Unsteady standing vortex type treatment casing

A technology for dealing with casings and vortexes, applied in non-variable-capacity pumps, mechanical equipment, machines/engines, etc., can solve the problems of increasing flow mixing loss, reducing compressor efficiency, etc., to reduce mixing loss , The effect of suppressing leakage flow and improving stall margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the present invention more clearly, a typical example of the non-stationary resident vortex processing casing described in the present invention will be described below in conjunction with the accompanying drawings.

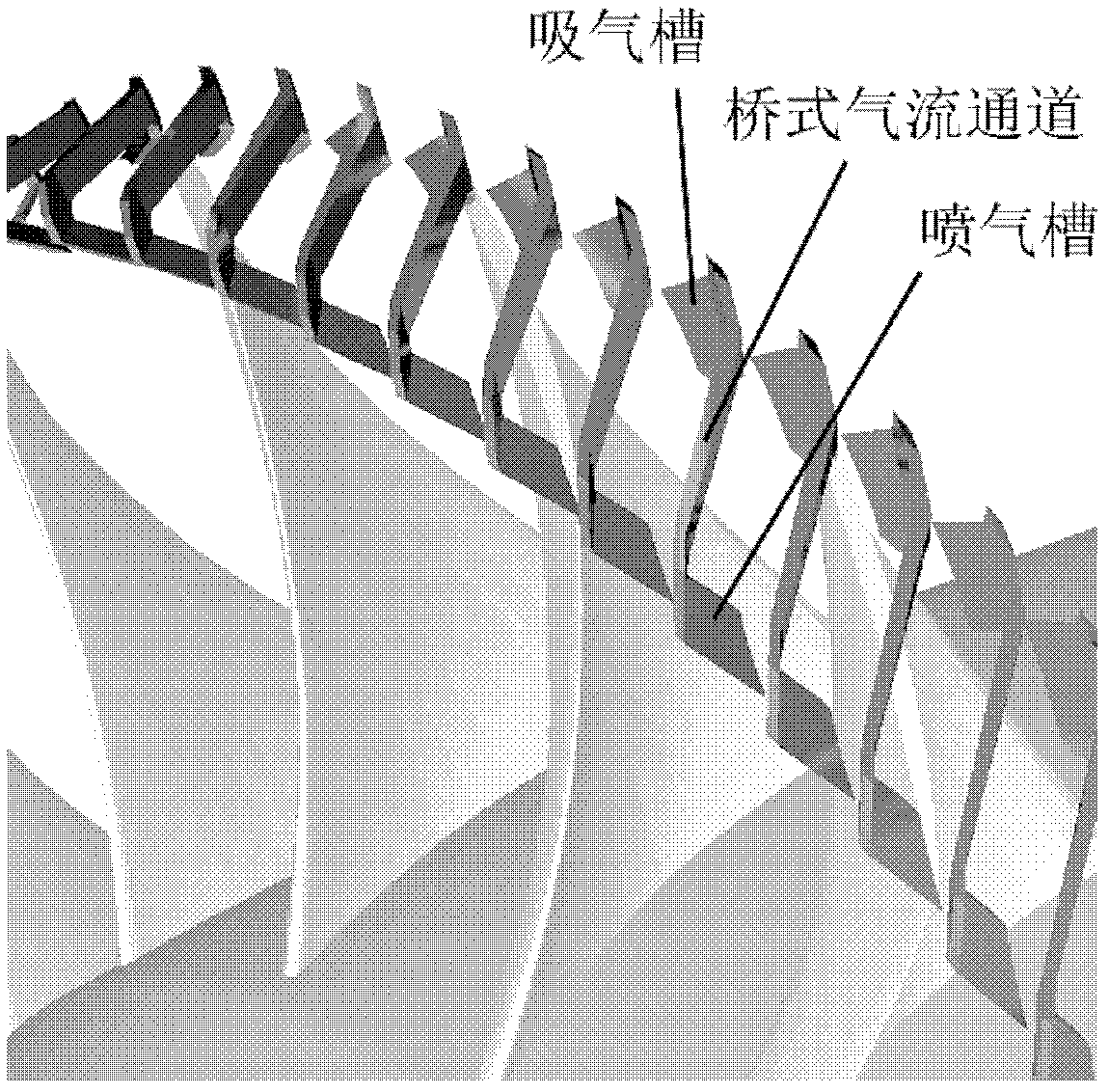

[0032] figure 1 It is a three-dimensional structural diagram of the present invention, showing the air jet grooves on the suction surface of the blades, the bridge-type airflow channel, and the air suction grooves on the pressure surface of the blades respectively.

