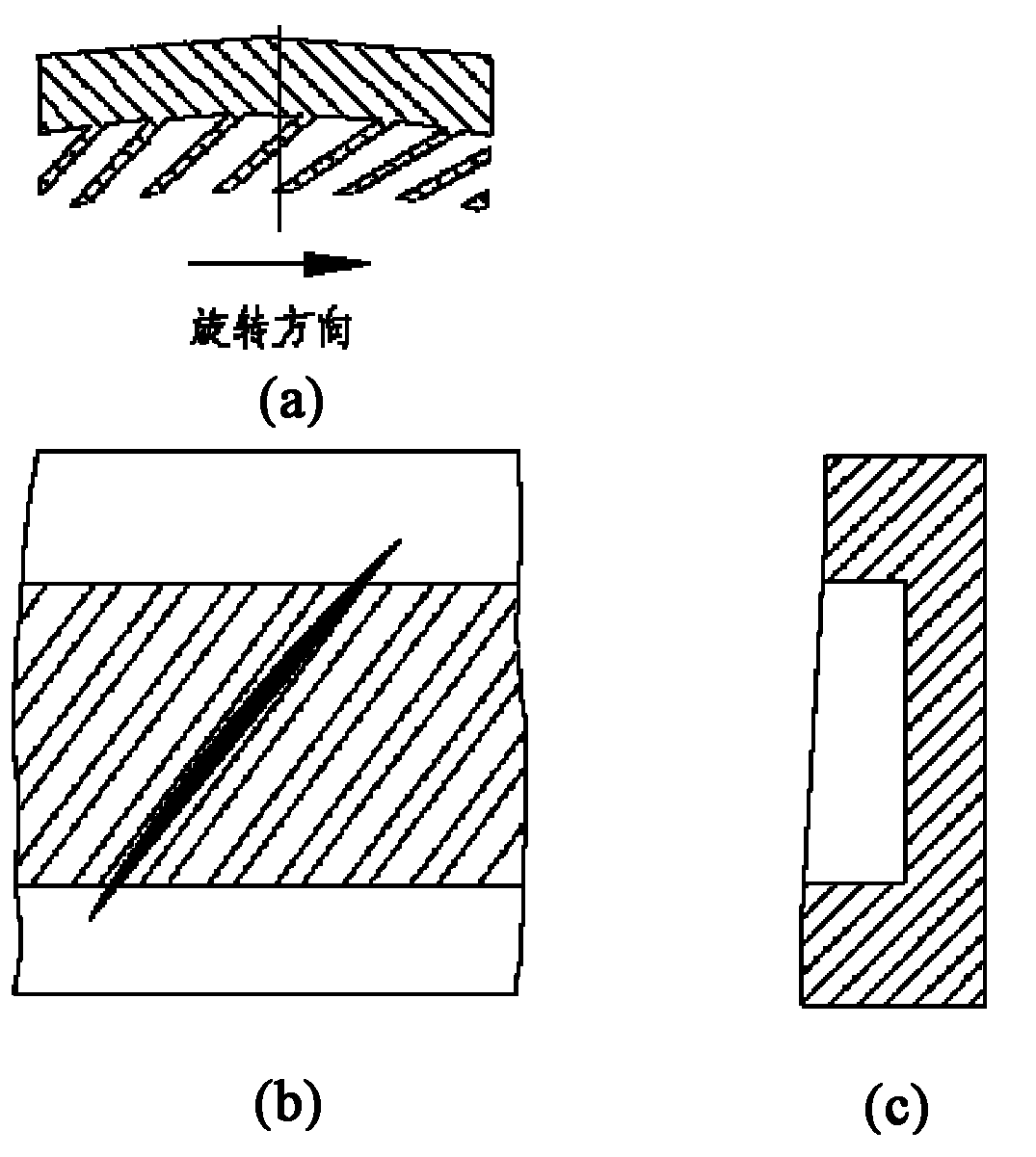

Suction type discrete and inclined seam casing treatment control device and method of compressor

ActiveCN107965465AImprove stable working rangeReduce intensityPump componentsPump controlMomentumAir pump

The invention discloses a suction type discrete and inclined seam casing treatment control device and method of a compressor. A plurality of discrete and inclined seams are formed in the wall surfaceof a compressor treatment casing in the circumferential direction, and the seams are inclined to the rotor rotation direction by a certain angle; then a certain number of suction holes are formed in the tops of the seams, and a back cavity is additionally arranged on the upper portion of the suction holes; by adjusting the angle of the suction holes, the air pumping volume and the air pumping position, flow vortex structures in the discrete and inclined seams and axial flow amount of the air flow of inflow and outflow of the discrete and inclined seams can be changed, and then the momentum ofa tip leakage flow and a mainstream can be changed; and the position of the interface of the tip leakage flow and the mainstream and flow loss caused by interaction between the seams and the tip flowfield can be adjusted. Compared with traditional discrete and inclined seam casing treatment, suction type discrete and inclined seam casing treatment can achieve the goal of reducing the efficiency loss while increasing the stable working range of the compressor.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

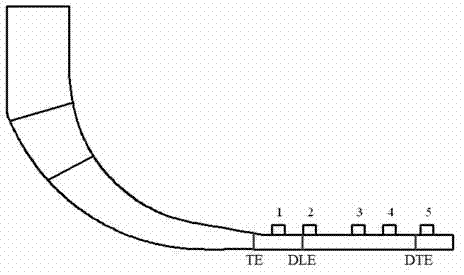

Processing method for radial slot cartridge receiver

The invention provides a processing method for a radial slot cartridge receiver, which synthetically considers structural features of a centrifugal compressor and internal flowing state. The position in a vane diffuser passenger, which is easy to have a stall phenomenon, is provided with a radial slot along the side of a wheel cover. The processing method is characterized by processing a coverage range of a slot along the radial direction and the slot depth by using the designed result of another processing method for a circumferential slot cartridge receiver, i.e., comprising the following steps of: designing a processing proposal for the circumferential slot cartridge receiver to determine the best slot depth and the coverage range of the processed slot along the radial direction; and designing the processing proposal for the radial slot cartridge receiver, wherein the radial slot is specifically a straight slot distributed along the radial direction in a discrete manner. The basic thinking for the design is that the trend and distance of the radial slot are expected to guide the trend of low-speed fluid at the side of the diffuser wheel cover, and a reflow passage for low-speed fluid is provided, therefore, the blockage of a top passage is weakened, a stable working range of the compressor is greatly improved, and simultaneously, the peak-value efficiency and small-flow lateral pressure ratio are improved.

