Patents

Literature

62results about How to "Increase jet power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

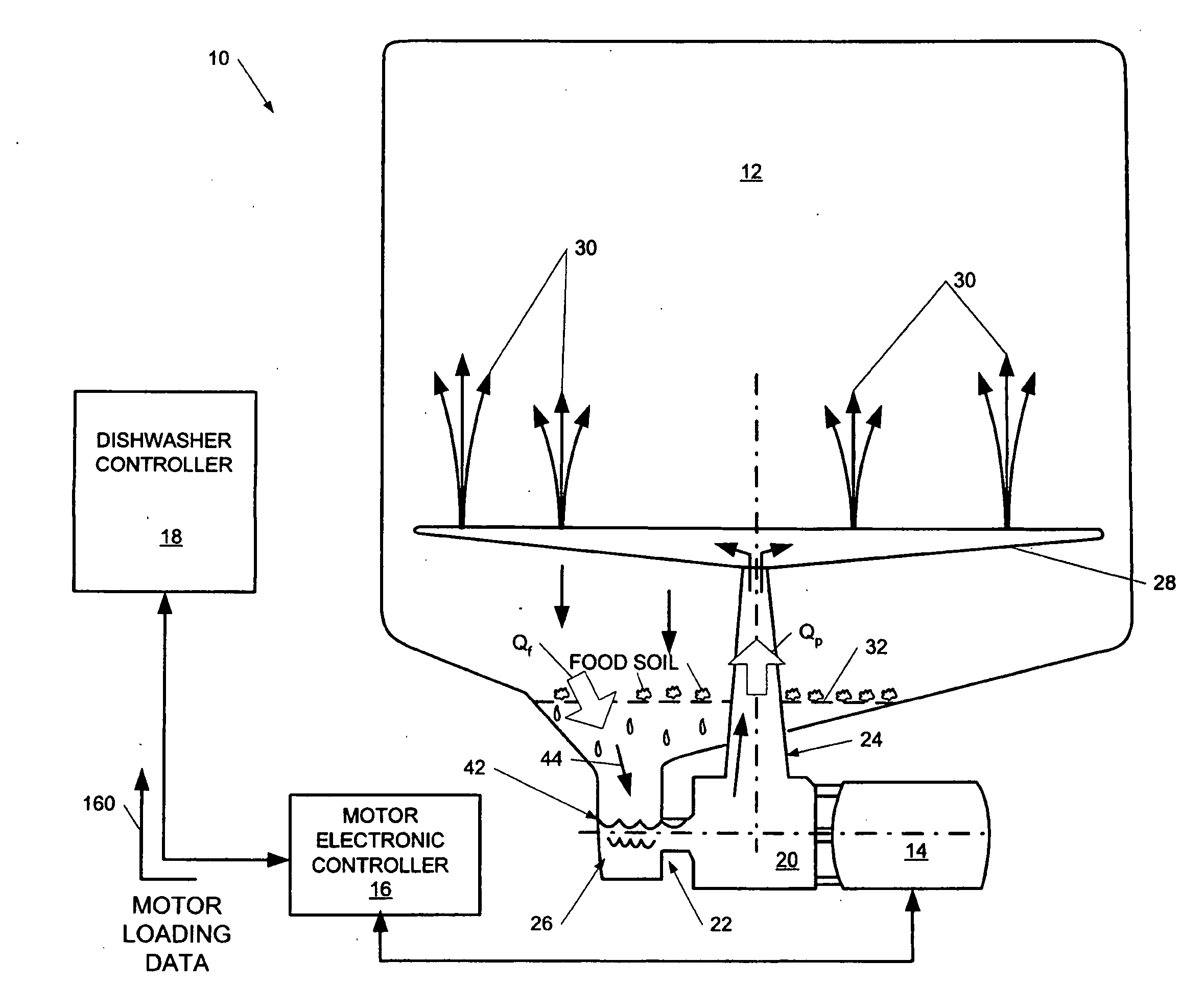

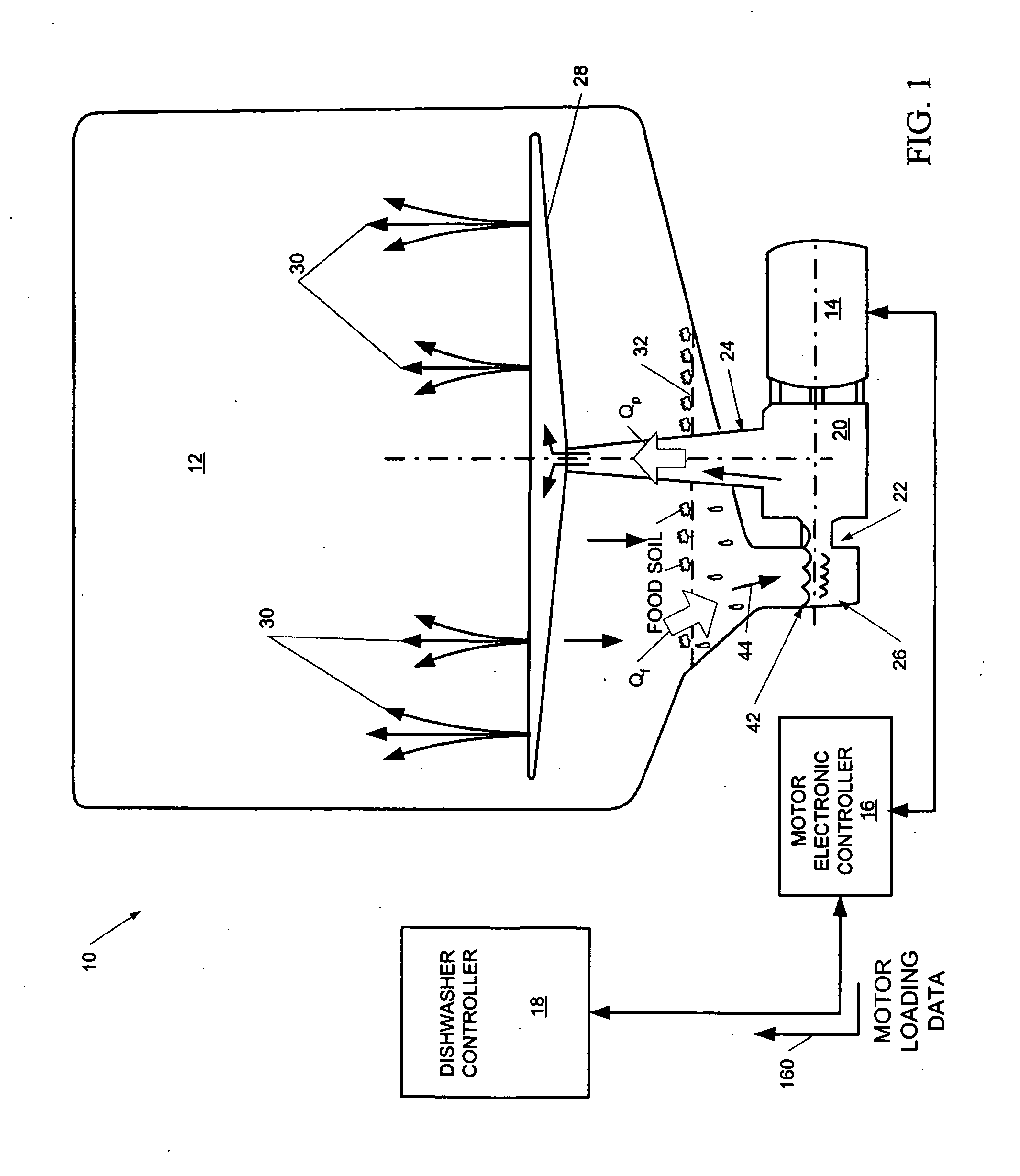

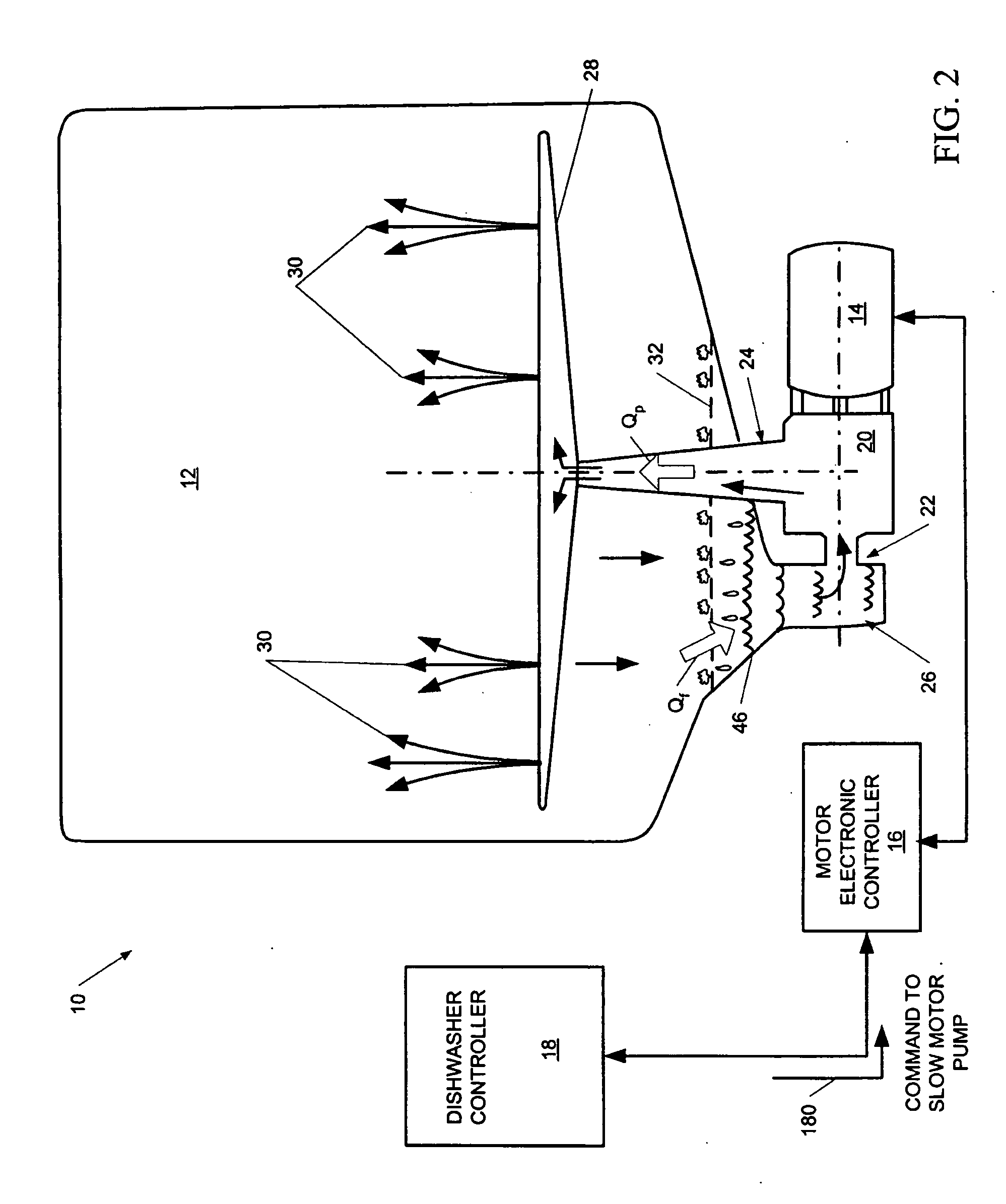

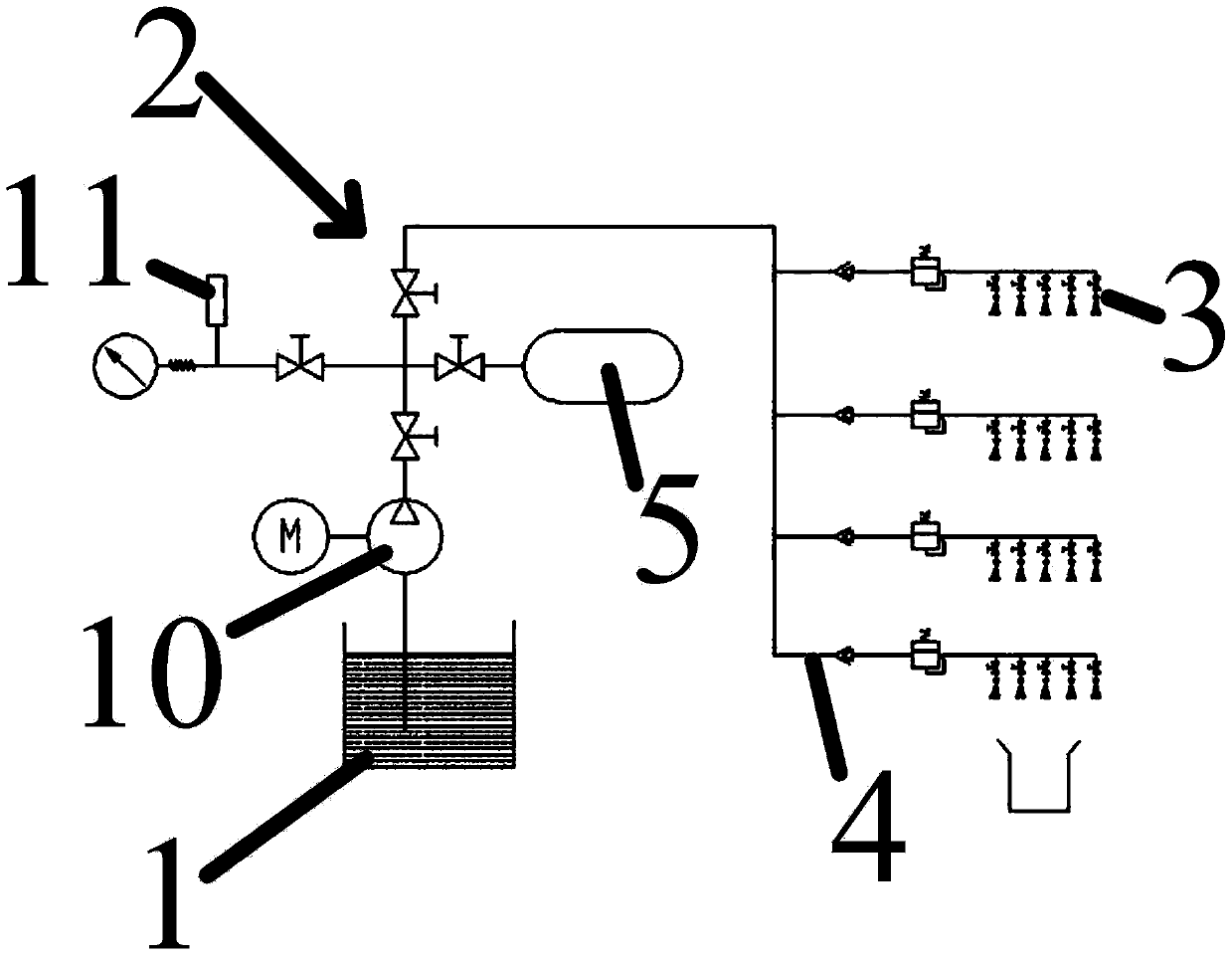

Dishwasher with controlled induction motor/pump

InactiveUS20060237044A1Easy to coverEasy to cleanAC motor controlAutomatic washing/rinsing machine detectionMotor speedMotor controller

A dishwasher having a speed-controlled induction motor coupled to a pump to drive the pump during dishwasher operation. A motor controller is connected to the induction motor to control the speed of operation of the induction motor. A dishwasher controller is connected to the motor controller for sending signals to, and receiving signals from, the motor controller during operation to control the motor speed. The flow rate of water through the pump discharge to a spray arm is controlled based on the phase of the wash cycle and the condition of the filter that blocks food debris from entering the sump. The motor speed is decreased to decrease the pump flow rate when the flow rate through the filter decreases in an early phase of the wash cycle. The motor speed is increased to increase the pump flow rate during later phases of the wash cycle. In steady state operation, the flow rate through the filter is matched to the flow rate through the pump discharge.

