Microjet forming method for controlling leakage flow of rotor blade tip of gas compressor

A compressor rotor and leakage flow technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problem of centrifugal force affecting rotor blade strength, etc. Efficiency, the effect of reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

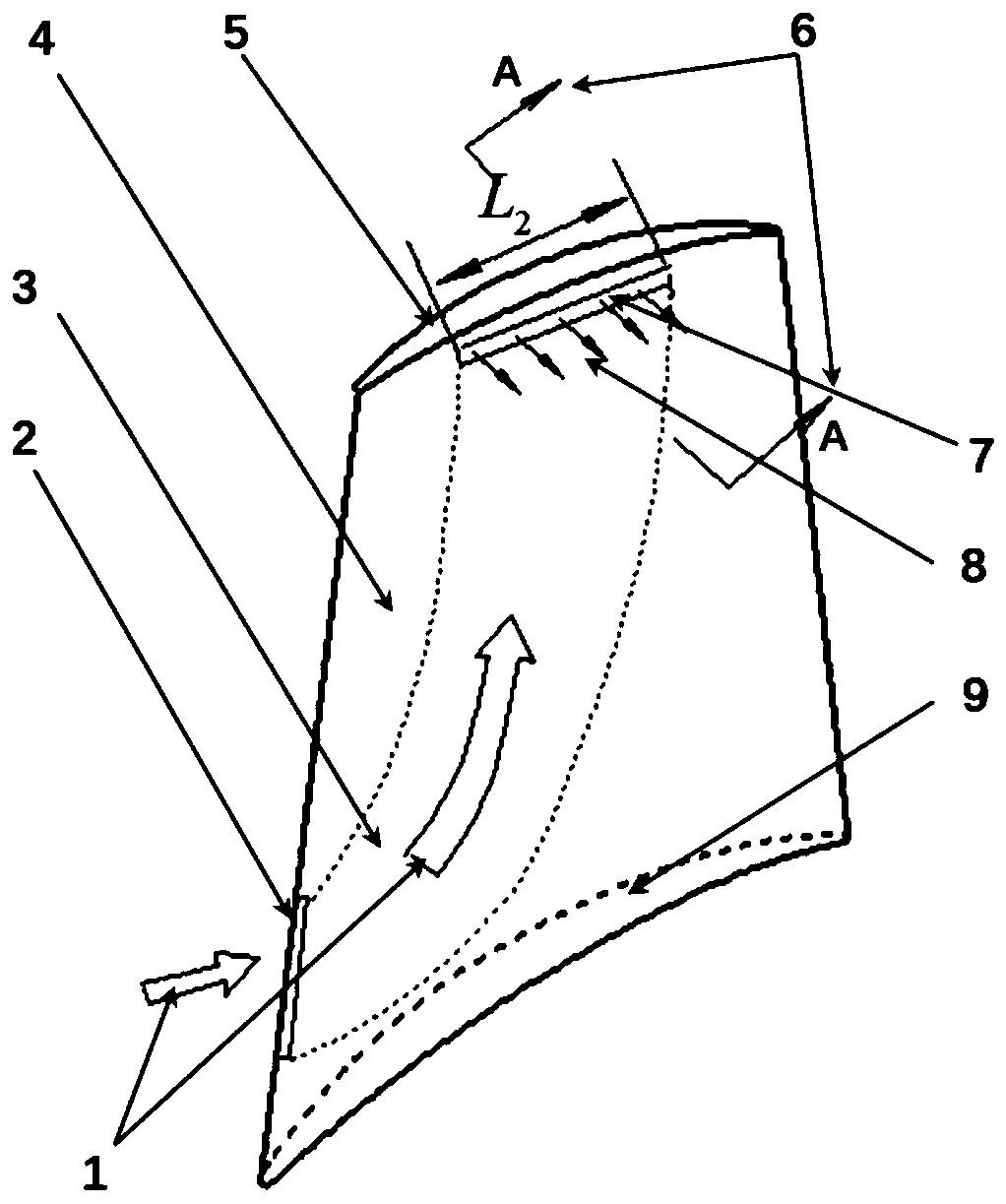

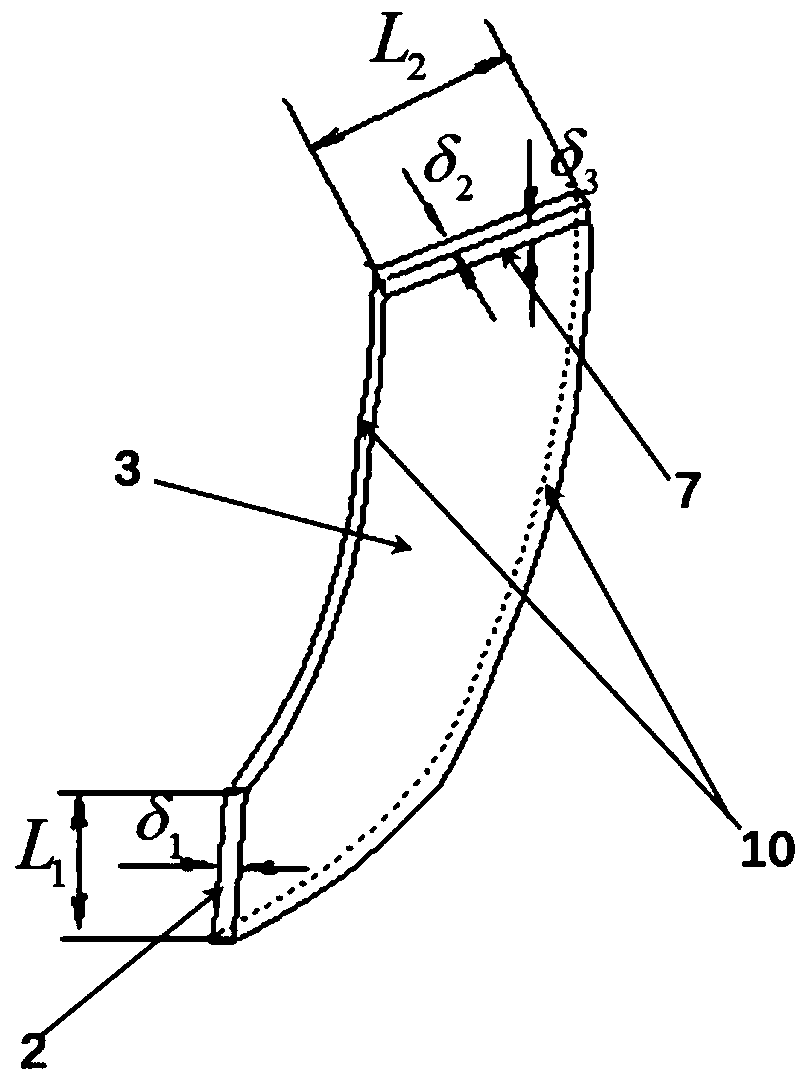

[0016] The following combination Figure 1 to Figure 4 The present invention uses centrifugal force and velocity impulse to form a micro jet to control the implementation method of compressor rotor blade tip leakage flow.

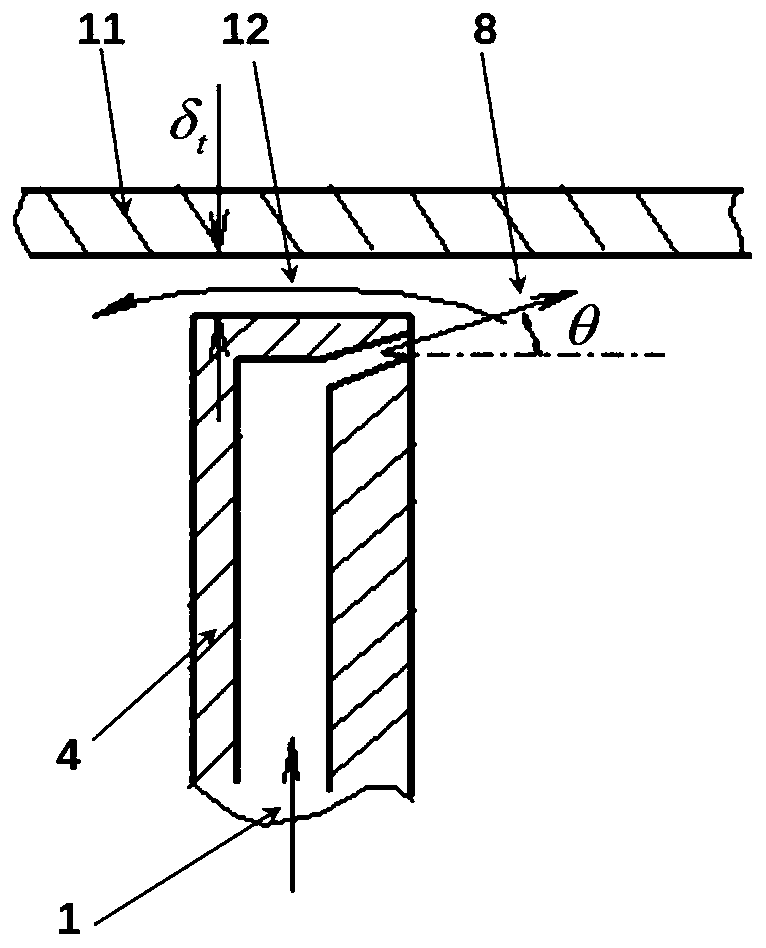

[0017] A method for controlling the leakage flow of a compressor rotor blade tip by using centrifugal force and velocity impulse to form a micro-jet. The slit is connected to the hollow chamber. The high-speed rotating compressor rotor inhales gas, most of which flows into the vane passage. From the perspective of relative motion, standing on the rotor blade, the air flow flows through the rotor blade at high speed, in which the trace gas 1 flows into the gap 2 at the leading edge of the blade, moves from the blade root to the blade tip through the blade hollow chamber 3 under the action of centrifugal force, and is transported by the blade The pointed slit 7 flows out, forming a micro-jet 8. The blade tip gap can be opened on the side of the blade tip c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com