Processing method for radial slot cartridge receiver

A casing processing and radial groove technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of expanding the stable working margin of the compressor and decreasing efficiency, and achieve high social benefits and promotion value. Ease of processing and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

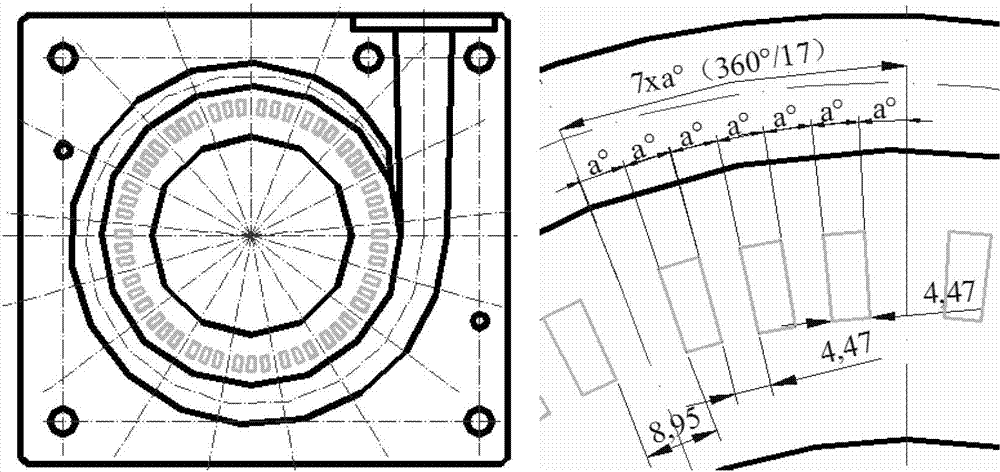

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] 1) First, model the compressor without slots on the side of the wheel cover, and conduct numerical simulation and flow analysis of its internal flow field to determine the dominant flow field structure and flow characteristics in the compressor, and clarify the compressor flow Areas within the track prone to stalling;

