Manufacture method of microchannel heat exchange body of heat exchanger

A manufacturing method and micro-channel technology, applied in the field of heat transfer and heat exchange, can solve the practicability of the manufacturing method of a micro-channel heat exchange body without a heat exchanger, no process and manufacturing parameters, no description of structural size characteristics, etc. problems, to achieve good heat exchange effect, good thermal conductivity, and the effect of meeting the requirements of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

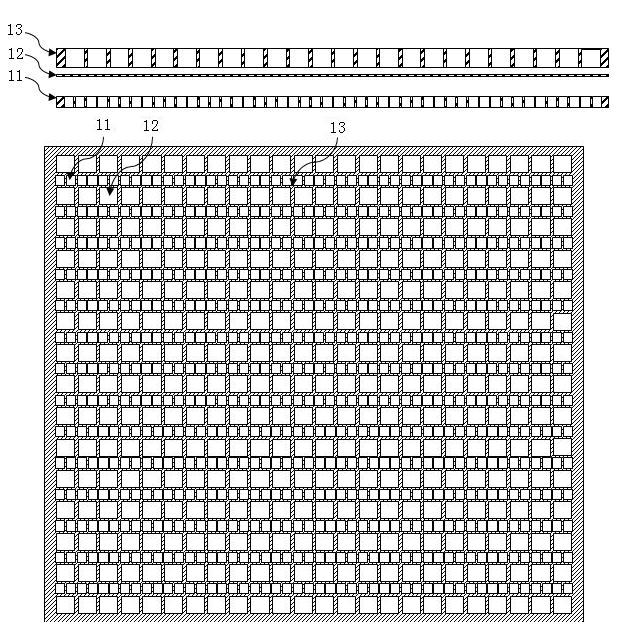

[0037] The structure of the microchannel heat exchange body of the heat exchanger of the present invention is as follows figure 1 As shown, several microchannel units are included, and the microchannel unit includes a refrigerant layer 11 microchannel, a working fluid layer 13 microchannel and a partition layer 12, and the refrigerant layer 11 microchannel and a working fluid layer 13 The microchannels are separated by the separator layer 12 and arranged at intervals, and the ratio of the hydraulic diameter of the microchannels in the refrigerant layer 11 to the hydraulic diameter of the microchannels in the working fluid layer 13 is 1:2.

[0038] The hydraulic diameter of the microchannels in the refrigerant layer 11 is 0.25mm.

[0039]The hydraulic diameter of the microchannels in the working fluid layer 11 is 0.5mm.

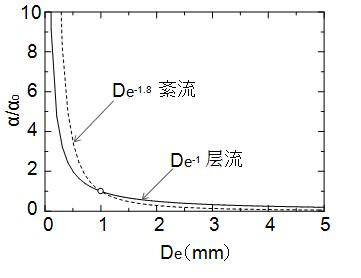

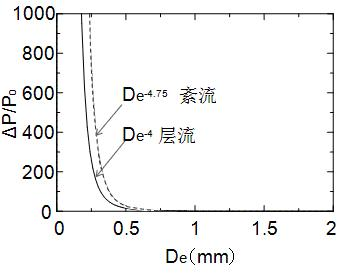

[0040] When the hydraulic diameter of the microchannel on the working fluid side is 0.5mm, its forced convection heat transfer coefficient is about 2 times ...

Embodiment 2

[0048] The structure of the microchannel heat exchanger of the heat exchanger in this embodiment is roughly the same as that described in Embodiment 1, the difference is that the cross section of each microchannel is circular, and the microchannel of the refrigerant layer 11 The hydraulic diameter of the channel is 0.0675mm. The hydraulic diameter of the microchannels in the working fluid layer 11 is 1.0125mm. The refrigerant layer 11, the partition layer 12, and the working fluid layer 13 are made of copper.

[0049] The method for manufacturing the microchannel heat exchange body of the heat exchanger comprises the following steps,

[0050] a. The refrigerant layer 11, the working fluid layer 13, and the partition layer 12 are formed into a circular cross-section through the original plate production, material cleaning, fitting of the protective layer, exposure, phenomenon, corrosion, peeling of the protective layer, and inspection. Shaped microchannel;

[0051] b. After ...

Embodiment 3

[0055] The structure of the microchannel heat exchange body of the heat exchanger of this embodiment is roughly the same as that described in Embodiment 1, the difference is that the cross section of each microchannel is elliptical, and the microchannel of the refrigerant layer 11 The hydraulic diameter of the channels is 0.5 mm. The hydraulic diameter of the microchannels in the working fluid layer 11 is 0.125mm. The refrigerant layer 11, the separator layer 12, and the working fluid layer 13 are made of aluminum.

[0056] The method for manufacturing the microchannel heat exchange body of the heat exchanger comprises the following steps,

[0057] a. The refrigerant layer 11, the working fluid layer 13, and the partition layer 12 are formed into an elliptical cross-section through the original plate production, material cleaning, fitting of the protective layer, exposure, phenomenon, corrosion, peeling of the protective layer, and inspection. Shaped microchannel,;

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com