Patents

Literature

33results about How to "Homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

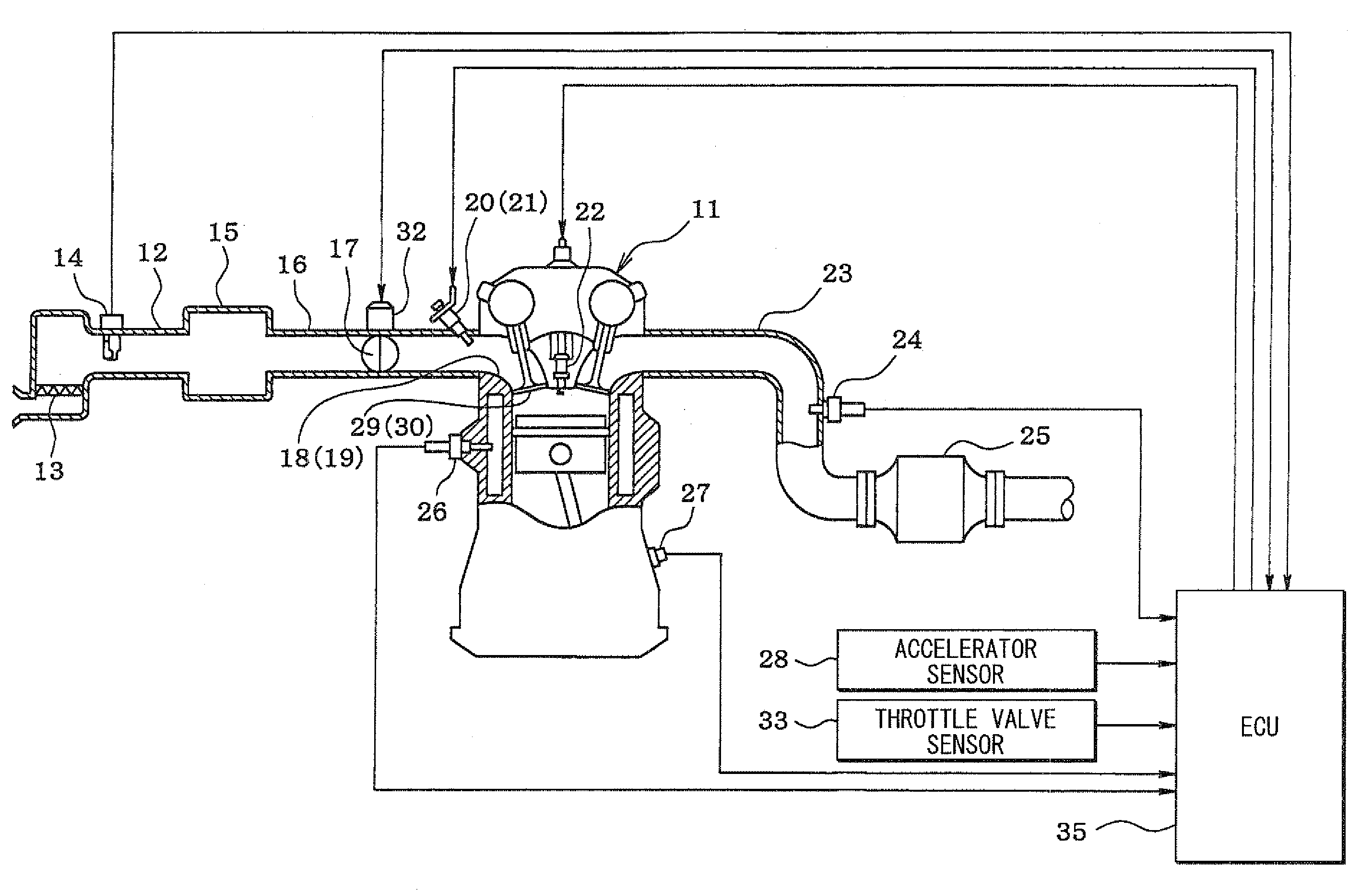

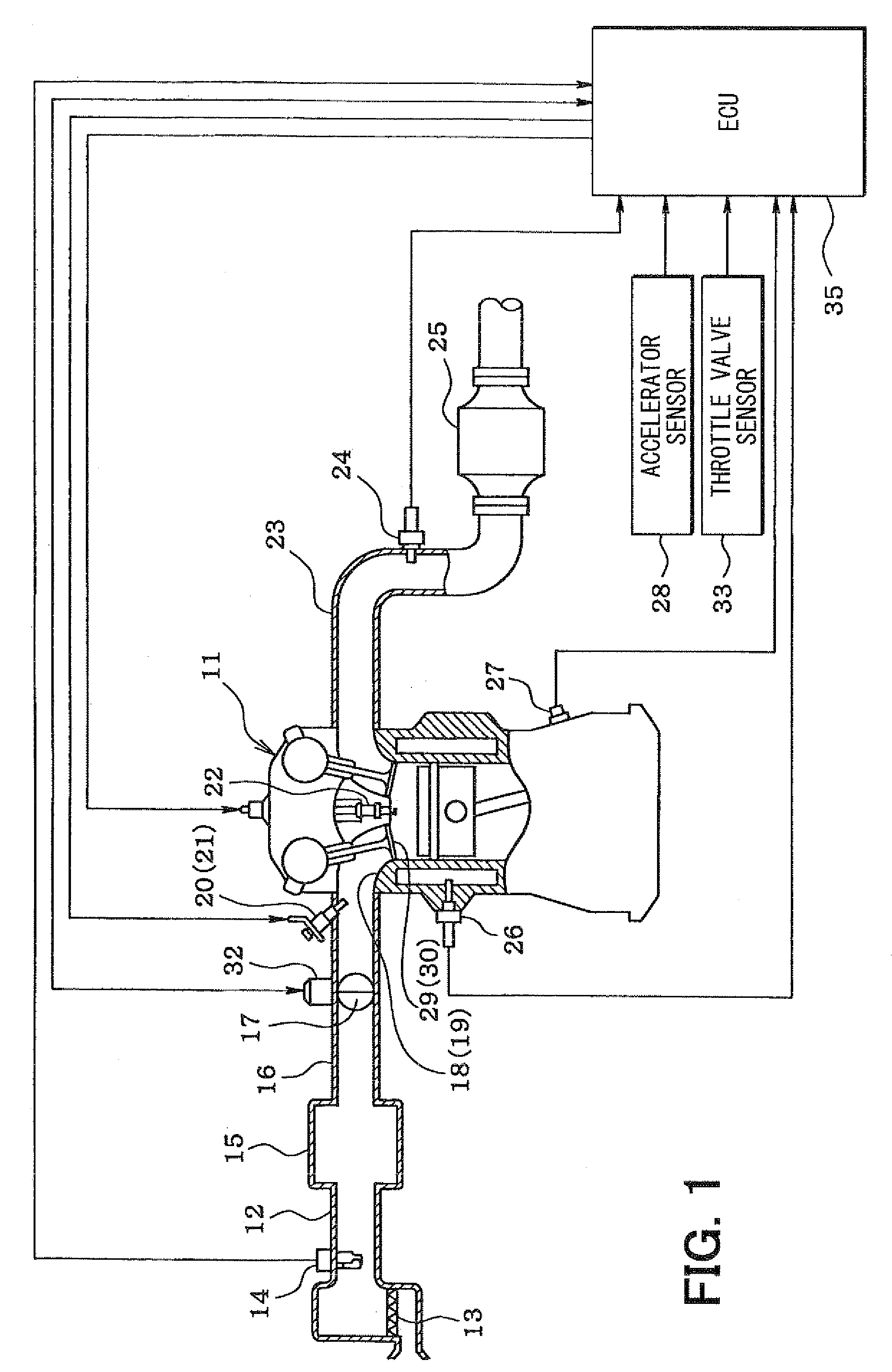

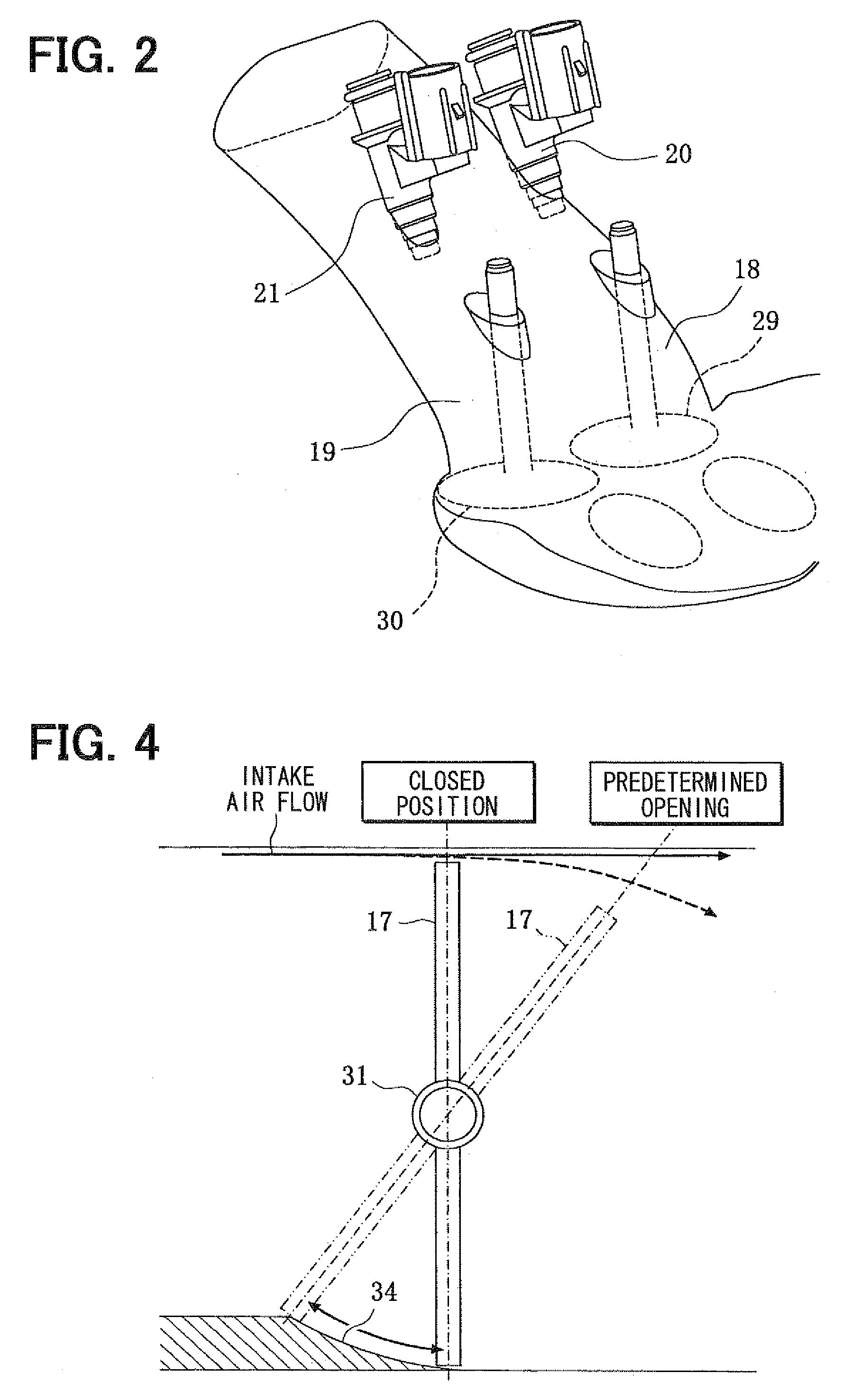

Valve control device and valve control method for internal combustion engine

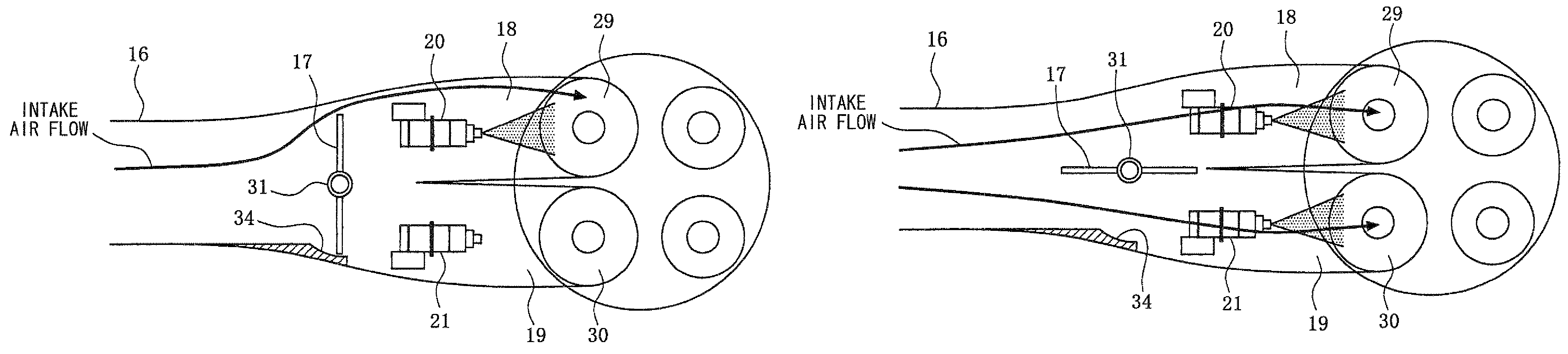

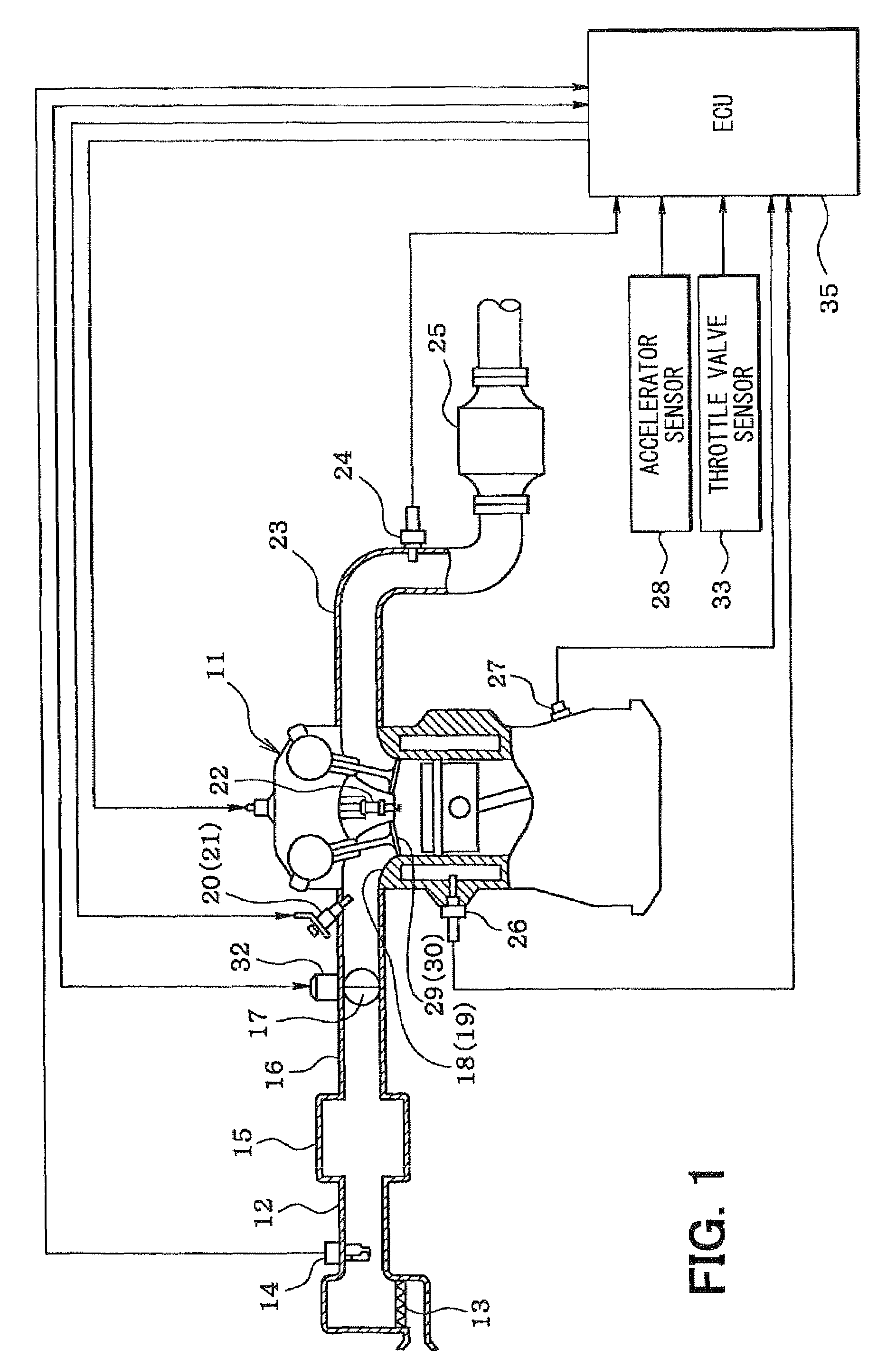

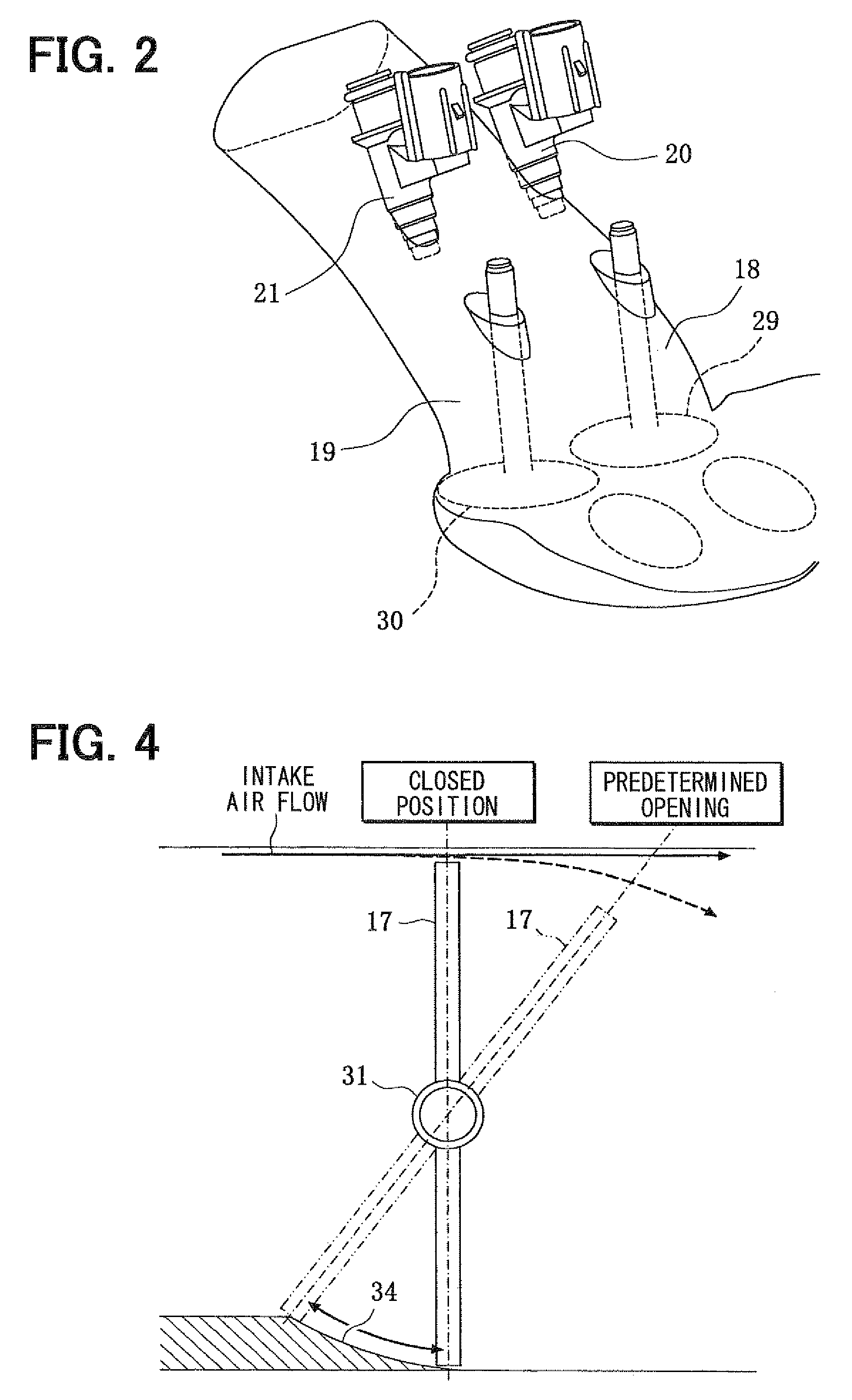

InactiveUS7472679B2Promote homogenizationEasy to controlElectrical controlInternal combustion piston enginesInternal combustion engineThrottle