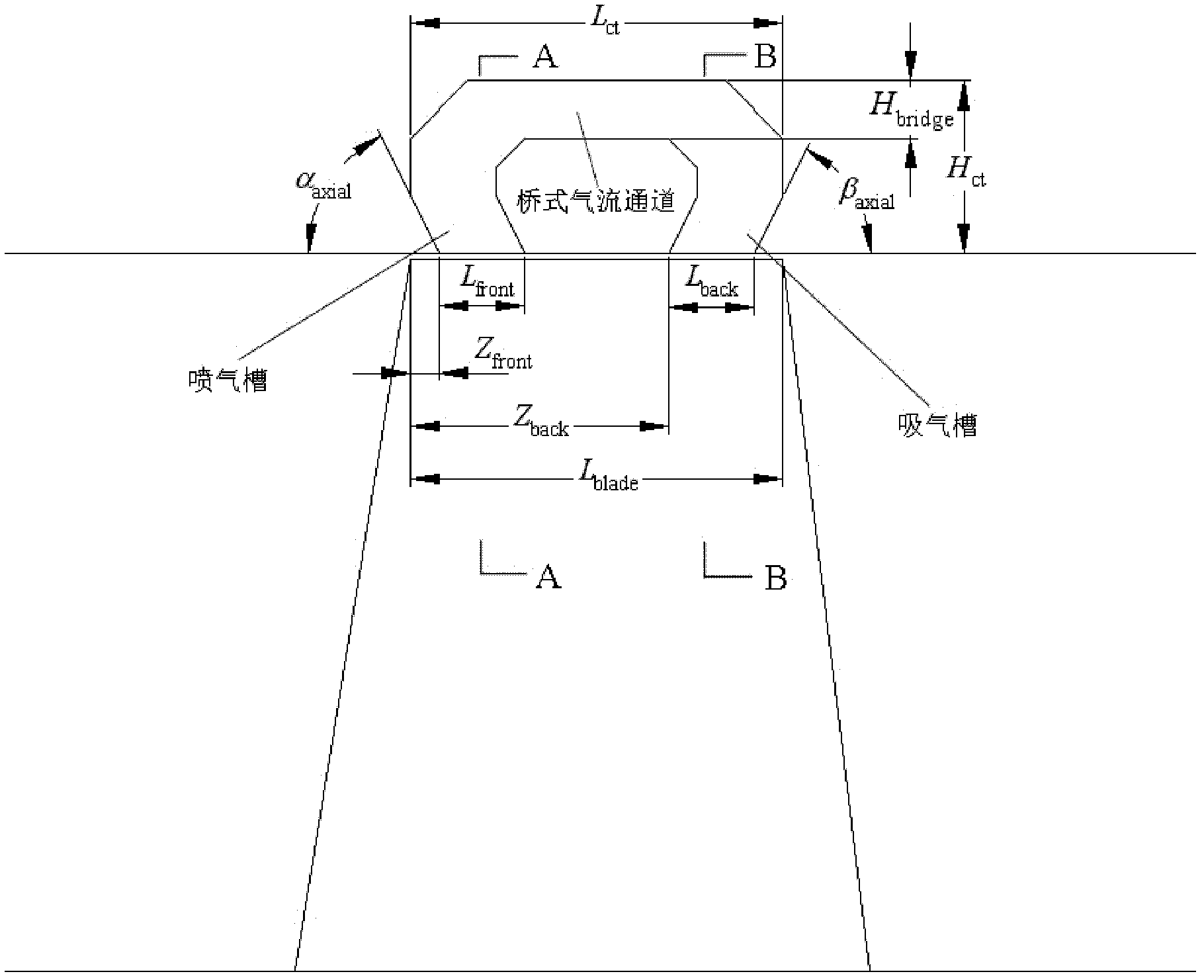

[0033] figure 2 It is a meridian view of the present invention, L in the figure blade is the chord length of the tip of the blade in the axial direction, according to the method described in the summary of the invention, the geometric parameters of the processing casing are sequentially determined.

[0034] The projected length L of the processing casing in the axial direction ct = 1.0L blade ;

[0035] Projection height H of the processing casing in the radial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com