Asymmetric double-circular-arc chute processing casing

A processing casing, asymmetric technology, used in mechanical equipment, non-variable displacement pumps, machines/engines, etc., can solve the problem of reducing the peak efficiency of the compressor, large vortex loss in the processing tank, and inconsistency in the geometric structure design and distribution of the processing tank. Reasonableness etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

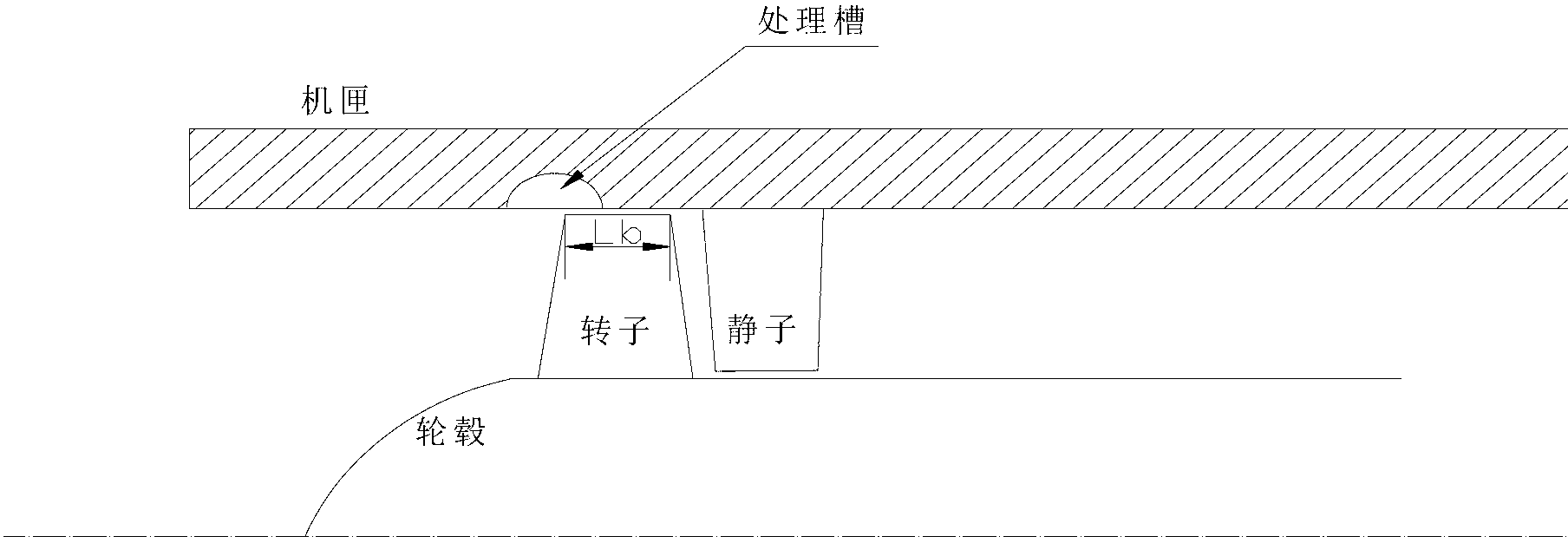

[0029] Taking a single rotor of a transonic compressor as an example to illustrate the specific implementation of the present invention, the design parameters of the compressor rotor and stator are shown in Table 1 and Table 2. Due to the large corner, the stator adopts a tandem design.