Owner:DENSO CORP

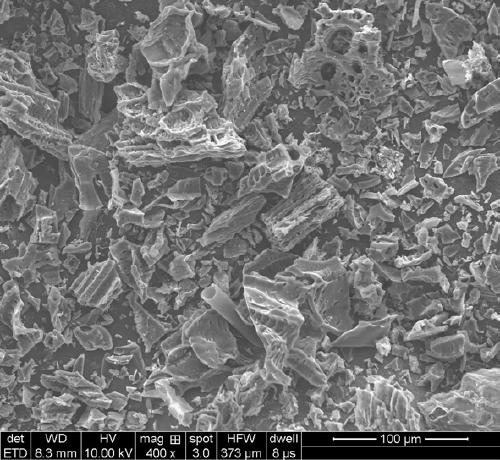

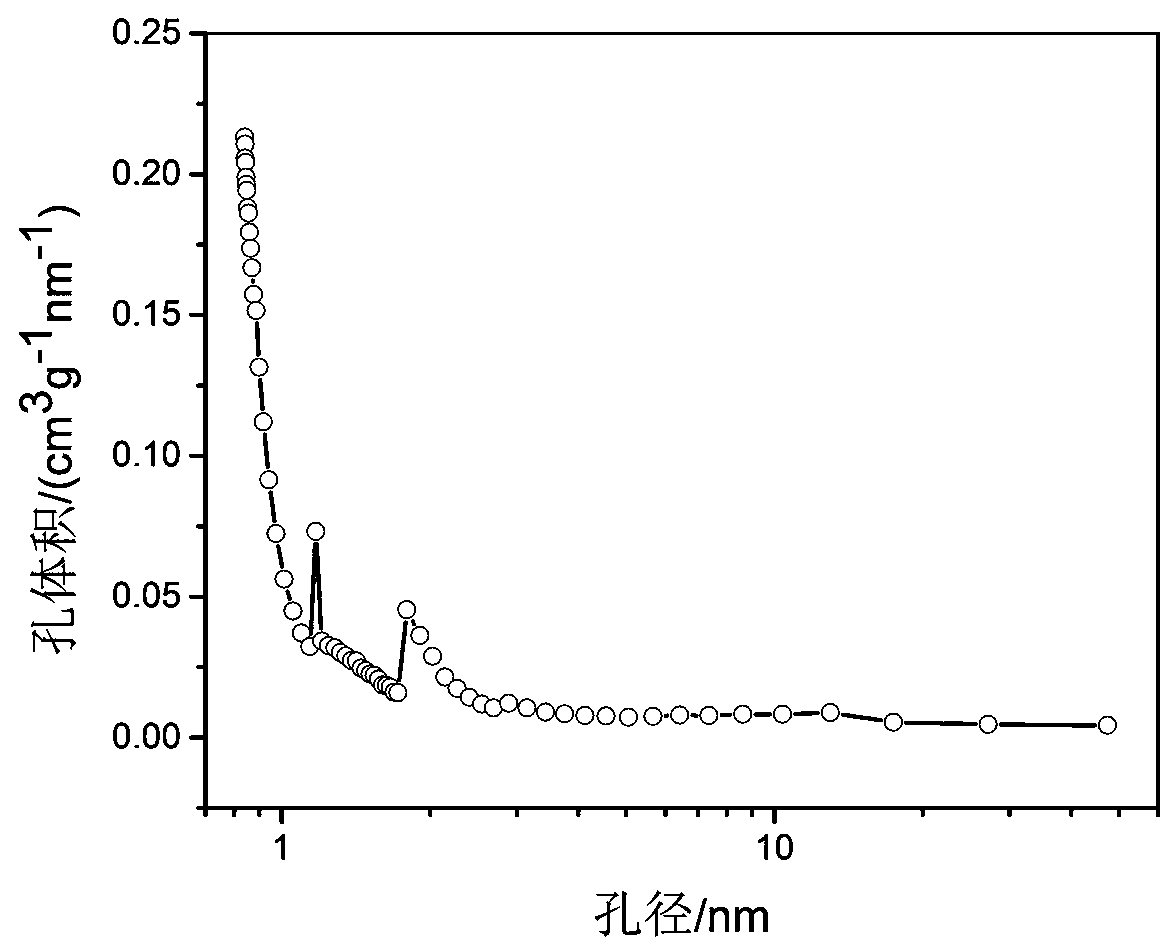

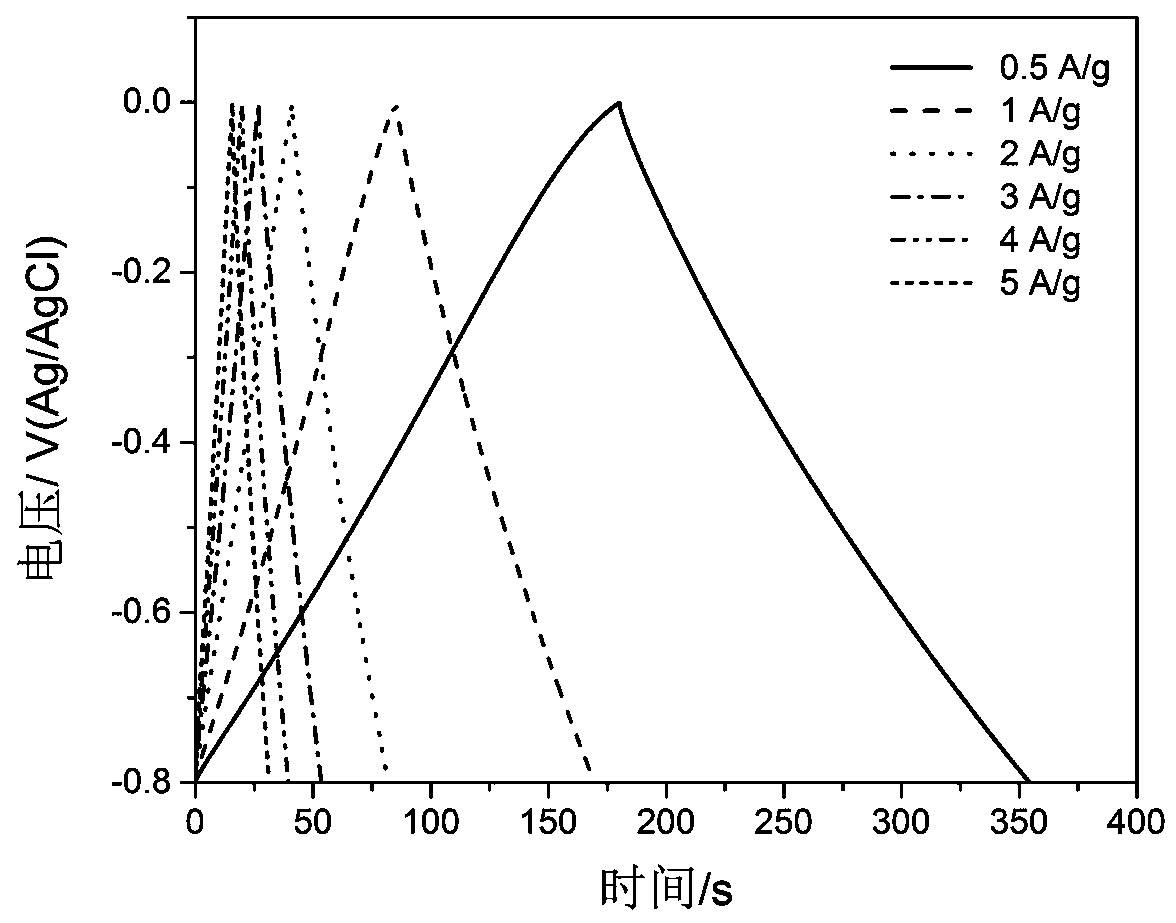

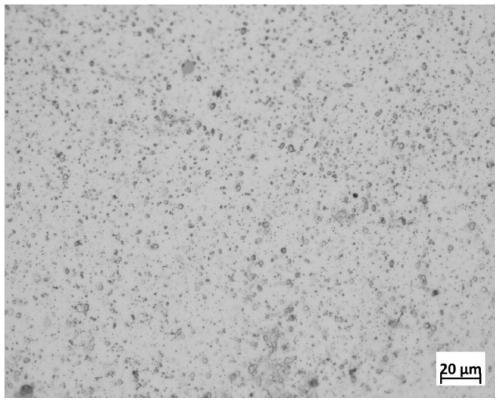

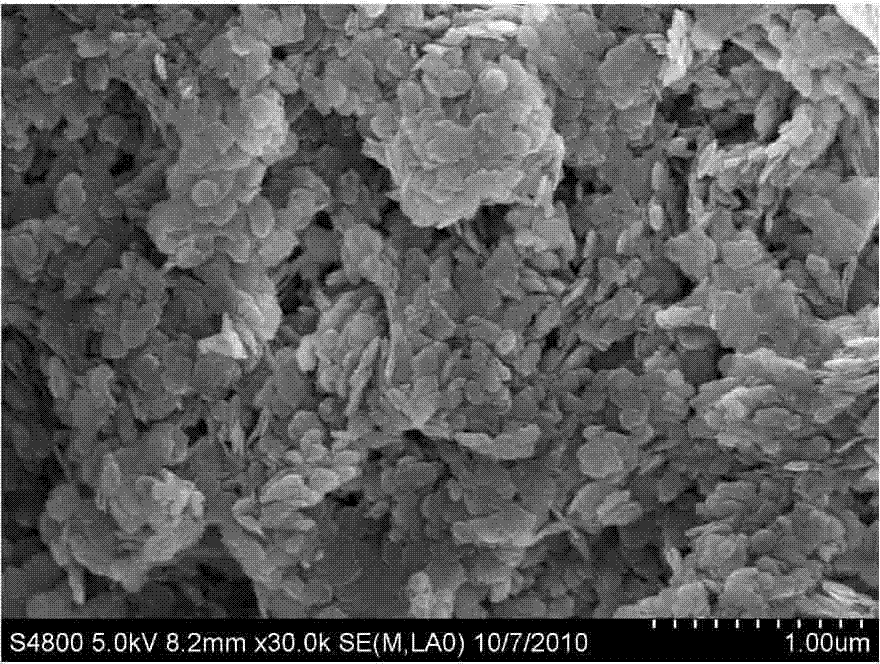

Homogeneous corncob derived carbon electrode material and preparation method thereof

ActiveCN109110756AOvercome the defect of polluting the environmentHomogenizationCarbon compoundsHybrid capacitor electrodesCapacitanceAcid washing

The invention discloses a homogeneous corncob derived carbon electrode material used for a supercapacitor and a preparation method thereof. According to the method, by adopting screening preselectionand subsequent carbonization and activation, homogenizing preparation of corncob derivative carbon particles is achieved; the method comprises the following specific preparation process steps that firstly, biomass corncobs are crushed, through screening, corncob powder particles in different particle size distribution ranges are obtained, and high temperature carbonization is conducted; then an activator is adopted for conducting high temperature activation on obtained carbonized powder particles; finally, an activated product is subjected to acid washing and drying to obtain the homogeneous corncob derivative carbon electrode material. When being used as an electrode material of the supercapacitor, the homogeneous corncob derivative carbon electrode material shows high specific capacitance and rate performance. The method has the characteristics of being simple in process, rich in raw material, environmentally friendly, higher in added value and the like.

Owner:UNIV OF JINAN +1

Valve control device and valve control method for internal combustion engine

InactiveUS20080098977A1Promote homogenizationEasy to controlElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

An intake throttle valve is located in an intake passage upstream of first and second intake ports, such that intake air flows into mainly the first intake port to generate a swirl flow when an opening degree of the intake throttle valve is not larger than a predetermined value, and flows into both the first and second intake ports when the opening degree thereof is larger than the predetermined value. Furthermore, first and second fuel injection valves for respectively injecting fuel to the first and second intake ports are controlled to inject fuel from the first fuel injection valve when the opening degree of the intake throttle valve is not larger than about the predetermined value, and to inject fuel from both the first fuel injection valve and the second fuel injection valve when the opening degree of the intake throttle valve is larger than about the predetermined value.

Owner:DENSO CORP

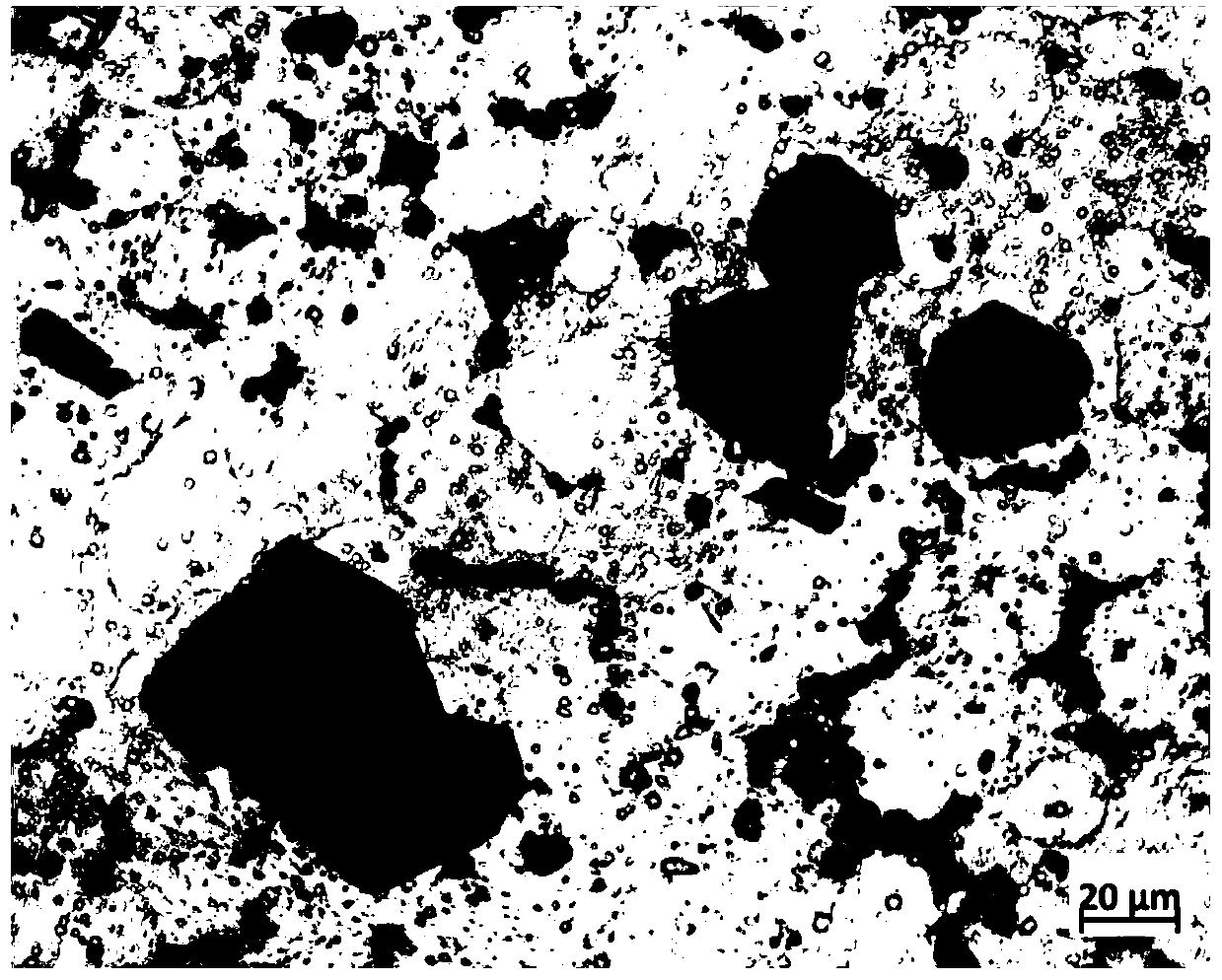

High-strength Al-Si alloy welding wire and preparation method thereof

InactiveCN110205511AImprove mechanical propertiesExcellent welding fluidityWelding/cutting media/materialsSoldering mediaMaterials preparationSilicon alloy

The invention relates to the technical field of metal material preparation, and particularly discloses a high-strength Al-Si alloy welding wire and a preparation method thereof. The method comprises the following steps that an Al-Ti-B intermediate alloy with TiB2 particles in-situ generated is subjected to violent plastic deformation to obtain the Al-Ti-B intermediate alloy containing the nano TiB2 particles, wherein the size of the nano TiB2 particles ranges from 50 nm to 1000 nm; the Al-Ti-B intermediate alloy containing the nano TiB2 particles is used as a matrix raw material, and an Al-Scintermediate alloy and an Al-Si intermediate alloy are added for smelting treatment to obtain an alloy melt; the alloy melt is prepared into a wire blank with the diameter of 8-10 mm; and hot rolling,cold drawing, intermediate annealing and surface treatment processes are carried out on the wire blank to obtain the aluminum-silicon alloy welding wire with the nano-scale TiB2 particles. Accordingto the aluminum-silicon alloy welding wire prepared through the method, the mechanical property of a welding seam is remarkably improved while the original excellent welding mobility and the low welding crack sensitivity are inherited, the aluminum-silicon alloy welding wire can be used for welding high-strength and ultrahigh-strength aluminum alloys, is especially suitable for alloys which are high in welding crack sensitivity (such as a 7000 series aluminum alloy) and the field which has high requirements on the welding strength, and has high industrial application value.

Owner:JIANGXI UNIV OF SCI & TECH

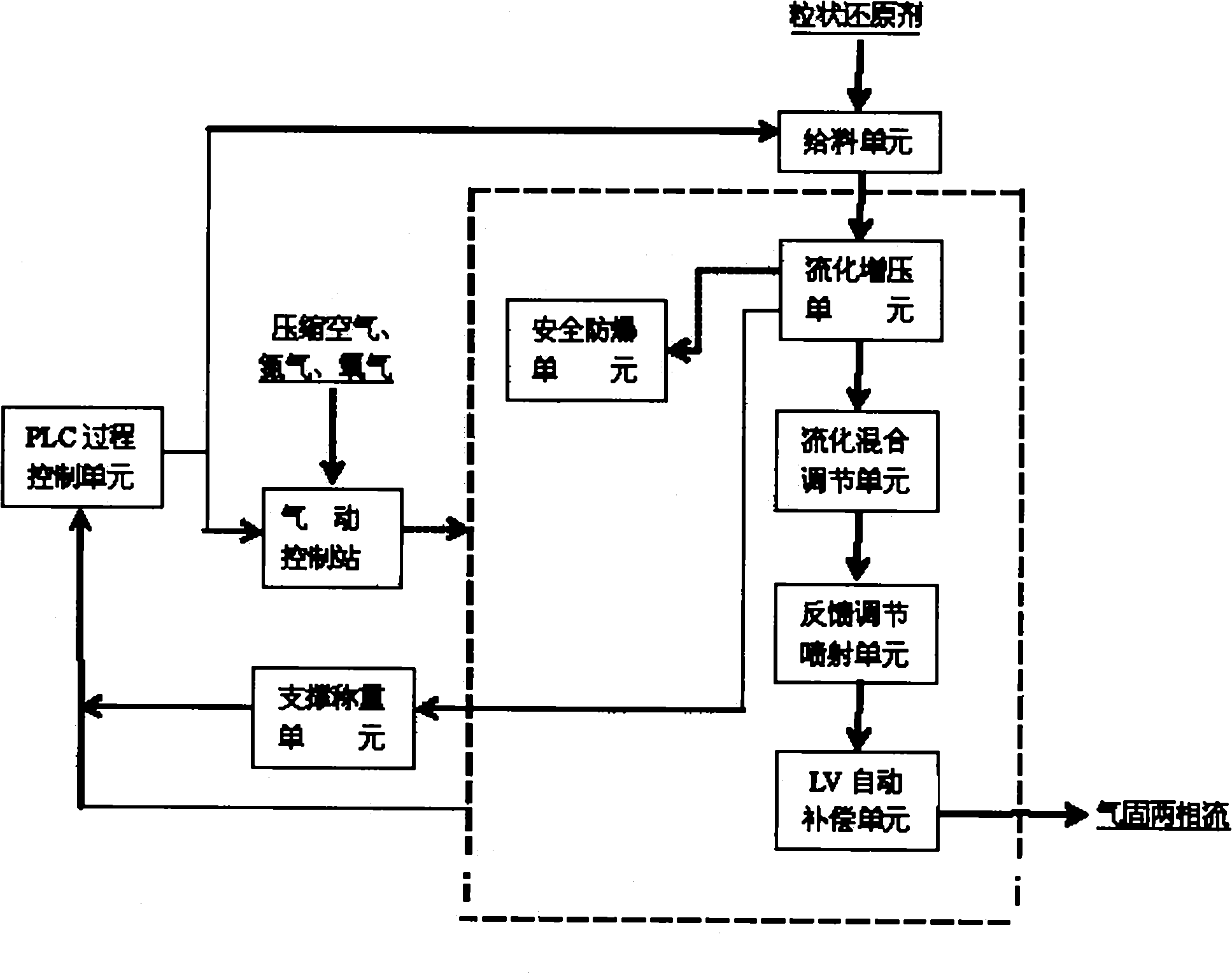

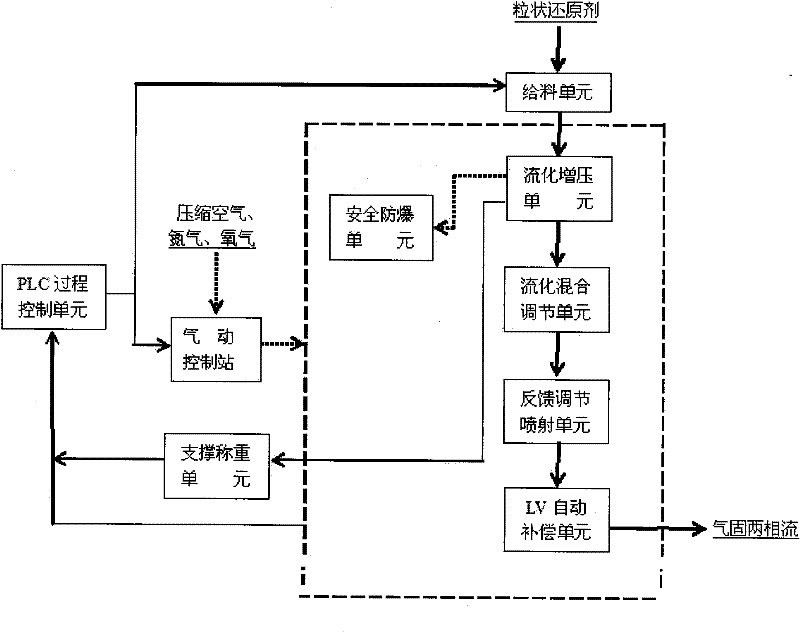

New automatic spraying system for solid reducing agent

The invention discloses a new automatic spraying system for a solid reducing agent. The system is provided with a feeding unit, a fluidized boosting unit, a fluidized hybrid adjusting unit, a feedback adjustment spraying unit, an LV automatic compensation unit, a supporting and weighing unit, a pneumatic control station and a PLC process control unit, wherein the reducing agent enters the fluidized boosting unit through the feeding unit by means of the dead weight and forms initial gas-solid two-phase flow in the fluidized hybrid adjusting unit after being boosted to flow out; the feedback adjustment spraying unit adjusts the proportion of the initial two-phase flow to meet the requirements of the reducing technology; the LV automatic compensation unit detects and rapidly responds to the gas-solid two-phase flow to ensure no recharging of liquid copper; the pneumatic control station distributes compressed air, nitrogen gas and oxygen required by the process and a meter gas source required for controlling each unit to each point; and the PLC process control unit programs, processes the switching value and the analog quantity, sends a control signal and gives an instruction to the feeding unit to ensure that the feeding unit is in a normal operating state. The automatic spraying system can realize automatic spraying of the solid reducing material and ensure uniform and controllable material supply.

