Multi-arc chute processing machine box

A technology for processing casings and arcs, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as unreasonable geometric structure design of processing tanks, reduced adiabatic efficiency, and reduced peak compressor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

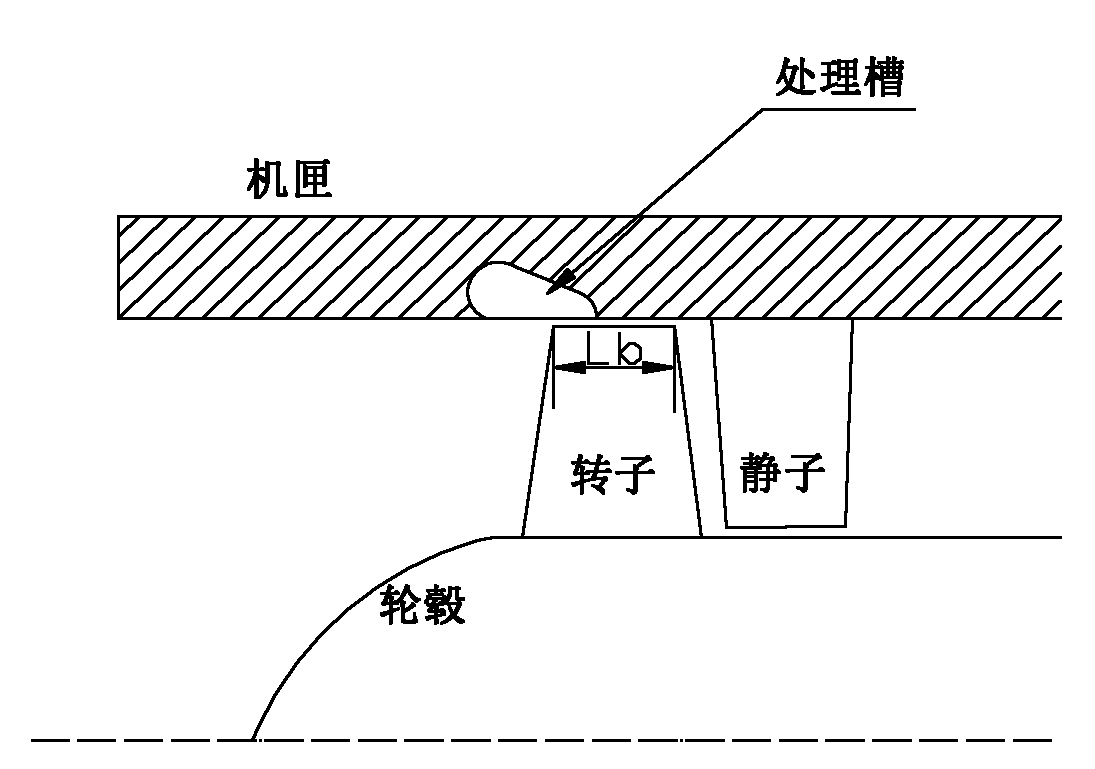

[0028] Taking a single rotor of a transonic compressor as an example to illustrate the specific implementation of the present invention, Table 1 shows the basic aerodynamic and structural parameters of the single rotor of the transonic compressor.

[0029] Table 1 Design parameters of transonic axial flow compressor rotor

[0030]

[0031]

[0032] Carry out following design according to the design method in the summary of the invention:

[0033] (1) Determine the number of processing tanks N=17×6=102

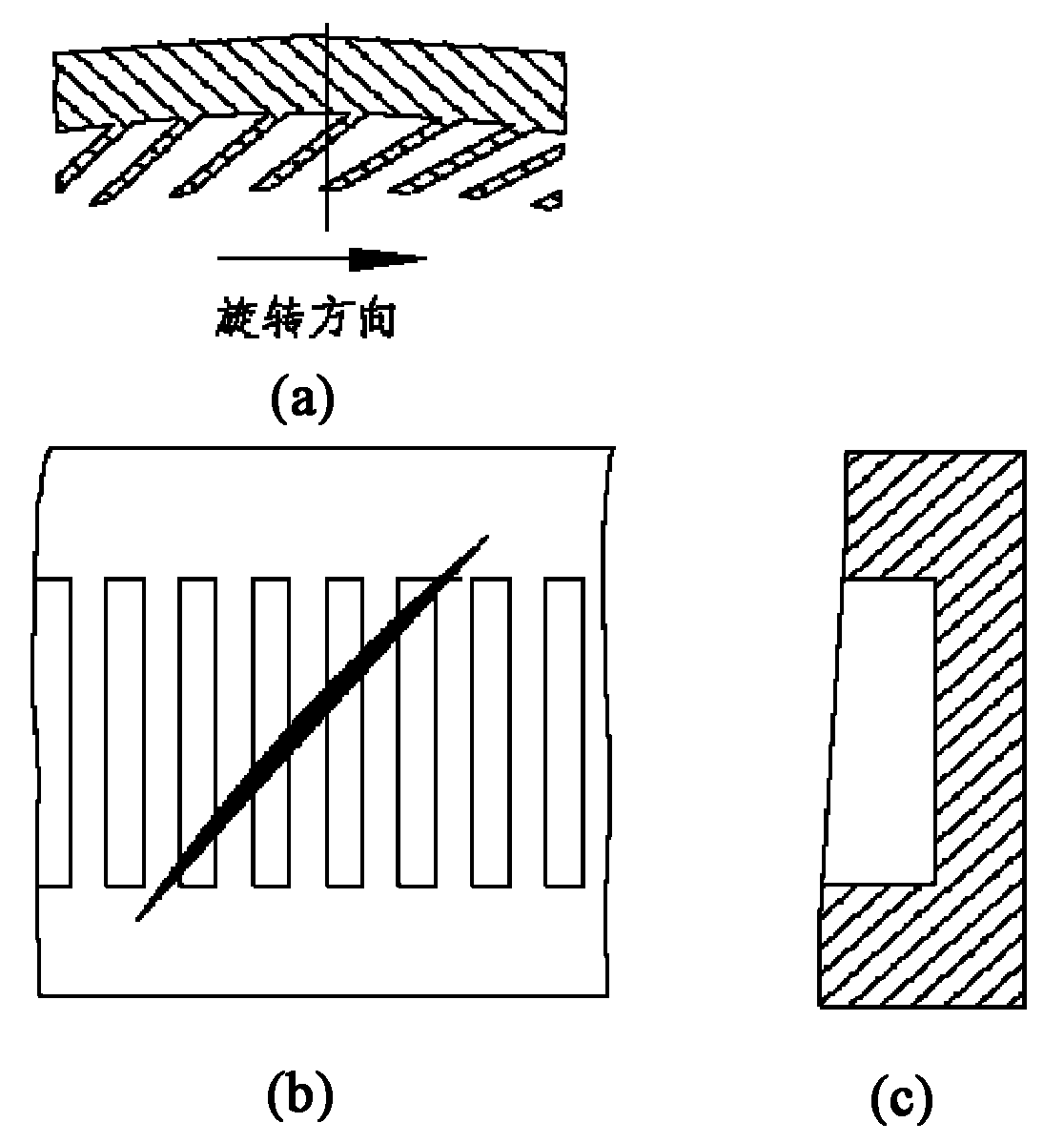

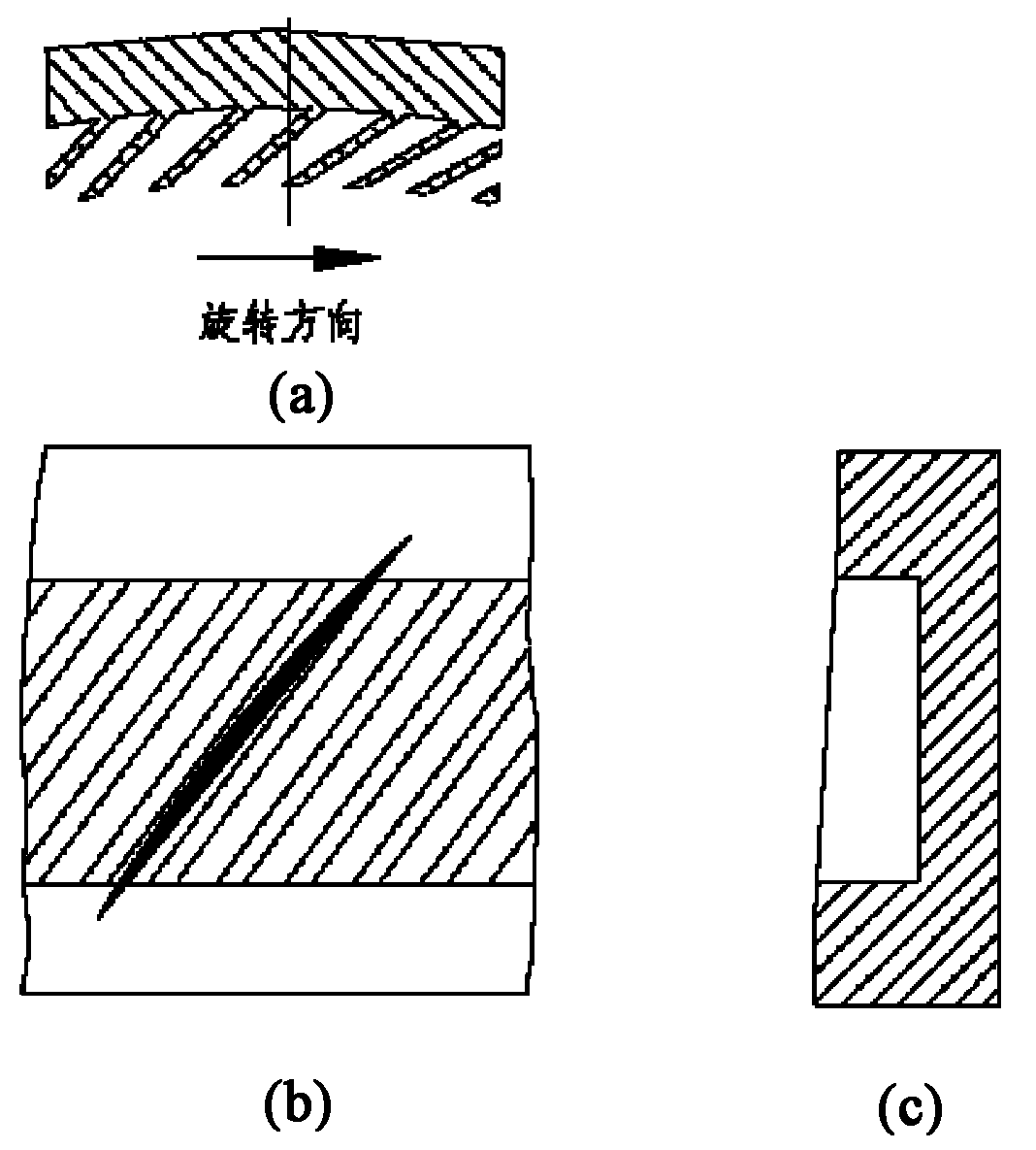

[0034] (2) The axial projection length L of the treatment tank H =1.085×35mm=38mm, L b =35mm

[0035] (3) The radial inclination angle Alpha of the treatment tank is 45°

[0036] (4) The radii of the two arcs are R1=14mm; the angle between the line connecting the two ends of the semi-arc at the front (that is, the diameter) and the casing line is 50°

[0037] (5) The treatment tank adopts an arc shape in Z (axial direction), the overlap of the treatment tank is 35%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com