Owner:XI AN JIAOTONG UNIV

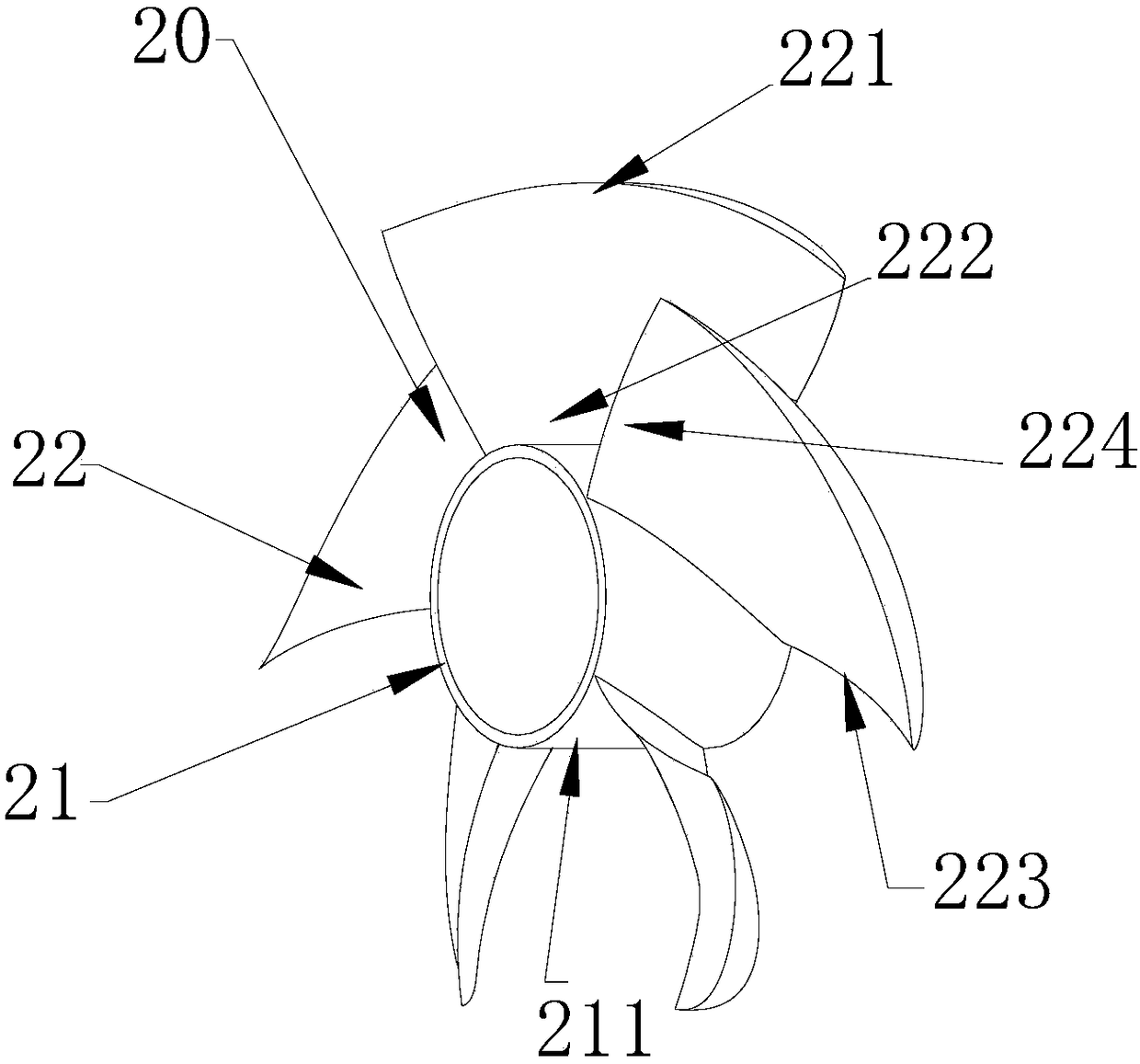

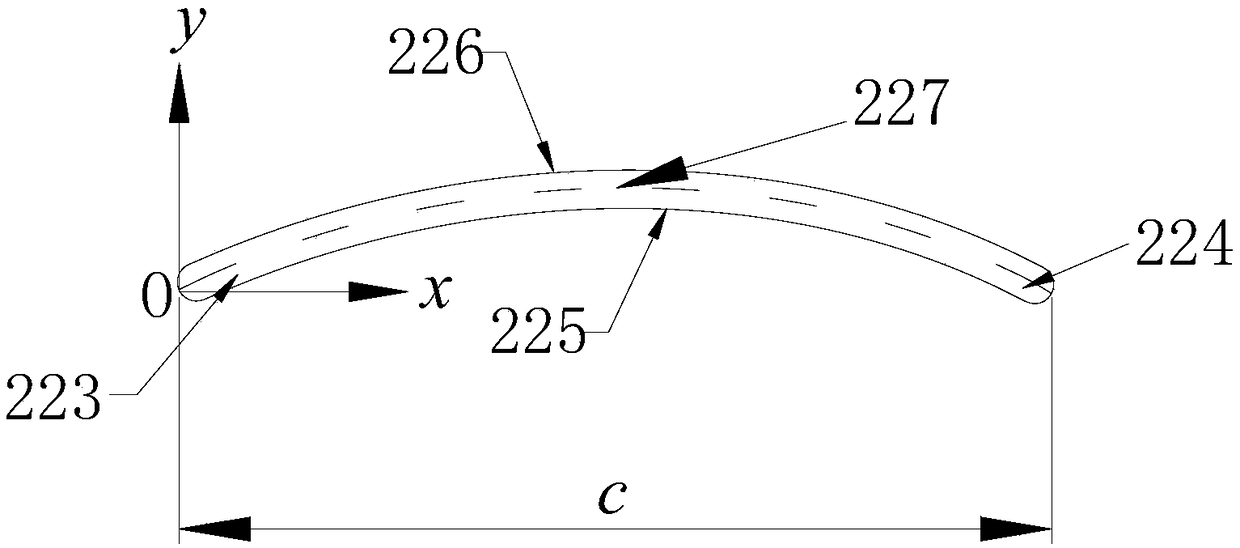

Fan and microwave oven

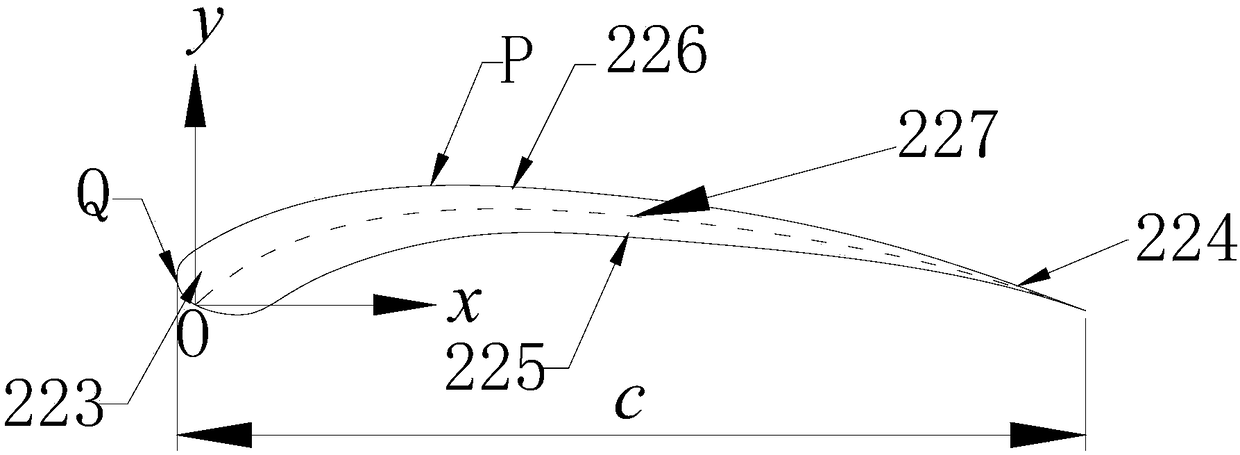

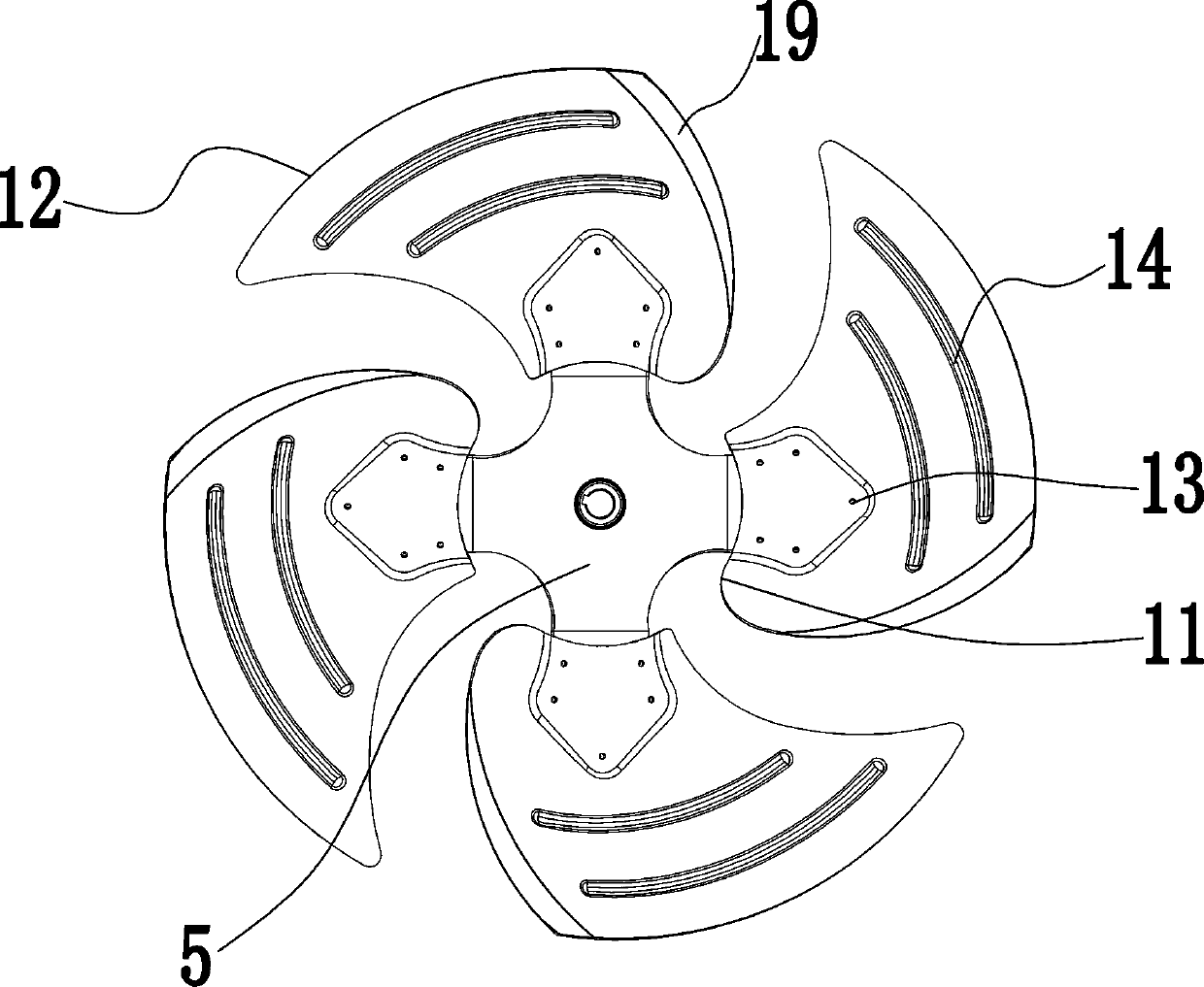

PendingCN108180169AIncrease stall marginLarge air volumeDomestic stoves or rangesPump componentsLeading edgeMicrowave oven

The invention discloses a fan and a microwave oven. The fan comprises a hub (22) and multiple blades (22) which are arranged at intervals in the circumferential direction of an outer ring (211) of thehub (21), the blade thickness of the blade-shaped cross section of the blades (22) is gradually reduced from leading edges (223) to tailing edges (224) of the blades, and the blade-shaped cross section is cut out from a radial concentric circle of the outer ring (211) of the hub (21). Therefore, the fan has large stall margin, even if the incoming flow of the inlet blast capacity is high incidence, the separation of boundary layers still cannot occur on the blades, thus generation of stall is avoided, and normal work can still be conducted. Meanwhile, the fan has higher adaptability to the inlet incoming flow, the aerodynamic performance of the fan is better, the blast capacity is larger, and the efficiency is higher. Besides, due to the design of sharp angles of trailing edges of the blades, the tails of the blades are a series of fragmentized small vortex structures, the generation of high broad-band noise is avoided, and thus a certain noise-reduction effect is achieved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Treatment method and device for gas compressor communicating type contraction joint casing

ActiveCN106286394AIncrease stall marginImprove the blow-off effectPump componentsPumpsGas compressorEngineering

The invention discloses a treatment method and device for a gas compressor communicating type contraction joint casing. The wall face of the gas compressor casing is provided with a plurality of dispersed contraction joints in the circumferential direction, and the joint depth direction is in the radial direction of a gas compressor. The sectional area of the contraction joints increases gradually in the axial direction, and the ratio of the rear end width to the front end width of the contraction joints is lowered gradually in the radial direction. Meanwhile, the sectional area of the rear portions of the contraction joints decreases gradually in the radial direction, and the sectional area of the front portions of the contraction joints increases gradually. Connection channels are formed between the rear portions of all the contraction joints, and thus the dispersed contraction joints communicate with one another. After accelerated in radial and axial contraction runners in the joints, sub-sound gas flow entering the contraction joints from the downstream parts of blade channels is jetted into the blade channels again from the upstream parts, and low-energy leakage flow at the blade tops can be blown away. Fluid in all the contraction joints can be exchanged through the connection channels, the backflow quantity in the contraction joints in different positions can be adjusted automatically according to the circumferential pressure distribution at the blade tops, thus blocking of different circumferential positions can be reduced effectively, and the stable work range of the gas compressor is increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