Owner:昆明理工精诚科技有限责任公司 +1

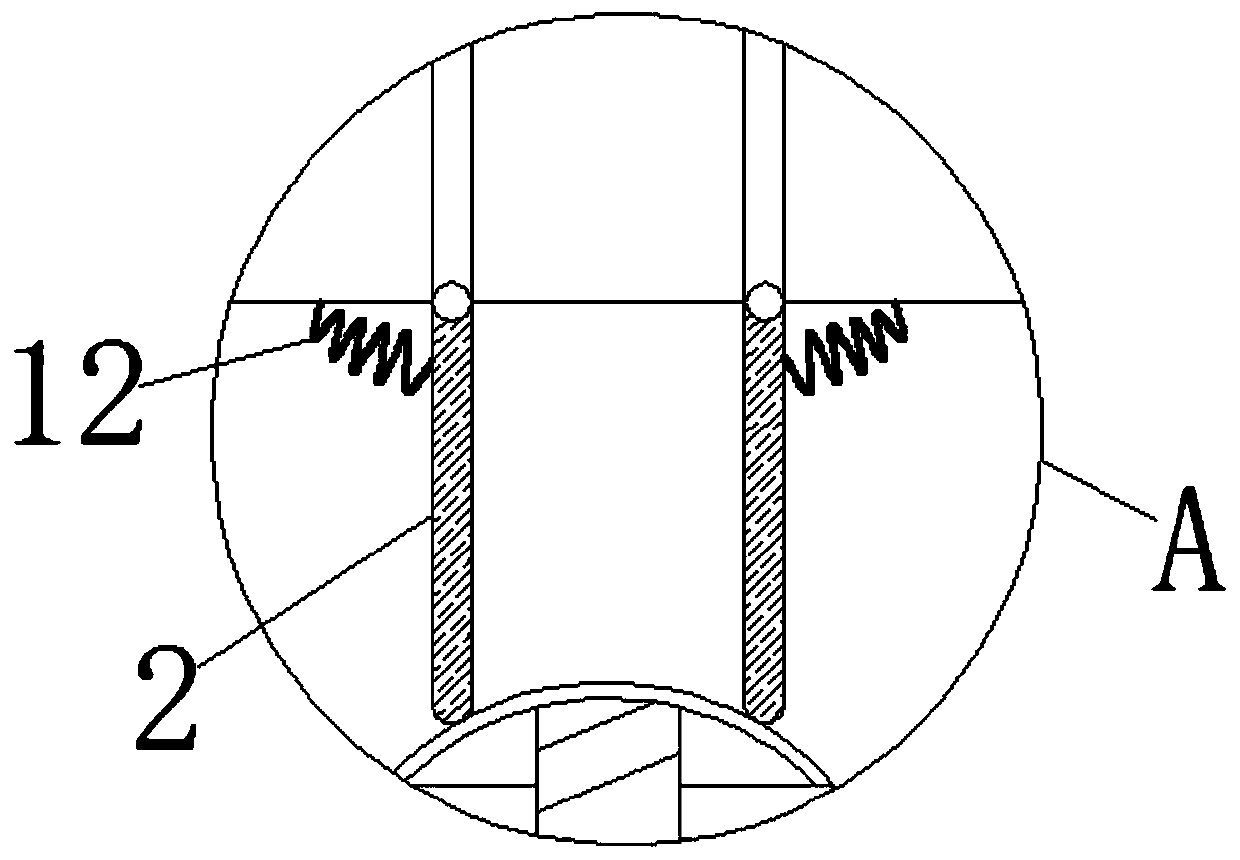

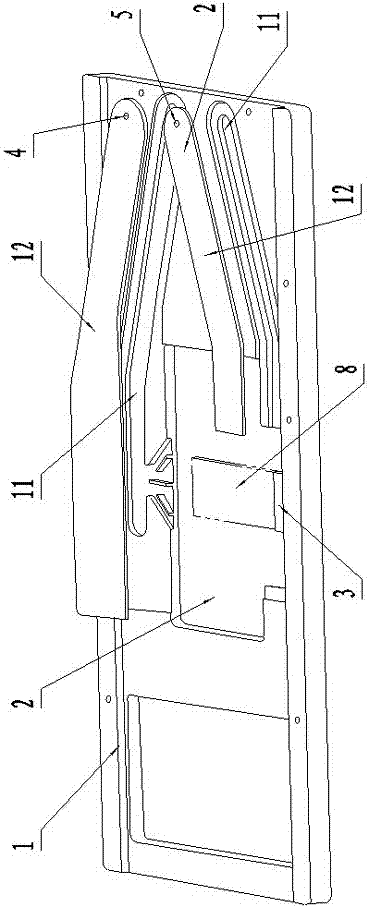

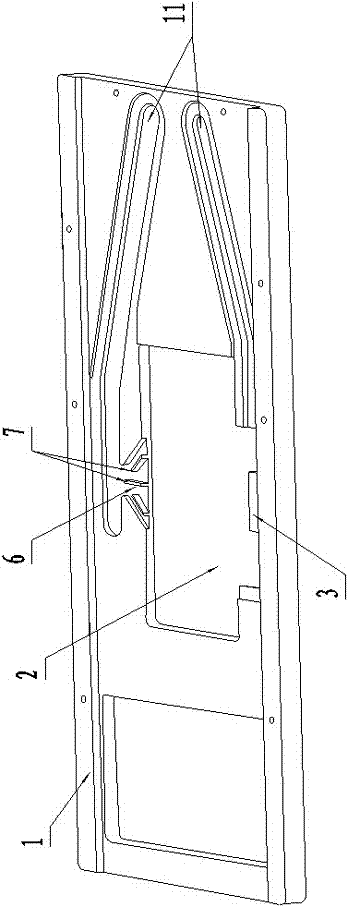

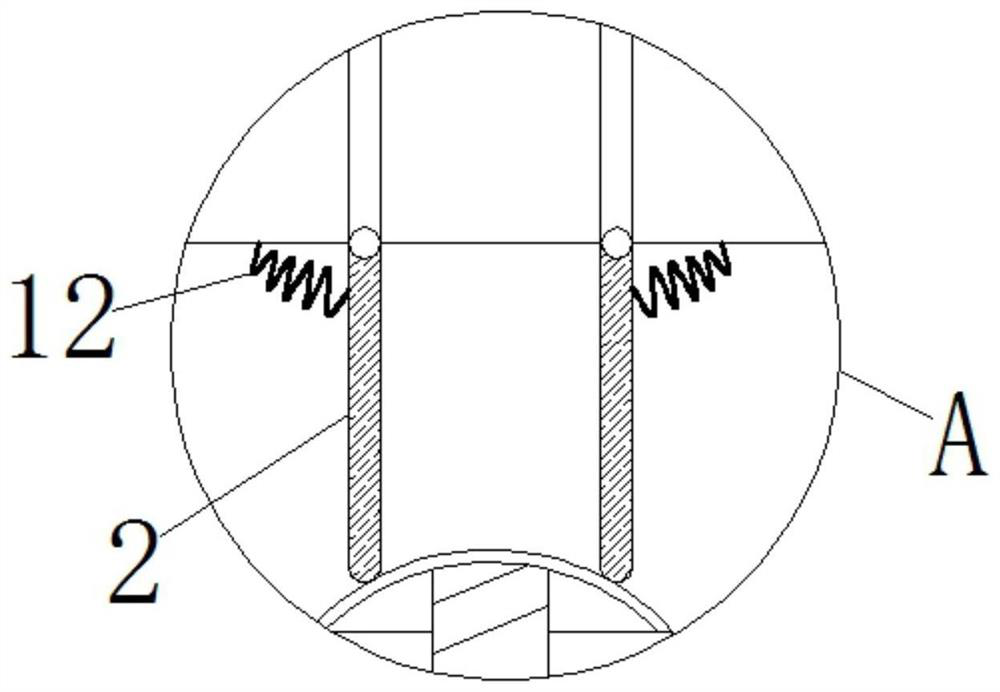

Laboratory department anti-pollution type bacterial culturing device

InactiveCN107254403AHomogenizationGuaranteed sealing performanceBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringScrew thread

The invention provides a laboratory department anti-pollution type bacterial culturing device. A base, a mixing device and a storage barrel are designed in a split manner; an opening is formed in the top of the base, and two vertical lifting rods are arranged on the outer wall of the base; the storage barrel is detachably arranged in the base; the mixing device consists of a shell, a mixing cavity, a stirring motor and a controller; the mixing cavity is arranged at the bottom in the shell, and a circular discharge hole positioned in the center is formed in the bottom of the mixing cavity; the stirring motor is arranged at the top of the stirring motor, and a crankshaft enters the mixing cavity through a first bearing arranged on the upper part of the shell and penetrating through the shell; the bottom of the crankshaft is connected with a bottom cover through a second bearing in a rotating manner, and a stirring spiral is arranged on the crankshaft; two groups of sliding mechanisms each of which comprises an upper sliding bush and a lower sliding bush are arranged on the side wall of the shell; the upper sliding bush and the lower sliding bush are fixed on the vertical lifting rod in a sliding manner, so that the shell can move up and down relative to the base; and positioning bolts matched with threads of the upper sliding bush and the lower sliding bush are arranged on the upper sliding bush and the lower sliding bush.

Owner:日照市中心医院

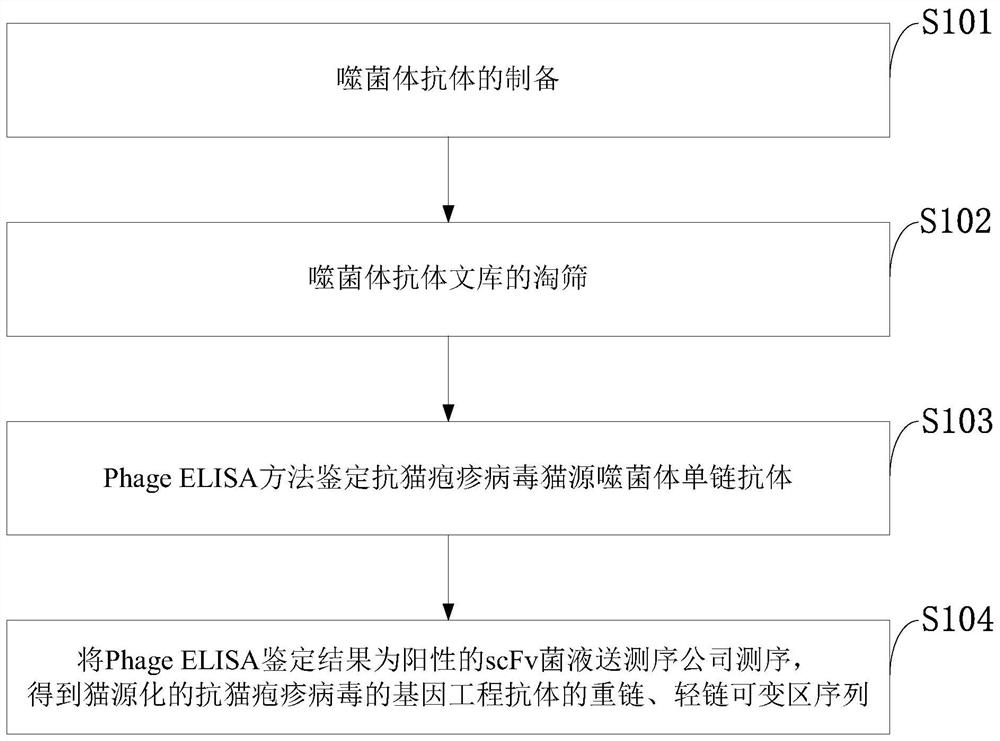

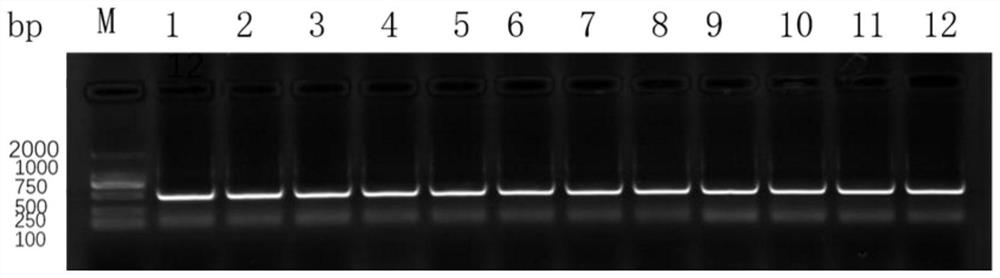

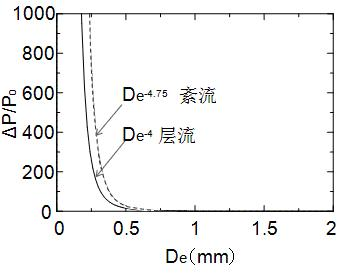

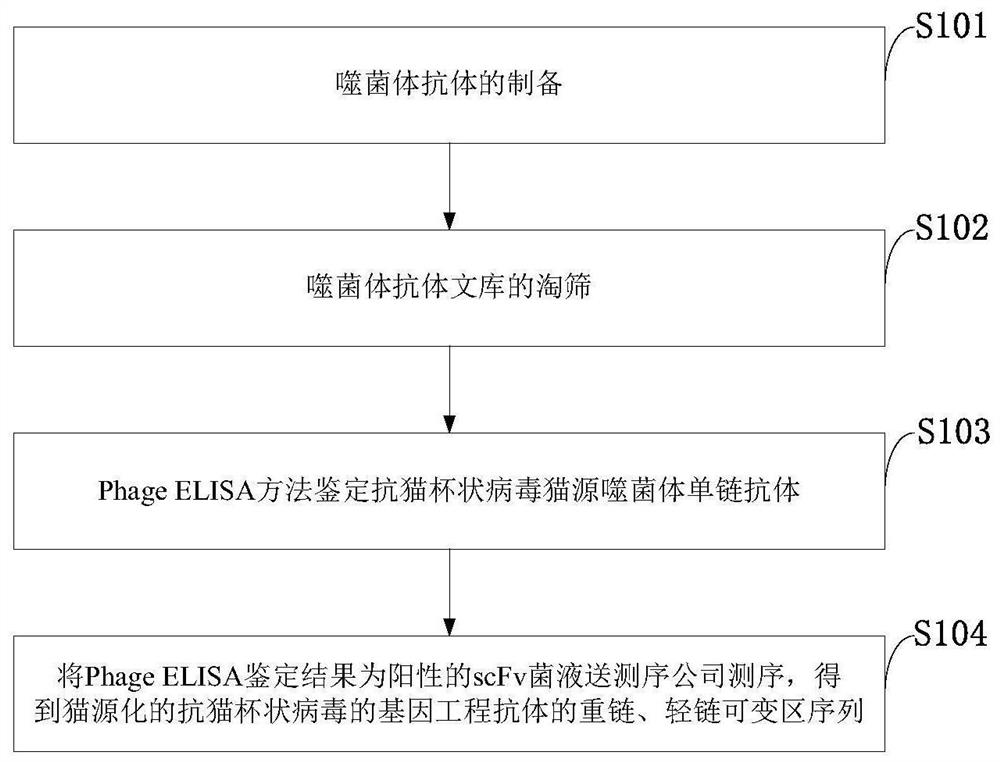

Feline herpes virus antibody sequence, tetrapeptide chain molecule and immunoglobulin molecule

ActiveCN111848785AHomogenizationBiological material analysisImmunoglobulins against virusesPhage antibodiesViral antibody

The invention belongs to the technical field of virus antibodies, and discloses a feline herpes virus antibody sequence, a tetrapeptide chain molecule, an immunoglobulin molecule and an application thereof, and the sequences are a heavy chain variable region amino acid sequence SEQ ID NO: 1 and a nucleotide sequence SEQ ID NO: 3; and the amino acid sequence of the light chain variable region is SEQ ID NO: 2 and the nucleotide sequence is SEQ ID NO: 4. The sequence screening method comprises the following steps: preparing a bacteriophage antibody; screening the phage antibody library; identifying an anti-feline herpes virus feline phage single-chain antibody by using a PhageELISA method; sending the scFv bacterial liquid with a positive Phage ELISA identification result to a sequencing company for sequencing to obtain variable region sequences of a heavy chain and a light chain of the feline-derived anti-feline herpes virus genetic engineering antibody. The invention provides support for constructing a feline-derived anti-feline herpes virus genetic engineering antibody with high affinity and low immunogenicity. The product has important significance for promoting the development ofcat-derived antibody drugs.

Owner:青岛博隆基因工程有限公司

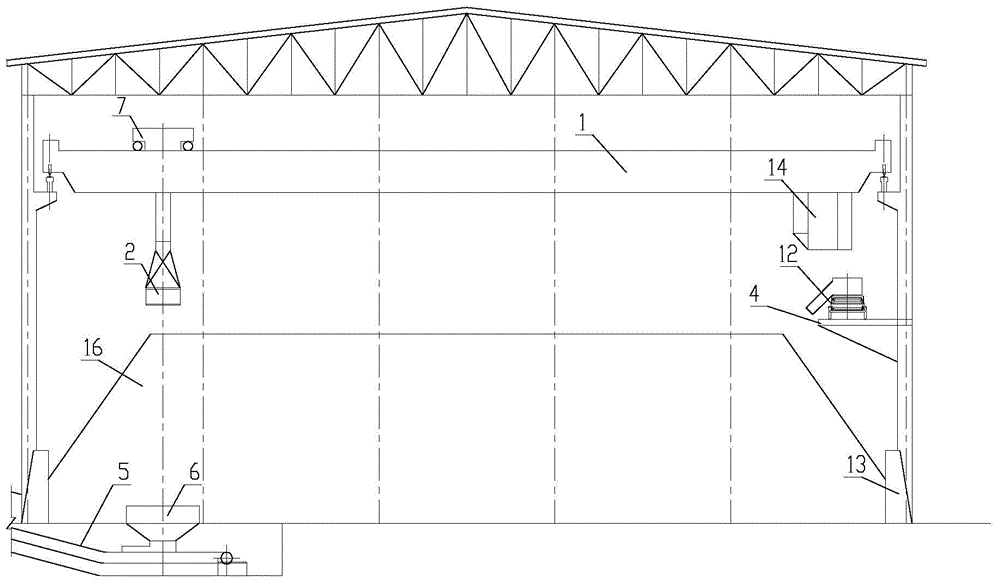

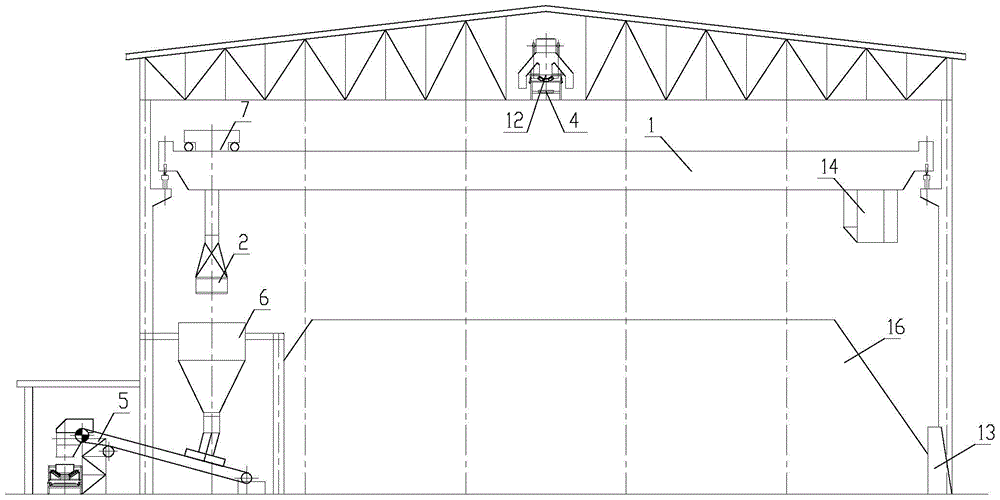

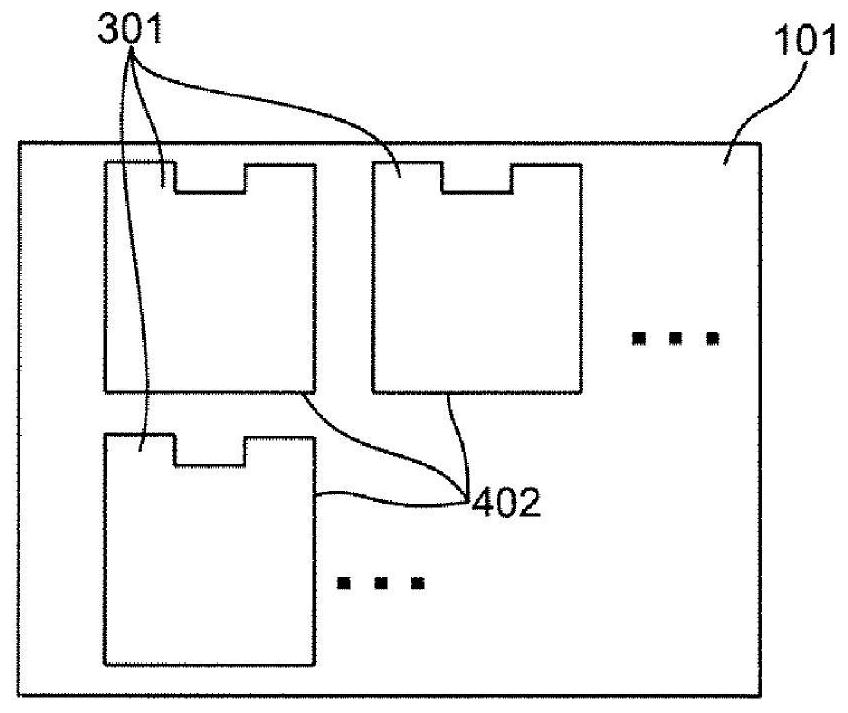

Grab Overhead Crane Warehouse

ActiveCN105129621BLower the altitudeSmall footprintTravelling cranesLoad-engaging elementsBridge deckCentral line placement

The invention discloses a warehouse with a bridge grabbing crane. The warehouse comprises the bridge grabbing crane which is transversely arranged at the top of the warehouse. The bridge grabbing crane can move back and forth in the length direction of the warehouse and is provided with grab buckets which can move back and forth along the bridge grabbing crane. An overhead trestle is longitudinally arranged below the bridge grabbing crane, and the operating direction of the overhead trestle is the same as the operating direction of the bridge grabbing crane. The overhead trestle is located in the position of the longitudinal center line of the warehouse. A feeding conveyer is arranged on the bridge surface of the overhead trestle. A discharging conveyer is longitudinally arranged below the overhead trestle. Receiving hoppers are arranged on the discharging conveyer. The warehouse with the bridge grabbing crane has the advantages that firstly, the way that feeding and discharging are conducted in the warehouse is adopted, and uniform operation is facilitated; secondly, the two grab buckets are used for grabbing materials, and thus the production capacity and the working efficiency are improved; thirdly, the discharging height is reduced, raising dust is reduced, and the operating environment of the warehouse with the bridge grabbing crane is improved; and finally, the way that discharging is conducted in the warehouse is adopted, part of facilities outside the warehouse are omitted, and construction investment cost is reduced.

Owner:SINOPEC NANJING ENG & CONSTR +1

Corn stalk, root and plastics, composite material

The present invention relates to a corn stalk root plastics composite material. Its composition includes 49-79% of corn stalk root, 19-49% of thermoplastic plastics and 2%-4% of adjuvant. The described corn stalk root can be corn stalk and corn leaf or mixture of corn stalk, corn leaf, corn cob and corn root, and the described adjuvant contains one kind of the following components: lubricating agent, plasticizer, UV-ray-resisting agent, antioxidant, filling agent, reinforcing agent, fire-retardant, anti-static agent, coupling agent and binding agent or combination of several kinds of them. Its production method includes the following steps: cutting corn stalk and root, drying, pulverizing to 20-300 meshes, adding the corn stalk and root powder into high-speed mixer, mixing it with plastic powder, granules and adjuvant, homogenizing, then mixing them, extruding and granulating, cooling, solidifying and making them into the invented corn stalk root plastics composite material.

