Distributed parameterized impeller self-circulation treatment casing

A technology for handling casing and self-circulation, applied in mechanical equipment, non-variable-capacity pumps, non-displacement pumps, etc., can solve the problem that the structural parameters of the air bleed channel and the bridge path are not optimized, the impeller efficiency is negative, Simple structure and other problems, to achieve the effect of expanding stable working range, reducing efficiency loss and improving stall margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a distributed parameterized impeller self-circulation processing casing.

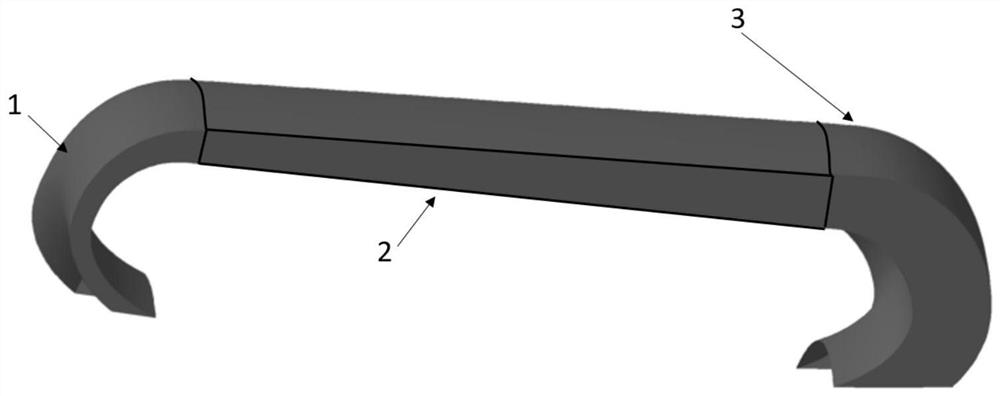

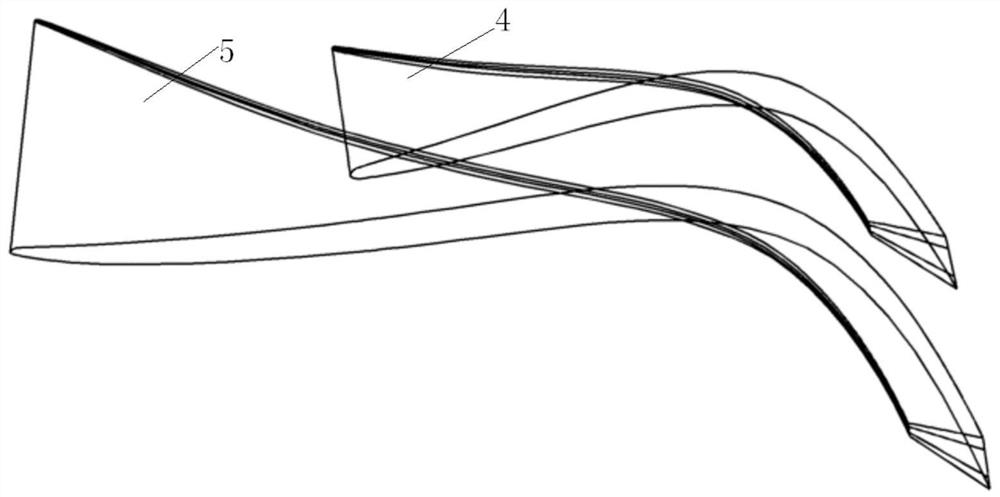

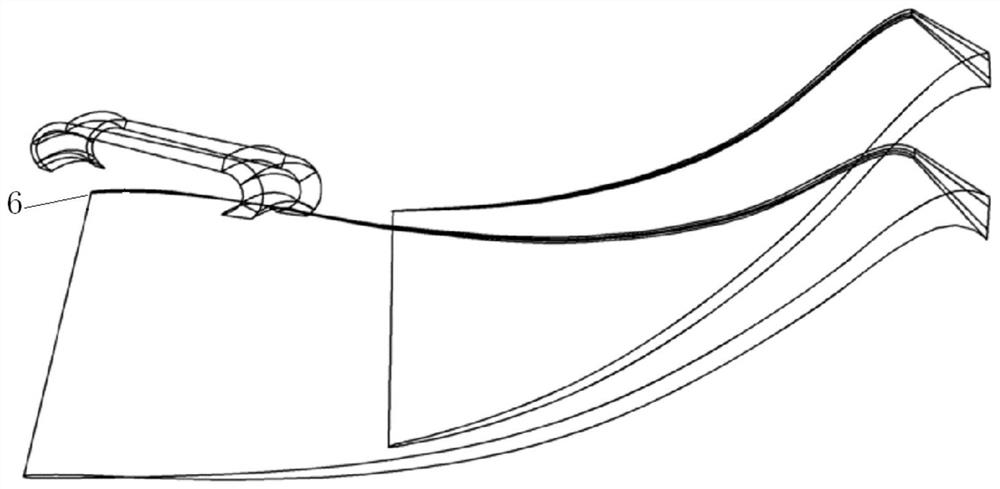

[0021] refer to Figure 1 ~ Figure 3 , the distributed parameterized impeller self-circulation processing casing in this embodiment is composed of impeller casing, channel leading edge 6, impeller blades, front channel 1, rear channel 2 and bleed air bridge 3; wherein, bleed air bridge The road is fixed on the outside of the impeller casing, by connecting the front channel 1 and the rear channel 2 of the front edge 6 of the upper channel of the impeller casing, the gas backflow in the bridge circuit is realized by using the pressure difference between the front and rear of the centrifugal impeller channel.

[0022] In this embodiment, there are multiple bleed bridges 3, and the two impeller passages correspond to a bleed bridge of a self-circulating casing. The circumferential coverage angle of each bleed bridge 3 is 22.5°; the inner wall surface is two-dimensional The profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com