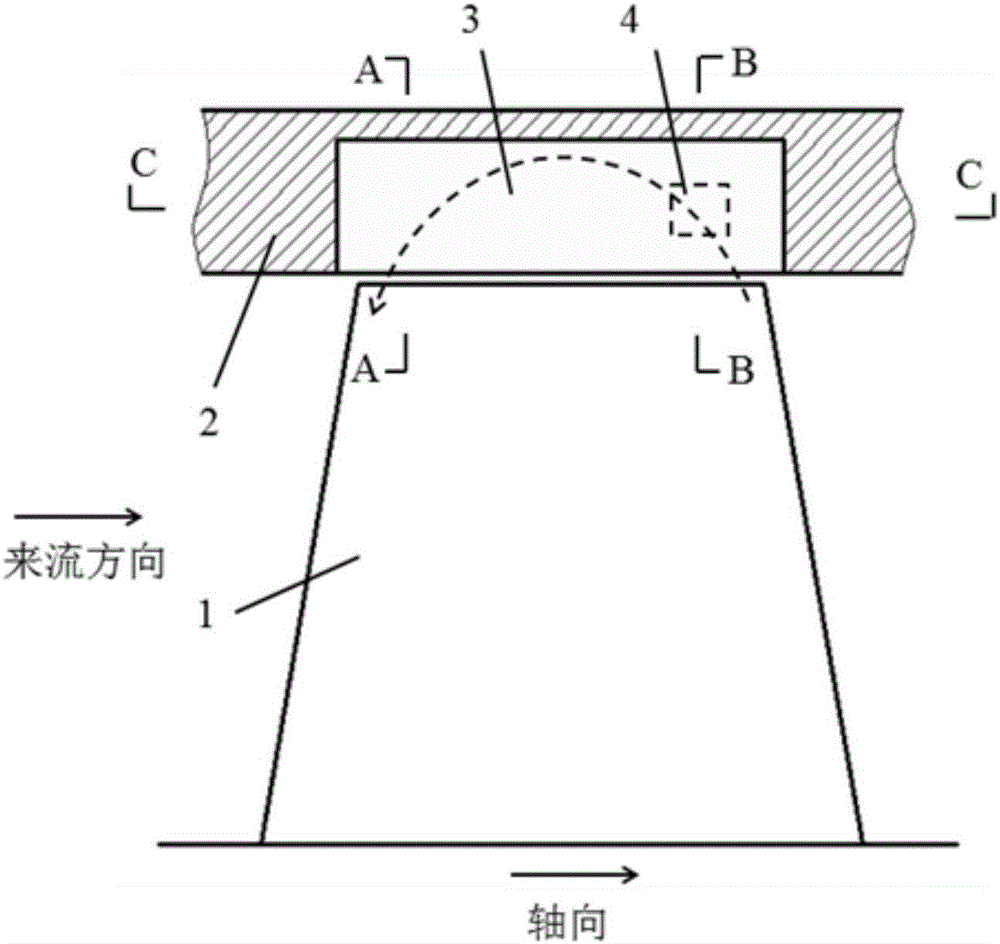

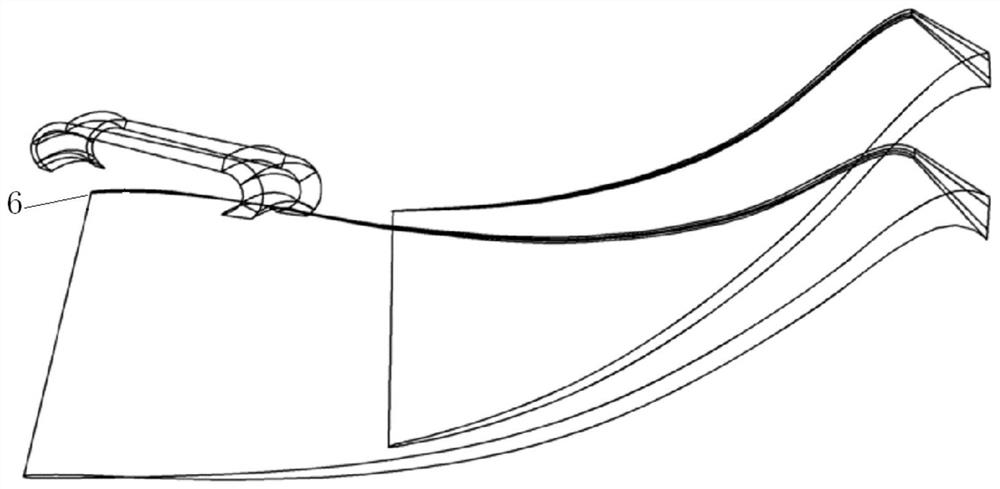

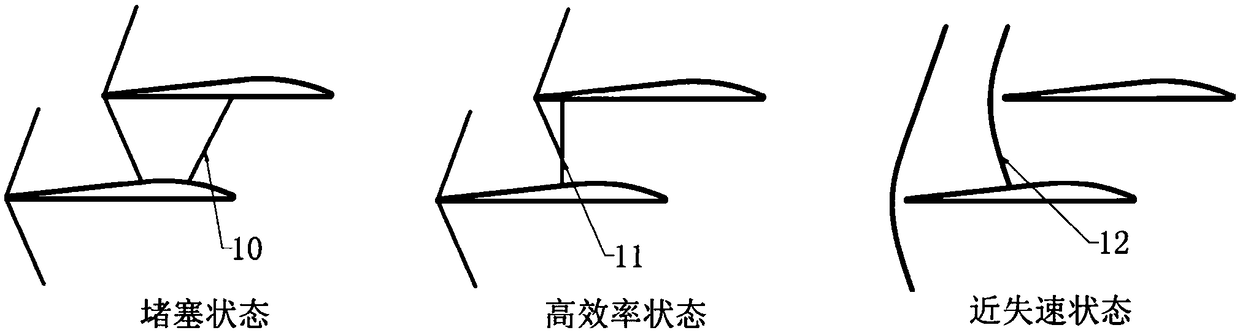

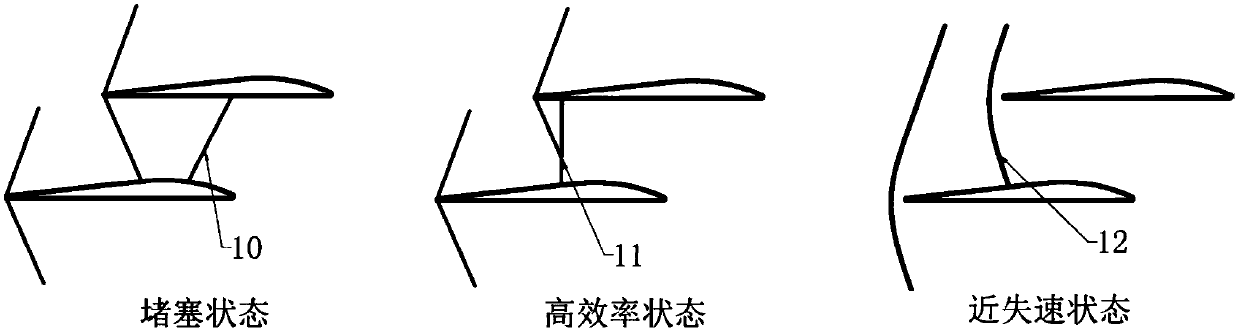

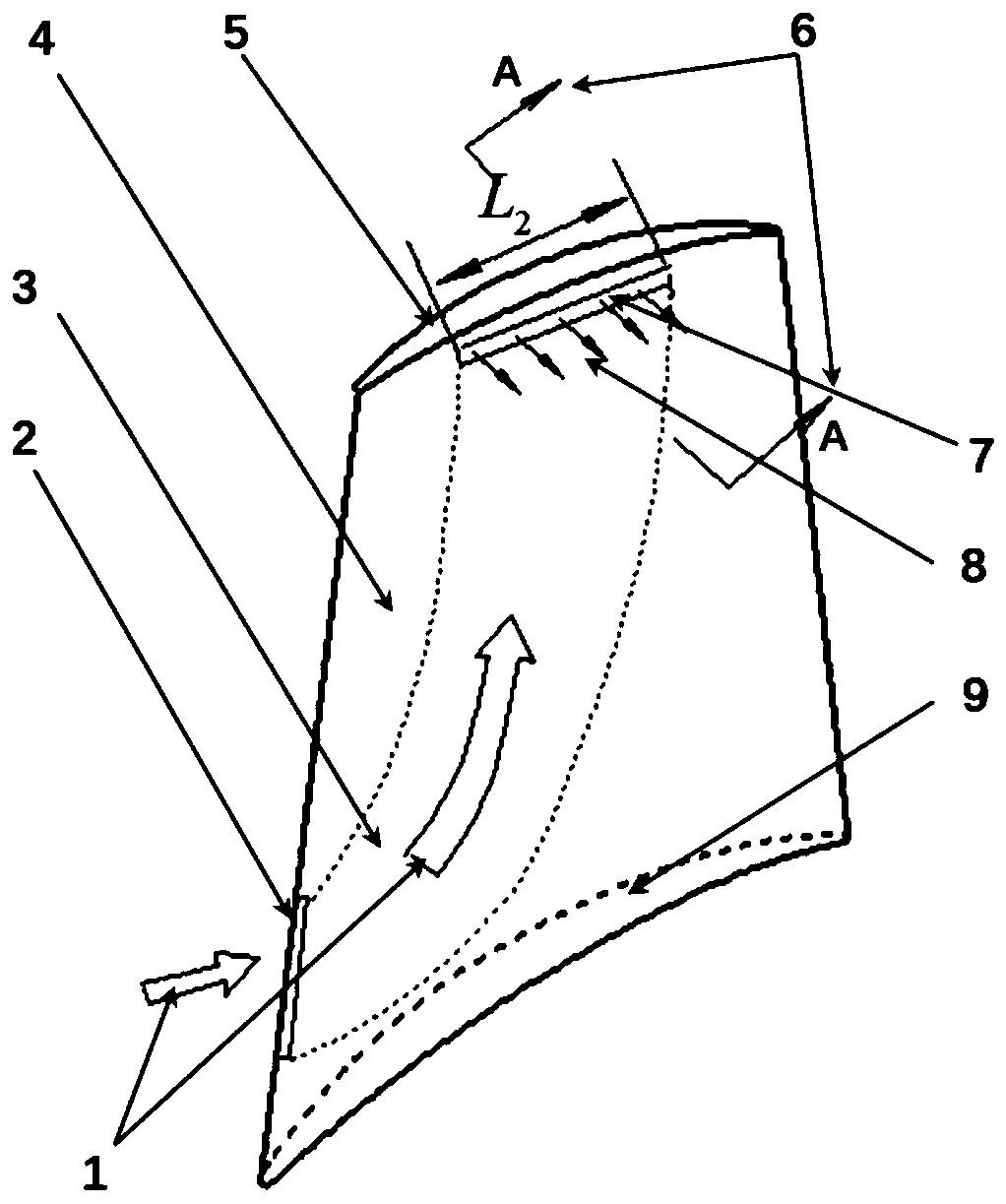

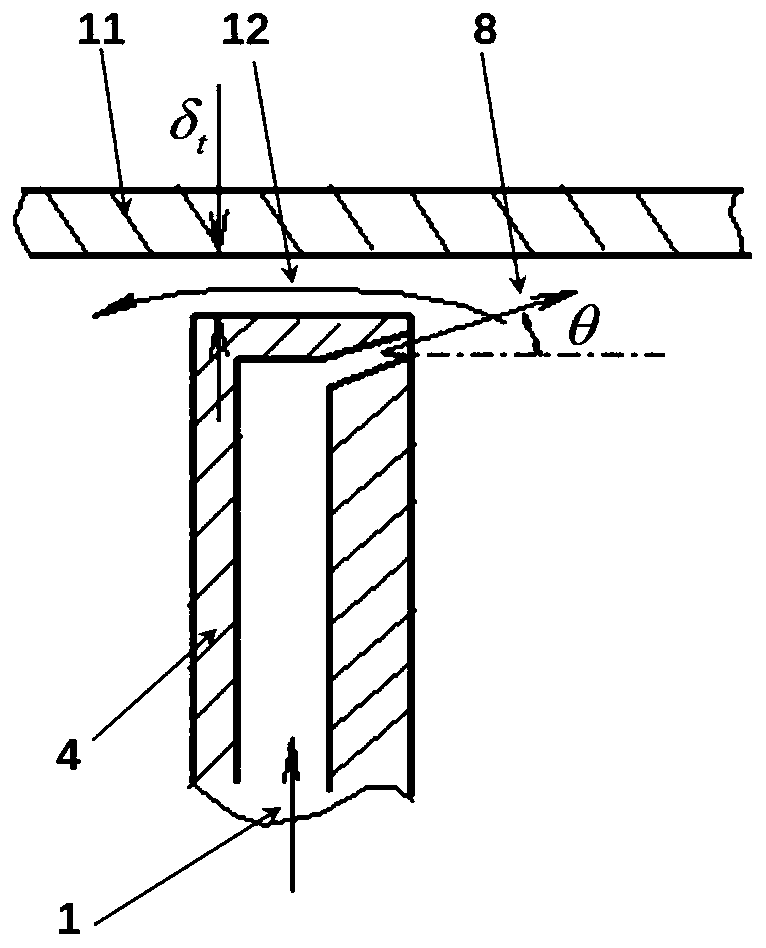

Distributed parameterized impeller self-circulation treatment casing

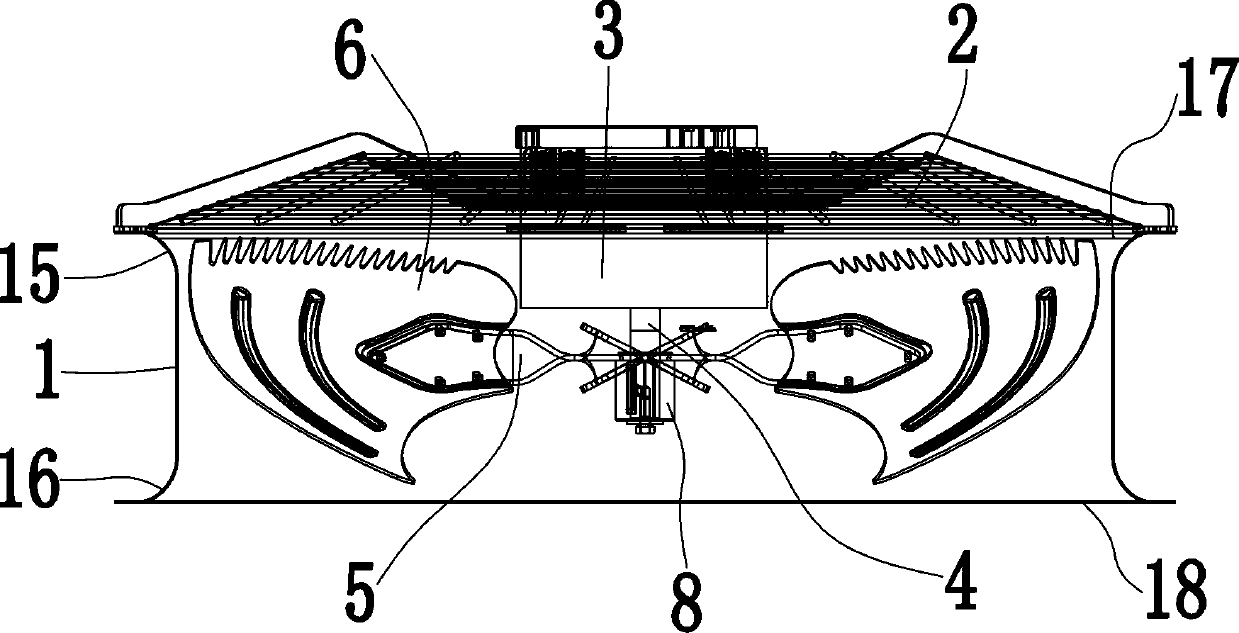

ActiveCN112539184AIncrease stall marginReduce efficiency lossPump componentsRadial flow pumpsImpellerInlet channel

The invention discloses a distributed parameterized impeller self-circulation treatment casing which is composed of a casing body, an air inlet channel, impeller blades, a front channel, a rear channel and air entraining bridge circuits; the air entraining bridge circuits are fixed to the outer side of an impeller casing, and air flows back in the bridge circuits through the front channel and therear channel connected to a channel front edge of the impeller casing; and the front channel and the rear channel of the impeller self-circulation treatment casing are located at the positions with different axial chord lengths away from an impeller inlet respectively, an inner wall face two-dimensional molded line is formed by fitting and optimizing a structured curve so as to ensure that jet flow is close to the wall face as much as possible, and the outer wall face molded line is a controllable contraction molded line, so that the effects of guiding and accelerating airflow are achieved. The impeller self-circulation treatment casing utilizes the airflow pressure difference in rotor channels corresponding to the self-circulation front channel and the self-circulation rear channel to perform air exhaust and air injection. According to the treatment casing structure, the blocking margin and the stall margin of the centrifugal impeller can be improved, the purpose of reducing the efficiency loss is achieved, and the impeller can operate and work at a larger margin.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