Owner:上海铭新环卫工程科技有限公司

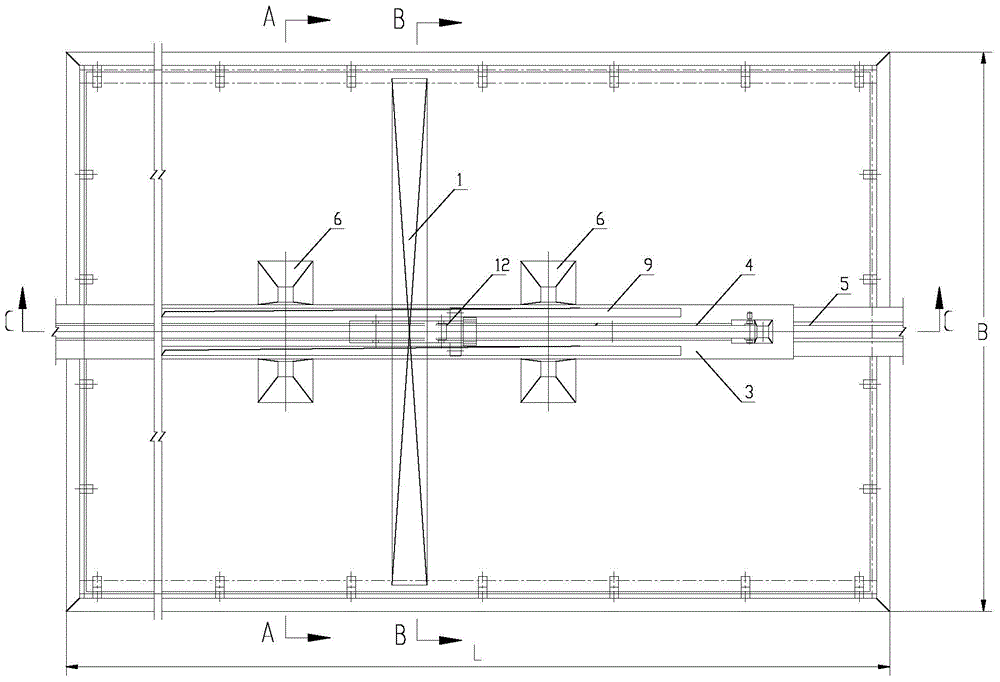

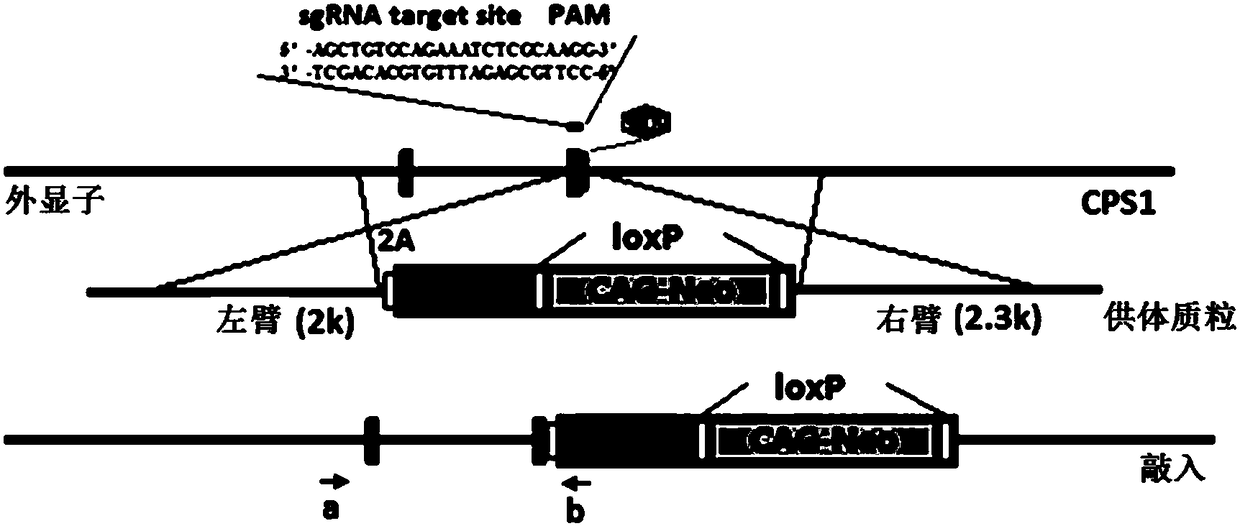

CPS1 report gene stem cell, and building method and application thereof

InactiveCN108660156AHigh ammonia metabolism capacityHigh purityMicrobiological testing/measurementVector-based foreign material introductionMetabolism studyCarbamyl Phosphate

The invention discloses a carbamyl phosphate synthetase 1 report gene stem cell (CPS1 report gene stem cell), and a building method and application thereof. Experiments prove that by using the induction scheme obtained through CPS1 report gene human embryonic stem cell (hESCs) screening, the induced differentiation to effectively enhanced hepatocyte-like cells is realized. The CPS1 report gene stem cell can be applied to the screening of induction agents in a liver direction induction differentiation system; hepatocyte-like cells obtained through induction differentiation can be applied to liver medicine metabolism study and liver medicine toxicity evaluation; and wide application prospects are realized.

Owner:ACADEMY OF MILITARY MEDICAL SCI

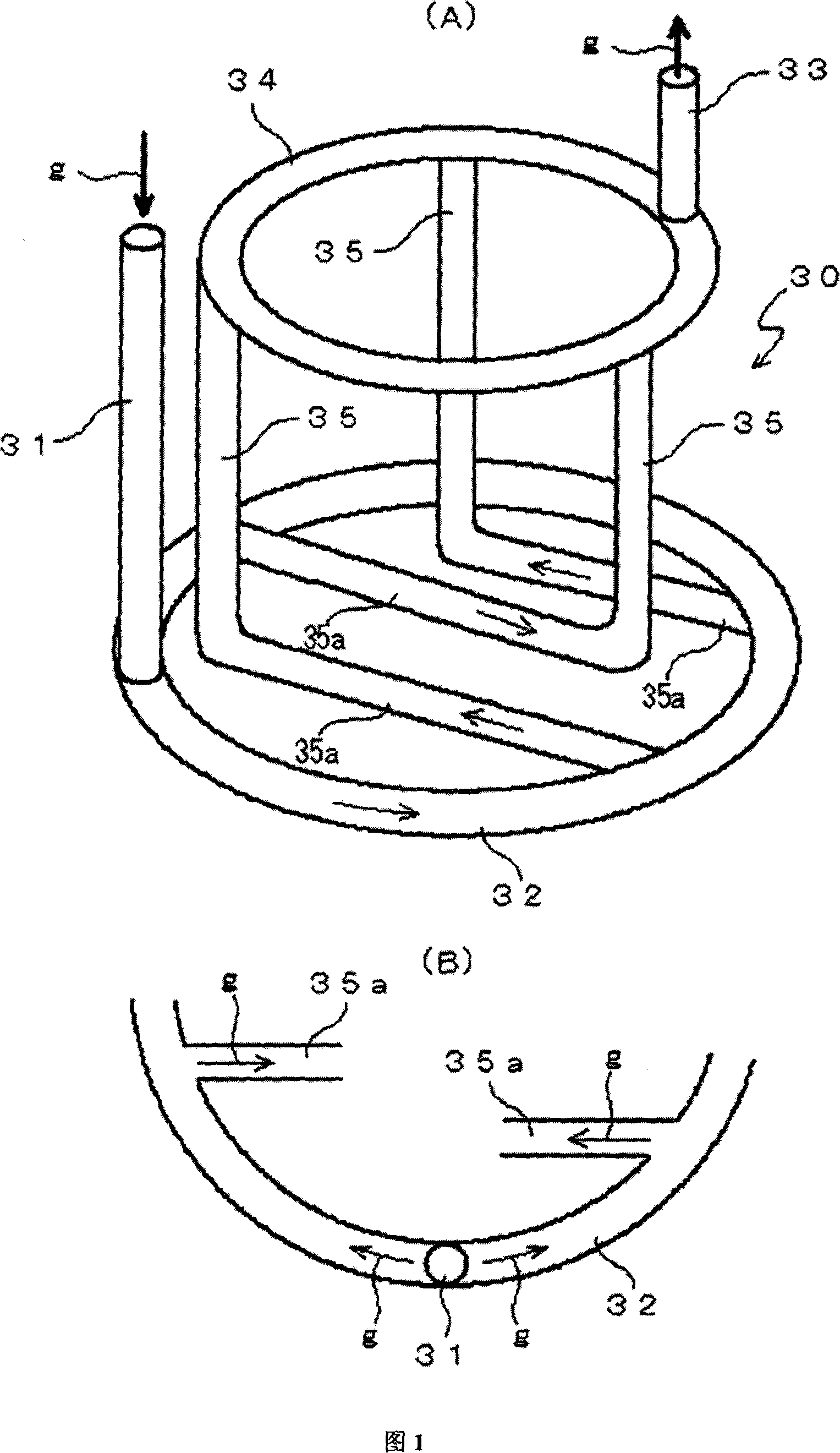

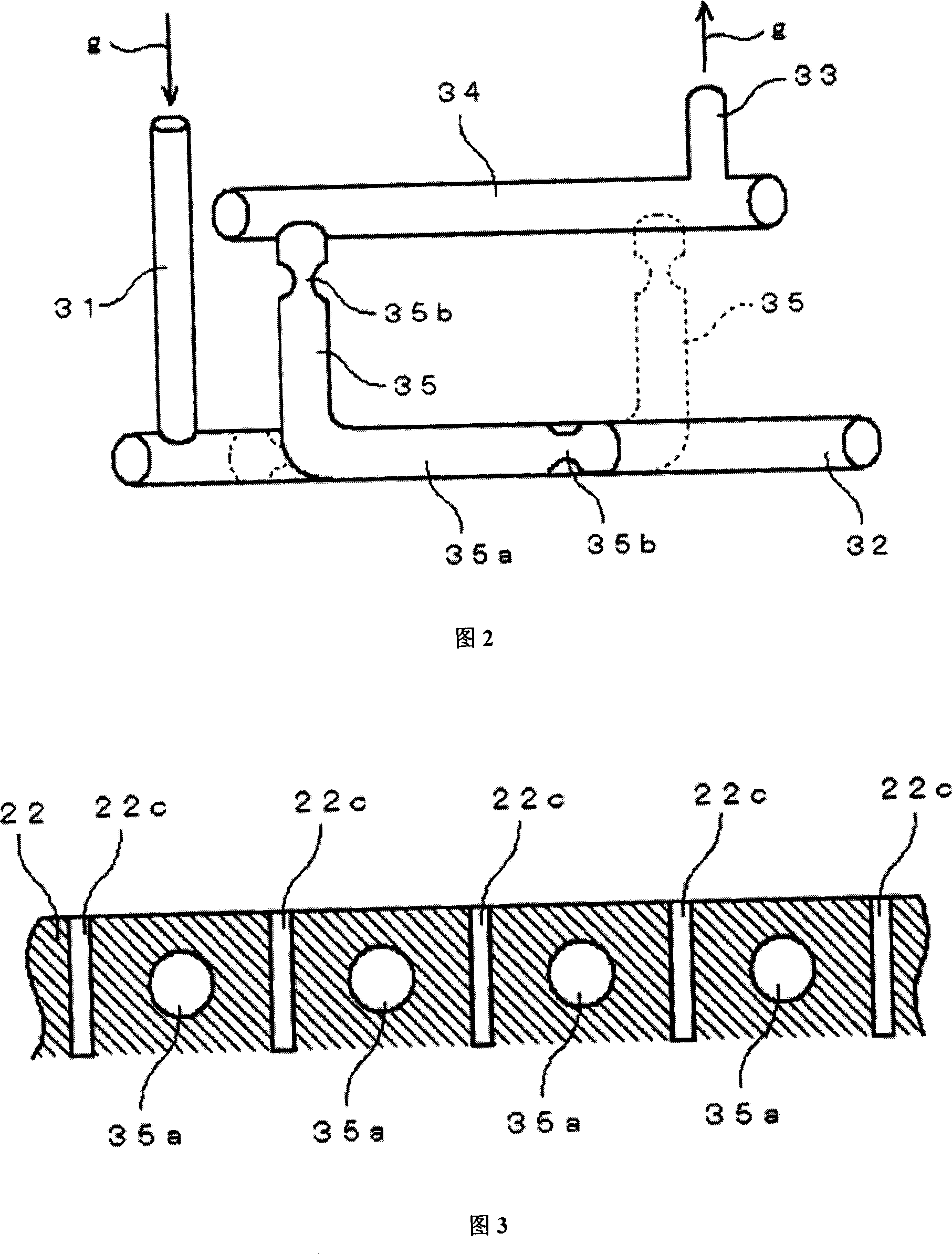

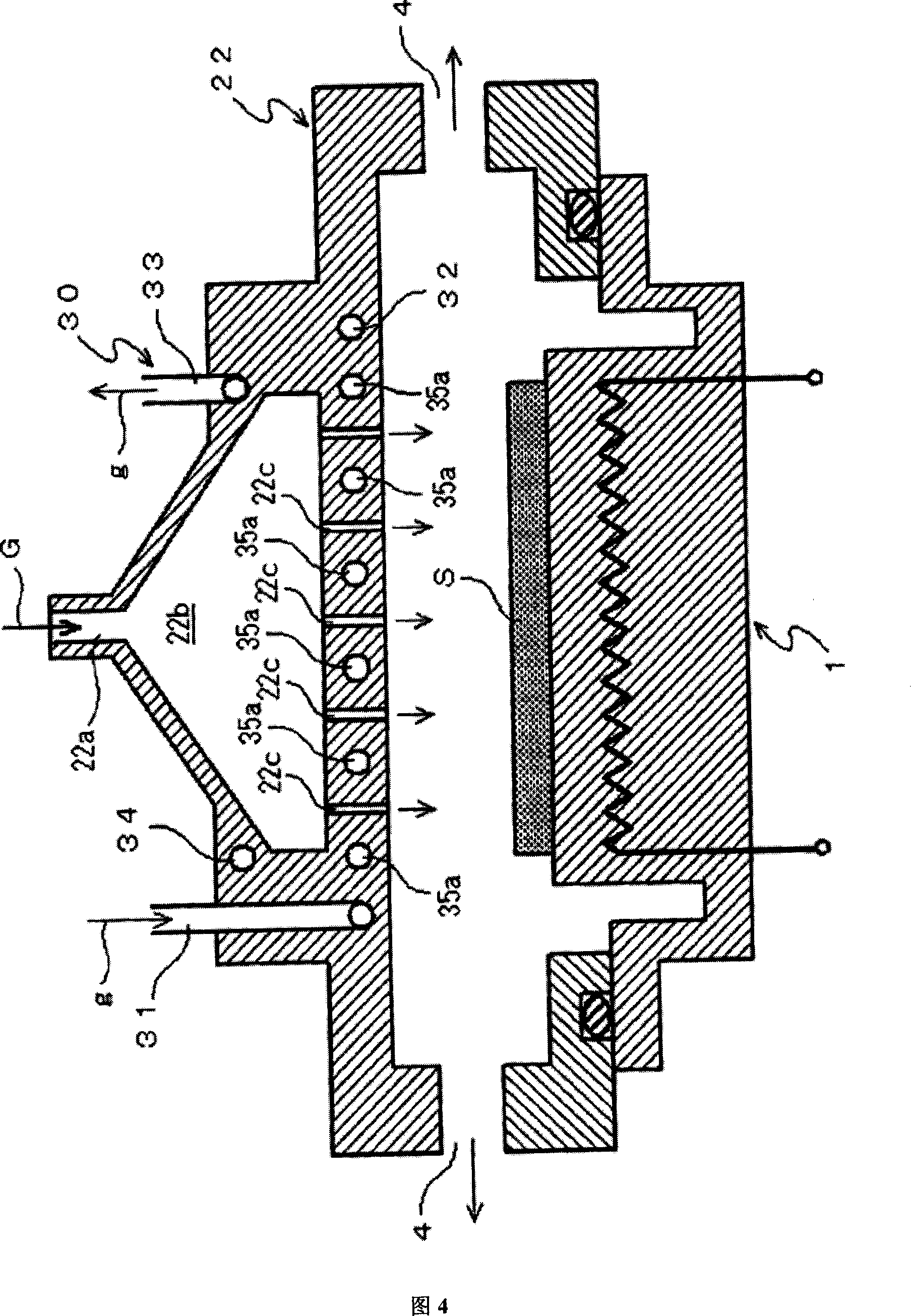

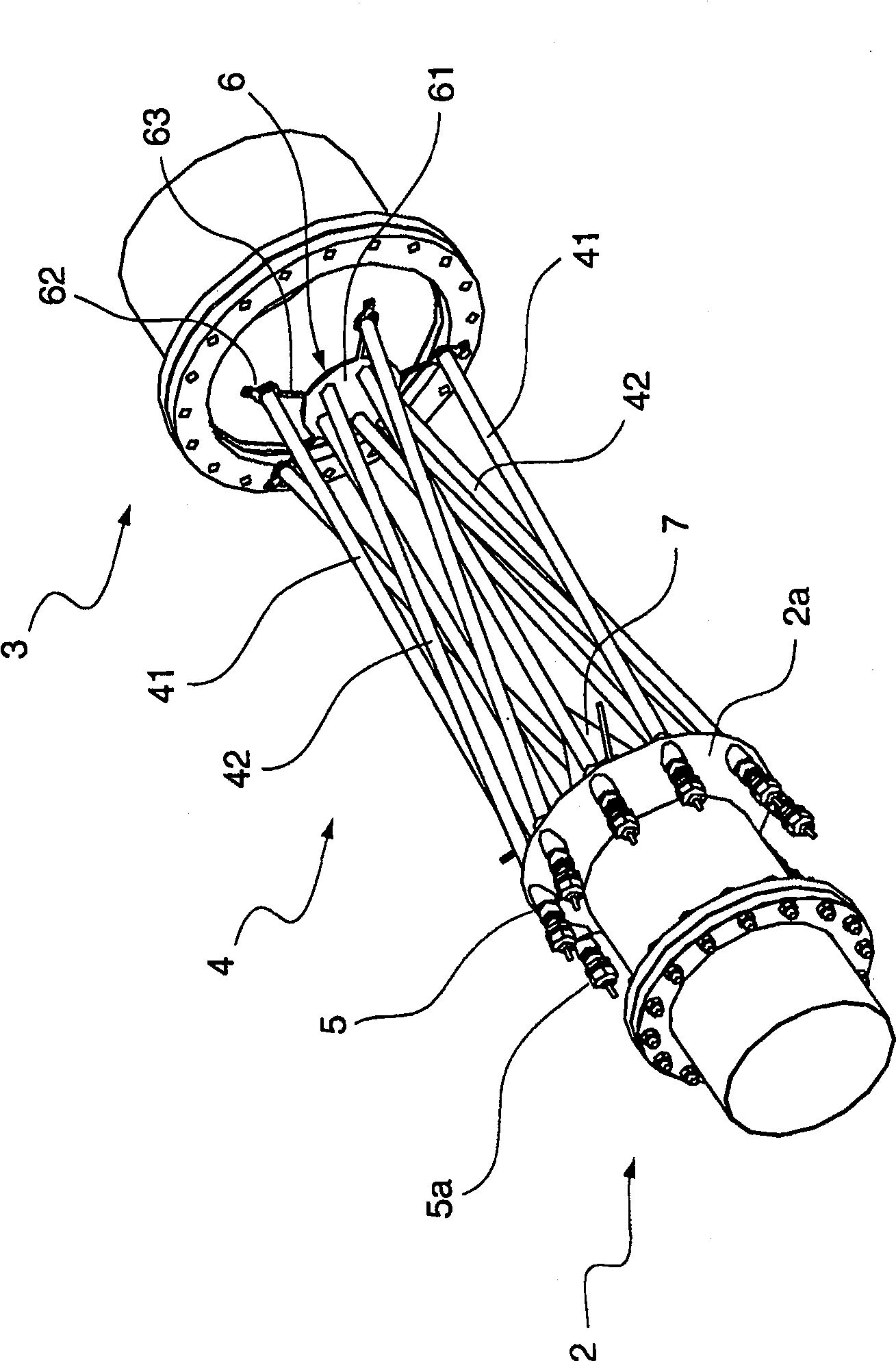

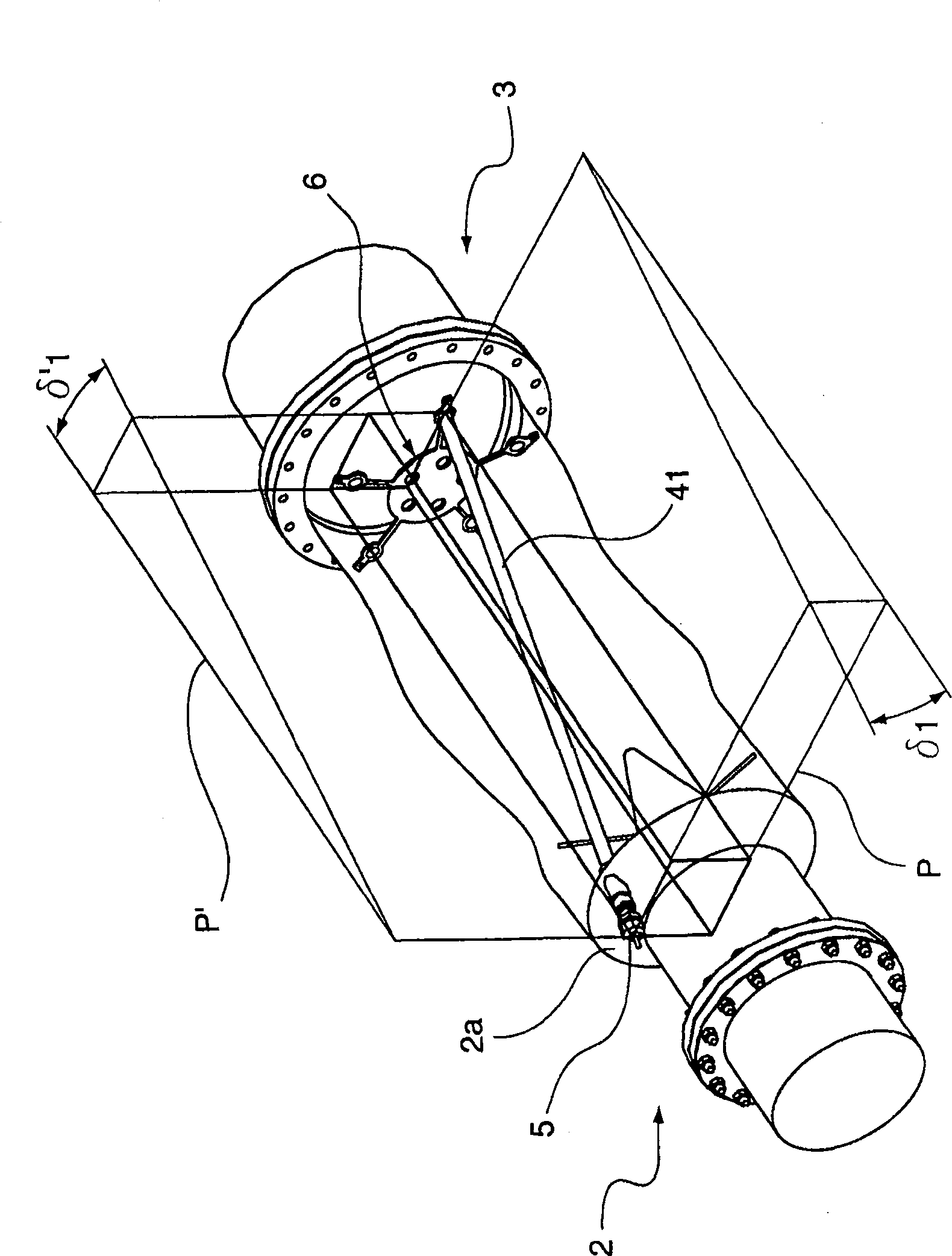

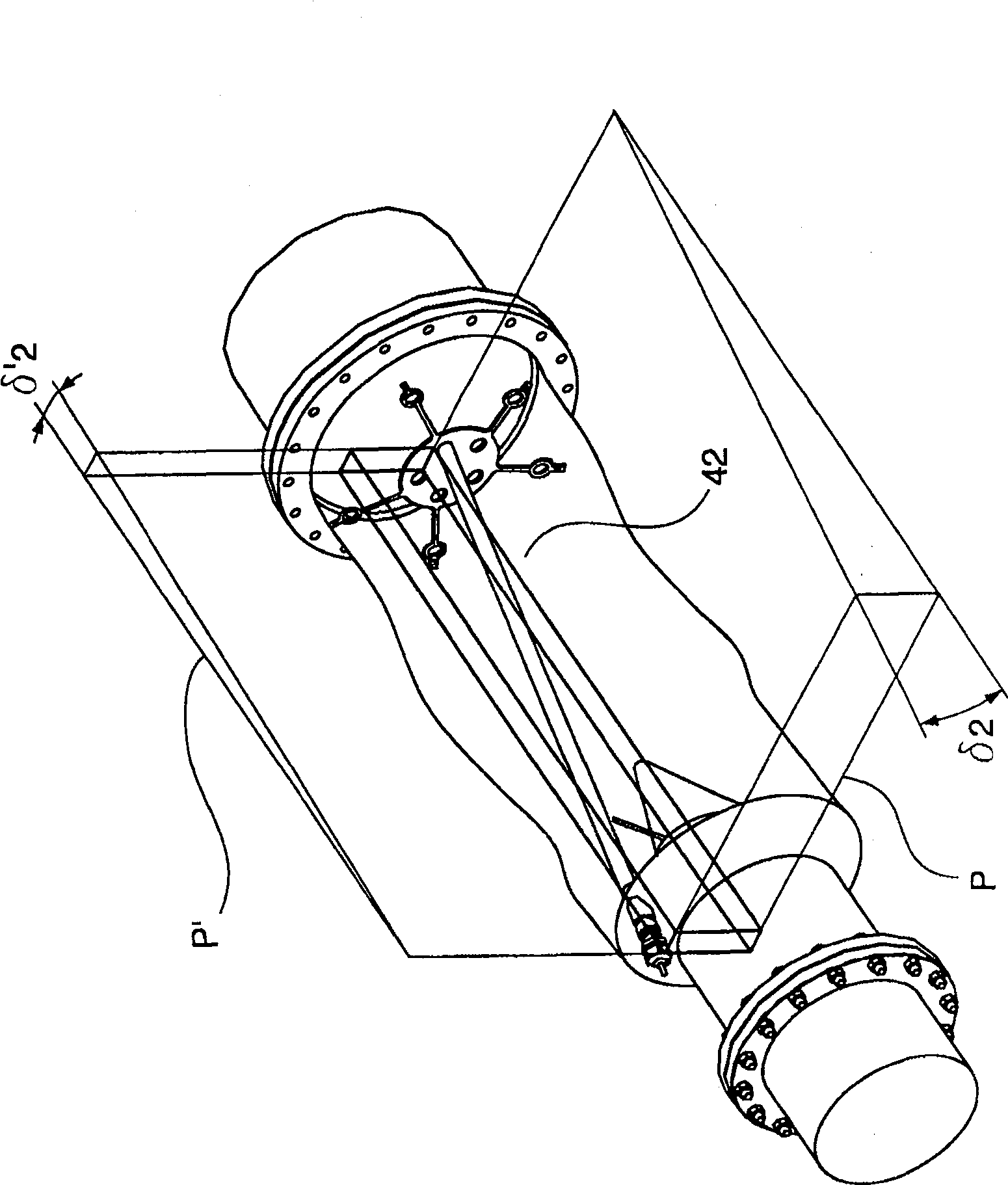

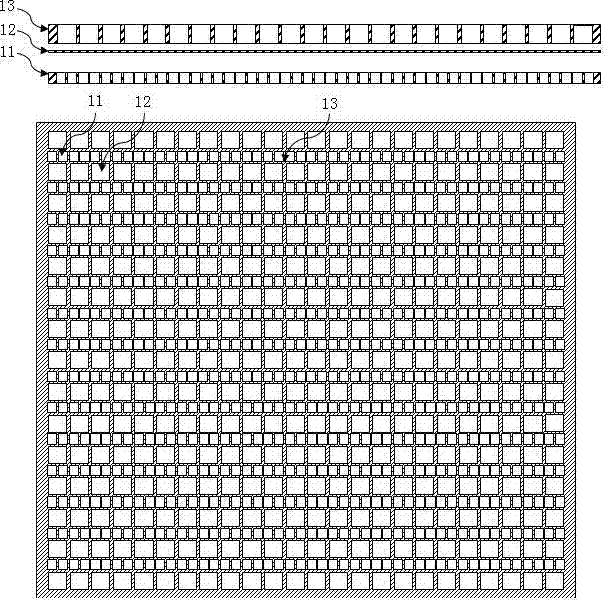

Substrate surface treating apparatus

InactiveCN101088146AAchieve high temperatureHighly homogeneous surface treatmentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSubstrate surfaceHot Temperature

