Valve for controlling a fluid

A fluid, throttle valve technology, applied in valve details, valve devices, valve operation/release devices, etc., to solve problems such as sticking on the valve body, tilting of the valve armature, material wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

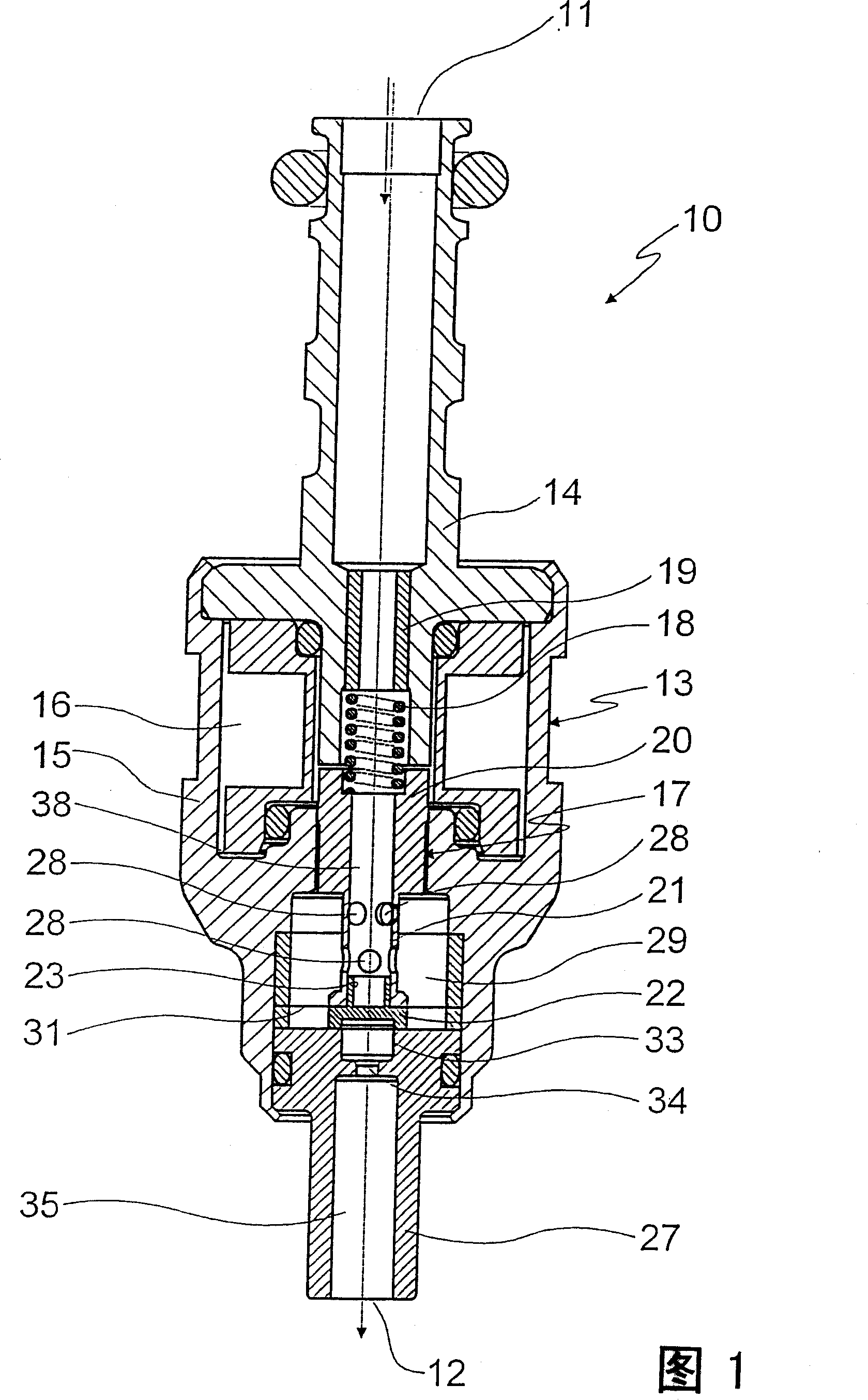

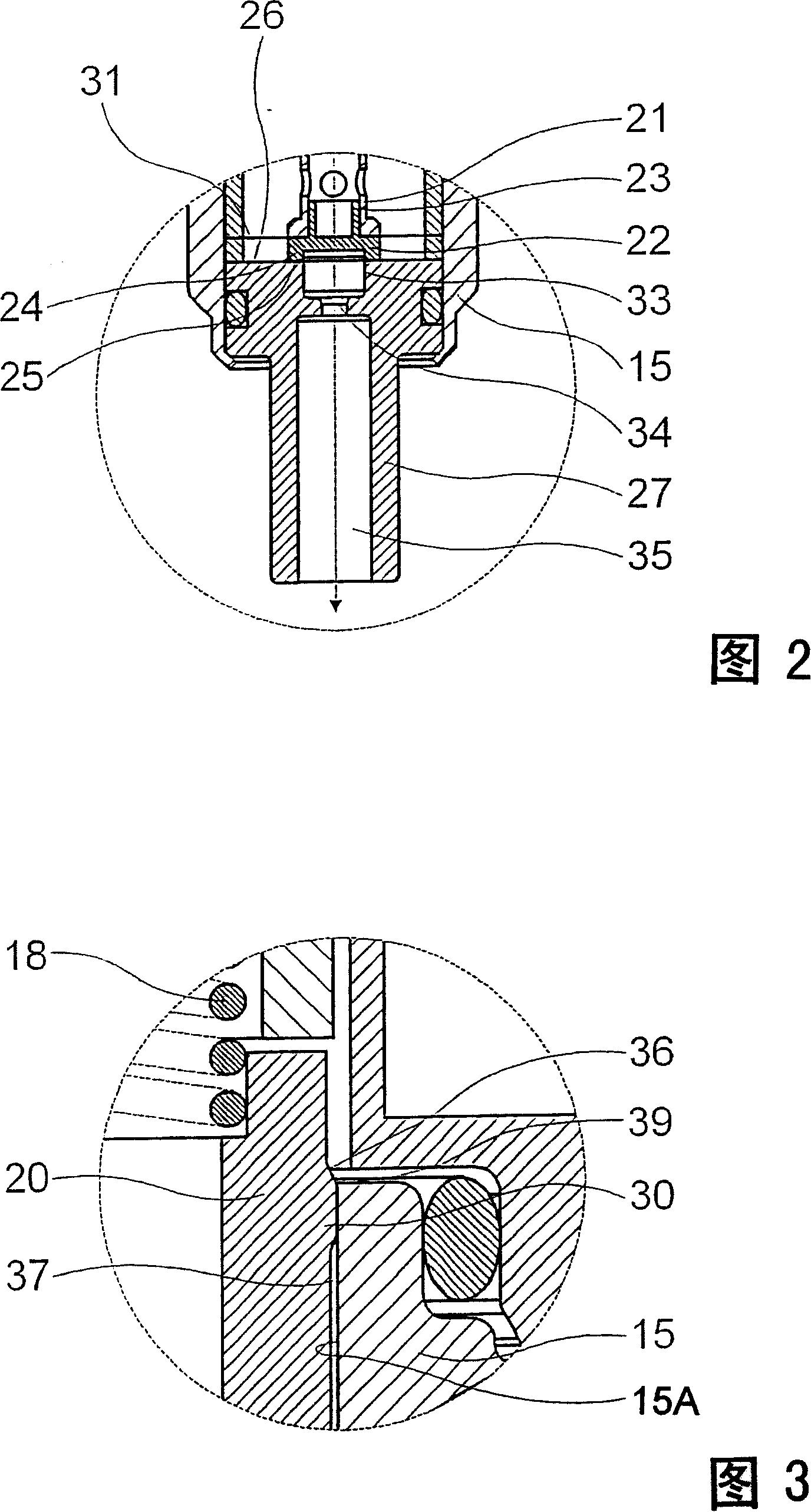

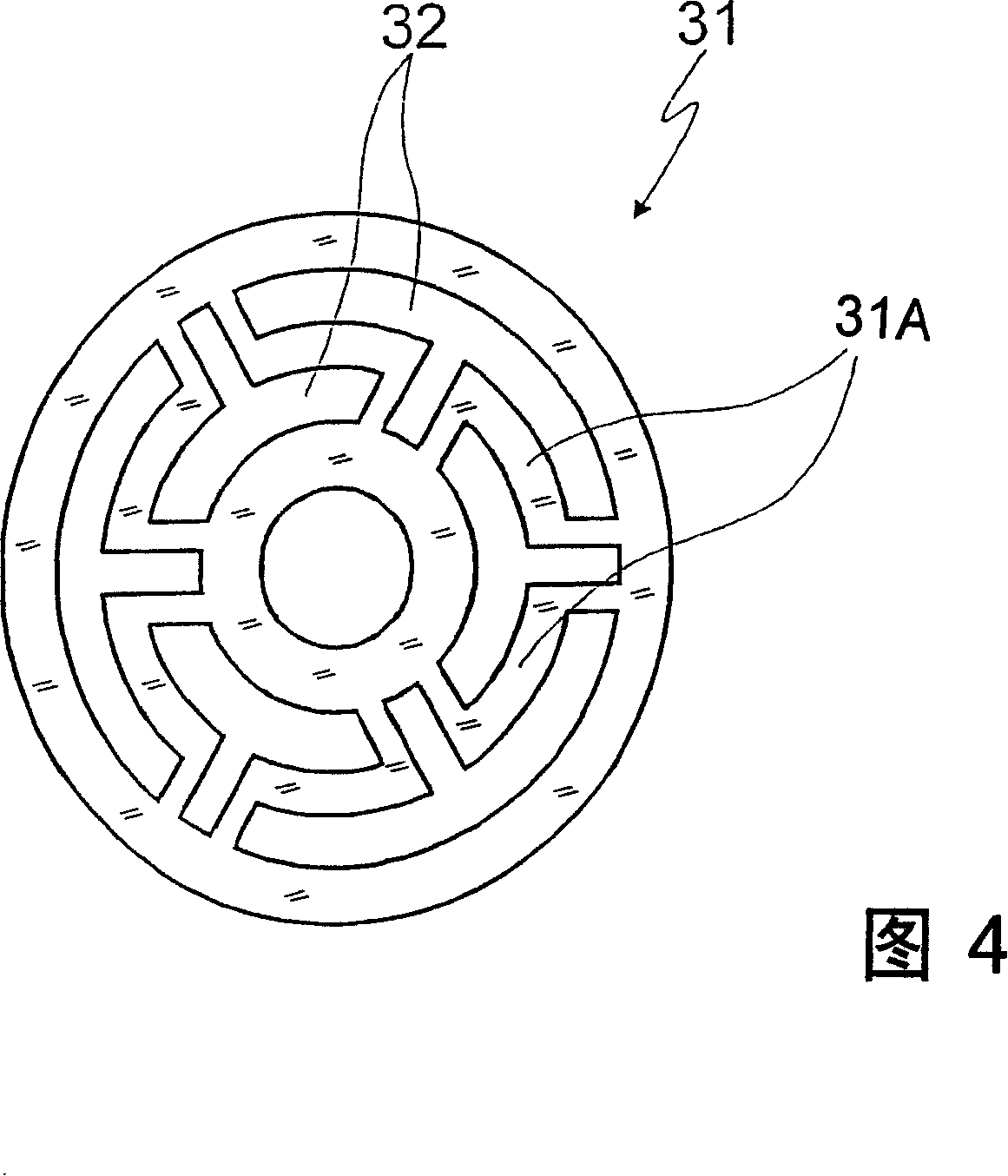

[0032] A gas valve 10 is shown in FIGS. 1-4 , which is designed for use in a fuel cell or a gas engine and serves to regulate the flow of hydrogen or natural gas from the inflow side 11 to the outflow side 12 .

[0033] The gas valve 10 comprises a multi-part housing 13 with a substantially tubular joint 14 forming the fluid inflow side 11 on the joint 14, which is passed through a flange-shaped flange with an outer diameter The flange of the enlargement is inserted axially into an essentially hollow-cylindrical central valve body 15 . A space 16 is formed in the central valve body 15 for the solenoid actuating unit, which interacts with a valve armature 17 which is supported via a helical spring 18 on a sleeve inserted into the bore of the connection 14 19 on.

[0034] The valve armature 17 comprises a large-diameter area 20 and a small-diameter area 21 formed in a constricted form, on the end face of the small-diameter area is connected a valve closing element 22, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com