A rotary incremental forming device for magnesium alloy sheet metal tools

A progressive forming and magnesium alloy technology, applied in the direction of spraying device, etc., can solve problems such as increased labor intensity, adjustment of lubricant coating thickness, scratches on the surface of formed parts, etc., to achieve scientific and reasonable lubrication, controllable spray volume, spray The effect of quantitative science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

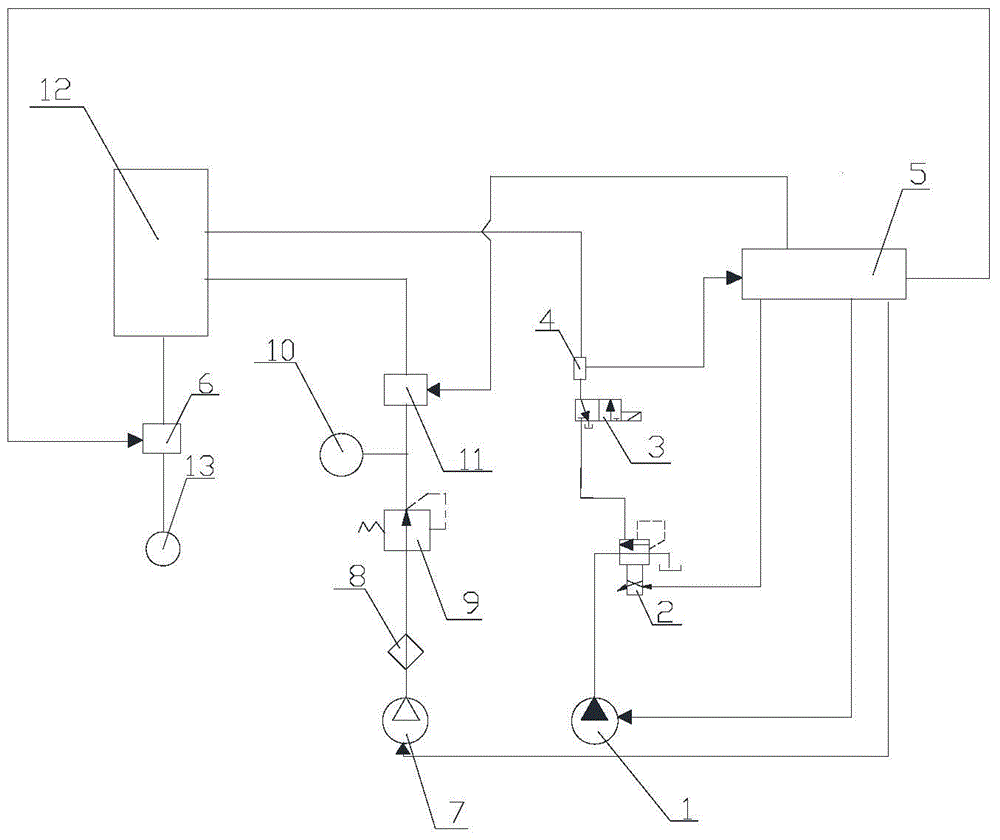

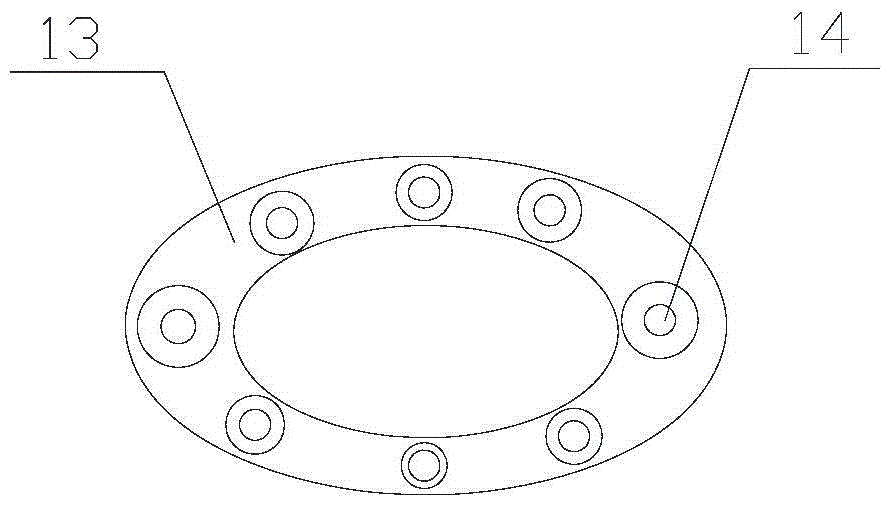

[0034] like figure 1 , figure 2 As shown, the rotary progressive forming device for magnesium alloy sheet metal tools of the present invention includes a frame and a forming tool head, and is characterized in that a lubricating oil spraying device is also arranged on the frame, and the lubricating oil spraying device is externally connected to the controller ; In the progressive forming process, the above-mentioned lubricating oil injection device is under the control of the controller 5, spraying lubricating oil towards the working end around the forming tool head, and forming a bubble-like oil film on the magnesium alloy plate blank.

[0035] The distance between the outlet end of the lubricating oil injection device and the working end of the forming tool head is greater than the radius of the bubble-like oil film.

[0036] The above-mentioned lubricating oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com