A substrate surface treating apparatus by which the temperature of a carrier gas can be increased high and thus treatment can be more uniformly performed. An upstream ring is connected to a heating medium inlet for applying a prescribed heating medium, and a downstream ring is connected to a heating medium outlet for ejecting the heating medium. A plurality of heat transmitting paths are connected to the upstream ring and the downstream ring by having flow directions of the adjacent heating medium reaching the downstream ring from the upstream ring are opposite, and a gas is used as the heating medium.

Owner:M WATANABE CO LTD

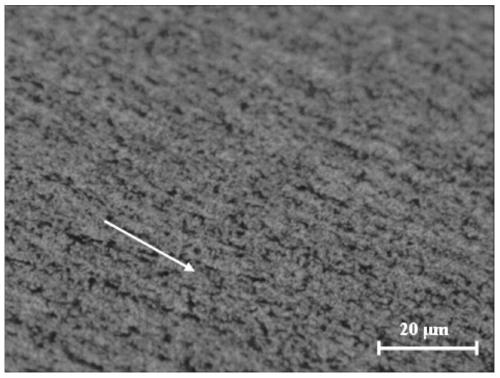

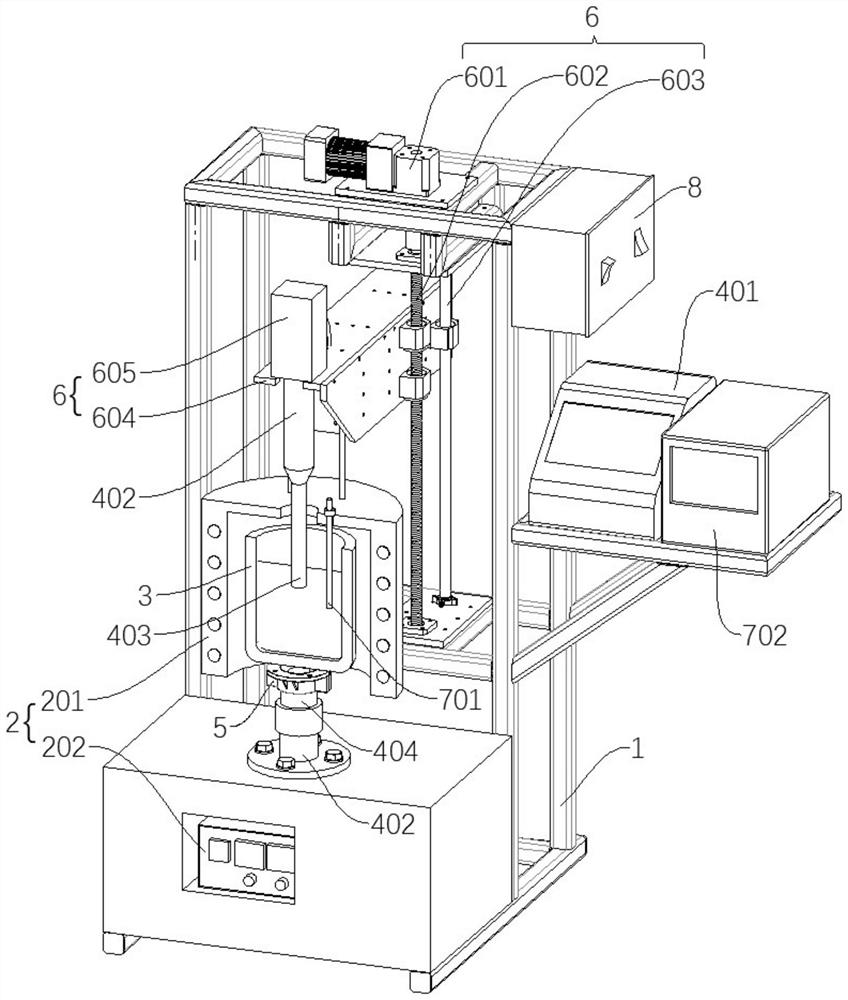

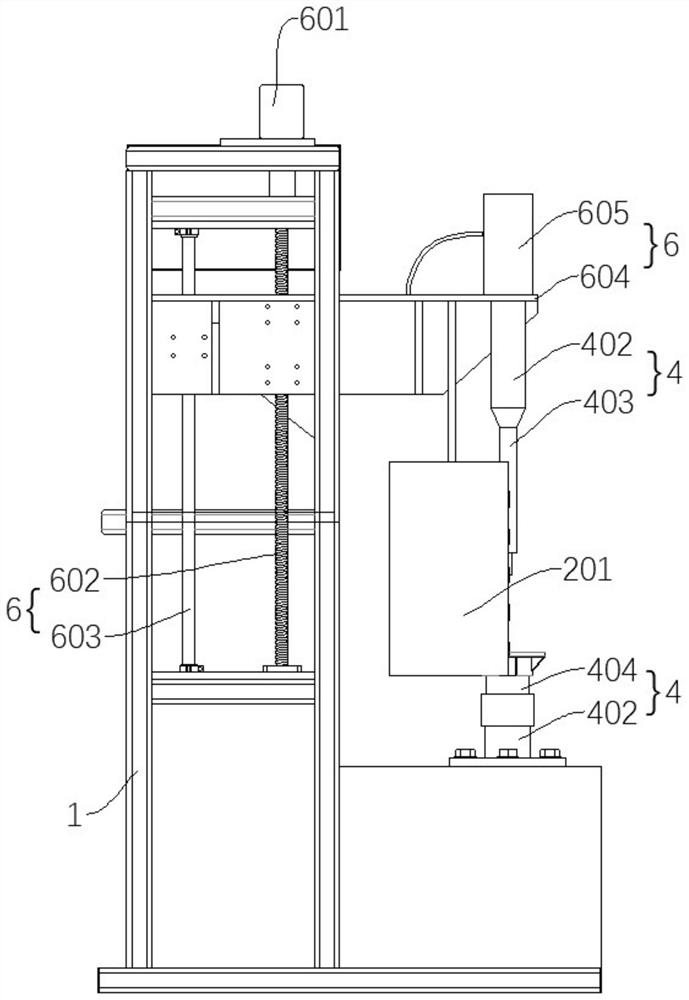

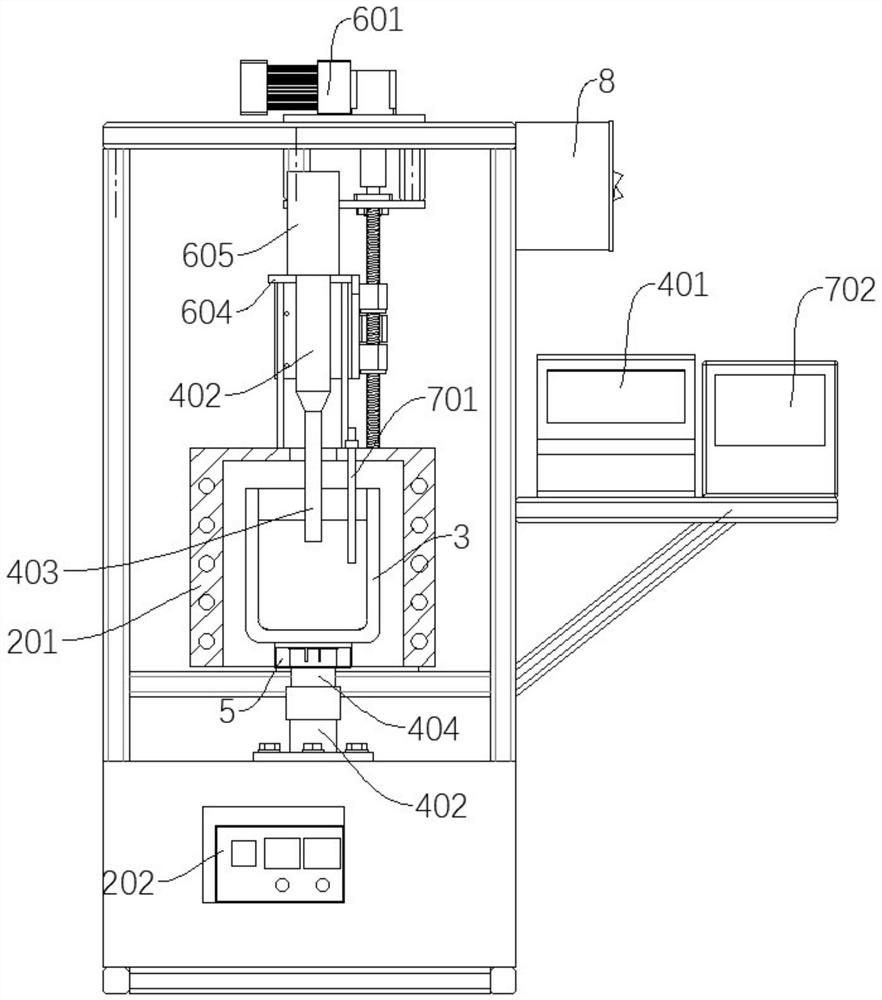

Preparation device and preparation method of rare earth magnesium alloy

ActiveCN113999980AImprove the cavitation effect inside the meltImprove liquidityProcess efficiency improvementMg alloysCrucible

The invention discloses a preparation device of a rare earth magnesium alloy. The preparation device comprises: a machine table; a heating furnace, which is connected with the machine table; a crucible, which is positioned in the heating furnace; and an ultrasonic assembly. The ultrasonic assembly comprises: an ultrasonic controller and a plurality of transducers which are electrically connected with the ultrasonic controller; an immersion type amplitude-change pole, which is connected with the transducers, wherein the end part of the immersion type amplitude-change pole is positioned in the crucible; and a leading-in type amplitude-change pole, which is connected with the transducers, wherein the leading-in type amplitude-change pole is located on the outer side of the crucible, and the leading-in type amplitude-change pole and the immersion type amplitude-change pole are oppositely arranged. According to the invention, the problems that magnesium alloy rare earth and other high-specific-weight components are prone to sedimentation, and rare earth phases are prone to enrichment in a grain boundary can be effectively solved.

Owner:HEFEI UNIV OF TECH

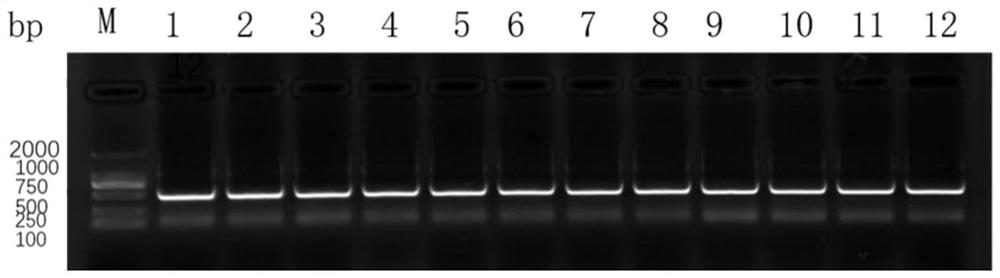

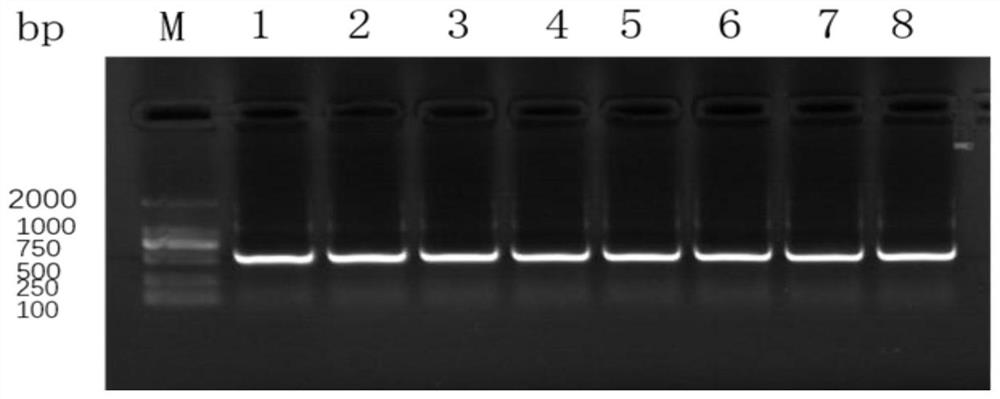

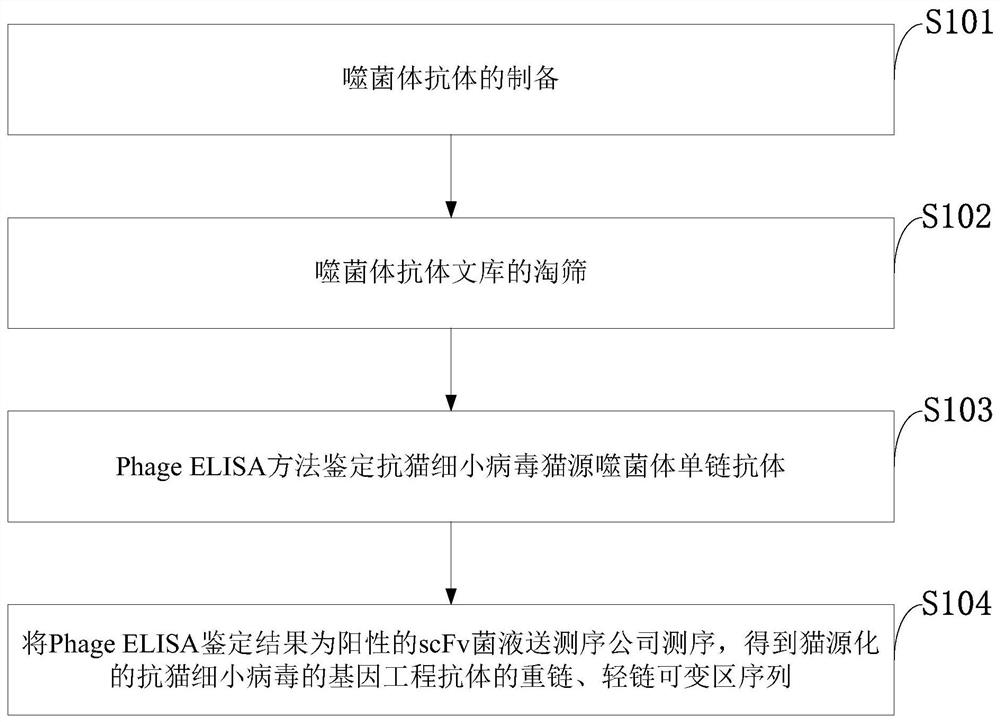

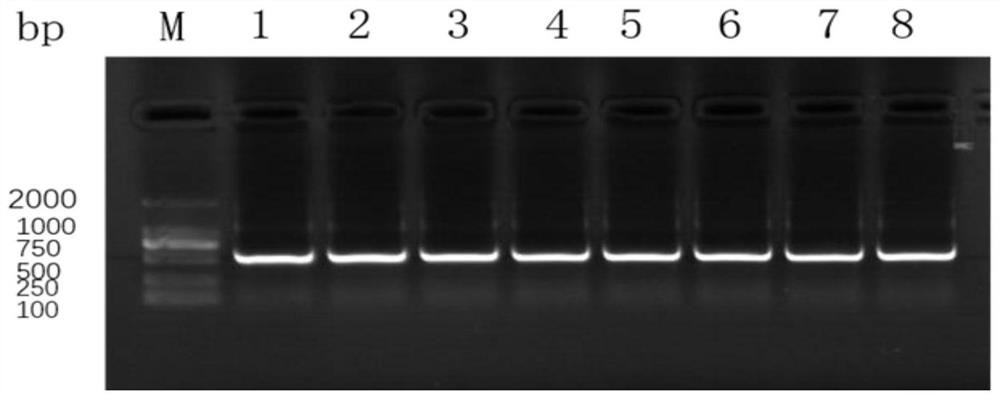

Feline panleukopenia virus antibody sequence, tetrapeptide chain molecule, globulin molecule and application

InactiveCN111909259AHomogenizationHigh affinityBiological material analysisImmunoglobulins against virusesFeline panleukopeniaFeline parvovirus

The invention belongs to the technical field of virus antibodies, and discloses a feline panleukopenia virus antibody sequence, a tetrapeptide chain molecule, an immunoglobulin molecule and application, wherein the feline panleukopenia virus antibody sequence is a heavy chain variable region amino acid sequence SEQ ID NO: 1 and a nucleotide sequence SEQ ID NO: 3; and a light chain variable regionamino acid sequence SEQ ID NO: 2 and a nucleotide sequence SEQ ID NO: 4. A sequence screening method comprises the following steps of preparing a bacteriophage antibody; screening a bacteriophage antibody library; identifying an anti-feline panleukopenia virus feline-derived bacteriophage single-chain antibody by using a PhageELISA method; sending a scFv bacterial liquid with a positive PhageELISAidentification result to a sequencing company for sequencing to obtain variable region sequences of a heavy chain and a light chain of the feline-derived anti-feline panleukopenia virus genetic engineering antibody. The invention provides support for the construction of feline-derived anti-feline panleukopenia virus genetically engineered antibodies with high affinity and low immunogenicity. Themethod has important significance for promoting the development of feline-derived antibody drugs.

