Mechanism for active control over blade top gap and case shape of air compressor within full working condition range

A blade tip clearance and active control technology, applied in engine control, pump control, machine/engine, etc., can solve the problems of compressor aerodynamic loss, blade tip clearance size increase, structural form and relative position adjustment, etc., to achieve Effect of increasing stall margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

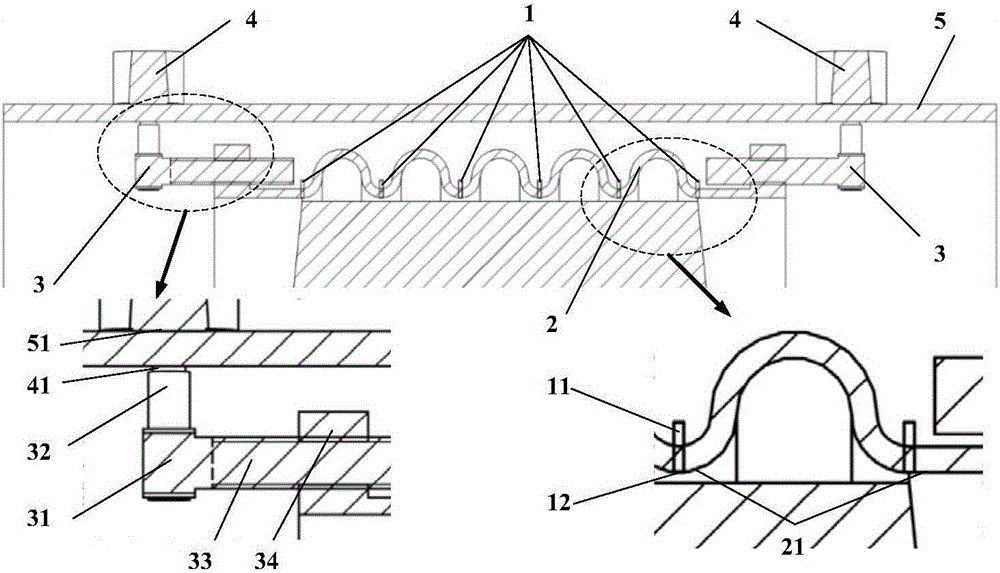

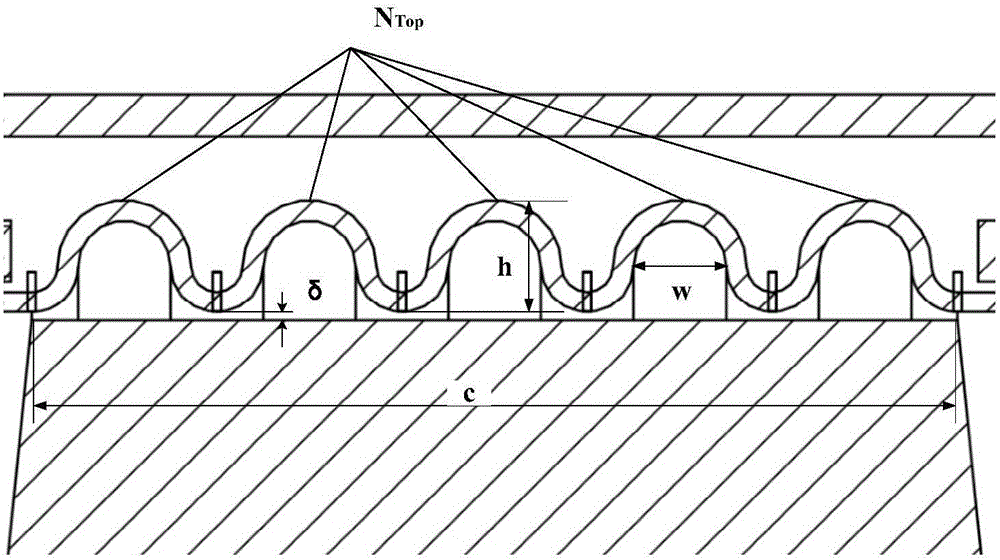

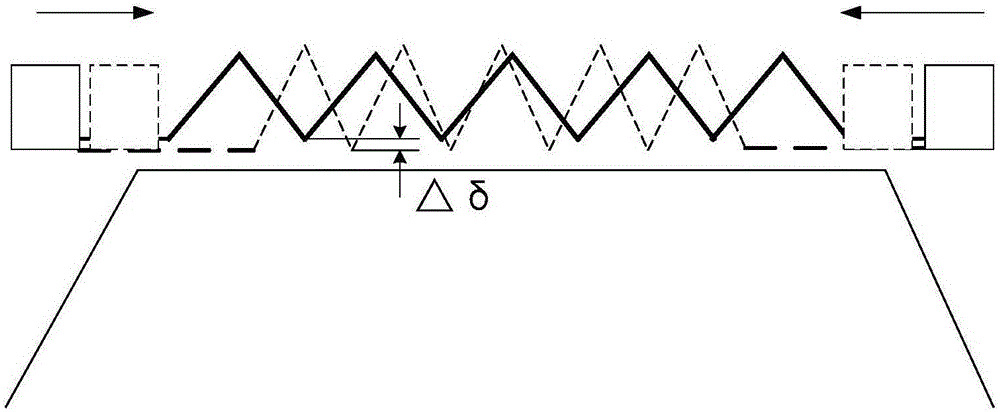

[0020] As an implementation method, for example, the axial chord length of the blade tip is selected to be c=45mm, the initial value of the blade tip clearance δ=0.4mm, the coefficient A=10, and the coefficient B=10; it can be calculated by the relationship h=A c / 100 Obtain the corrugation depth h=4.5mm of the corrugated inner casing, that is, the groove depth of the circumferential groove processing casing is 10% of the axial chord length of the blade tip; the corrugation can be calculated by the relation w=B c / 100 The corrugated opening width of the inner casing w=4.5mm, that is, the equivalent groove width of the circumferential groove processing casing is 10% of the axial chord length of the blade tip; the corrugated inner casing is selected at the axial chord length of the blade tip Number of peaks N in the range of c Top In the case of = 5, that is, when the number of circumferential grooves is 5, the ratio of the grooved area of the circumferential grooves to the trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com