Axial and radial flowing compressor with axial chute processor casing structure

A technology for processing casings and compressors, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., and can solve problems such as narrow compressor stable flow range, performance deterioration, and narrow stable operating range of axial-flow compressors. Achieve the effects of improving the stable operating range, uniform flow, improving efficiency and stable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The working principle, working process and specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

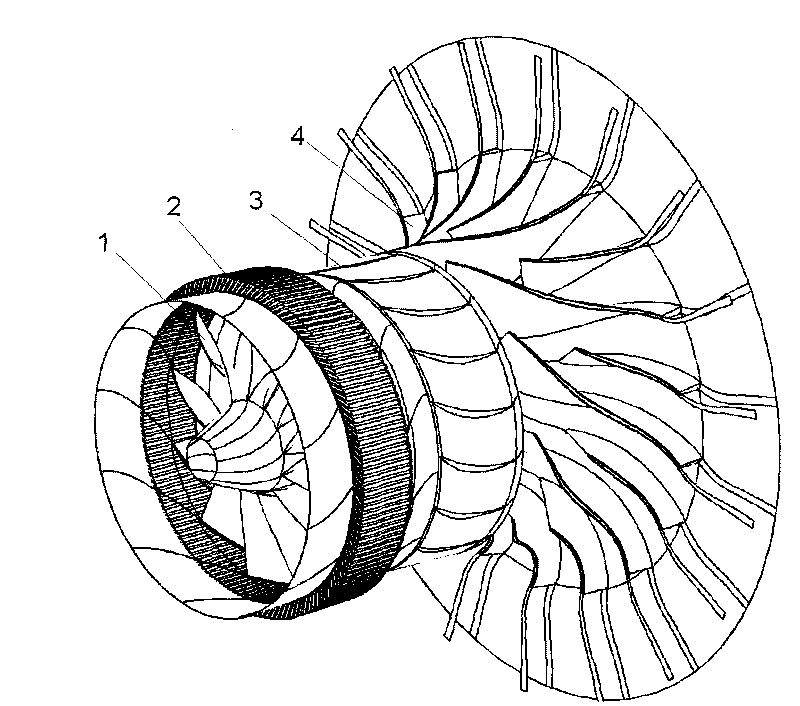

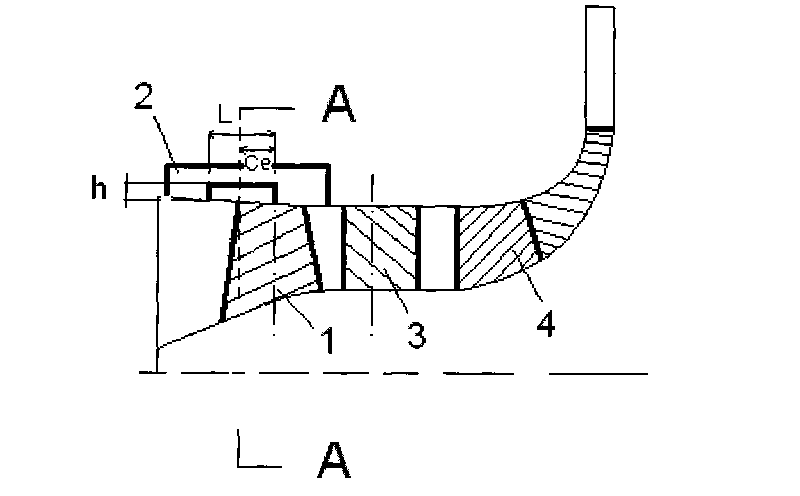

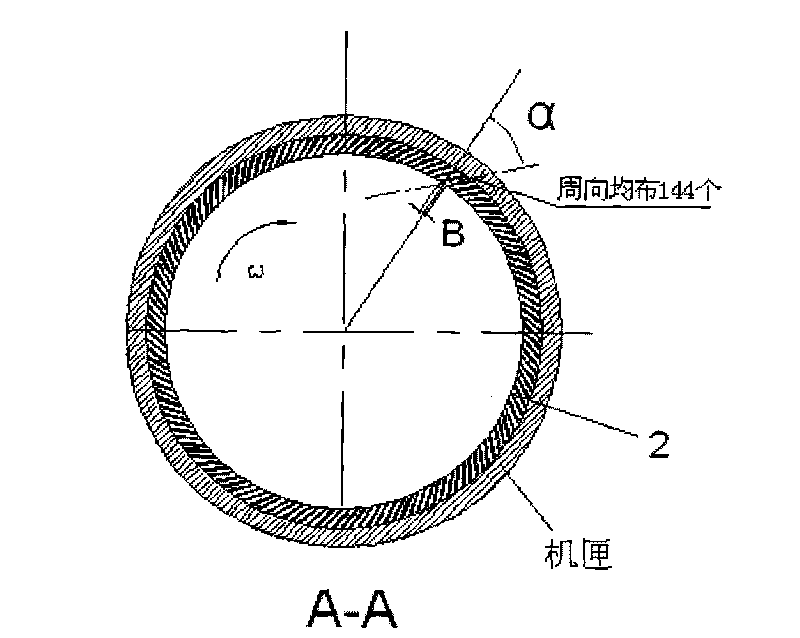

[0022] figure 1 is a three-dimensional structural view of the present invention. figure 2 is the meridian view of the axial flow compressor.

[0023] Such as figure 1 , 2 As shown, the axial-radial compressor mainly includes an axial-stage rotor 1 , an axial-flow stator 3 , and a radial-stage compressor 4 . The axial-flow stage rotor, stator, and radial-flow stage compressor are sequentially connected coaxially and in series. On the casing of the axial-flow stage rotor of the axial radial-flow compressor, a casing processing structure with an axial chute is adopted to widen the stable flow range of the whole-stage compressor. Since the stable flow range of the axial flow stage is narrower than that of the centrifugal stage, the stable flow range of the radial flow compressor is not wide. The resear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com