Owner:青岛博隆基因工程有限公司

Device for utilizing dead load of concrete to eliminate gap of continuous wall

Owner:GUANGDONG YUANTIAN ENG

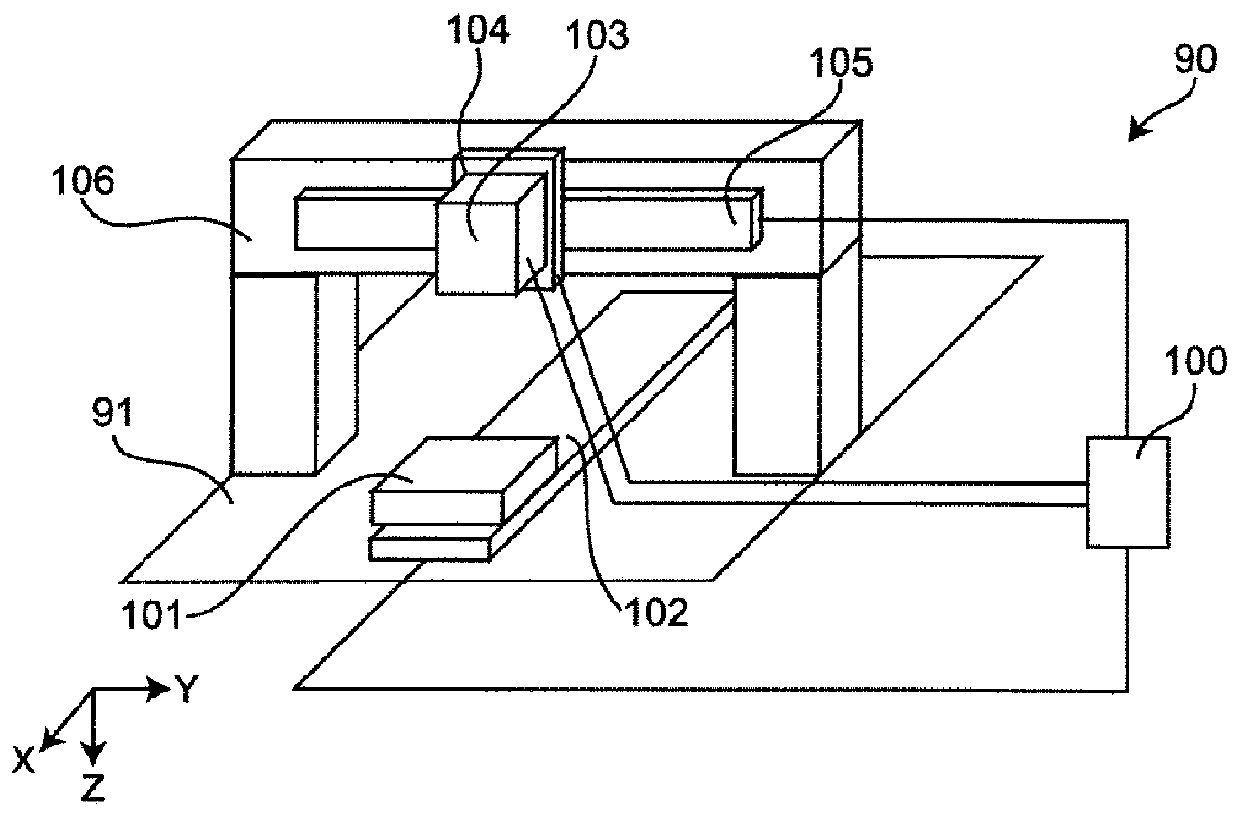

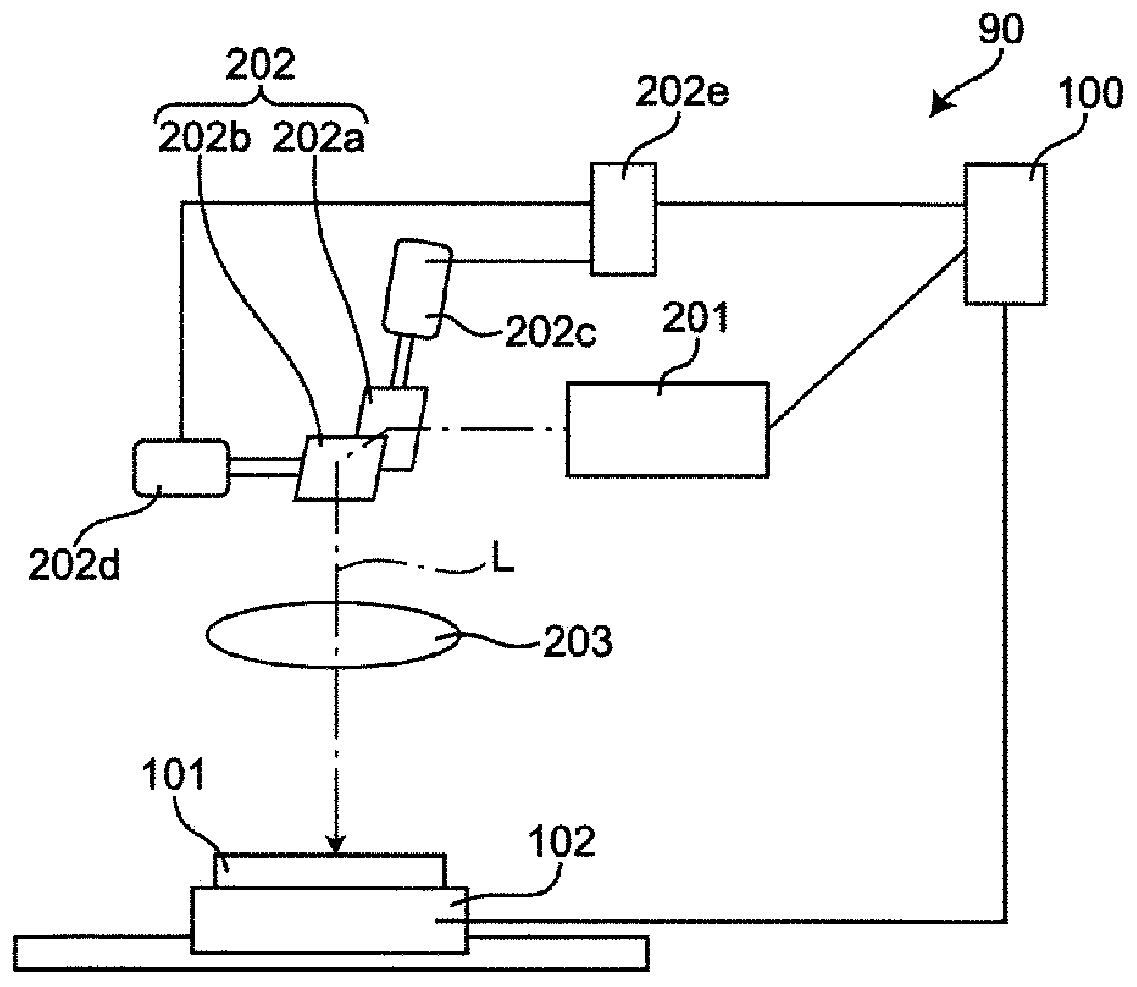

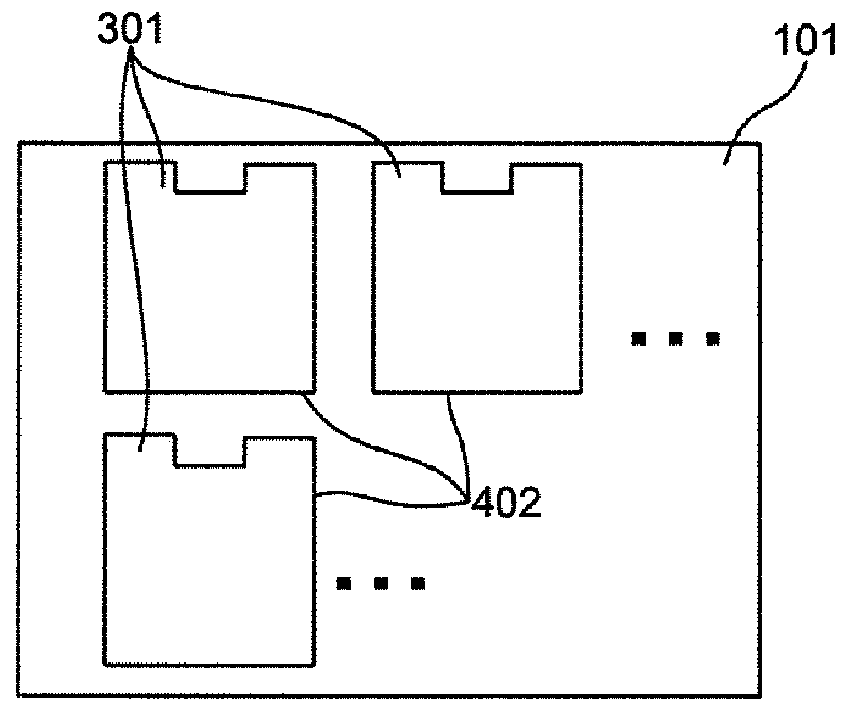

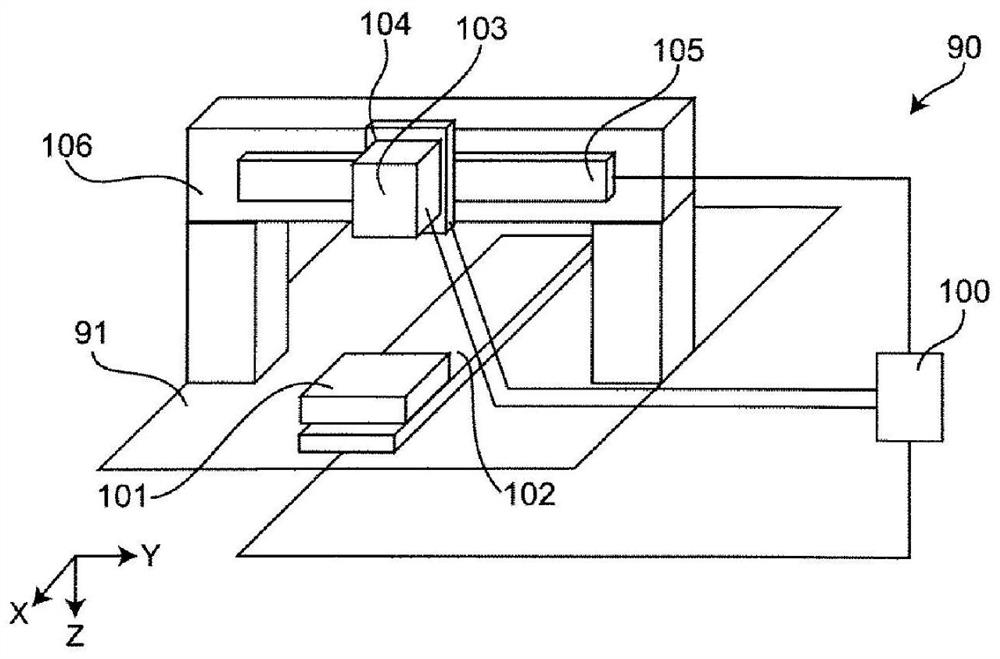

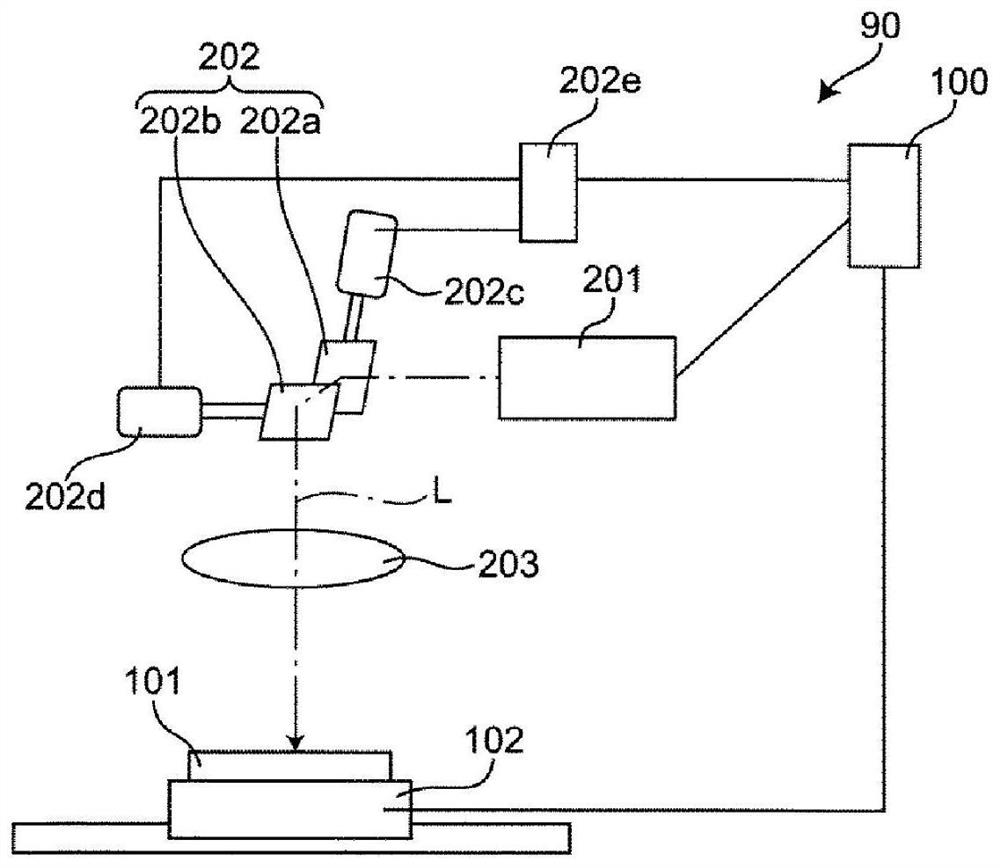

Laser processing method and laser processing device

ActiveCN110814522AReduce machining accuracyReduce production capacityLaser beam welding apparatusLaser processingEngineering

The present invention provides a laser processing method and a laser processing device, which can suppress a reduction in processing accuracy and productivity. An object to be processed is held on a drive table that moves in the first direction X. Then, the object to be processed is moved in the first direction by driving the table, and through a current detection scanner, laser L irradiating theobject to be processed from the current detection scanner and an ftheta lens are allowed to move for three or more than three times in the first direction and the opposite direction of the first direction on a part of same straight line of a processing predetermined line and then to be scanned relative to the object to the processed. The linear speed V0 of the scanning of the laser light is controlled in a relatively fixed manner. The linear velocity V0 in the departure scanning and return scanning is the difference between the departure scanning velocity Vs1 and the movement velocity Vt of the object to be processed and the difference between the return scanning velocity Vs2 and the movement velocity Vt. The moving speed Vt is equal to (Vs1-Vs2) / 2, the departure scanning speed Vs1 is greater than the return scanning speed Vs2, and the scanning speed Vs is greater than 2 * the moving speed Vt.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Dispersive copper alloy drawing process

ActiveCN111957755ANot brittleHigh tensile strengthExtrusion cleaning devicesAC - Alternating currentGraphite

The invention discloses a dispersive copper alloy drawing process. The dispersive copper alloy drawing process comprises the following step: step 1, substrate softening: placing an alloy body in a cobalt chloride solution firstly, then treating the mixture with alternating current, and then washing the treated mixture with boiling water 1-3 times. According to the drawing process, substrate softening is first performed before drawing, and a substrate is first placed in the cobalt chloride solution and then treated with alternating current, which is aimed to disperse the internal structure of the substrate and enable the substrate to be more easily infiltrated by a wetting agent. Raw materials such as sodium dodecyl polyoxyethylene ether sulfate and triethanolamine of the wetting agent cansoften the internal structure of the substrate, and graphene can enhance the toughness and drawability of the substrate, so that the substrate is easier to be drawn.

Owner:EAST CHINA JIAOTONG UNIVERSITY

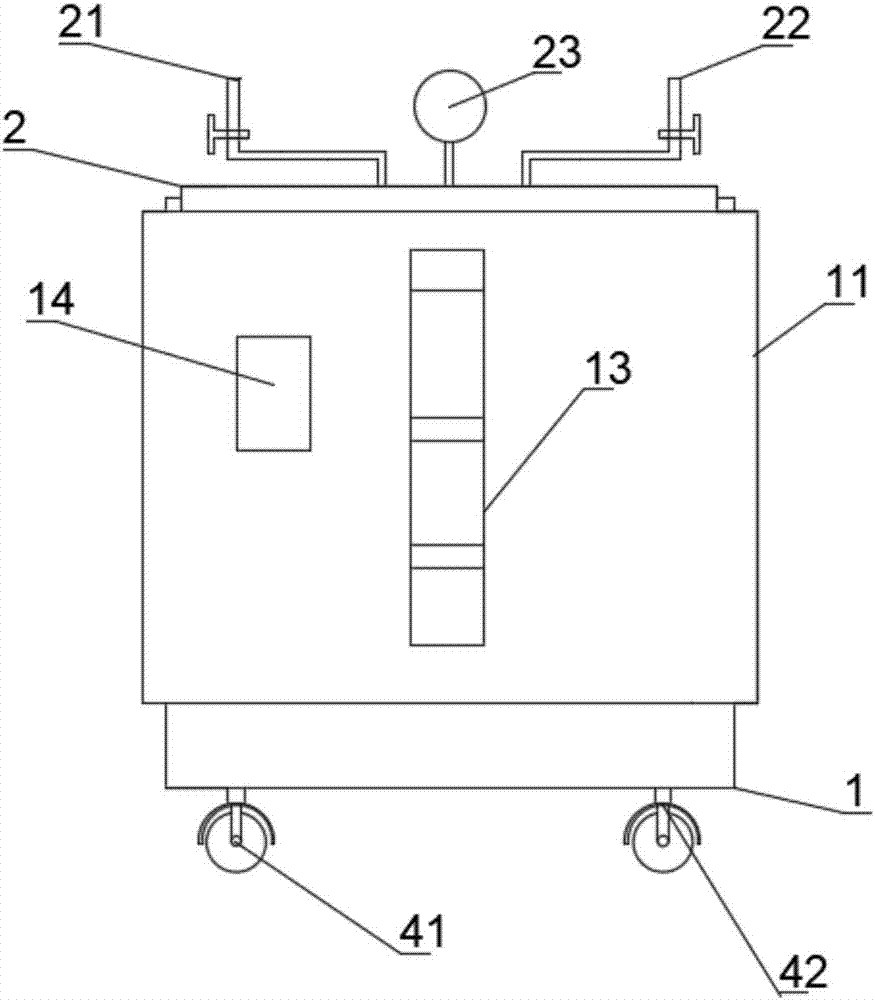

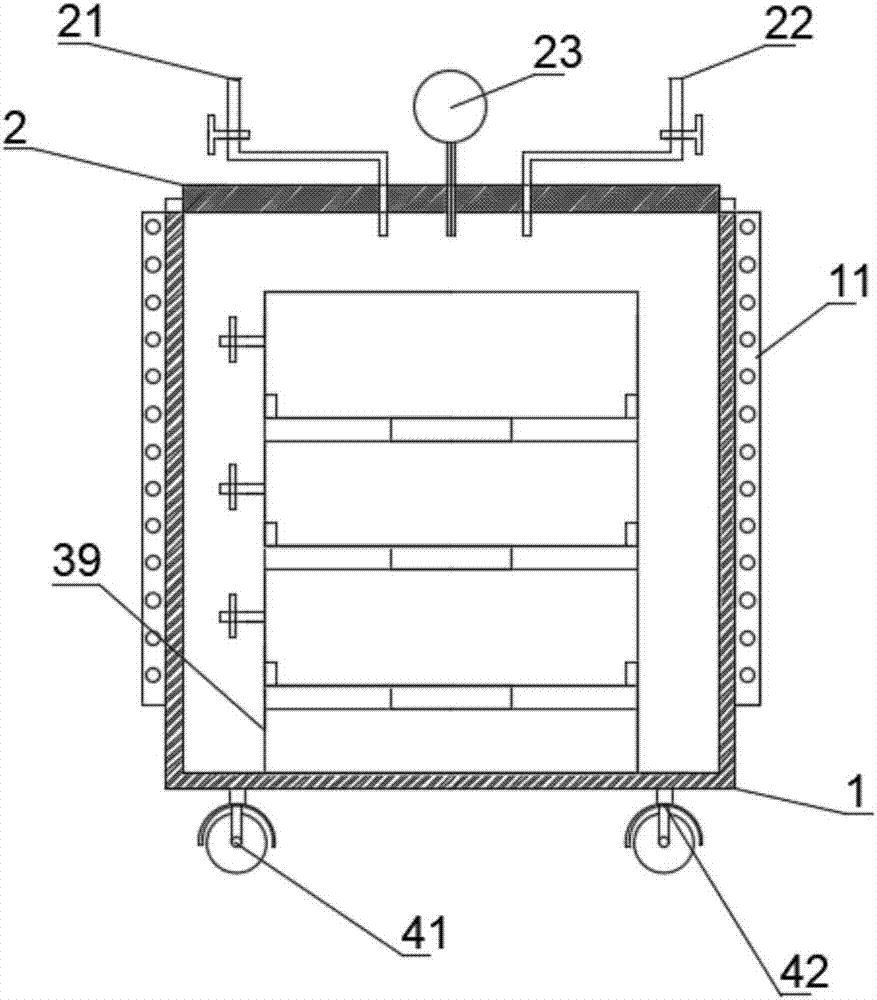

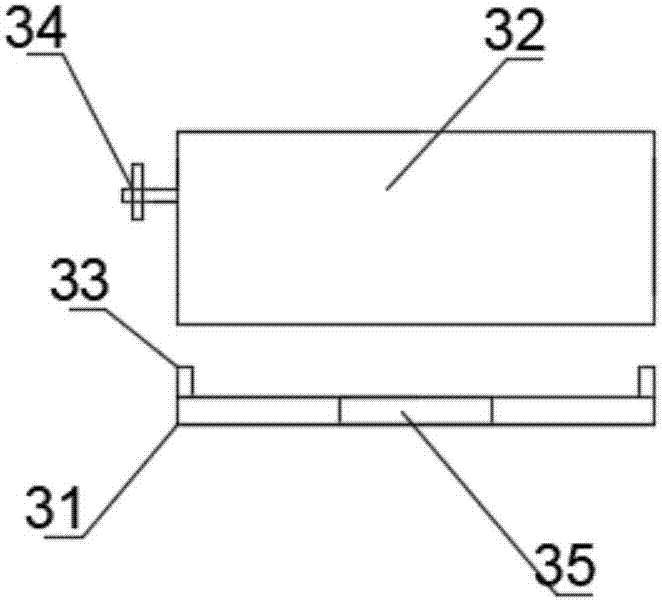

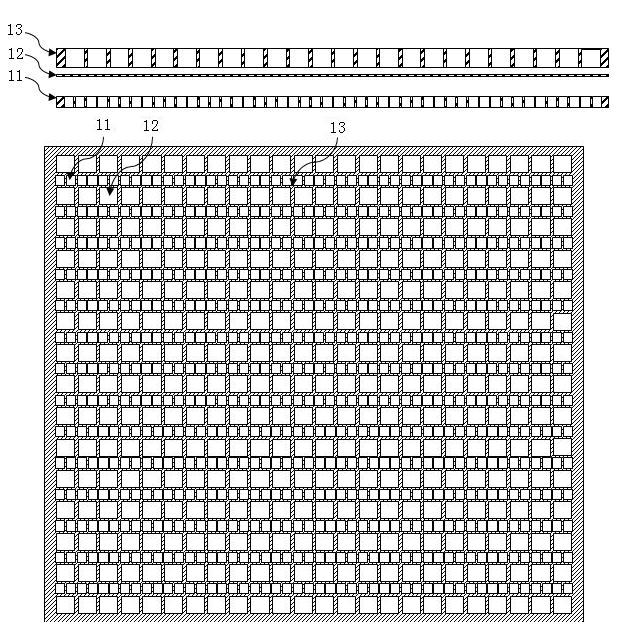

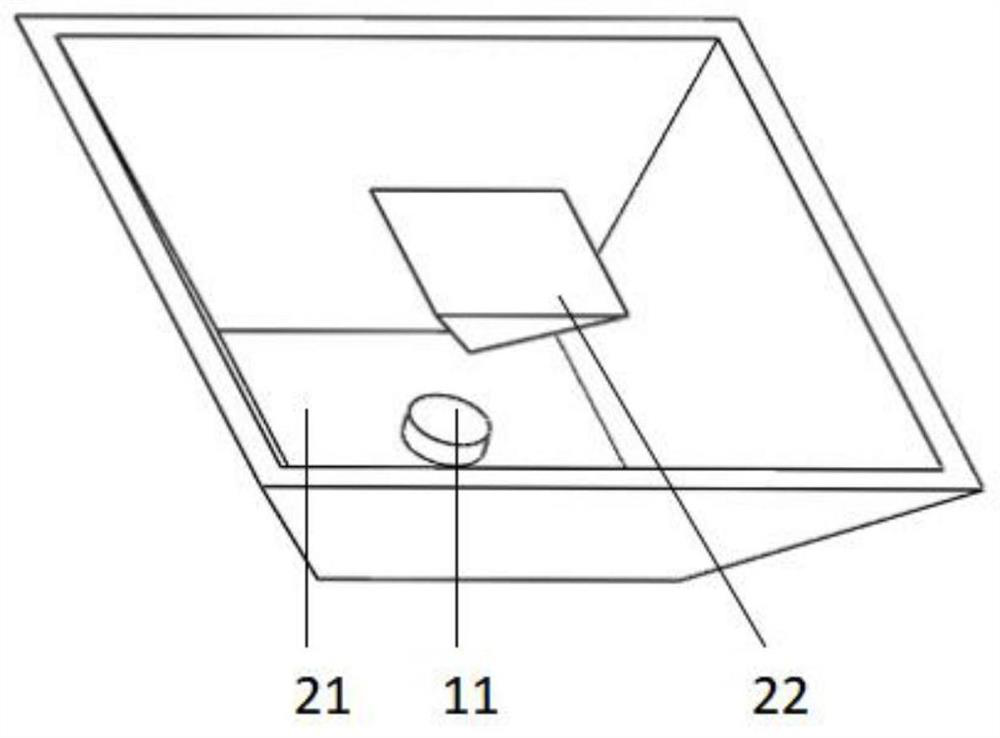

Gas medium homogenizer for high power laser diode sintering

ActiveCN104577705BImproving the quality of sintering infiltrationUniform atmosphereLaser detailsSemiconductor lasersHigh power lasersHigh power diode laser