Owner:VIKING RANGE

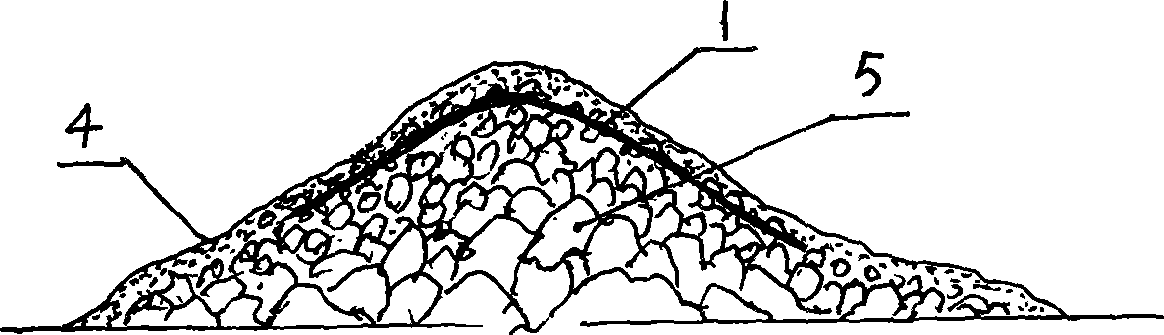

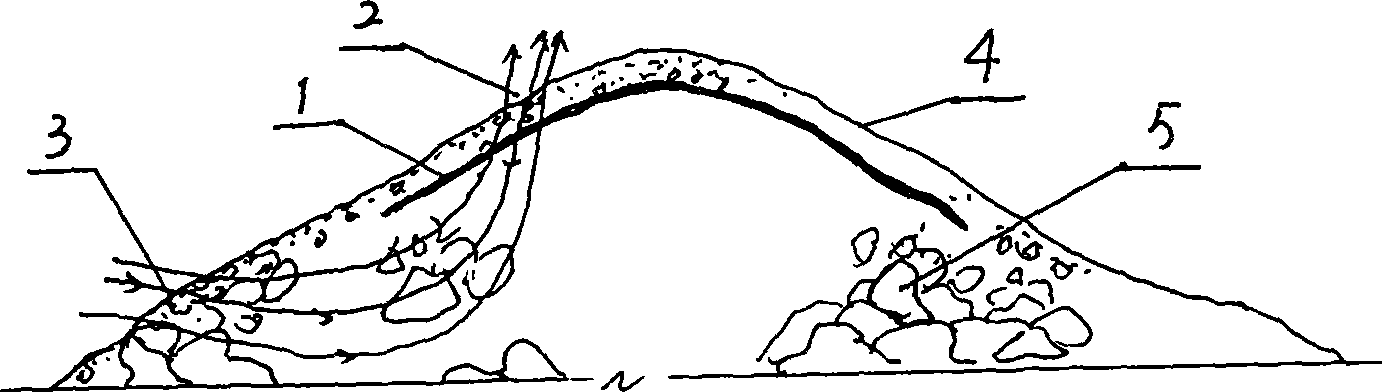

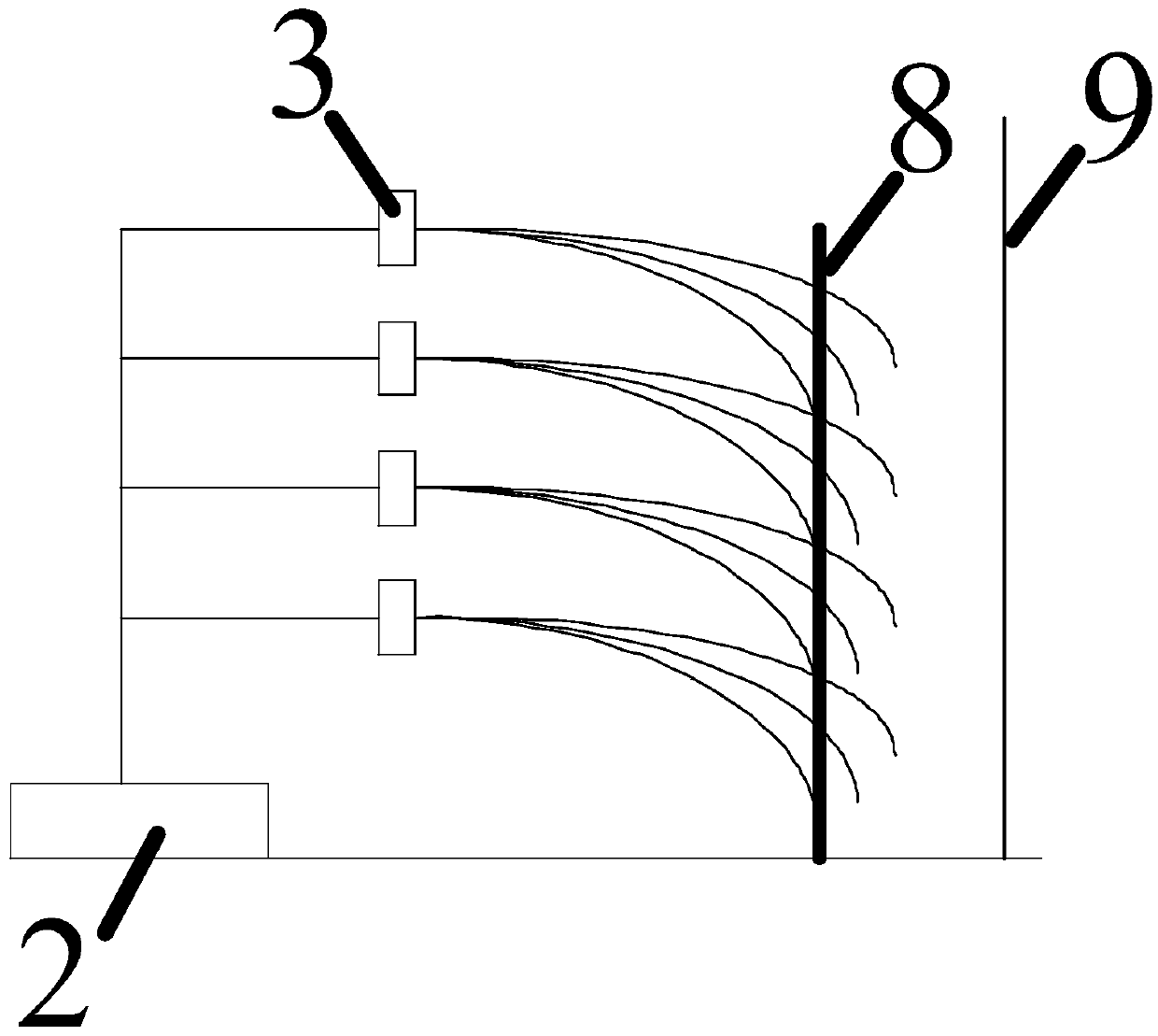

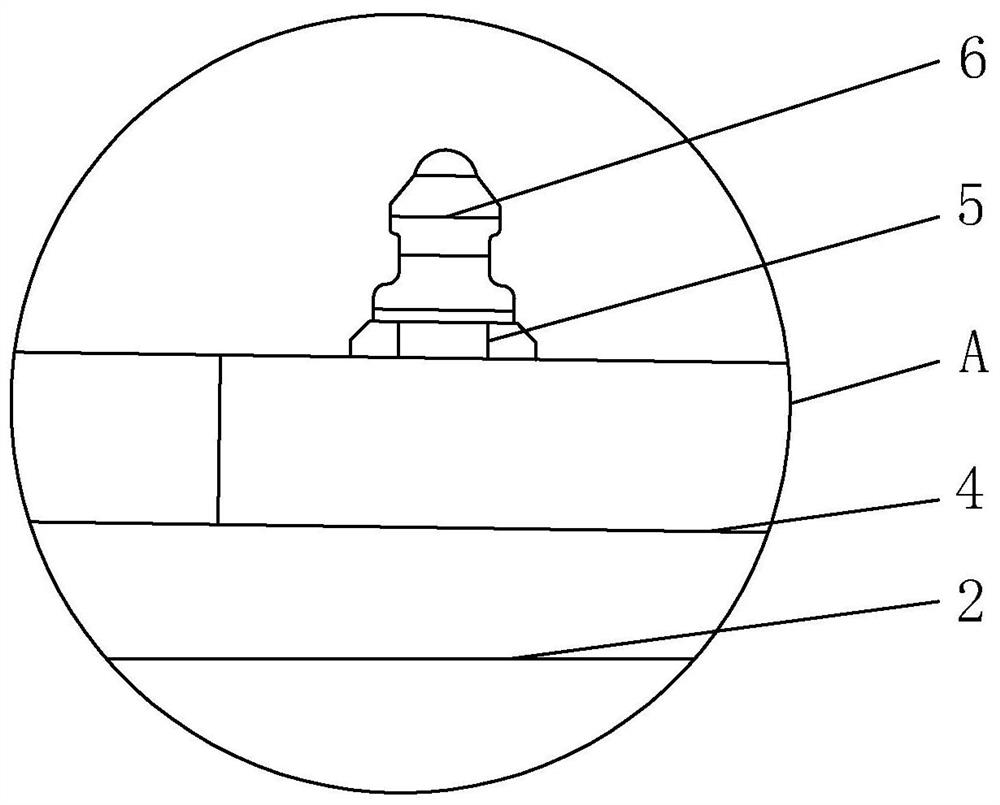

Method for comprehensively treating ecological environment of coal gangue hill

InactiveCN101519966AReduce flowAvoid formingUnderground miningSurface miningRevegetationEcological environment

The invention relates to a method for comprehensively treating the ecological environment of a coal gangue hill, which belongs to the field of mineral waste treatment and ecological environment restoration. The method mainly solves the problems of fire extinction, fire prevention and vegetation construction of the coal gangue hill. The method comprises the steps: the on-site reconnaissance of the coal gangue hill is carried out, and a construction operation plan is established; with fire prevention as principal and the combination of fire prevention and fire extinction, the fire prevention is crucial and is combined with the fire extinction, a thin layer of slurry is firstly sprayed on the coal gangue hill by a mechanical method to completely seal to form a sealing layer (8), transition slurry is sprayed on the sealing layer (8) to completely cover the sealing layer (8) to form a transition layer (9), slurry containing grass-shrub vegetation is spayed on the transition layer (9) to completely cover the transition layer (9) to form a planting layer (10); the contour line girdle band type operation in the spraying process is carried out from bottom to top to gradually and completely cover the hill, and different operating modes are selected according to practical conditions. The invention can not disturb the structure of the coal gangue hill, takes the fire prevention as the principal, combines the fire prevention with the fire extinction, has good and durable fire prevention effect, uses reliable and effective fire prevention and fire extinction measures as guarantee conditions to construct the planting layer, adopts grass-shrub plants, carries out hill sealing management and ensures vegetation restoration; in addition, the method uses the prior specialized mechanical devices to carry out construction operation, is easy to implement, has little difficulty, high efficiency and low investment and can ensure treatment effect.

