New automatic spraying system for solid reducing agent

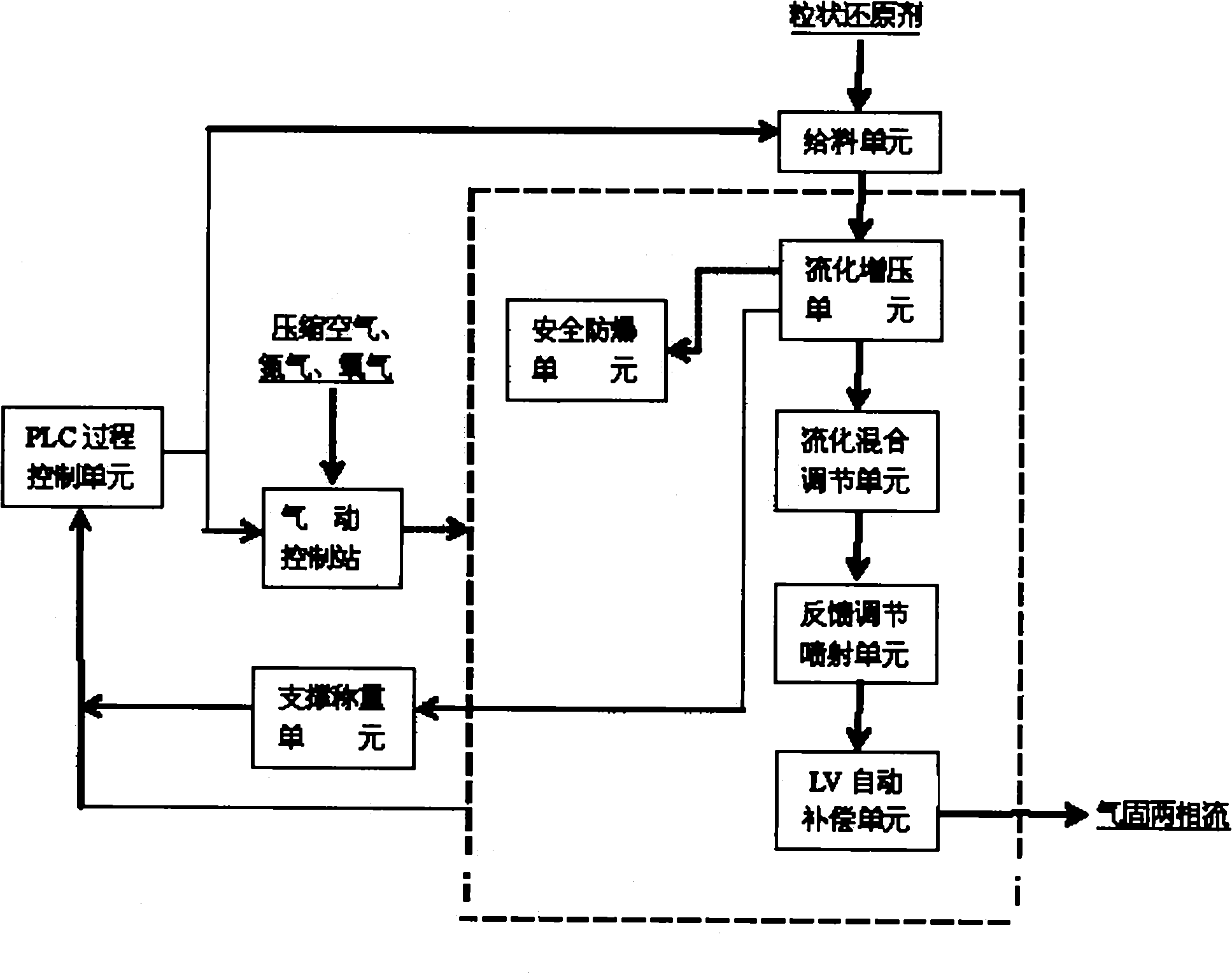

A reducing agent and solid technology, which is applied in the field of the new solid reducing agent automatic injection system, can solve the problems of cumbersome hoisting of the tank back and forth, difficult to control the supply of materials, and high labor intensity, so as to reduce the amount of labor and achieve uniform and controllable supply. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 One 400t tilting anode furnace, equipped with two redox ports, granular reducing agent ≤ 5mm, bulk density 0.6-0.7t / m 3, water content ≤ 5%. Configure the feeding unit, fluidized pressurization unit, fluidized mixing adjustment unit, feedback adjustment injection unit, LV automatic compensation unit, safety explosion-proof unit, support weighing unit, pneumatic control station, and PLC process control unit according to the requirements of the aforementioned embodiments. . One tank corresponds to one oxidation-reduction port and one set of control system. The capacity of each tank is 4.5t of reducing agent. LV-4.5 adjustable Laval tube is used. The pressure and dosage of compressed air and compressed nitrogen are both 0.4-0.8MPa, 250m 3 Under the condition of 1 / h, the granular reducing agent can be injected automatically, the inner diameter of the reduction tube is 25mm, the depth of inserting the copper liquid is 600mm, the injection volume is 2-5t / h, and th...

Embodiment 2

[0036] Example 2 One 150t rotary anode furnace, with two redox ports, granular reducing agent ≤ 4mm, bulk density 0.6-0.8t / m 3 , water content ≤ 6%. Configure the feeding unit, fluidized pressurization unit, fluidized mixing adjustment unit, feedback adjustment injection unit, LV automatic compensation unit, safety explosion-proof unit, support weighing unit, pneumatic control station, and PLC process control unit according to the requirements of the aforementioned embodiments. . One tank corresponds to two redox ports, the capacity of the tank is 3.0t reducing agent, LV-2.5 adjustable Laval tube is adopted, the pressure and dosage of compressed air and compressed nitrogen are 0.3-0.5MPa, 150m 3 Under the condition of 1 / h, the granular reducing agent can be injected automatically, the inner diameter of the reduction tube is 25mm, the depth of insertion into the copper liquid is 500mm, the injection volume is 1-3t / h, and the reduction time of a single furnace is 0.6-1.5h. Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com