[0030] Table 1 Transonic axial flow compressor rotor Table 2 Transonic axial flow compressor stator design parameters

[0031]

[0032]

[0033] According to the design method in the summary of the invention, the following design is carried out:

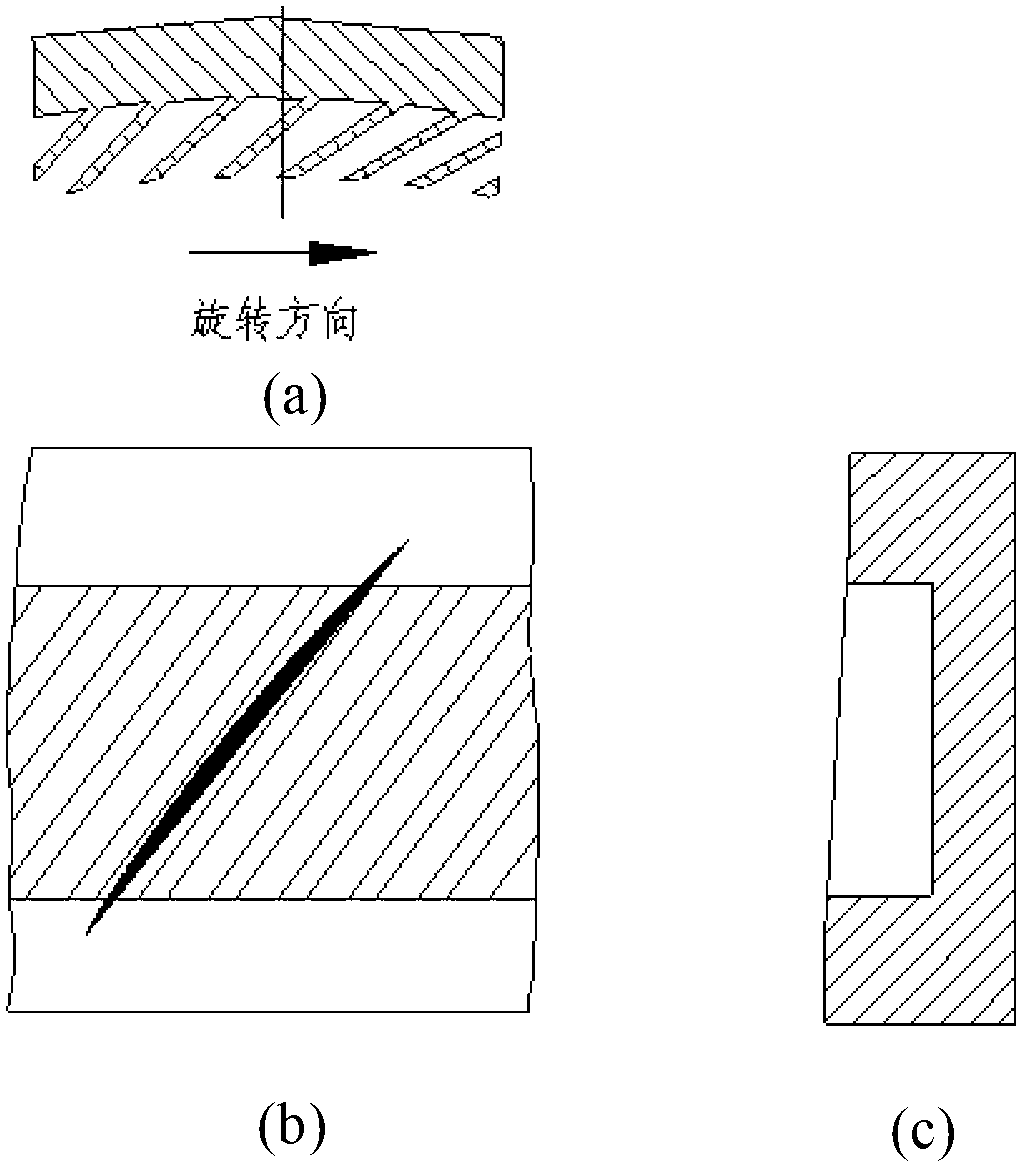

[0034] (1) Determine the number of processing tanks in the entire circumference N=88, remove 44 tanks in the non-processing area, and place 26 processing tanks and 18 processing tanks in the remaining 106° and 74° processing areas, respectively.