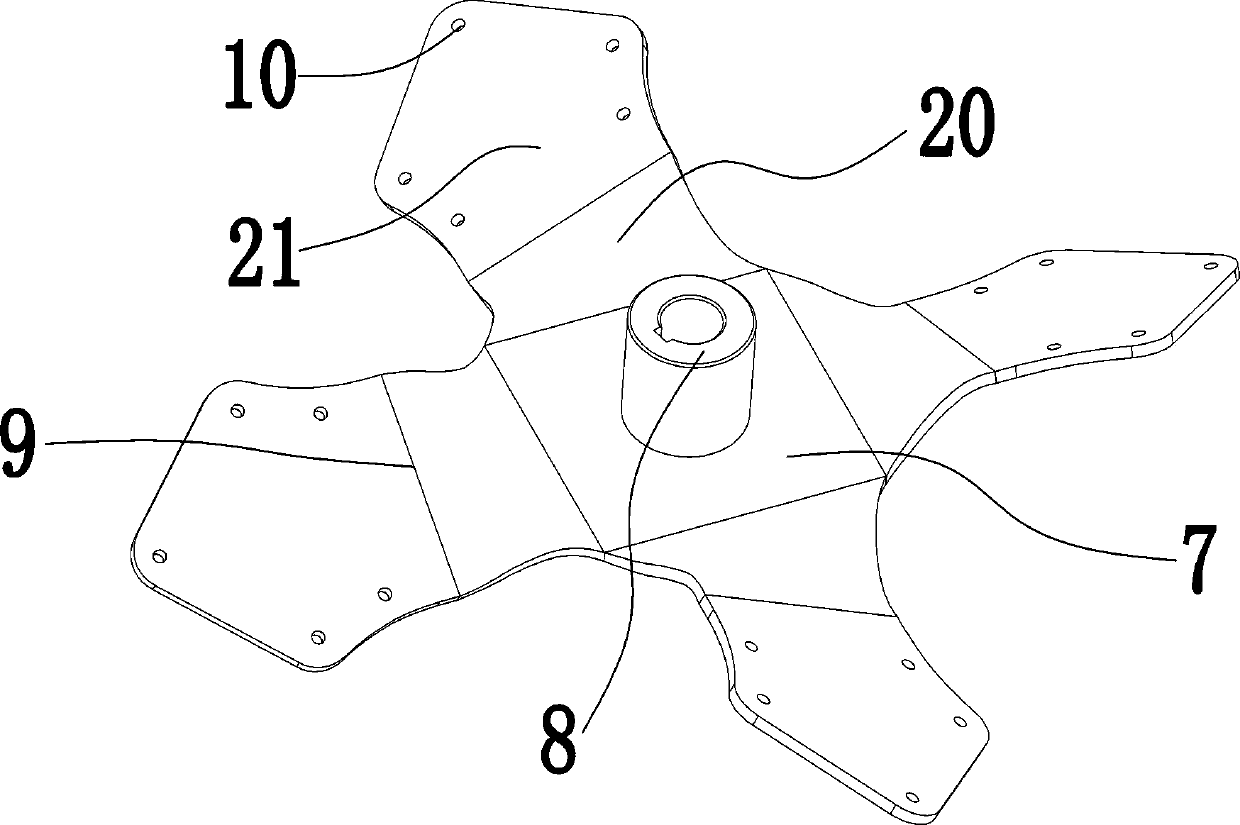

Low-noise and efficient cooling axial flow fan of central air conditioner outdoor unit

ActiveCN103629156AImprove efficiencyControl Radial Pressure GradientPump componentsPumpsLow noiseRotational axis

The invention discloses a low-noise and efficient cooling axial flow fan of a central air conditioner outdoor unit. The low-noise and efficient cooling axial flow fan comprises an air duct, a motor support, a motor, a hub a plurality of blades which are fixed on the hub, wherein the motor support is arranged above the air duct, the motor is arranged at the center of the motor support, and the hub is connected with a motor rotary shaft. The hub comprises a hub inner lining panel and a shaft sleeve which is connected to the center of the hub inner lining panel in a welded mode; the shaft sleeve is matched with the motor rotary shaft; the periphery of the hub inner lining panel extends to form a plurality of hub connection boards which are evenly distributed with the shaft sleeve as the center; each hub connection board is provided with a plurality of thread hole; each hub connection board is twisted in the reverse direction from the two side edges of the primary portion where the hub inner lining panel extends. The low-noise and efficient cooling axial flow fan of the central air conditioner outdoor unit lowers vortex loss of the wall surface by decreasing the hub ratio, and decreases flowing speed of air flow, thereby effectively lowering noises caused by the air flow.