Owner:赵平 +1

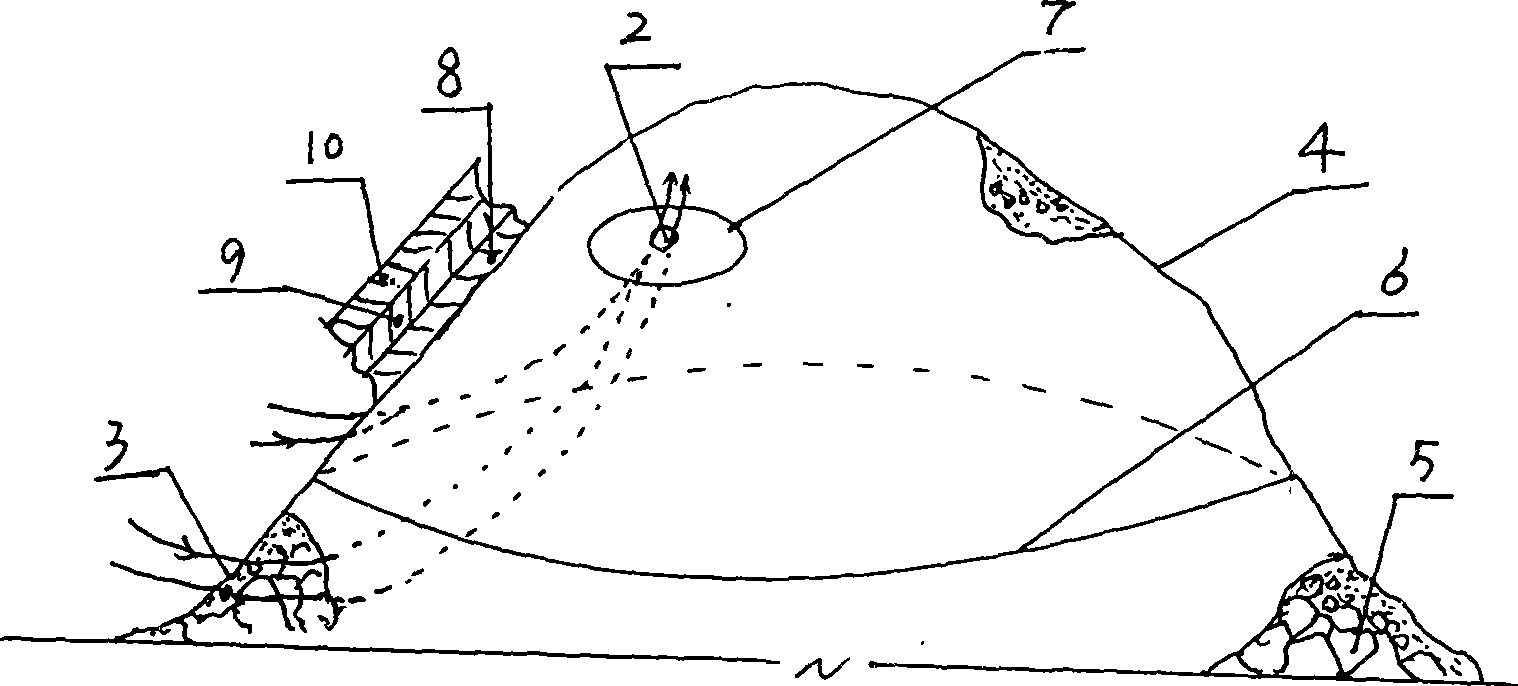

