Paint jetting gun

A technology for spray guns and coatings, which is applied in the direction of spraying devices, liquid spraying devices, etc., and can solve the problems of not being able to monitor the spraying pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

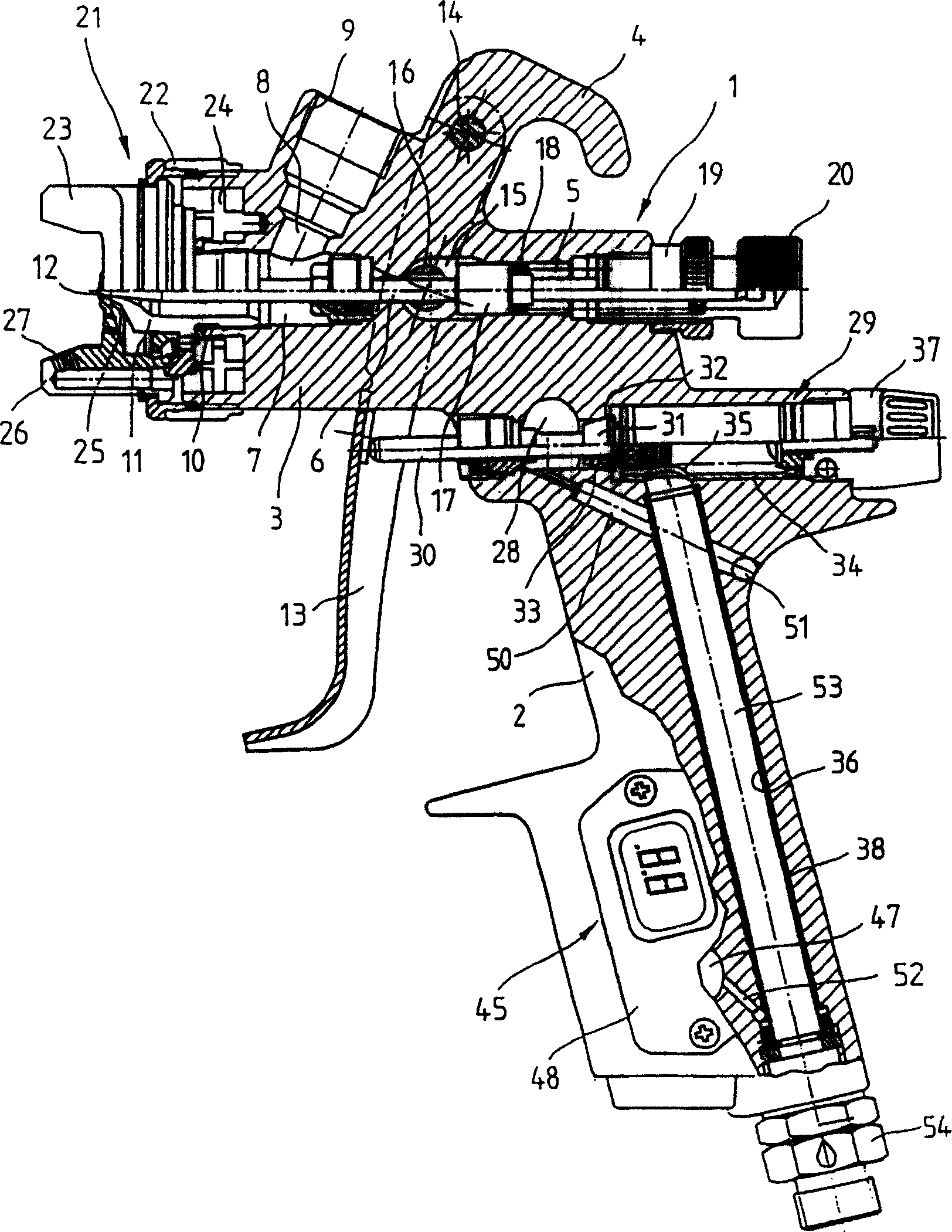

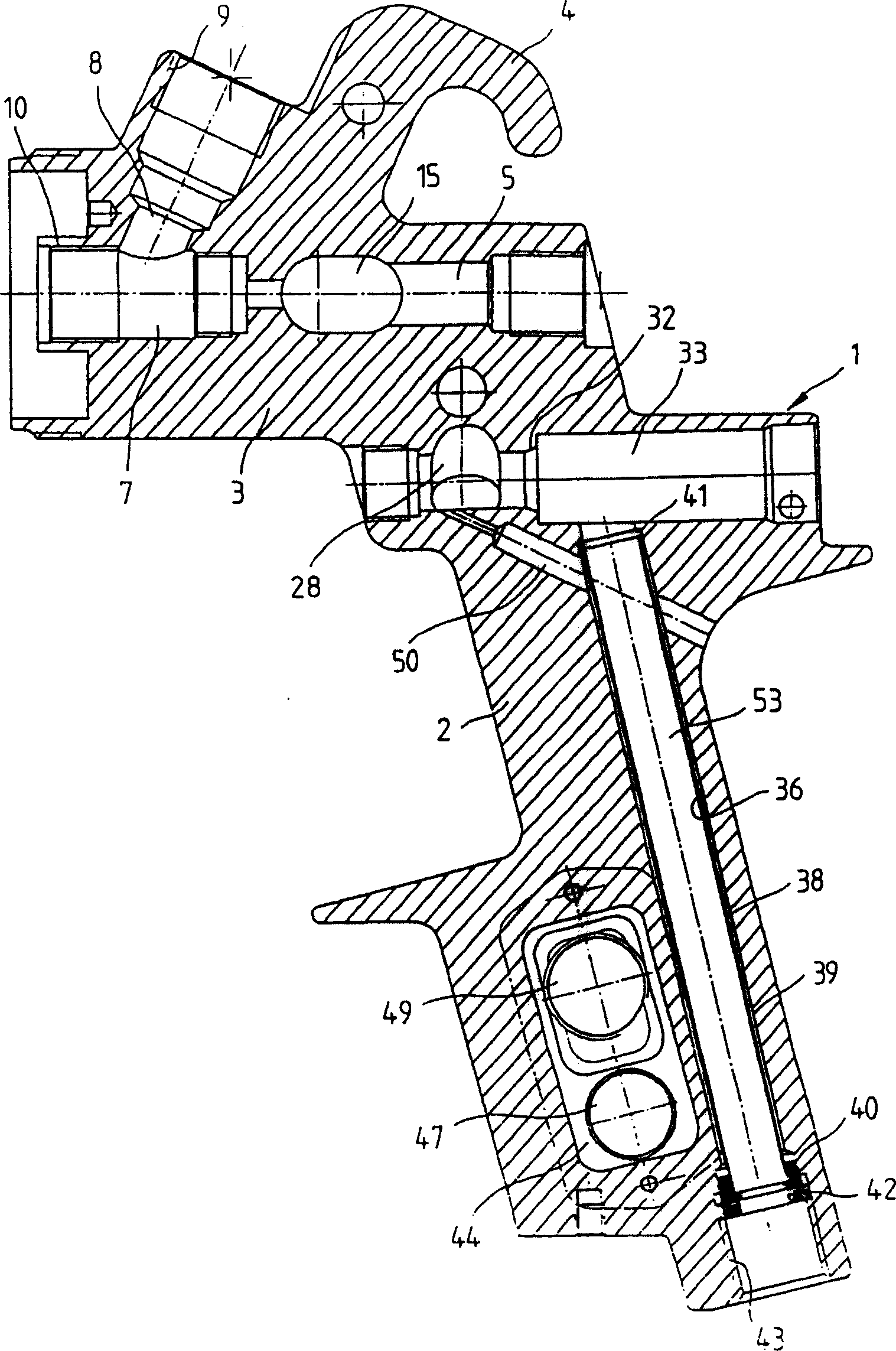

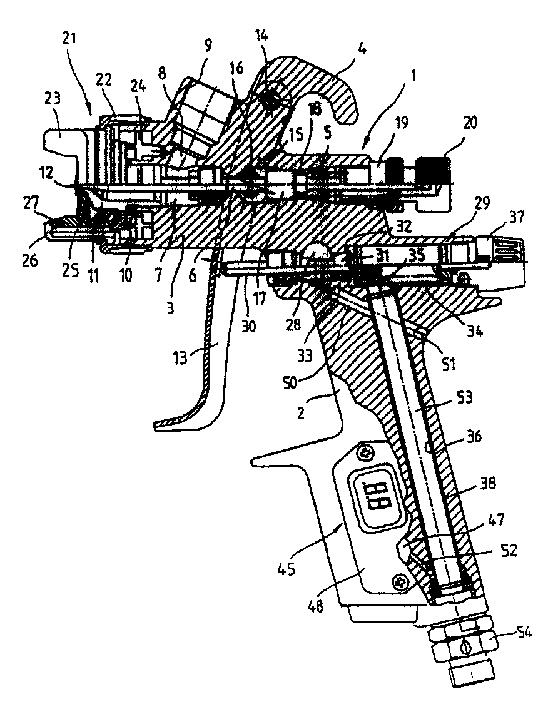

[0016] exist figure 1 The paint spray gun shown in includes a gun body 1 with a handle 2 and an upper body 3 on which a hook 4 is (integrated). A through hole 5 penetrating from front to back and forming multi-level steps passes through the upper body 3, and a spray needle 6 can move axially in the through hole. Through-opening 5 has a diameter-enlarged front region 7 into which an oblique inlet opening 8 with an internal thread 9 for screwing on a paint storage container (not shown) leads.

[0017] An internal thread 10 is provided at the front end of the through hole 5, and the paint nozzle 11 is screwed into the upper body 3 of the gun body 1 through this internal thread. Paint nozzle 11 contains a nozzle hole 12 on its front end, and it and can pass through the shrinkage of the spray needle 6 of a discharge trigger lever 13 axial movement or the front end of a tip together form a nozzle for paint, paint or the like. Adjustable entry. In order to move the needle through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com