Production method of bridge weathering steel with optimized alloy components

A production method and technology of alloy composition, applied in metal rolling, temperature control, etc., can solve the problems of high processing cost, high use cost of alloy elements, and rising user cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

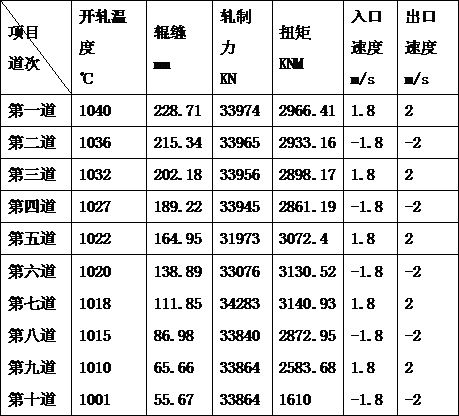

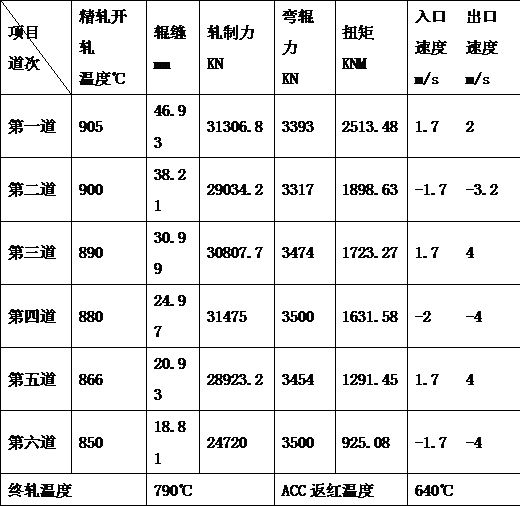

[0013] A method for producing bridge weathering steel with optimized alloy composition, comprising the following two steps: 1. The mass percentage of alloy components: C 0.05%, Si 0.3%, Mn 1.2%, Nb 0.025%, V 0.08%, Ti 0.01%, Cr 0.45%, Ni 0.33%, Cu 0.3%, Mo 0.06%, N 0.005%, Als 0.03%, the balance is iron and impurities; 2. Medium and heavy plate rolling process: steelmaking and smelting according to the design alloy element requirements The thickness of the billet is 250mm, the width is 1800mm, and the length is 2450mm~3470mm. After that, it needs to be rolled on the middle plate to make a finished product with a specification of 12~20mm: 1) Heating system design: heating furnace temperature 1140°C, rough rolling temperature 1050°C , Finish rolling temperature is 790°C, and temperature of turning red is 640°C; 2) Rough rolling process design, the rough rolling mill is a single-stand reversible rolling mill, and the negative value of the speed is the speed in the reverse rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com