The invention discloses a gas medium homogenization device for high-power laser diode sintering, which relates to the field of optoelectronic technology. The suction nozzles of the equipment are sealed and matched, and the support is provided with an intake passage and an exhaust passage that communicate with the intake pipe and the exhaust pipe, and the other ends of the intake passage and the exhaust passage communicate with the hollow area in the middle of the support. Install the bracket on the sintering table, so that the heat sink with solder is fixed to the connecting plate in the hollow area, a high-power laser diode is placed on the heat sink with solder, and the suction nozzle of the sintering equipment is adsorbed above the hollow area, reducing the gas Entering from the intake passage, it can fully cover the surface of the solder, which can fully restore the solder in the sintering area of the laser diode chip, and then use the exhaust passage to export the reduced exhaust gas to form a complete circuit. The invention has the advantages of simple structure, homogenization of reducing gas, and improvement of consistency of solder reduction.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

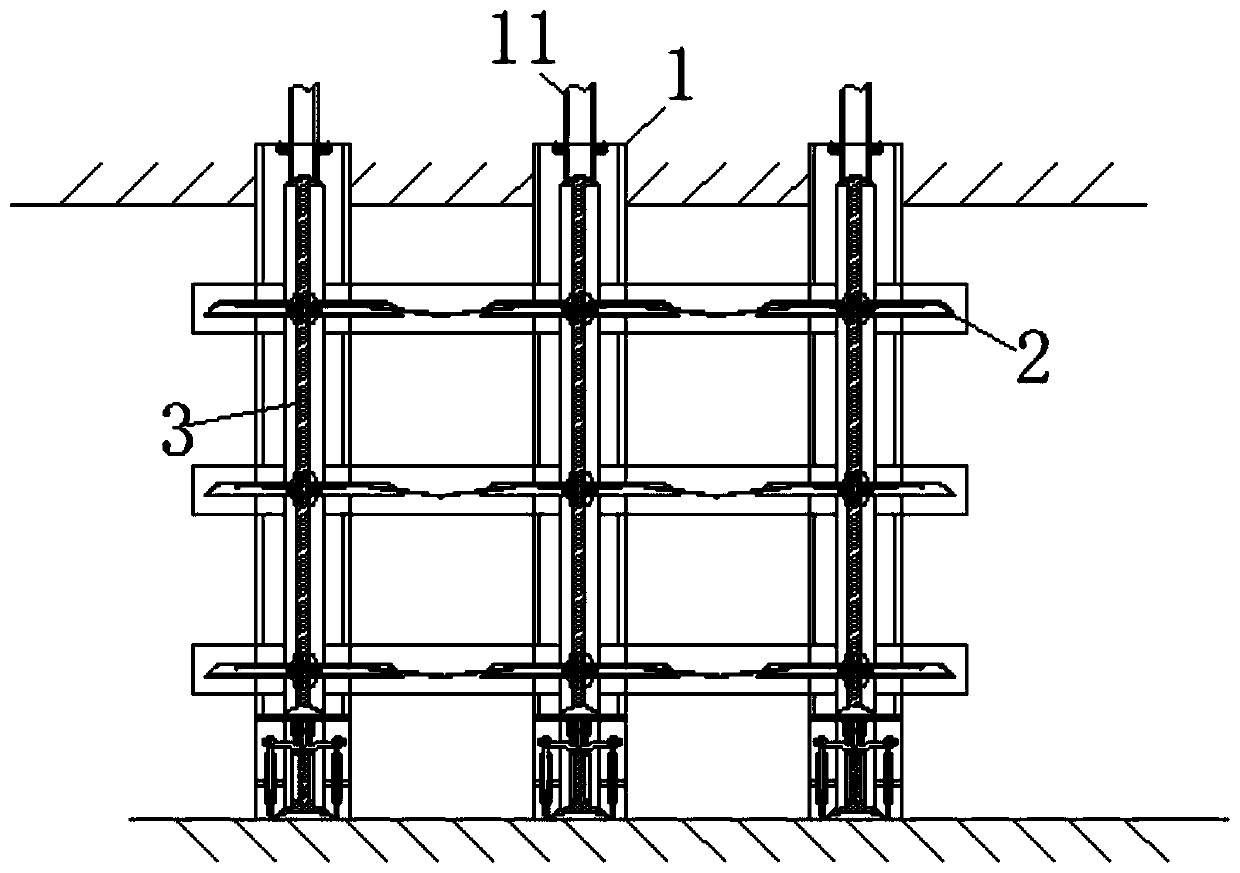

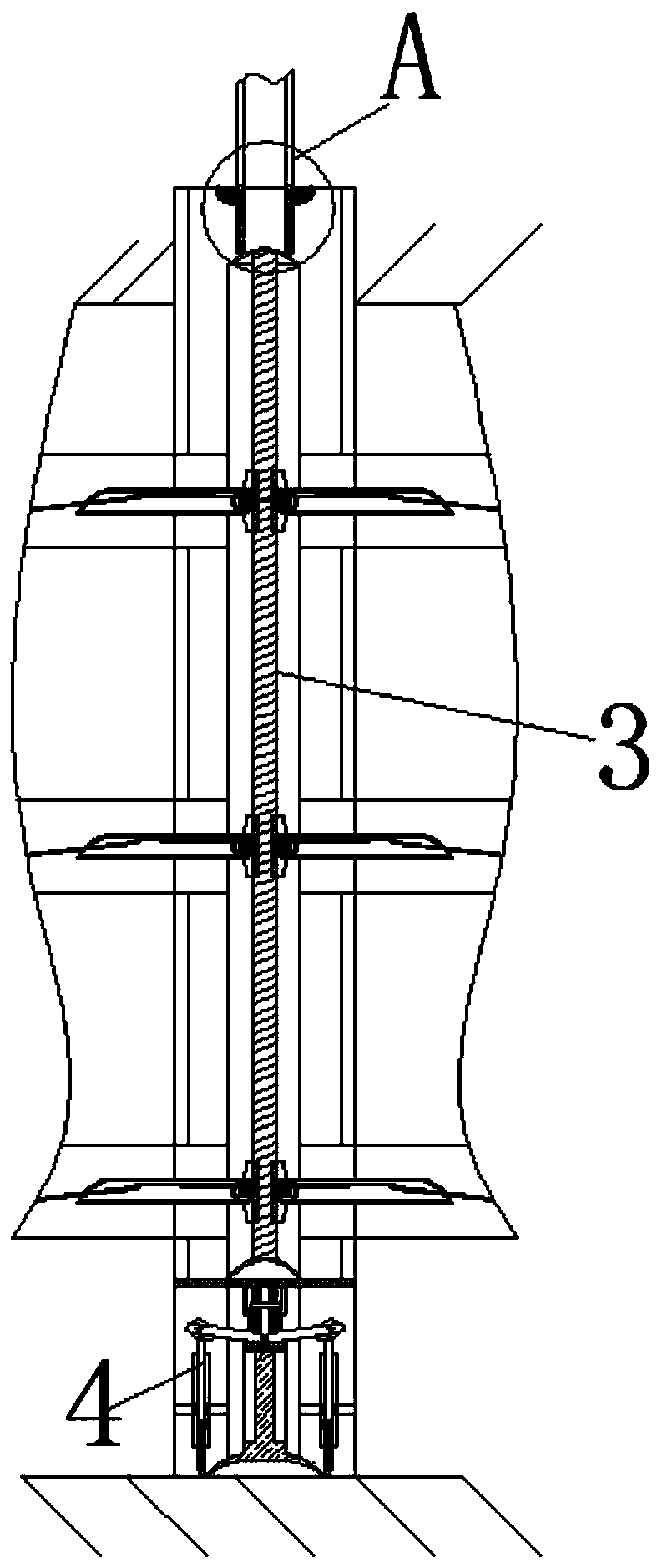

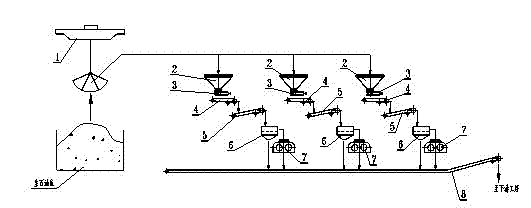

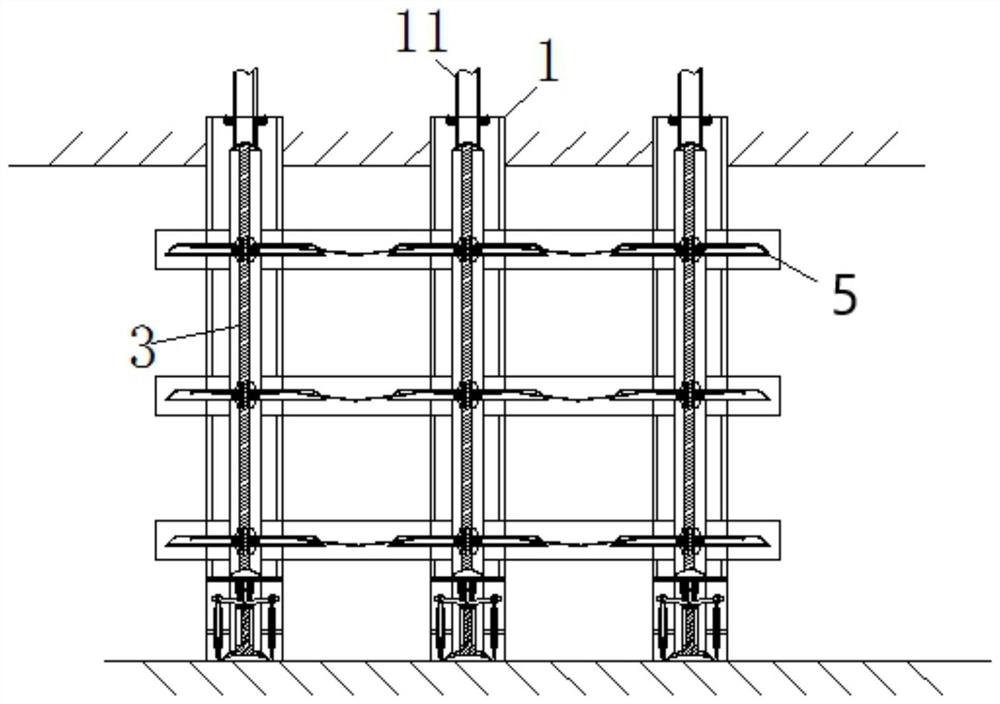

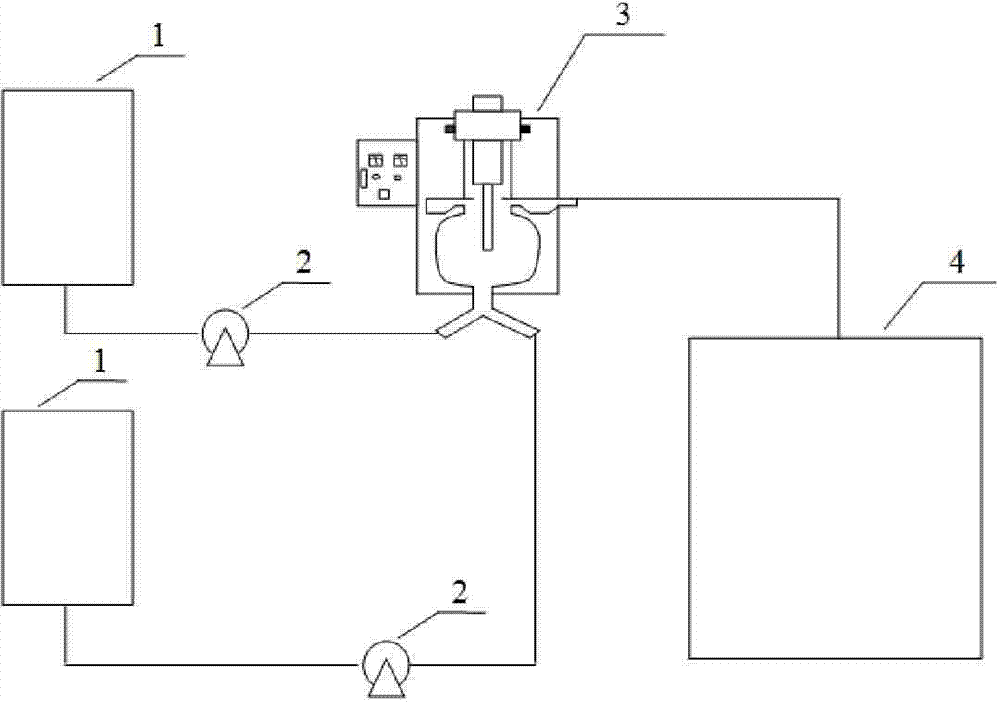

Green petroleum coke mixing and homogenizing system device

InactiveCN102949951AEnsure stable qualityHomogenizationMixer accessoriesCarbon preparation/purificationAdhesiveEngineering

The invention discloses a green petroleum coke mixing and homogenizing system device which is characterized in comprising a grab overhead crane (1) and three sets of feeding, blending, screening, crushing, mixing and homogenizing systems. Each set of system comprises a grid screen funnel (2). A gate valve (3) is arranged below the grid screen funnel (2). An adhesive tape dosing machine (4) is arranged below the gate valve (3). An adhesive tape conveyor (5) is arranged below the adhesive tape dosing machine (4). A vibration sieve (6) is arranged below the adhesive tape conveyor (5). A master adhesive tape conveyor (8) is arranged below the vibration sieve (6). A crusher (7) is arranged beside the vibration sieve (6). The gate valve (3) is a normally open manual gate valve. According to the invention, through the three sets of systems, green petroleum cokes came from different production places are subjected to precise mixing according to a certain ratio, such that the stabilities of parameters such as volatile contents and ash contents of green petroleum coke entering a subsequent production process can be realized. With the technical scheme provided by the invention, mixing and homogenizing of green petroleum cokes with three different qualities can be realized.

Owner:GUIYANG AL-MG DESIGN & RES INST

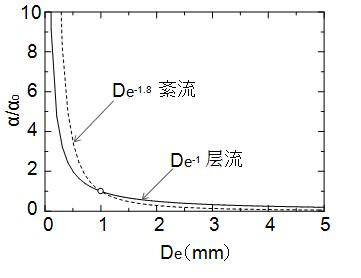

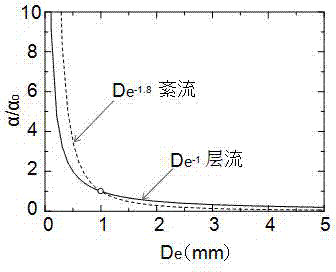

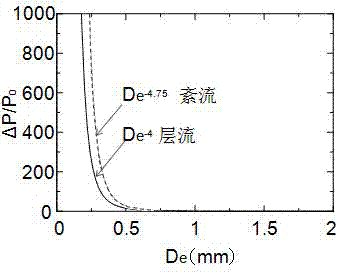

Manufacture method of microchannel heat exchange body of heat exchanger

ActiveCN102095284AGuaranteed diffusionGuaranteed normal formationEvaporators/condensersProcess engineeringHeat transfer efficiency

The invention discloses a manufacture method of a microchannel heat exchange body of a heat exchanger, belonging to the technical filed of heat transfer and heat exchange. The manufacture method comprises the following steps of: obtaining a set of optimized refrigeration media and a hydraulic diameter of a working fluid microchannel by calculation and analysis based on the use condition of a heatpump system, then respectively machining and forming the refrigeration media, the working fluid microchannel and a baffle plate layer, carrying out surface treatment, and separating and overlaying a refrigeration media layer from a working fluid microchannel layer through baffle plates to form a plurality of microchannel units; increasing both the temperature and the pressure after placing the overlaid microchannel units in a vacuum cavity to generate atomic diffusion on the surfaces of the refrigeration media layer, the working fluid microchannel layer and the baffle plate layer until atoms are combined into a whole with a homogeneous structure. The heat exchanger applying the manufacture method has higher heat exchange efficiency than the traditional products.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

Feline calicivirus antibody sequence, tetrapeptide chain molecule and immunoglobulin molecule

ActiveCN111848788AHomogenizationBiological material analysisImmunoglobulins against virusesFeline calicivirus infectionPhage antibodies

The invention belongs to the technical field of virus antibodies, and discloses a feline calicivirus antibody sequence, a tetrapeptide chain molecule, an immunoglobulin molecule and applications thereof, and the sequences are as follows: the amino acid sequence of a heavy chain variable region SEQ ID NO: 1 and a nucleotide sequence SEQ ID NO: 3; the amino acid sequence of a light chain variable region is SEQ ID NO: 2, and the nucleotide sequence of the light chain variable region is SEQ ID NO: 4. The screening method of the virus antibody sequence comprises the following steps: preparing a bacteriophage antibody; screening the phage antibody library; identifying an anti-feline calicivirus feline phage single-chain antibody by virtue of a Page ELISA method; sending the scFv bacterial liquidwith the positive Page ELISA identification result to a sequencing company for sequencing to obtain sequences of variable regions of the heavy chain and the light chain. The invention provides support for constructing a cat-derived anti-feline calicivirus genetic engineering antibody with high affinity and low immunogenicity, and has important significance for promoting the development of cat-derived antibody drugs.

Owner:青岛博隆基因工程有限公司

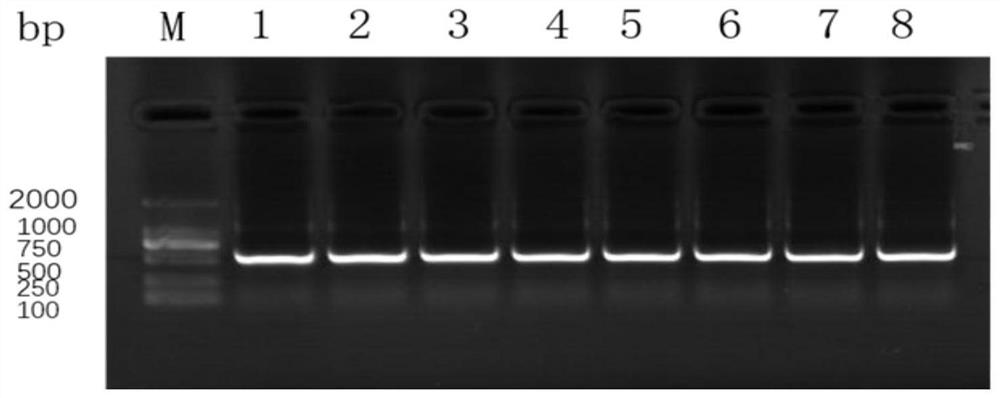

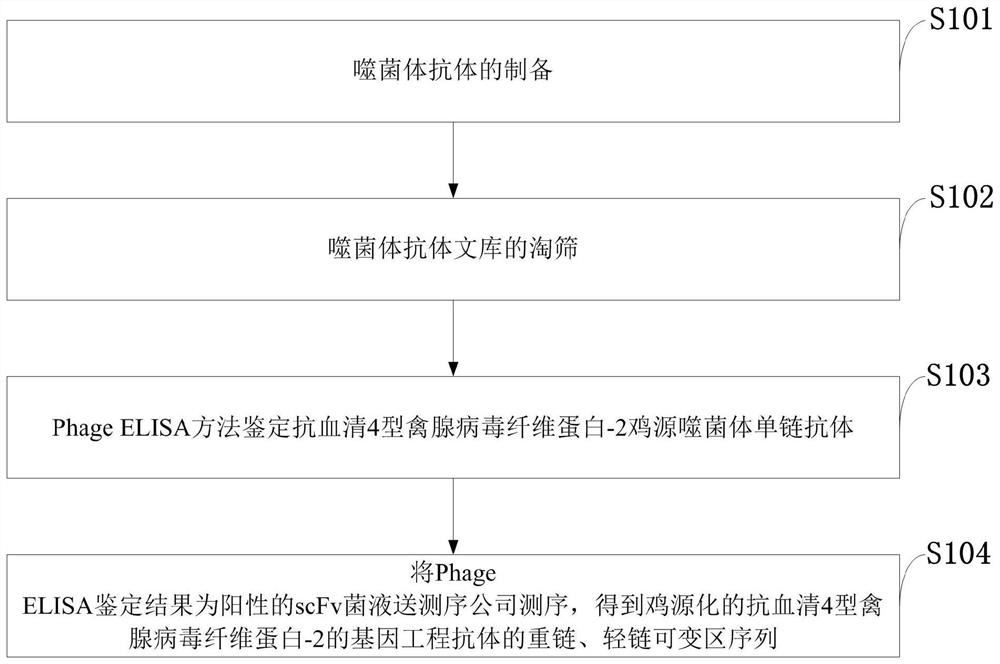

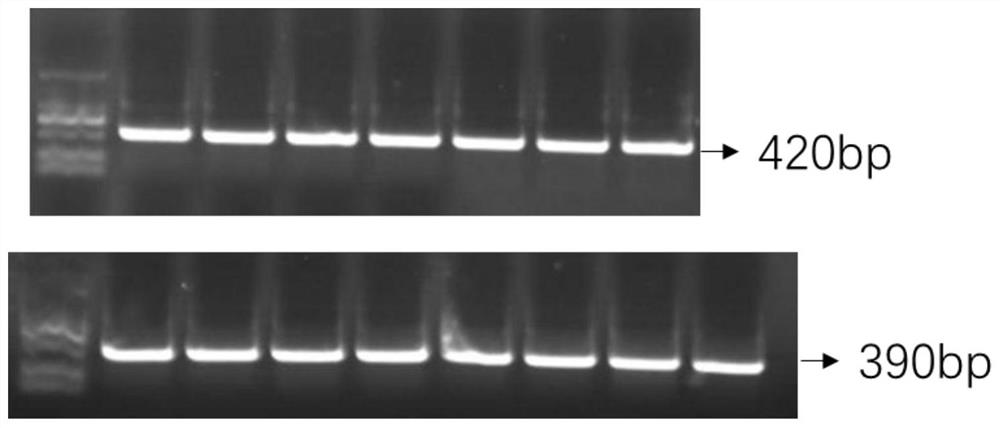

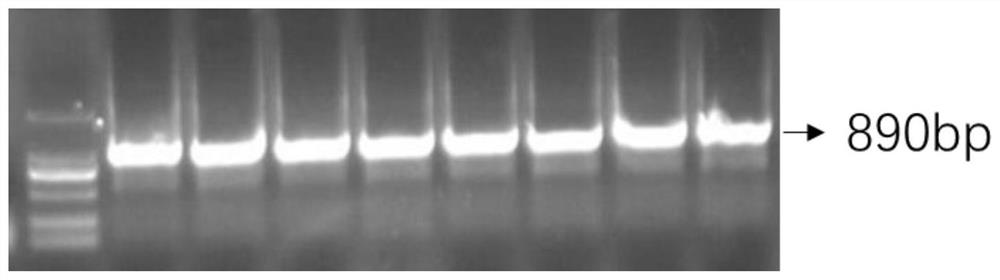

Antifibrin-2 antibody sequence, tetrapeptide chain molecule and immunoglobulin molecule

ActiveCN113173989AHomogenizationHigh affinityBiological material analysisImmunoglobulins against virusesNucleotideVirus Protein

The invention belongs to the technical field of virus protein antibodies, and discloses an antifibrin-2 antibody sequence, a tetrapeptide chain molecule and an immunoglobulin molecule, the virus protein antibody sequence is characterized in that the amino acid sequence of a heavy chain variable region is SEQ ID NO: 1, and the nucleotide sequence is SEQ ID NO: 3; the amino acid sequence of a light chain variable region is SEQ ID NO: 2, and the nucleotide sequence is SEQ ID NO: 4. The amino acid sequences and the nucleotide sequences of the variable regions of the heavy chain and the light chain of the chicken-derived antiserum type 4 fowl adenovirus fibrin-2 antibody provided by the invention provide support for constructing a gene engineering antibody of the chicken-derived antiserum type 4 fowl adenovirus fibrin-2 with high affinity and low immunogenicity, and are of great significance in promoting the diagnosis of serum type 4 avian adenovirus infection and the development of chicken-derived antibody drugs.