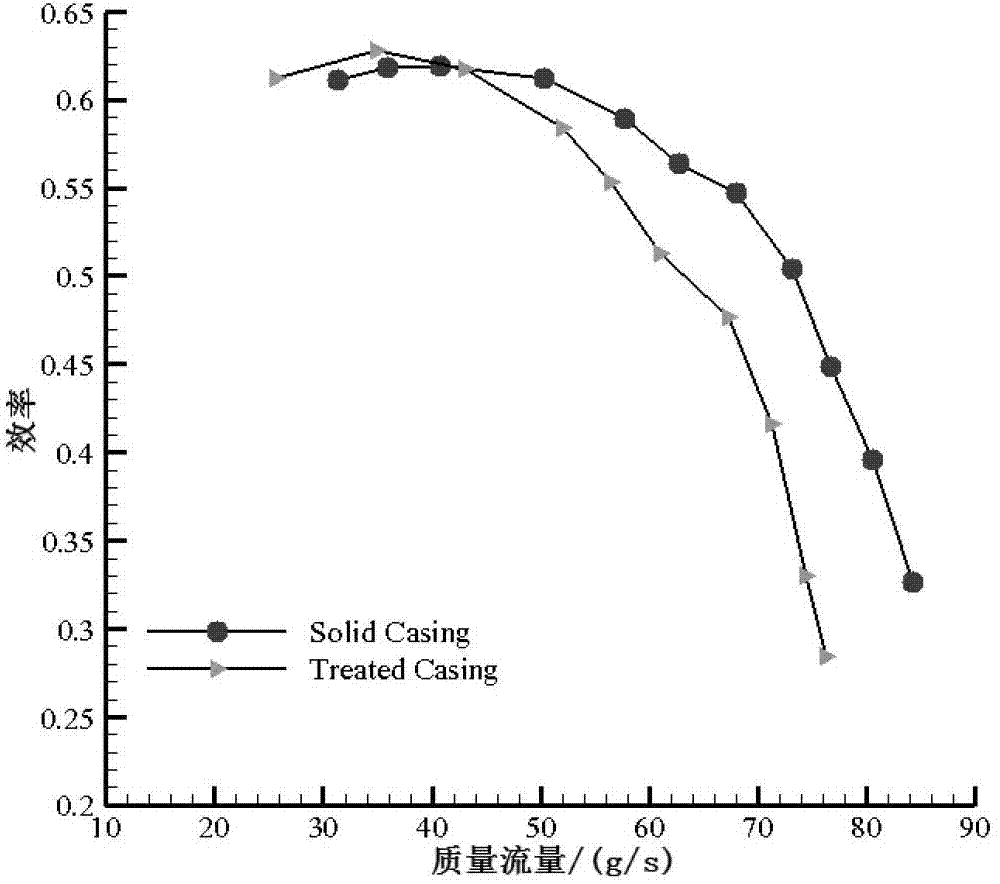

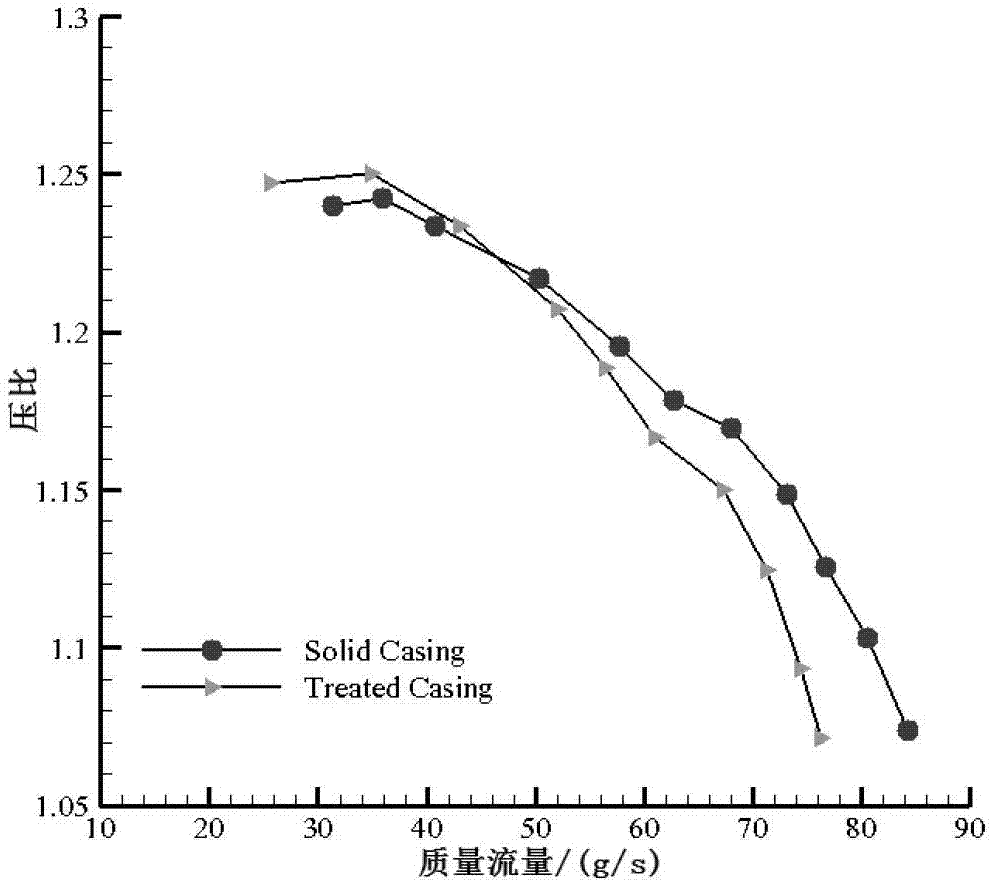

[0026] 2) Secondly, according to the area in the compressor flow channel determined in step 1) that is prone to stall, a single circumferential groove is opened along the different meridian positions of the compressor shroud side, and modeling and numerical simulation are performed on it, and the circumferential groove machines at different positions are compared Determine the best slotting position based on the expansion and stabilization effect of the casing and its influence on the efficiency of the compressor;

[0027] 3) Then, acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com