Transonic compressor rotors with non-monotonic meanline angle distributions

a compressor rotor and non-monotonic technology, applied in the direction of machines/engines, supersonic fluid pumps, liquid fuel engines, etc., can solve the problems of weaken or remove shock waves, and achieve the effect of improving compressor airfoil design, high efficiency and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]While specific embodiments of the invention are discussed herein and are illustrated in the drawings appended hereto, the invention encompasses a broader spectrum than the specific subject matter described and illustrated. As would be appreciated by those skilled in the art, the embodiments described herein provide but a few examples of the broad scope of the invention. There is no intention to limit the scope of the invention only to the embodiments described.

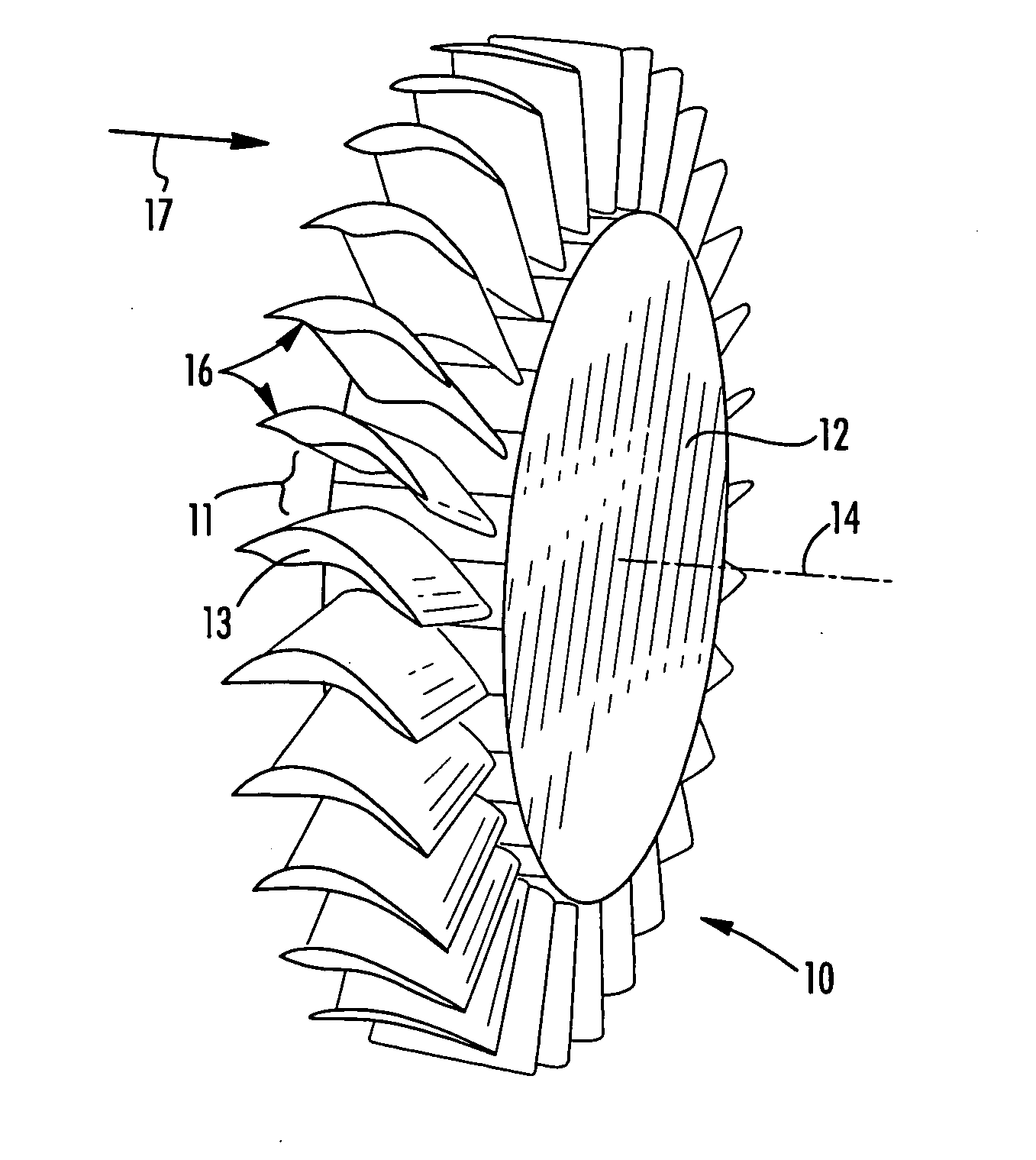

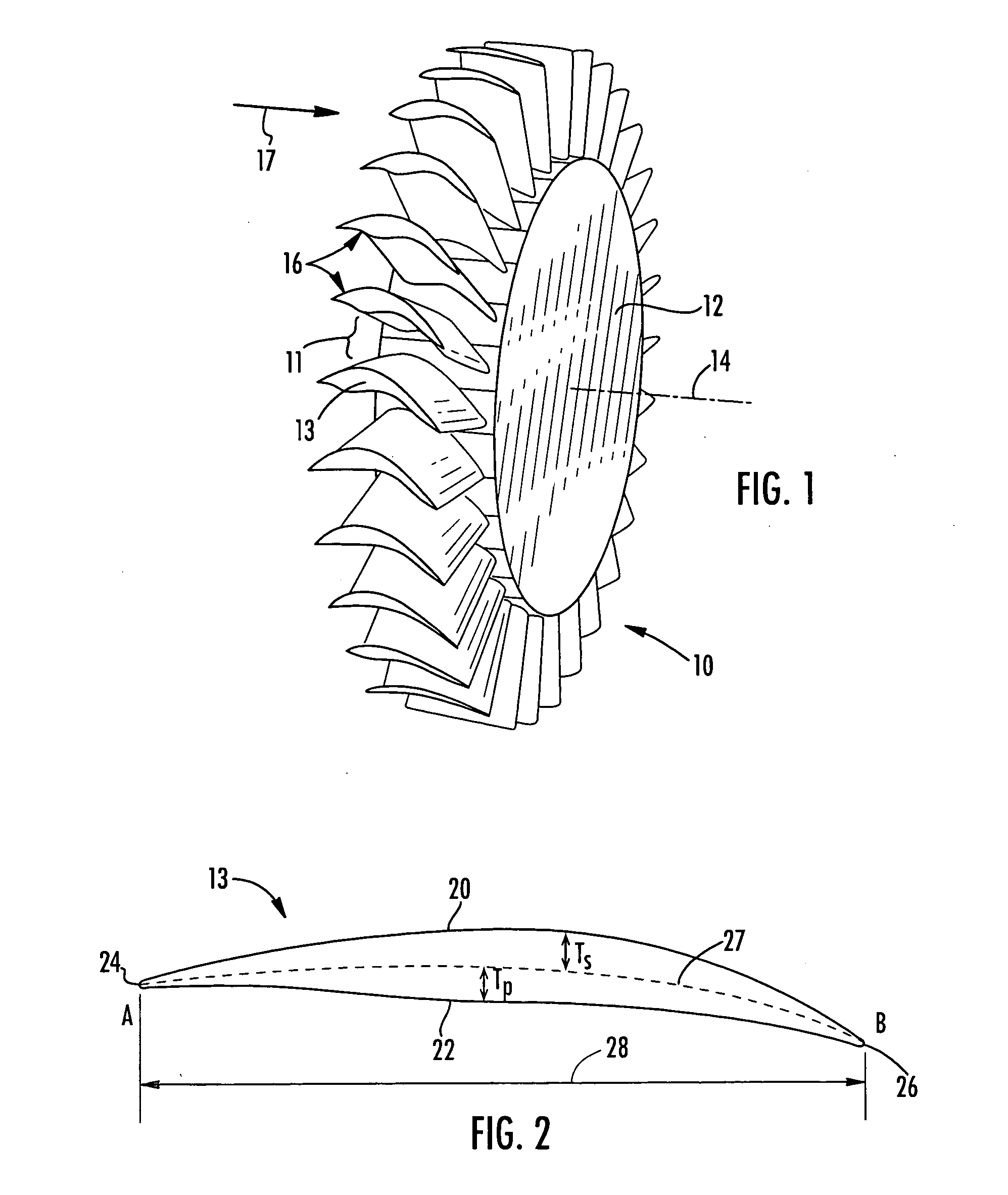

[0026]According to one embodiment of the invention illustrated in FIG. 1, a compressor rotor assembly 10 is provided for a gas turbine. The compressor rotor assembly 10 includes a rotor hub 12 that rotates about an axis 14. A plurality of rotors 16 extend outwardly from the rotor hub 12. According to one embodiment, the rotors 16 extend in a radial direction away from the rotor hub 12. Fluid 17 flows axially along direction 17 and passes between adjacent rotors 16 at passages 11. The rotors 16 are defined by airfoils 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com