Owner:ZHE JIANG YILIDA VENTILATOR CO LTD

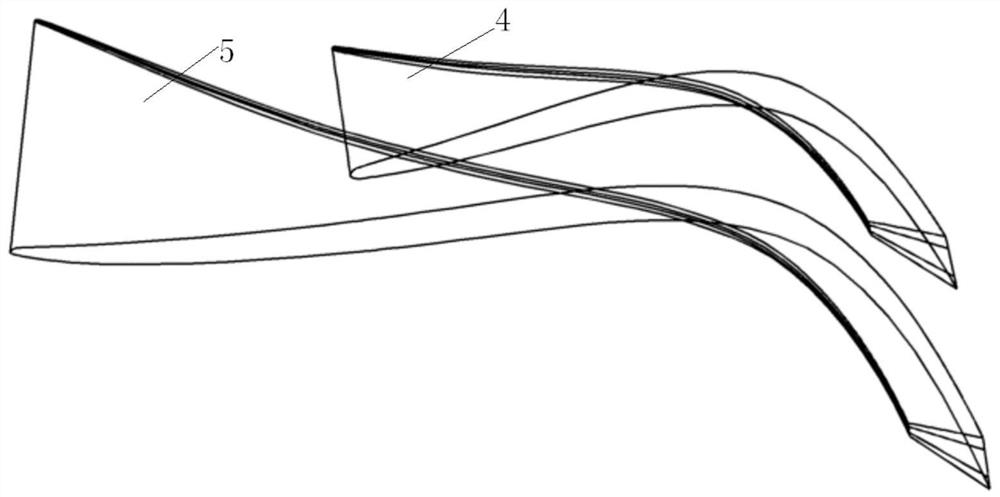

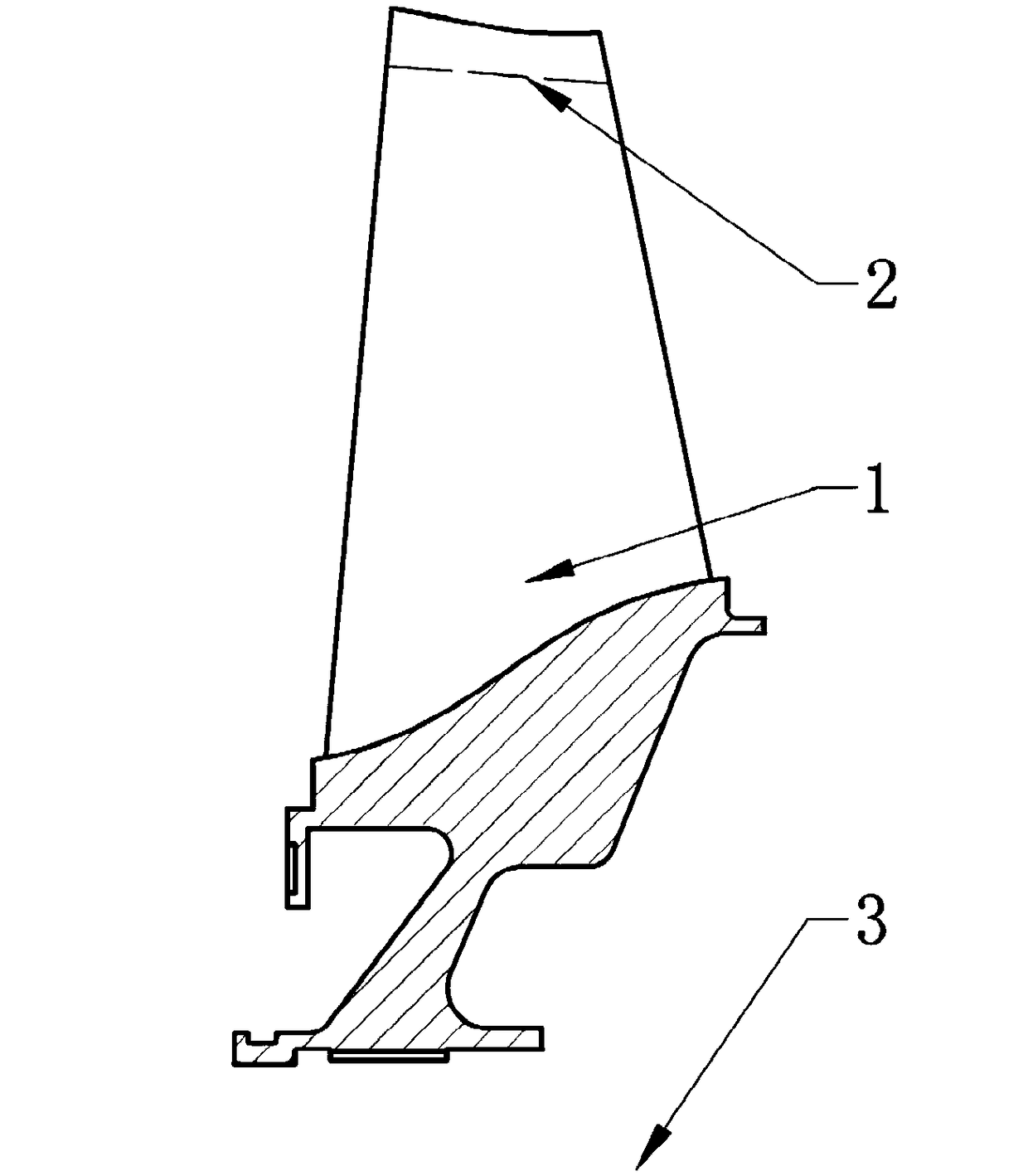

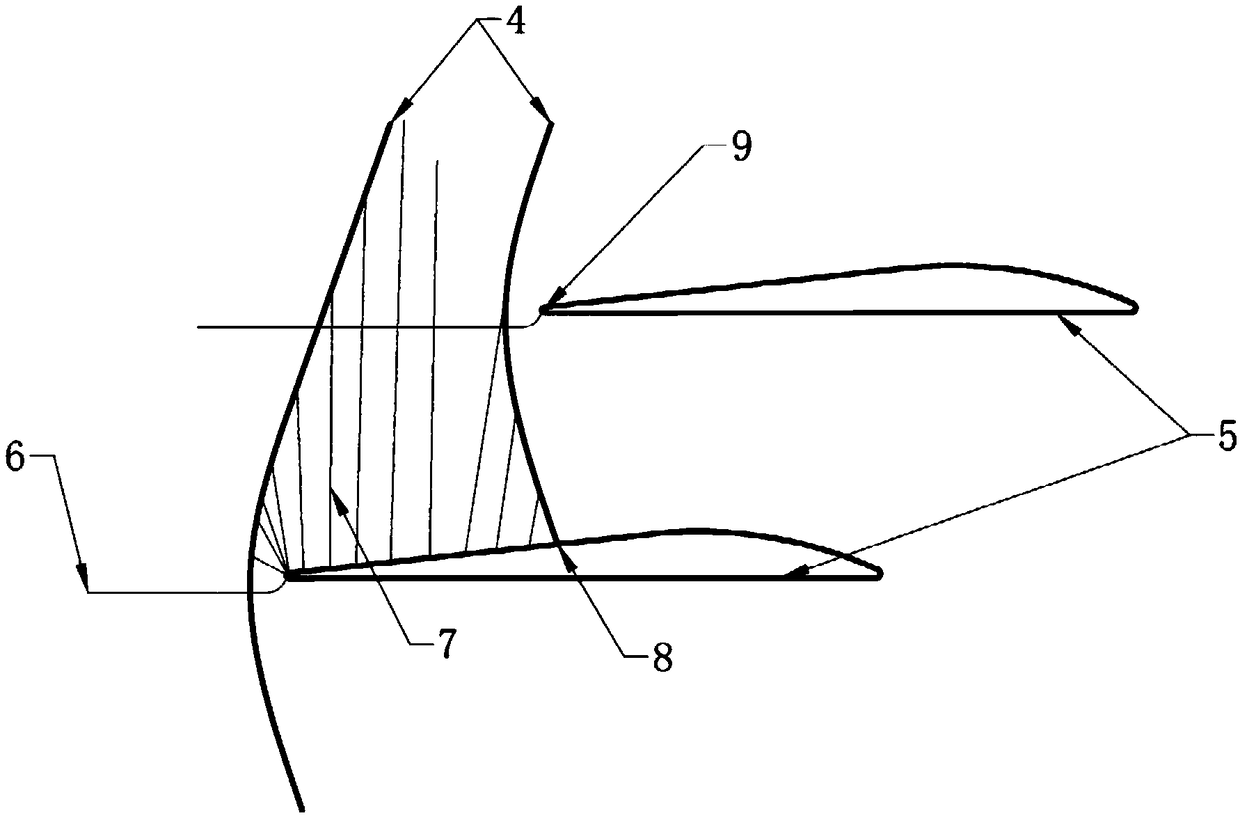

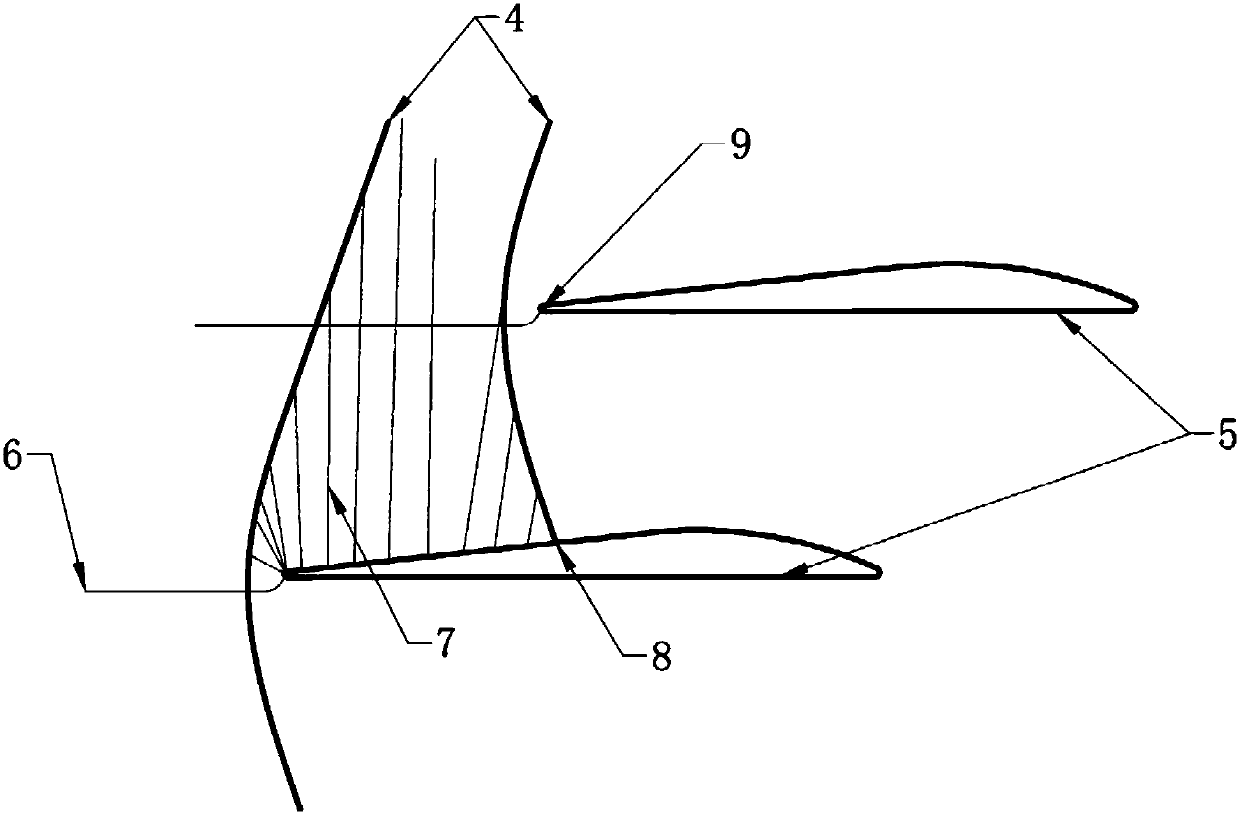

A sharpened leading edge structure and design method of a transonic fan blade top primitive blade profile

ActiveCN107869482BIncrease stall marginImprove efficiencyPump componentsPumpsEffective radiusFan blade

