Automatic injection instrument for radioactive substances

A radioactive substance and automatic injection technology, applied in the field of radiation protection, can solve the problem of the lack of automatic equipment for injecting radioactive drugs, and achieve the effect of avoiding radiation and improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

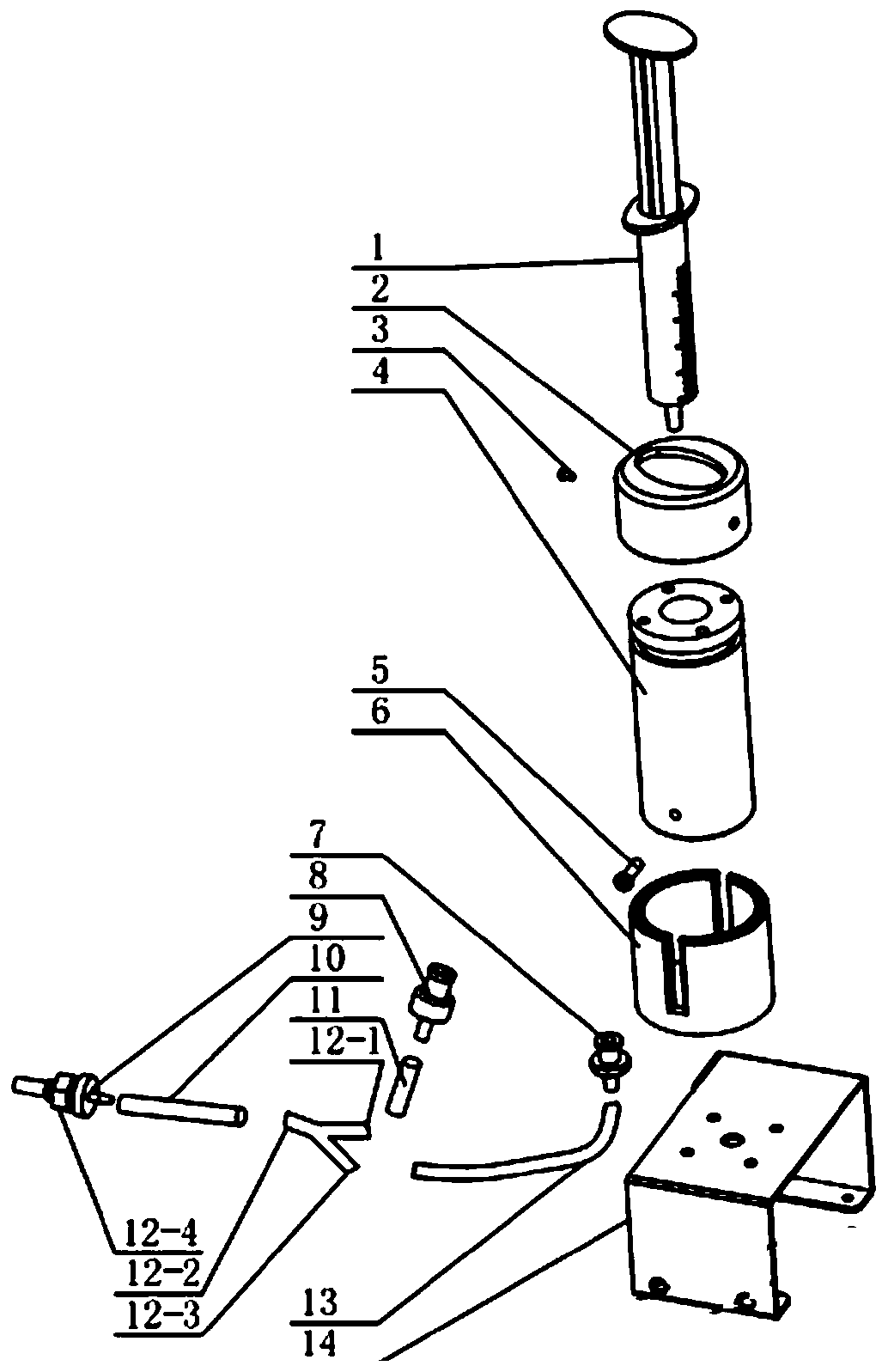

[0035] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

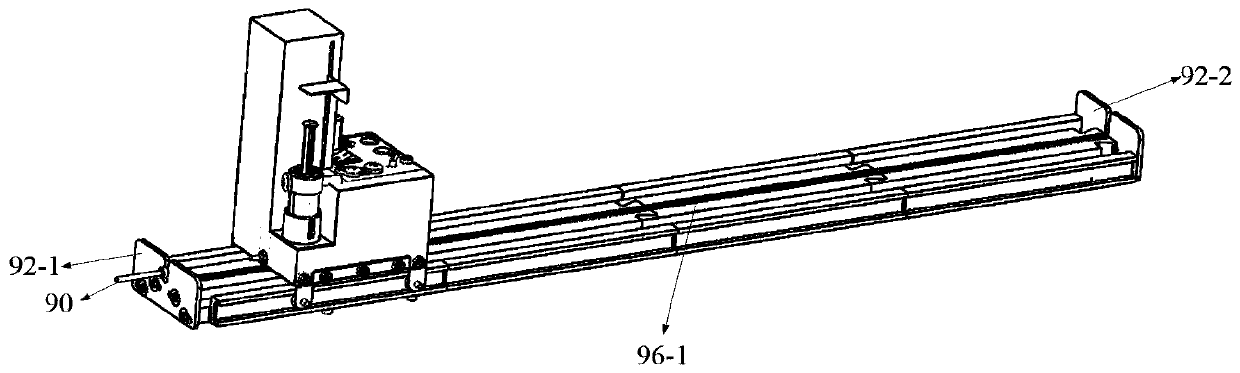

[0036] A: Power and stroke control part

[0037] Part 1: This part is the power compression and lifting part of the product, including standard motor, lead screw 29, lead screw slider 30, photoelectric touch panel 31, and syringe pressing sheet 33.