[0035] (2) The axial projection length of the processing tank L H =1.085×35mm=38mm, L b =35mm

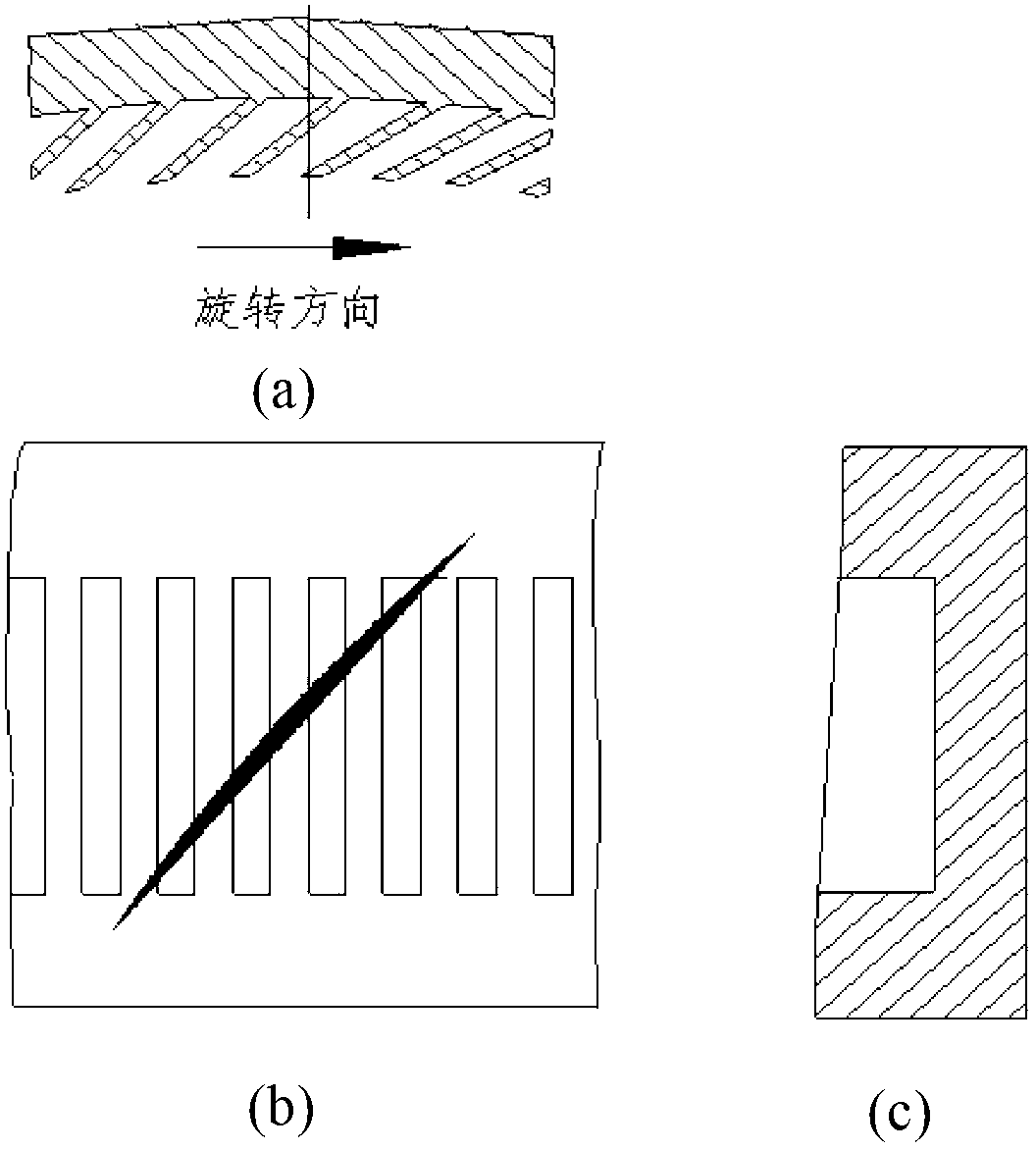

[0036] (3) The radial inclination angle of the processing groove Alpha is 45°

[0037] (4) The processing tank is on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com