The invention relates to a front edge design method of a transonic speed fan blade top primitive blade profile. The front edge design method comprises the steps that a reference point distant from anoriginal front edge by a certain length is obtained on a suction surface of a blade top original primitive blade profile; a linear section is made by passing the reference point, wherein a certain included angle is formed between the original suction surface and the linear section; and the linear section is connected with an original pressure surface by an arc section with a small radius, the other end of the linear section is in smooth transition with the original suction surface by a chamfer, and the axial positions of a new blade front edge and an old blade front edge are kept unchanged. Since the front edge of the blade top original primitive blade profile is subjected to sharpening treatment and the effective radius of the front edge is reduced, shock wave detachment may be delayed, and the surge-to-stall margin of a fan can be improved advantageously. In addition, with the introduction of a sharpening structure, an expansion wave at the blade front edge is split into two parts, wherein one part is an expansion wave triggered by the front edge radius and the other part is an expansion wave triggered by the transition part of the linear section and the suction surface, so thatthe mach number before a channel shock wave can be lowered advantageously, and the efficiency of the blade top original primitive blade profile is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Sharpened front edge structure and front edge design method of transonic speed fan blade top primitive blade profile

ActiveCN107869482AIncrease stall marginReduce the Mach numberPump componentsPumpsEffective radiusEngineering

The invention relates to a front edge design method of a transonic speed fan blade top primitive blade profile. The front edge design method comprises the steps that a reference point distant from anoriginal front edge by a certain length is obtained on a suction surface of a blade top original primitive blade profile; a linear section is made by passing the reference point, wherein a certain included angle is formed between the original suction surface and the linear section; and the linear section is connected with an original pressure surface by an arc section with a small radius, the other end of the linear section is in smooth transition with the original suction surface by a chamfer, and the axial positions of a new blade front edge and an old blade front edge are kept unchanged. Since the front edge of the blade top original primitive blade profile is subjected to sharpening treatment and the effective radius of the front edge is reduced, shock wave detachment may be delayed, and the surge-to-stall margin of a fan can be improved advantageously. In addition, with the introduction of a sharpening structure, an expansion wave at the blade front edge is split into two parts, wherein one part is an expansion wave triggered by the front edge radius and the other part is an expansion wave triggered by the transition part of the linear section and the suction surface, so thatthe mach number before a channel shock wave can be lowered advantageously, and the efficiency of the blade top original primitive blade profile is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A Two-Dimensional Compressor Airfoil Optimization Method Considering the Performance of Low Reynolds Number Conditions

ActiveCN109779972BImprove aerodynamic performanceIncrease stall marginGeometric CADPump componentsClassical mechanicsMechanical engineering

The invention relates to a two-dimensional blade profile optimization method for a compressor considering a low Reynolds number working performance; the optimization method is characterized by comprising the following steps of: step 1: analyzing the meridional flow performance of a prototype multistage axial flow compressor at different rotating speeds; step 2: determining a key two-dimensional blade profile section to be optimized; step 3: performing parametric fitting to the key two-dimensional blade profile in step 2; step 4: analyzing the aerodynamic performance of the two-dimensional blade profile, and analyzing the aerodynamic performance of the parameterized two-dimensional blade profile to obtain the variable attack angle performance of the blade profile under a low Reynolds numberworking condition and the variable attack angle performance under a high Reynolds number working condition; and step 5: optimizing the modeling parameters of the two-dimensional blade profile, adjusting the two-dimensional modeling parameters according to the variable attack angle performance parameters of the two-dimensional blade profile obtained in step 4 at different Reynolds numbers, using agenetic algorithm to circularly iterate steps 3 and 4 until a two-dimensional blade profile design reducing loss and increasing stall margin is obtained, and then obtaining a new two-dimensional blade profile. According to the invention, the performance optimization of the two-dimensional blade profile of the axial flow compressor at different Reynolds numbers and different attack angles is realized; the designed working performance of the compressor is improved while the aerodynamic performance of the compressor at the low rotation speed working condition is improved; and the flow efficiencyis improved while the normal starting and stable working of the compressor are ensured.

Owner:HANGZHOU TURBINE POWER GRP

End Wall Structure and End Wall Treatment Method of Centrifugal Compressor Diffuser

InactiveCN104763683BImprove stable working rangeImprove mobilityPump componentsPumpsLow speedEngineering

The invention provides an end wall structure and end wall treatment method of a centrifugal compressor diffuser. The invention comprehensively considers the structural characteristics and internal flow conditions of the centrifugal compressor. The cover side is treated with deflector-type end wall, which provides a return channel for the low-velocity fluid in the top area of the diffuser, and sucks the low-kinetic energy fluid mass into the treatment tank and transports it along the circumference and flow direction of the treatment tank. During this process, only part of the fluid is reinjected into the main flow, the area of the low kinetic energy fluid area is reduced and the flow rate is also increased, which improves the flow condition of the top channel of the diffuser, weakens the blockage of the top channel, and greatly improves the stability of the compressor. operating range, while peak efficiency and pressure ratio have also been improved.

Owner:XI AN JIAOTONG UNIV

Compressor cascade layout for improving pneumatic load of blades

InactiveCN101846099BIncreased airflow turning angleIncreased aerodynamic loadPump componentsPumpsEngineeringFront edge

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Asymmetric double-circular-arc chute processing casing

InactiveCN102705256AReduce flow lossIncrease stall marginPump componentsPumpsNon symmetricGas compressor

The invention relates to an asymmetric double-circular-arc chute processing casing, which is applied to a tip region of a rotor blade of an axial flow gas compressor. The design of the asymmetric double-circular-arc chute processing casing is as follows: firstly, a circular-arc chute processing casing is used as a base and a circular-arc groove bottom structure is additionally arranged, so that a radial direction and an axial direction of the processing casing are circular-arc structures; an asymmetric structure is adopted in a peripheral direction and the peripheral direction is divided into two processing regions and two non-processing regions in 360 degrees; and the two processing regions are 106 degrees and 74 degrees respectively and are divided by two 90-degree non-processing regions. Therefore, on one hand, a double-circular-arc structure is used for avoiding greater flowing loss caused by rectangular and trapezoid designs; and on the other hand, the asymmetric structure is used for simultaneously generating coupling stimulation effect on different vortexes, so that the margin of the gas compressor is greatly improved and the efficiency is not reduced.

Owner:BEIHANG UNIV

A treatment method and device for a compressor connected shrinkage joint casing

ActiveCN106286394BIncrease stall marginImprove the blow-off effectPump componentsPumpsGas compressorEngineering

The invention discloses a treatment method and device for a gas compressor communicating type contraction joint casing. The wall face of the gas compressor casing is provided with a plurality of dispersed contraction joints in the circumferential direction, and the joint depth direction is in the radial direction of a gas compressor. The sectional area of the contraction joints increases gradually in the axial direction, and the ratio of the rear end width to the front end width of the contraction joints is lowered gradually in the radial direction. Meanwhile, the sectional area of the rear portions of the contraction joints decreases gradually in the radial direction, and the sectional area of the front portions of the contraction joints increases gradually. Connection channels are formed between the rear portions of all the contraction joints, and thus the dispersed contraction joints communicate with one another. After accelerated in radial and axial contraction runners in the joints, sub-sound gas flow entering the contraction joints from the downstream parts of blade channels is jetted into the blade channels again from the upstream parts, and low-energy leakage flow at the blade tops can be blown away. Fluid in all the contraction joints can be exchanged through the connection channels, the backflow quantity in the contraction joints in different positions can be adjusted automatically according to the circumferential pressure distribution at the blade tops, thus blocking of different circumferential positions can be reduced effectively, and the stable work range of the gas compressor is increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

