Reaction system and method for preparing nano magnesium hydroxide

A nano-magnesium hydroxide and reaction system technology, applied in the field of nano-material preparation, can solve the problem that the stirring strength is not enough to disperse the nano-powder aggregates, it is impossible to control the nucleation and growth stages of the nano-powder, and the mixing and dispersing strengths are low. and other problems, to achieve the effect of good product quality stability, uniform appearance and fast mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

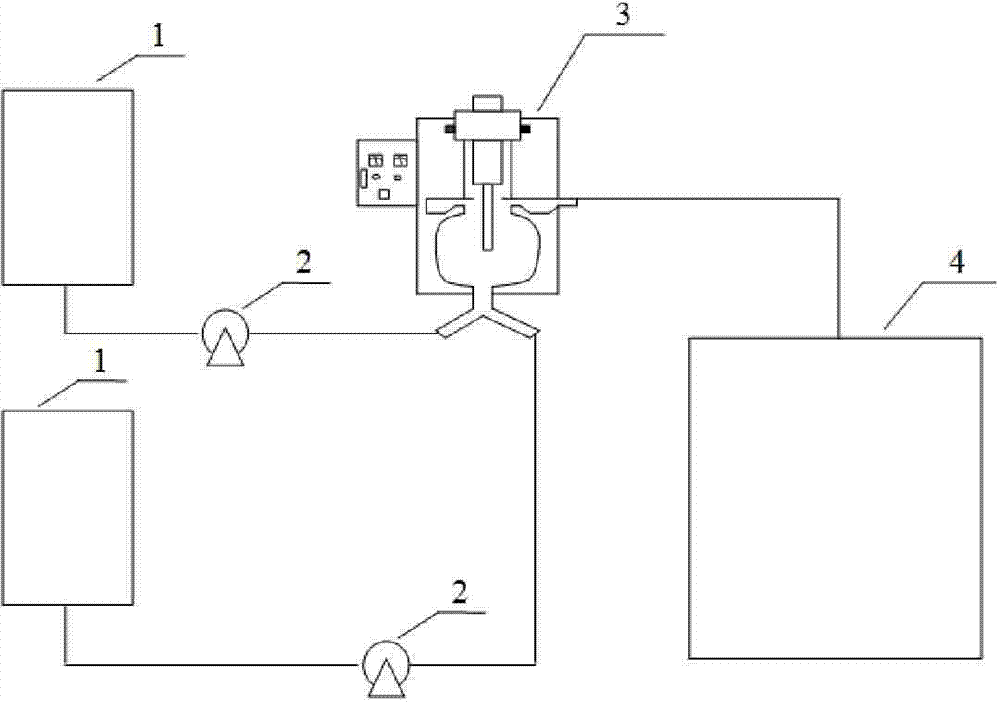

[0027] like figure 1 As shown, a reaction system for preparing nano-magnesium hydroxide: it is composed of at least two sets of feeding devices, a reaction device (3) and a storage tank (4); the feeding device is connected to the reaction device (3), and the reaction device ( 3) Connect with the storage tank (4).

[0028] The feeding device includes a material tank (1) and a constant flow pump (2).

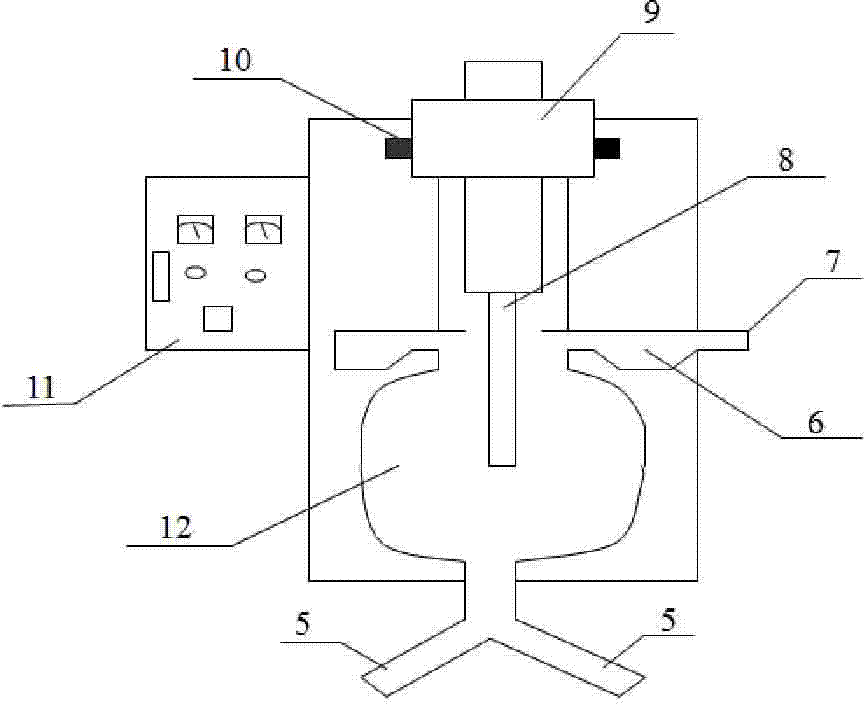

[0029] like figure 2 As shown, the reaction device (3) includes a reaction vessel (12), an ultrasonic probe fixed in the reaction vessel (12), an ultrasonic control system (11), which is combined at one end connected to the reaction vessel (12) The two feed pipes (5), the collection tank (6) located in the middle of the reaction vessel, and the discharge port (7) connected to the collection tank (6); the ultrasonic probe includes an ultrasonic transducer (9) and horn (8); the ultrasonic probe is tightly fixed in the reactor (12) through the sealing ring (10). An included angl...

Embodiment 2

[0033] MgCl 2 ·6H 2 O and polyethylene glycol 800 (PEG800) were dissolved in deionized water and stirred to form Mg 2+ Soluble magnesium salt solution with a concentration of 1.0mol / L, PEG800 added in an amount of 2% of the magnesium hydroxide output, placed in a material tank of the continuous reaction system; NaOH was also dissolved in deionized water to form OH - The lye with a concentration of 2.0mol / L is placed in another material tank of the continuous reaction system. Then two constant flow pumps are turned on at the same time, and equal volumes of soluble magnesium salt solution and lye are pumped into the reaction device at the same time, and the flow rate of the reaction solution is controlled at 5m / s. Simultaneously, turn on the ultrasonic wave of the reaction device, control the ultrasonic frequency to be 28KHz, and the ultrasonic power to be 100W. The quantitative production of nano-magnesium hydroxide can be realized by keeping the reaction conditions stable a...

Embodiment 3

[0035] MgCl 2 ·6H 2 O and polyvinyl alcohol (PVA) were dissolved in deionized water and stirred to form Mg 2+ Soluble magnesium salt solution with a concentration of 1.4mol / L, the amount of PVA added is 2.3% of the magnesium hydroxide output, placed in a material tank of the continuous reaction system; in addition, ammonia water is also dissolved in deionized water to form OH - Concentration is the lye of 2.8mol / L, is placed in another material tank of continuous reaction system. Then two constant flow pumps are turned on at the same time, and equal volumes of soluble magnesium salt solution and lye are pumped into the reaction device at the same time, and the flow rate of the reaction solution is controlled at 8m / s. Simultaneously, turn on the ultrasonic waves of the reaction device, control the ultrasonic waves to a frequency of 40KHz, and an ultrasonic power of 250W. The quantitative production of nano-magnesium hydroxide can be realized by keeping the reaction condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com