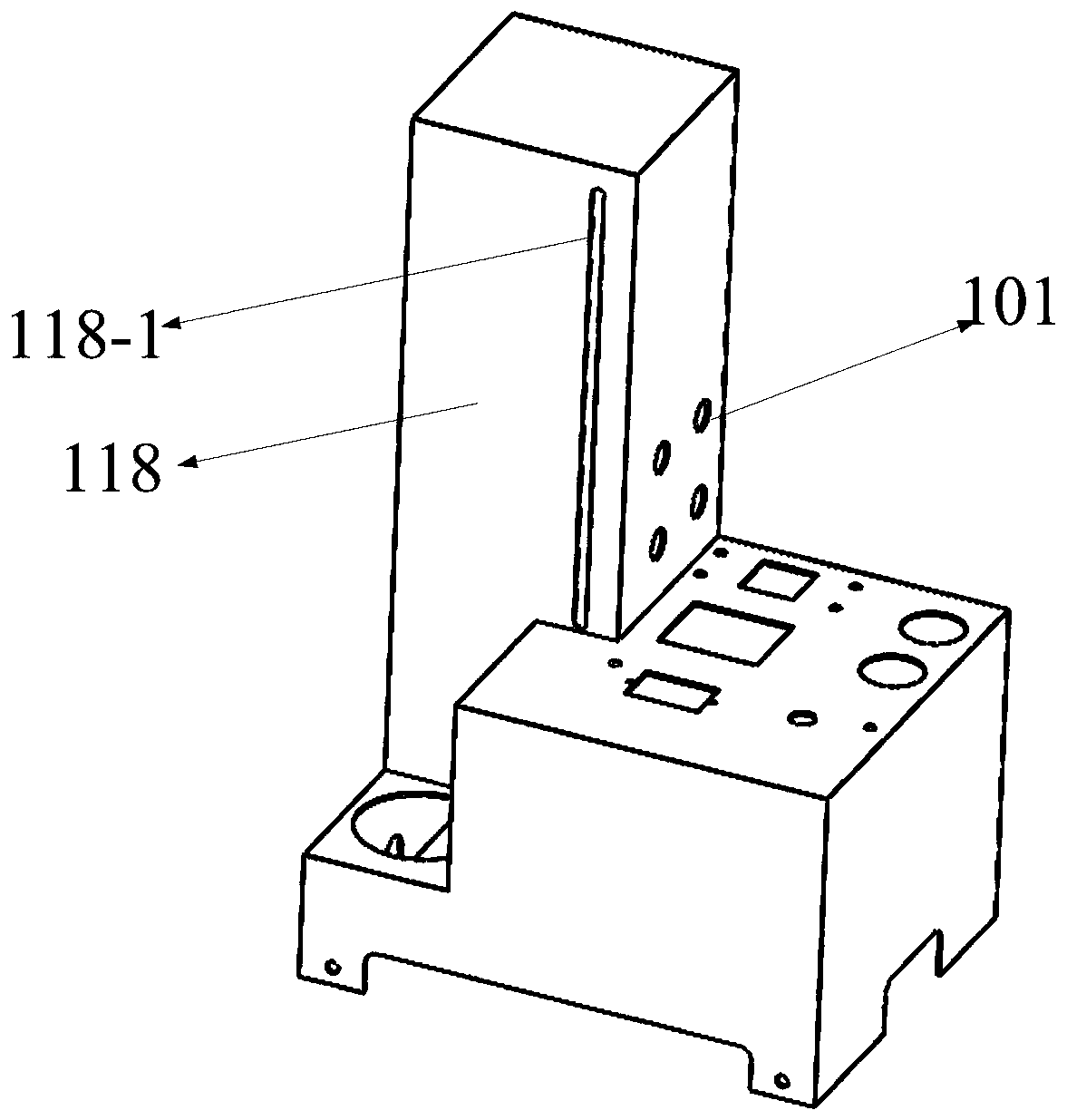

[0038] The standard motor controls the rotation of the lead screw 29, which drives the lead screw slider 30 to move up and down. The photoelectric touch sheet metal 31 is fixed on the side wall of the lead screw slider 30 with 2 photoelectric touch sheet metal screws 32 to play a role in controlling the photoelectric touch. When the control sheet metal 31 moves on the lead screw, its position is limited. The syringe presses the sheet metal 33 through the syringe and presses the side mounting hole 118-1 of the sheet metal. Use a screwdriver to pass the syringe and press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com