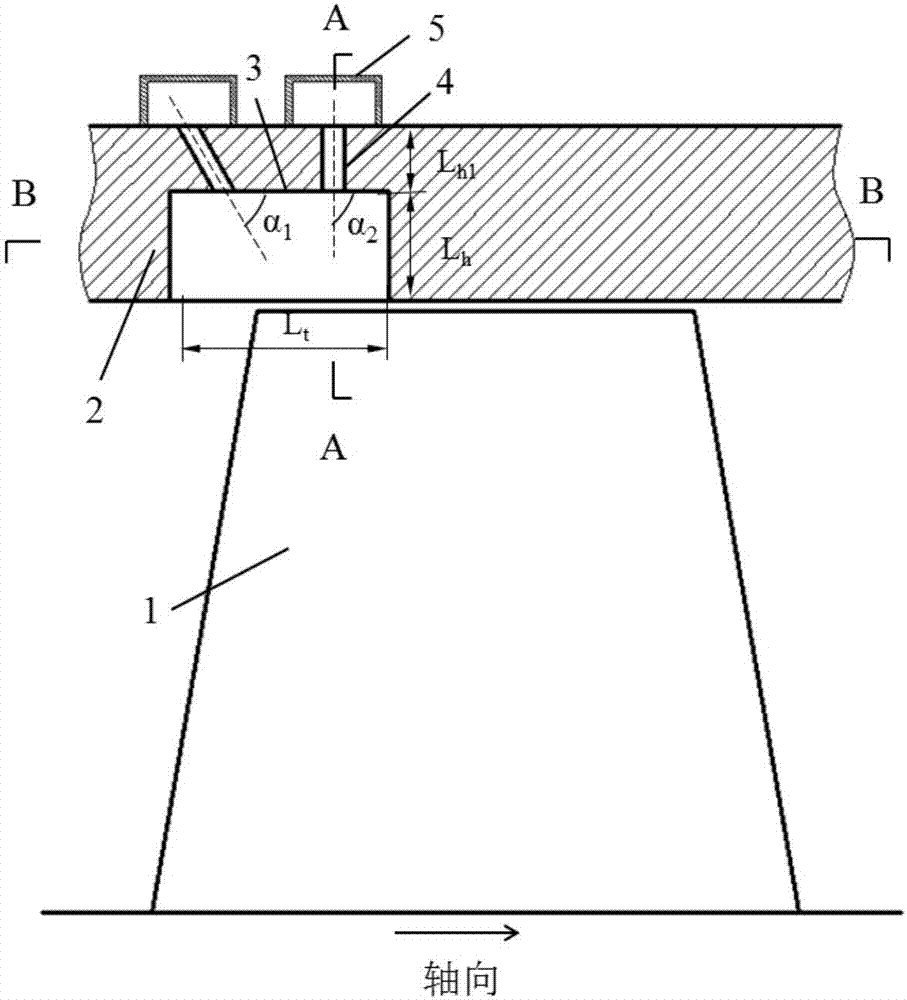

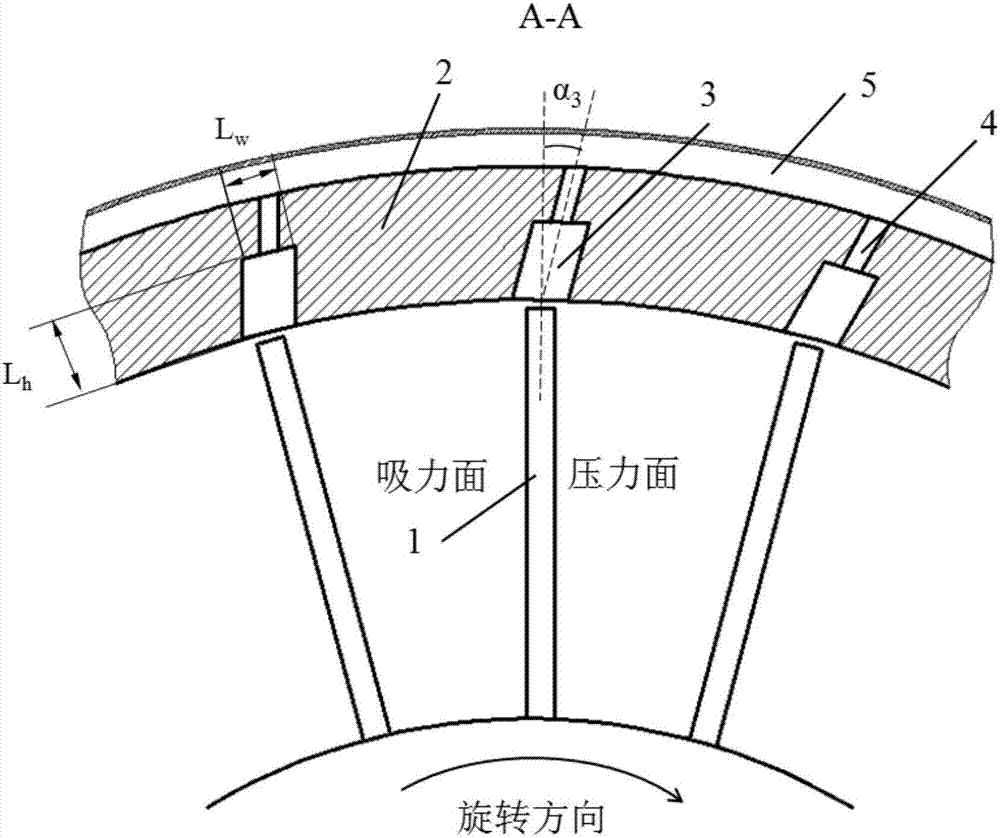

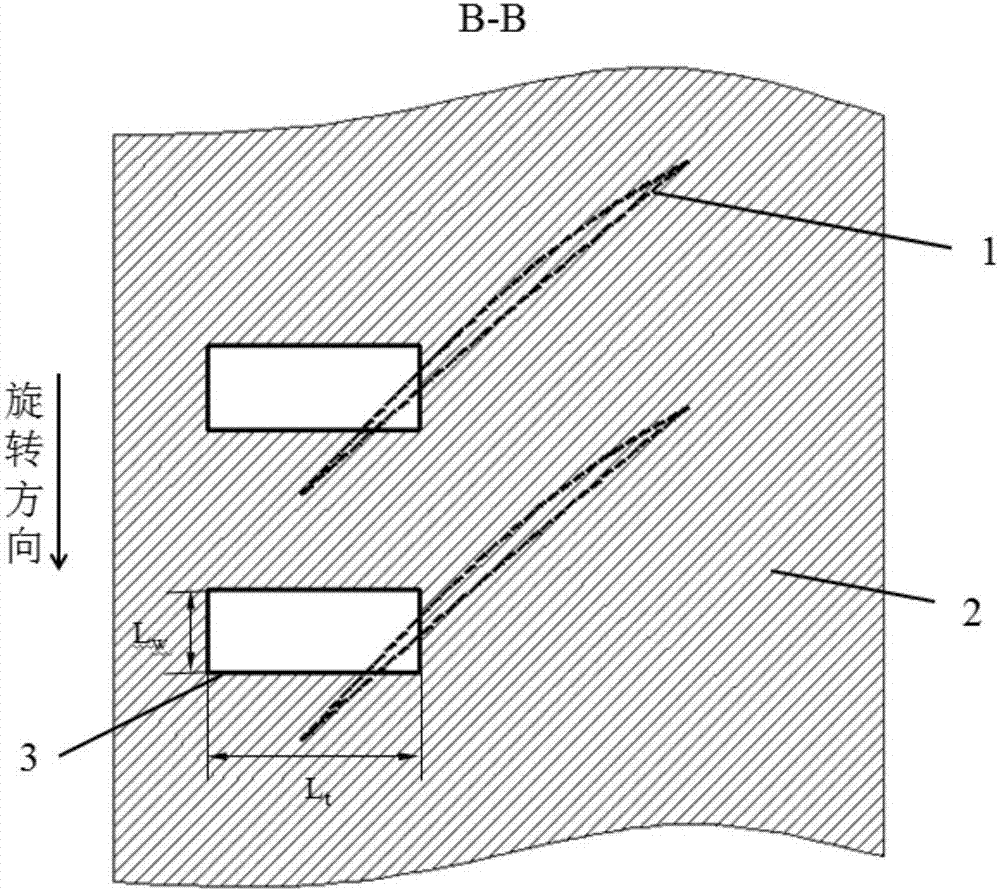

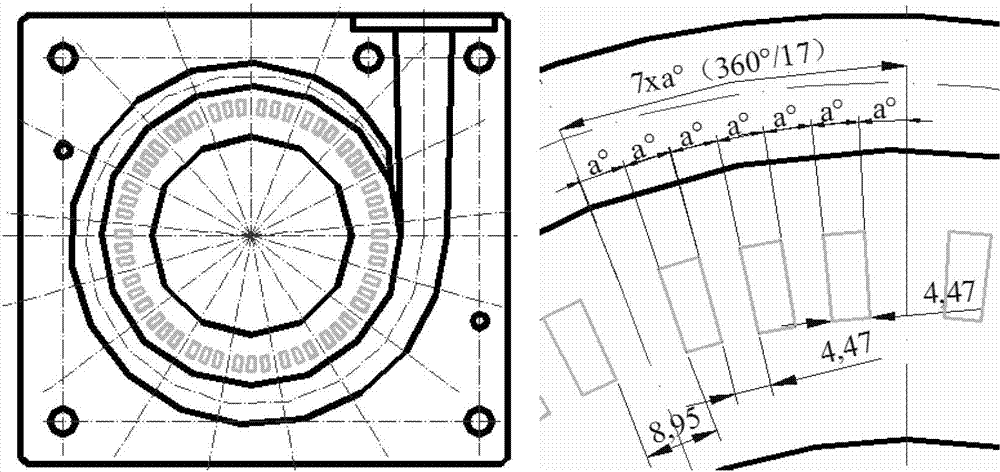

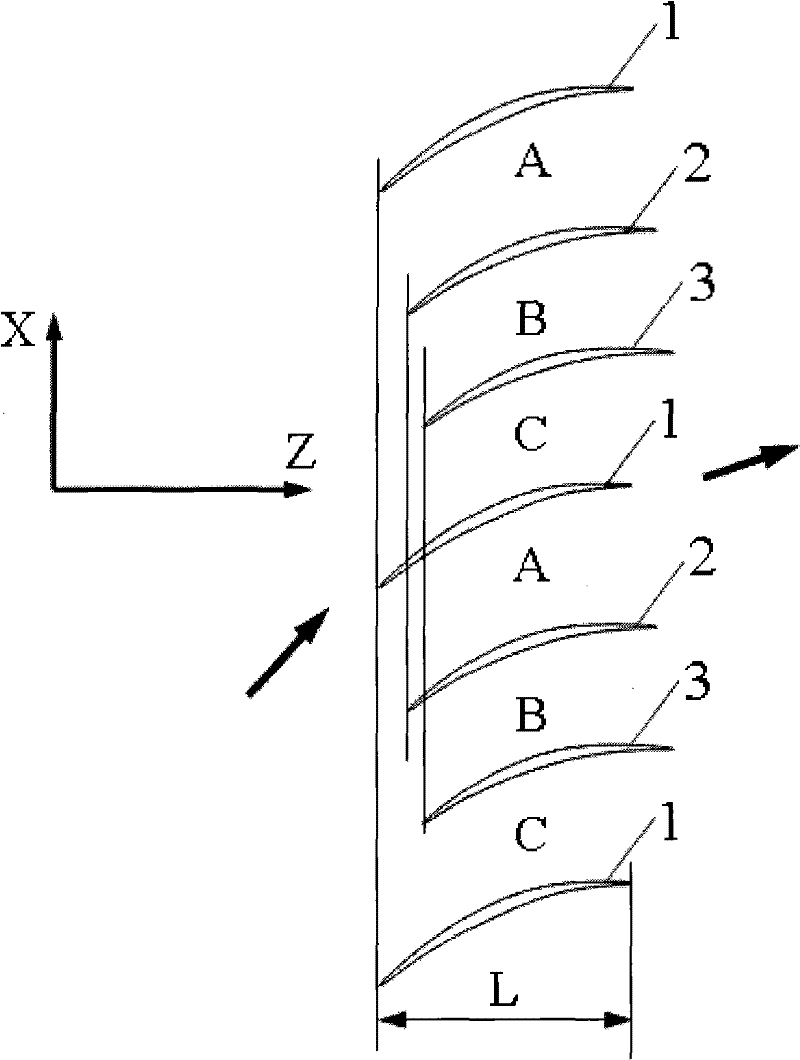

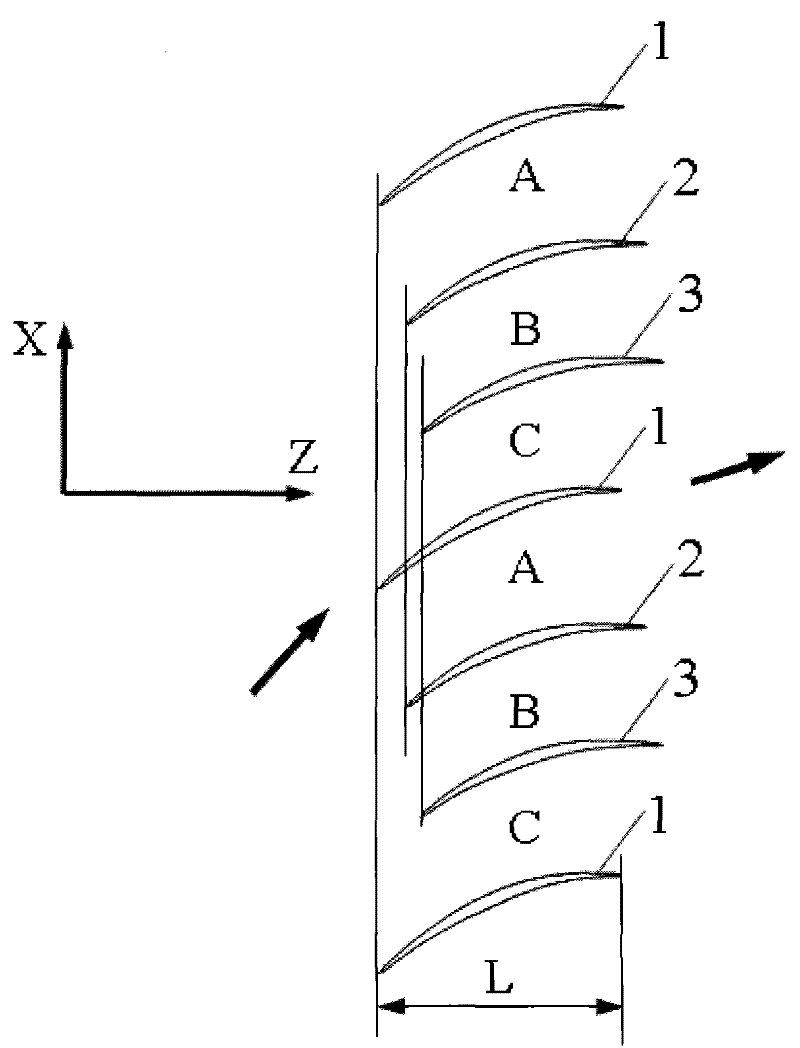

Blade arrangement mode of compressor blade row for enhancing air load and stability