Owner:QINGDAO AGRI UNIV

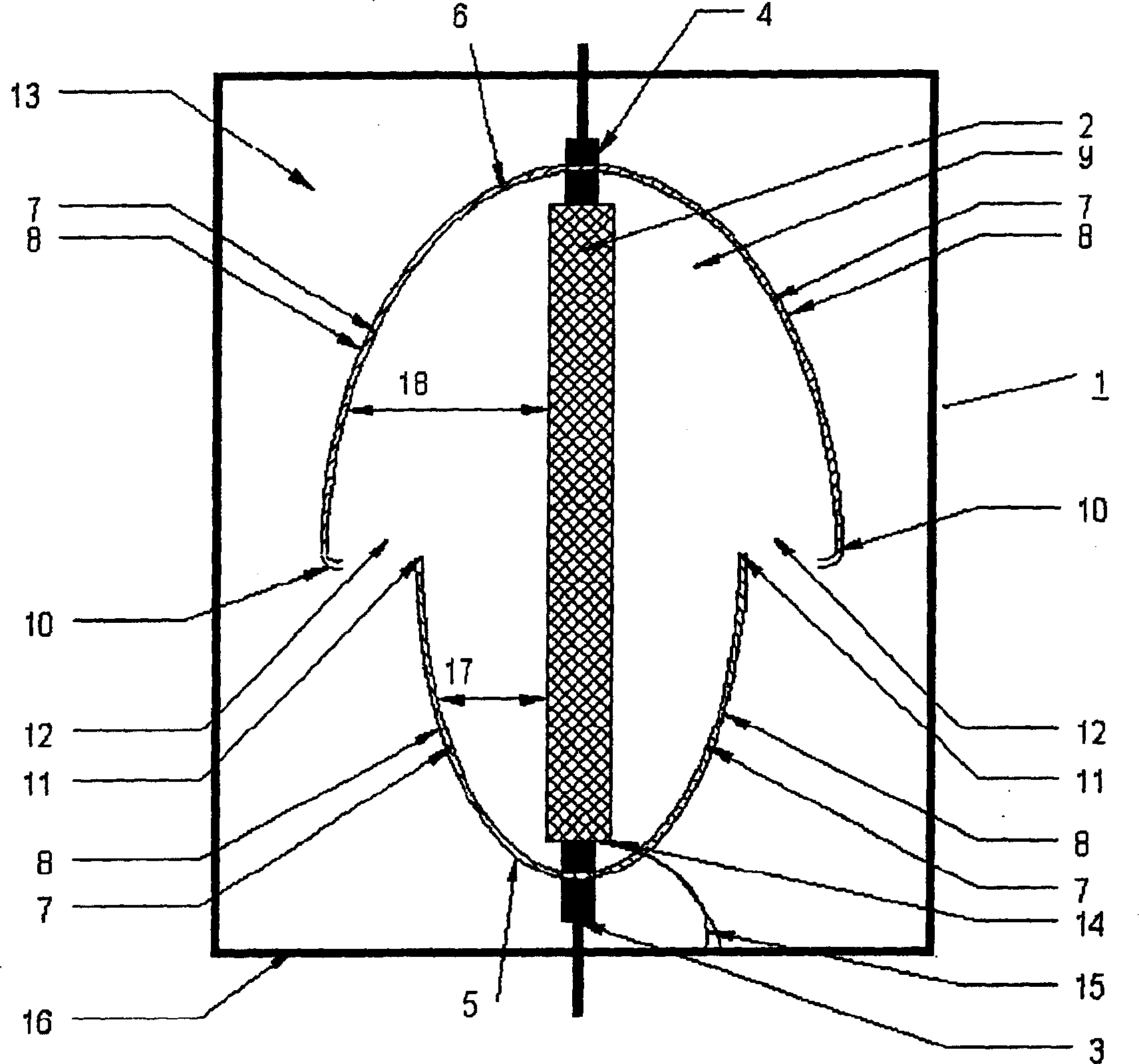

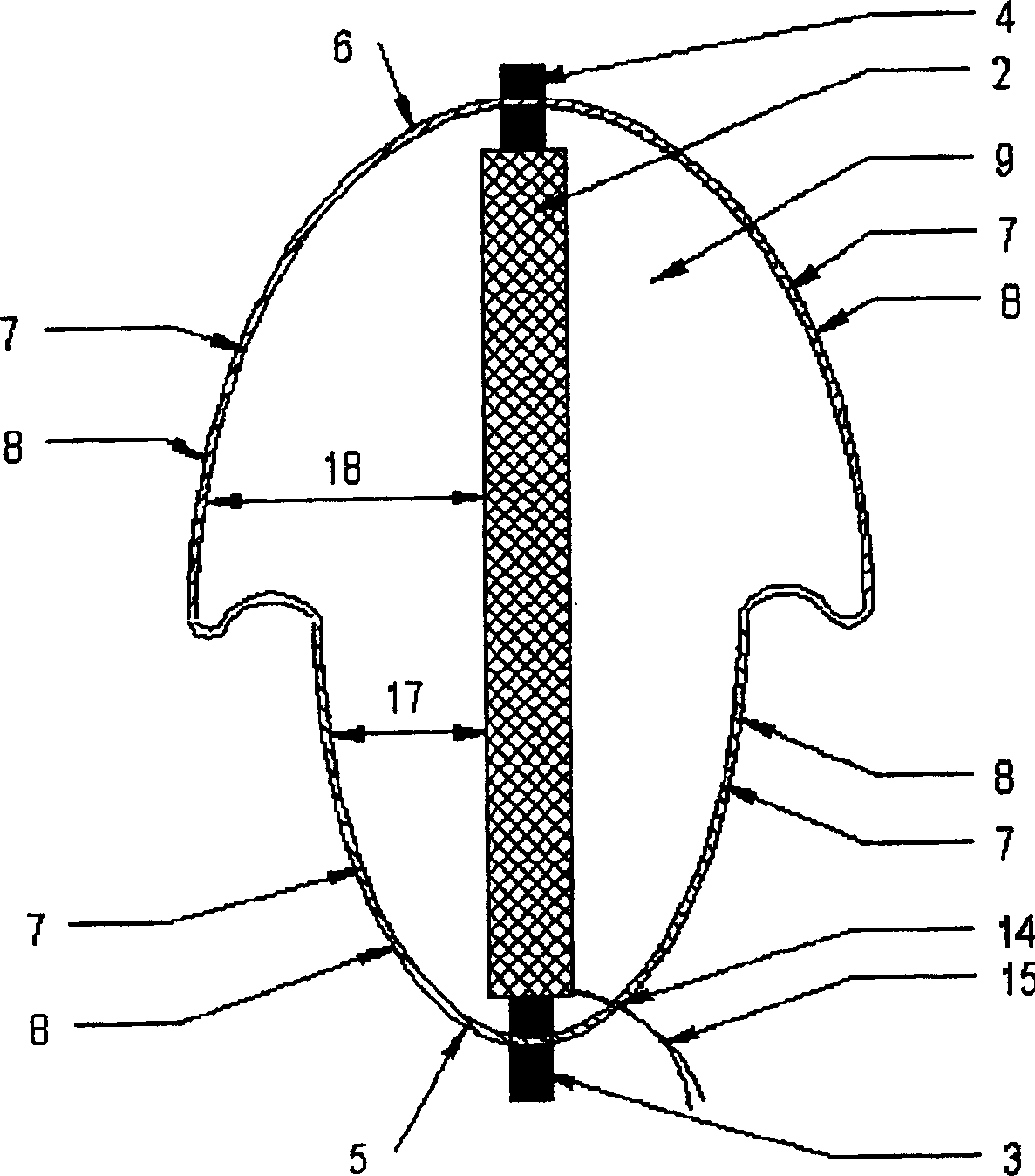

Insulating system with field control elements and method for making same

InactiveCN1642404AEffective controlPrecise changeMagnetic/electric field screeningScreening apparatusElectric fieldHigh pressure

An electrical functional unit (EFU) (2) has a high-voltage connection (4) and an earth connection (3). Field control elements (FCE) (5,6) fit around the EFU and influence the electrical field around the EFU, which is cast in insulating material (9,13) along with the FCE. All these produce an electrical field that is as homogenous as possible and that can be produced with particular benefit. - An INDEPENDENT CLAIM is also included for a method for producing an insulating system for medium high voltage installations.

Owner:DUROMER KUNSTVERARBEITUNGS

A device for eliminating gaps in continuous walls by using concrete self-weight

Owner:GUANGDONG YUANTIAN ENG

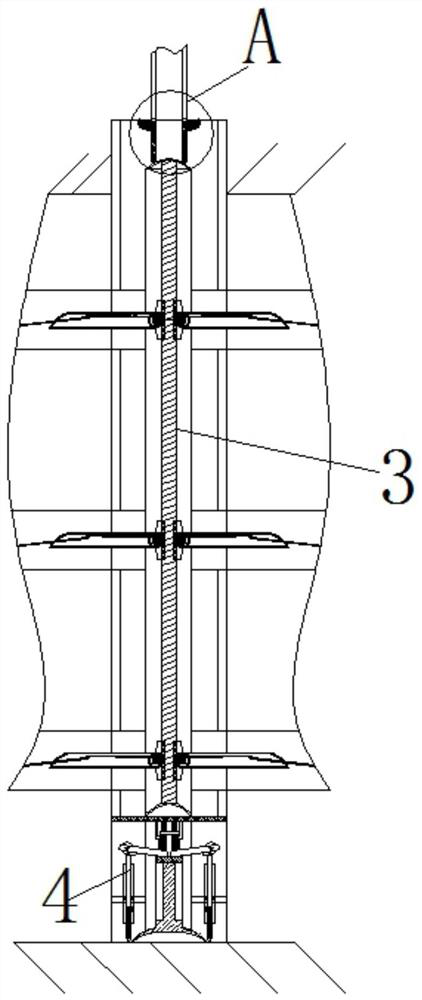

Water treating reactor for the drinkability thereof

InactiveCN100533346CSimple designLow costPower supply for data processingWater/sewage treatment apparatusWater treatment

Invented water treatment plant for the production of drinking water comprising a substantially cylindrical housing (1), means (2) interacting with the housing (1) for guiding the water to be treated and for discharging A means (3) of treated water, and a plurality of means forming UV lamps (4), wherein said apparatus is characterized in that said UV lamp forming means are arranged in said housing in such a way that at least The longitudinal axes of several of the devices form non-zero and different angles than 90 degrees relative to the longitudinal axis of the substantially cylindrical housing (1).

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

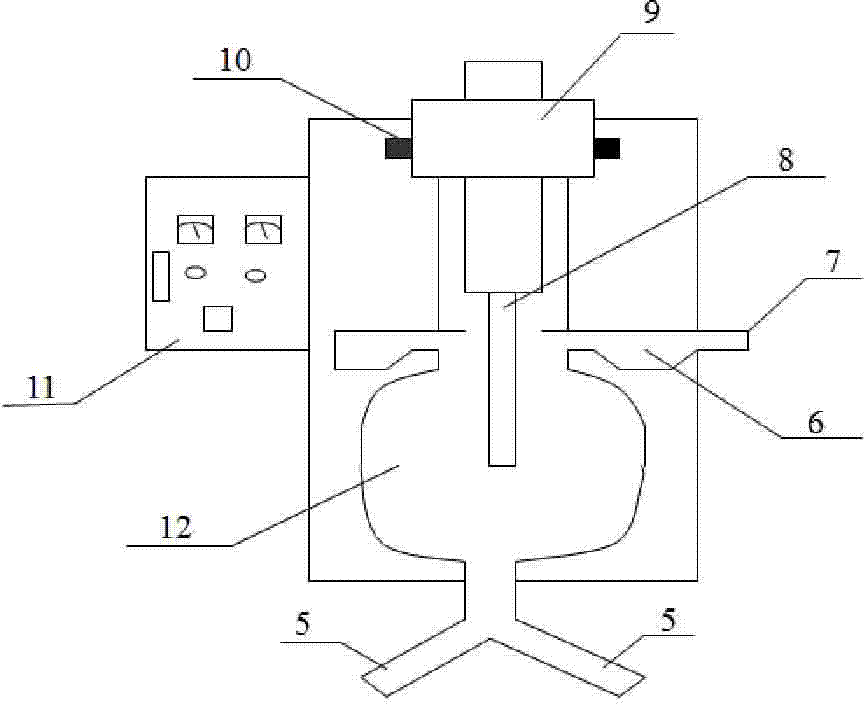

Reaction system and method for preparing nano magnesium hydroxide

InactiveCN102153114BAvoid reunionHomogenizationNanotechnologyMagnesium hydroxideMagnesium saltPhysical chemistry

The invention discloses a reaction system and a method for preparing nano magnesium hydroxide. The invention adopts the technical scheme that the reaction system comprises a feeding device, a reaction device and a storage tank; the feeding device is connected with the reaction device; and the reaction device is connected with the storage tank. The method for preparing the nano magnesium hydroxidecomprises the following steps of: respectively placing soluble magnesium salt solution and alkali liquor in different material tanks; simultaneously starting a constant flow pump of the feeding device, simultaneously feeding the same volume of the soluble magnesium salt solution and the alkali liquor into the reaction device, controlling the flowing speed of reaction solution in the range of 2 to20m / s, simultaneously starting ultrasonic waves of the reaction device, controlling the frequency of the ultrasonic waves in the range of 20 to 100kHz and controlling the power of the ultrasonic waves in the range of 50 to 800W; and carrying out washing, solid-liquid separation and drying on reacted slurry to obtain a target product. The reaction system and the method are simple to operate and have small investment, short production period and mild production condition. The prepared nano powder have homogeneous appearance, narrow size distribution and good dispersity and is particularly suitable for industrial production.

Owner:YINGKOU WOKERUI TECH

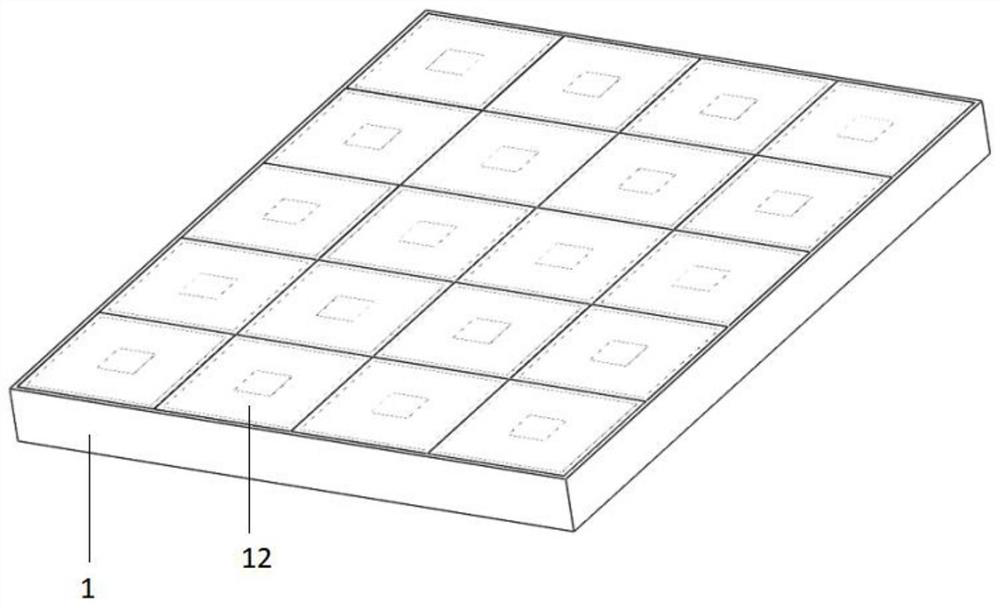

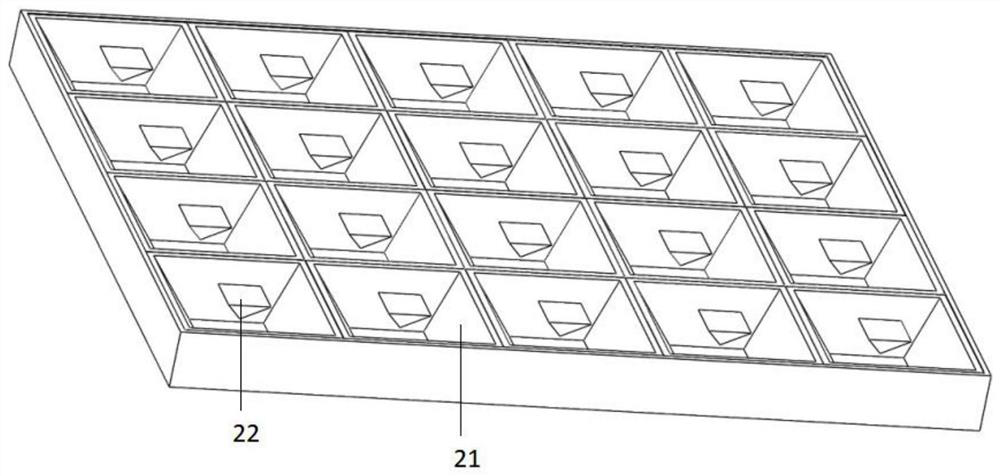

LED uniform light-emitting assembly conforming to human body

The invention relates to a LED uniform light-emitting assembly conforming to the human body, which comprises a flexible lamp panel with array LED lamp beads; the LED lamp beads emit ultraviolet light, red light or green light, and each LED lamp bead is arranged in one cavity; a light uniformizing structure capable of achieving short-distance light uniformizing and transmitting light rays to the upper portion (lateral upper portion) after light uniformizing is arranged near the LED lamp beads in the cavity, the light uniformizing structure is in a polyhedron shape, and preferably, the light uniformizing structure is a combination of a hollow hopper structure and a pyramid structure. One flexible lamp panel comprises a plurality of array LED lamp beads, and printed circuits connected with each other are arranged in any adjacent cavities; a control structure for controlling the flexible lamp panel to emit light is additionally arranged; and a direct-current power supply for providing energy for the control structure and the flexible lamp panel is arranged. The lamp beads are arranged at the bottom and the lamp beads on the side faces, and the corresponding dodging structures are arranged. The shape of the lamp panel is matched with that of the skin, and a humanized phototherapy instrument is manufactured, is used for physical therapy and disease treatment, and is particularly suitable for diseases with curative effects generated by ultraviolet light.

Owner:THE FIRST MEDICAL CENT CHINESE PLA GENERAL HOSPITAL

Laser processing method and laser processing device

ActiveCN110814522BReduce machining accuracyReduce production capacityLaser beam welding apparatusLaser processingEngineering

The present invention provides a laser processing method and a laser processing device capable of suppressing reductions in processing accuracy and productivity. The object to be processed is held on a drive table that moves in the first direction X, and then the object to be processed is moved in the first direction by driving the table, and the object to be processed is passed through the galvano scanner. The laser beam L irradiated with the fθ lens to the object is scanned by reciprocating three or more times in the first direction and the direction opposite to the first direction on the same straight line as a part of the line to be processed relative to the object. Laser scanning linear velocity V 0 Relatively fixed control, the linear velocity V in the forward and return scans 0 is the outbound scanning speed Vs 1 The difference from the moving speed Vt of the object to be processed and the return scanning speed Vs 2 The difference with the moving speed Vt, moving speed Vt=(Vs 1 ‑Vs 2 ) / 2, outbound scanning speed Vs 1 >Return scanning speed Vs 2 , scanning speed Vs>2×moving speed Vt.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

New automatic spraying system for solid reducing agent

ActiveCN101871051BRealize automatic injectionReduce laborProgramme controlComputer controlGas solidControl signal

The invention discloses a new automatic spraying system for a solid reducing agent. The system is provided with a feeding unit, a fluidized boosting unit, a fluidized hybrid adjusting unit, a feedback adjustment spraying unit, an LV automatic compensation unit, a supporting and weighing unit, a pneumatic control station and a PLC process control unit, wherein the reducing agent enters the fluidized boosting unit through the feeding unit by means of the dead weight and forms initial gas-solid two-phase flow in the fluidized hybrid adjusting unit after being boosted to flow out; the feedback adjustment spraying unit adjusts the proportion of the initial two-phase flow to meet the requirements of the reducing technology; the LV automatic compensation unit detects and rapidly responds to the gas-solid two-phase flow to ensure no recharging of liquid copper; the pneumatic control station distributes compressed air, nitrogen gas and oxygen required by the process and a meter gas source required for controlling each unit to each point; and the PLC process control unit programs, processes the switching value and the analog quantity, sends a control signal and gives an instruction to the feeding unit to ensure that the feeding unit is in a normal operating state. The automatic spraying system can realize automatic spraying of the solid reducing material and ensure uniform and controllable material supply.

Owner:昆明理工精诚科技有限责任公司 +1

Manufacture method of microchannel heat exchange body of heat exchanger

ActiveCN102095284BGuaranteed diffusionGuaranteed normal formationEvaporators/condensersWorking fluidProcess engineering

The invention discloses a manufacture method of a microchannel heat exchange body of a heat exchanger, belonging to the technical filed of heat transfer and heat exchange. The manufacture method comprises the following steps of: obtaining a set of optimized refrigeration media and a hydraulic diameter of a working fluid microchannel by calculation and analysis based on the use condition of a heat pump system, then respectively machining and forming the refrigeration media, the working fluid microchannel and a baffle plate layer, carrying out surface treatment, and separating and overlaying a refrigeration media layer from a working fluid microchannel layer through baffle plates to form a plurality of microchannel units; increasing both the temperature and the pressure after placing the overlaid microchannel units in a vacuum cavity to generate atomic diffusion on the surfaces of the refrigeration media layer, the working fluid microchannel layer and the baffle plate layer until atoms are combined into a whole with a homogeneous structure. The heat exchanger applying the manufacture method has higher heat exchange efficiency than the traditional products.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

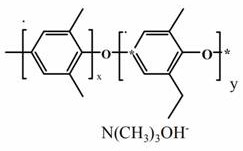

A kind of diaphragm of zinc-silver secondary battery and its preparation method and zinc-silver secondary battery

ActiveCN112531287BImprove cycle stabilityExtended service lifeSecondary cellsCell component detailsIon currentPhysical chemistry

The present application discloses a zinc-silver secondary battery diaphragm, a preparation method thereof and a zinc-silver secondary battery. The zinc-silver secondary battery diaphragm is formed by embedding a quaternized polymer anion exchange membrane with a porous filler. The porous filler Including at least one of inorganic oxides and metal-organic frameworks; the amount of the porous filler is 0.5%-20% of the weight of the quaternized polymer anion exchange membrane, and the pore size of the porous filler is less than 2nm. The zinc-silver secondary battery separator of the present application can not only suppress the loss of the active material of the positive electrode, but also prevent silver ions from passing through the separator to form dendrites at the negative electrode and cause a short circuit, thereby improving the cycle stability of the battery and prolonging the service life of the battery ; At the same time, it can also rectify the ion flow of hydroxide to make it evenly transmitted, ensuring that the zinc oxide on the electrode plane is transferred to Zn(OH) 4 2‑ The conversion is carried out uniformly, and its local aggregation is inhibited, thereby inhibiting the growth of zinc dendrites and ensuring the normal operation of the battery.

Owner:SHENZHEN AUTOMOTIVE RES INST BEIJING INST OF TECH (SHENZHEN RES INST OF NAT ENG LAB FOR ELECTRIC VEHICLES)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com