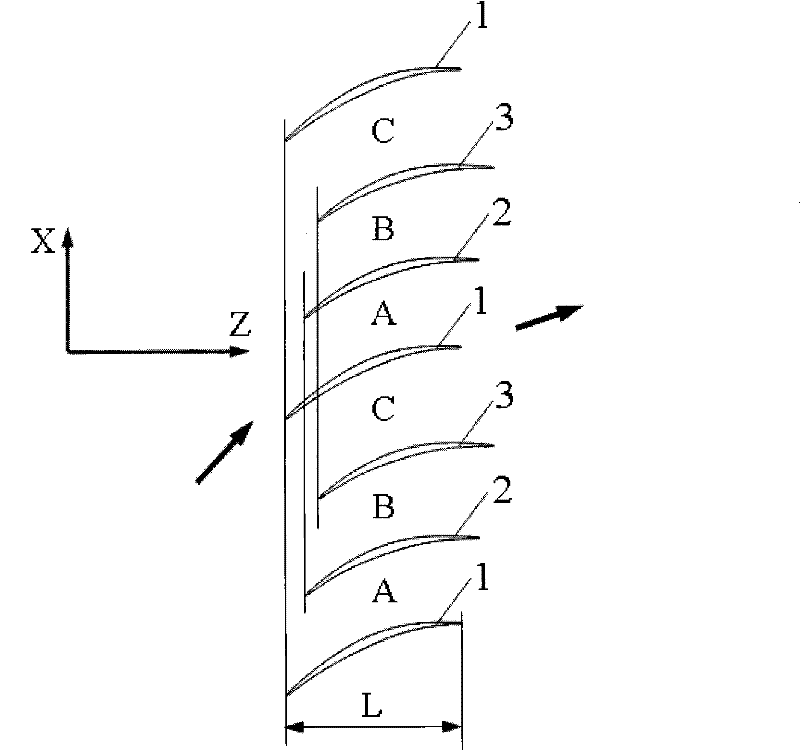

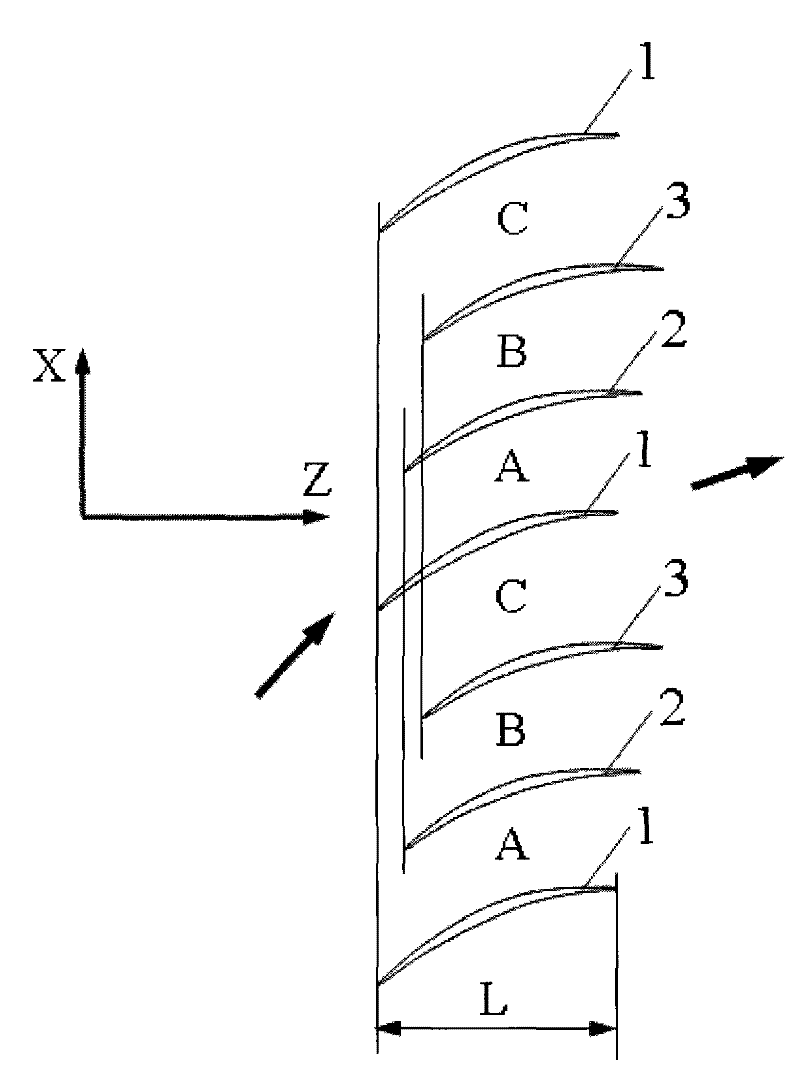

The invention discloses a blade arrangement mode of a compressor blade row for enhancing air load and stability. Every three adjacent blades in the same blade row form a group; based on the axial position of the front edge of a first blade (1), a second blade (2) adjacent to the first blade is positioned on one side of the blade basin surface of the first blade; the front edge of the second blade(2) moves backwards along the axial direction of the blade row and the movement distance accounts for 7 to 15 percent of the axial chord length L of the first blade; a third blade (3) adjacent to thesecond blade is positioned on one side of the blade basin surface of the second blade; the front edge of the third blade moves backwards relatively to the front edge of the second blade (2) along theaxial direction of the blade row and the movement distance accounts for 5 to 15 percent of the axial chord length of the first blade (1); and the third blade rotates around the front edge of the third blade by 1 to 3 degrees. Three different air flow passages are formed in one blade row, and air flow in the air flow passages can enhance the air stability of an air compressor and the air load of the blade is remarkably enhanced under the condition that the blade shape design bending deflection of each blade is not changed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Processing method for radial slot cartridge receiver

Owner:XI AN JIAOTONG UNIV

Circumferential groove casing treatment method

The invention provides a circumferential groove casing treatment method of a centrifugal compressor. The circumferential groove casing treatment method completely takes structure characteristics and internal flow situations of the centrifugal compressor into consideration. A groove is arranged in a position prone to speed reduction of a diffuser channel along the circumference of a wheel cap side so as to provide a backflow channel for low-speed fluid in a top area of the diffuser, and then lower-power fluid lump is pumped into a treatment groove and transported along the circumference direction and flow direction of the treatment groove. In the process, only part of the fluid refills into a main fluid, the area of lower-power fluid is reduced and flow speed is improved, flow situations of the top channel of the diffuser are improved, blocking of the top channel is weakened, steady operation range of the compressor is enlarged greatly, and meanwhile peak value efficiency and pressure ratios are improved.

Owner:XI AN JIAOTONG UNIV

Very high pressure intercooled cycle aviation turbofan engine

ActiveCN108661822BImprove cycle thermal efficiencyIncrease span heightGas turbine plantsJet propulsion plantsCombustion chamberSingle stage

The invention provides a very-high-pressure intercooling cycle turbofan engine. The engine comprises fans, a high-pressure air compressor, an intercooler, a very-high-pressure air compressor, a combustion chamber, a circular rotating fan transition section, a very-high-pressure turbine, a high-pressure turbine, a low-pressure turbine, a low-pressure shaft, a high-pressure shaft and a very-high-pressure shaft. The fans, the high-pressure air compressor, the intercooler, the very-high-pressure air compressor, the combustion chamber, the circular rotating fan transition section, the very-high-pressure turbine, the high-pressure turbine and the low-pressure turbine are connected in sequence. The very-high-pressure turbine drives the very-high-pressure air compressor to operate through the very-high-pressure shaft. The high-pressure turbine drives the high-pressure air compressor to operate through the high-pressure shaft. The low-pressure turbine drives the fans to operate through the low-pressure shaft. The rotation central axis of the very-high-pressure air compressor, and the axis of the combustion chamber are both parallel to the axis of the engine but not coincide with the axis ofthe engine. The high-pressure air compressor is composed of a multi-stage high-load axial flow air compressor and a single-stage high-through-flow centrifugal / oblique flow air compressor.

Owner:AERO ENGINE ACAD OF CHINA

A compressor suction type discrete inclined seam casing processing control device and method

ActiveCN107965465BImprove stable working rangeReduce intensityPump componentsPump controlMomentumAir pump

The invention discloses a suction type discrete and inclined seam casing treatment control device and method of a compressor. A plurality of discrete and inclined seams are formed in the wall surfaceof a compressor treatment casing in the circumferential direction, and the seams are inclined to the rotor rotation direction by a certain angle; then a certain number of suction holes are formed in the tops of the seams, and a back cavity is additionally arranged on the upper portion of the suction holes; by adjusting the angle of the suction holes, the air pumping volume and the air pumping position, flow vortex structures in the discrete and inclined seams and axial flow amount of the air flow of inflow and outflow of the discrete and inclined seams can be changed, and then the momentum ofa tip leakage flow and a mainstream can be changed; and the position of the interface of the tip leakage flow and the mainstream and flow loss caused by interaction between the seams and the tip flowfield can be adjusted. Compared with traditional discrete and inclined seam casing treatment, suction type discrete and inclined seam casing treatment can achieve the goal of reducing the efficiency loss while increasing the stable working range of the compressor.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Microjet forming method for controlling leakage flow of rotor blade tip of gas compressor

The invention discloses a microjet forming method for controlling leakage flow of the rotor blade tip of a gas compressor. The method is characterized in that a hollow cavity used for enabling the blade front edge to communicate with the blade tip is formed in a rotor blade, a blade front edge gap is formed in the position, close to the blade root, of the rotor blade and communicates with the hollow cavity, and a gap is formed in the top of the rotor blade and communicates with the hollow cavity; a rotor rotates at a high speed to suck gas inwards, and most of the gas flows into a blade channel; and trace gas flows into the blade front edge gap, moves from the blade root to the blade tip through the hollow cavity of the blade under the action of centrifugal force, and flows out from the blade tip gap to form a microjet. The method for forming the microjet and controlling the leakage flow of the rotor blade tip gap by means of centrifugal force acting and speed impulse can be used for axial flow compression machines such as an air compressor and a fan so as to reduce flow loss, improve the efficiency and enlarge the stall margin.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com