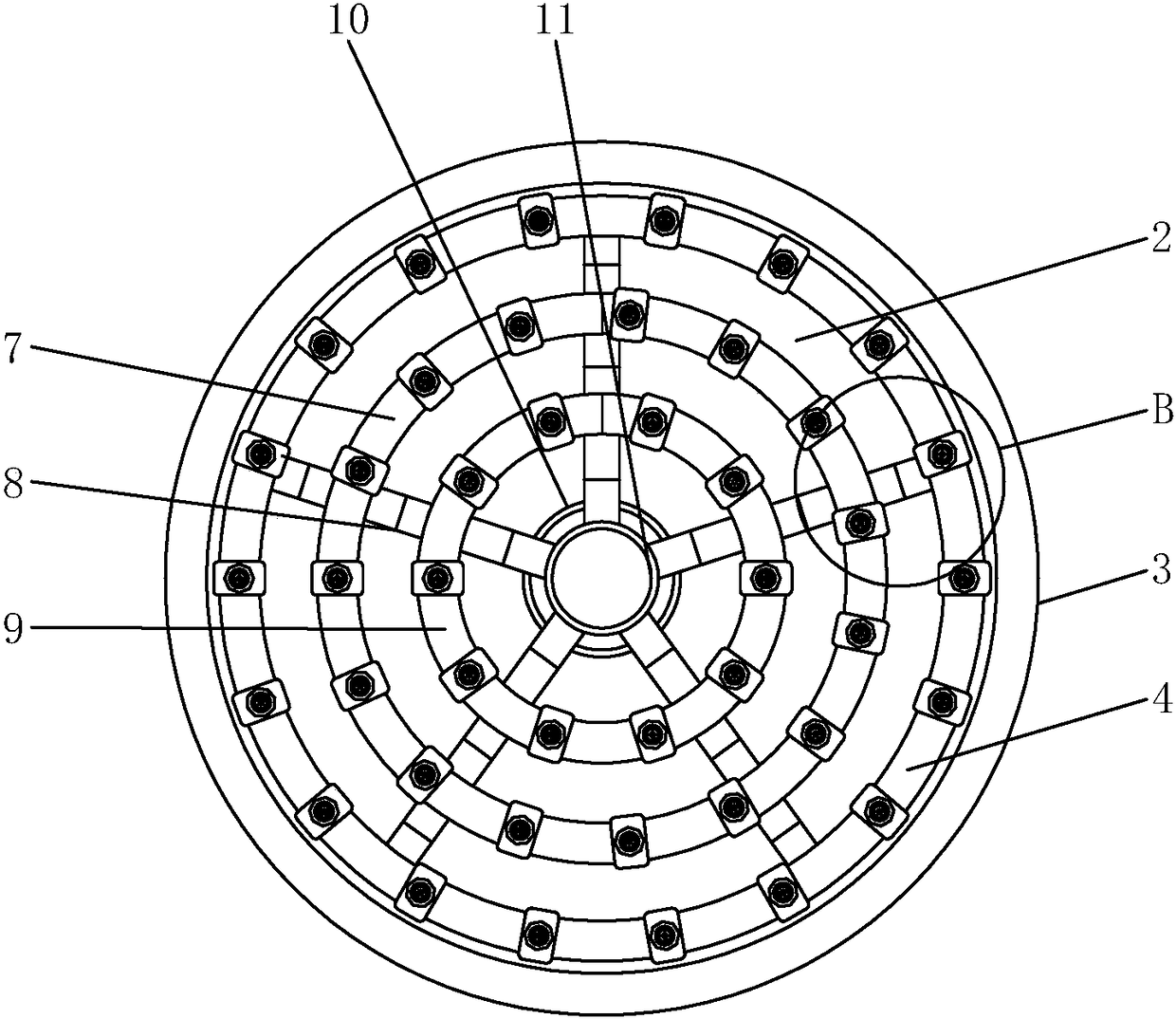

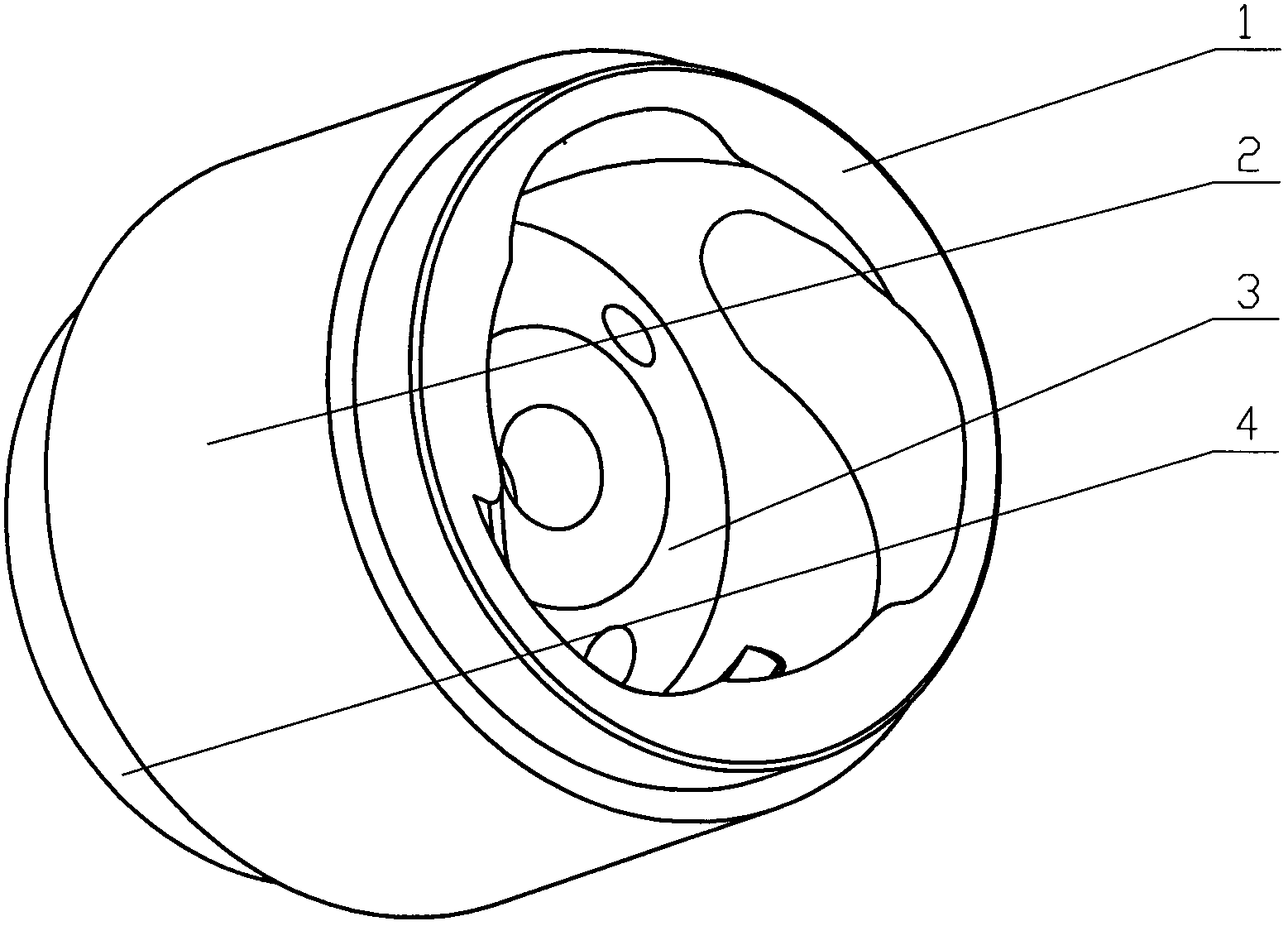

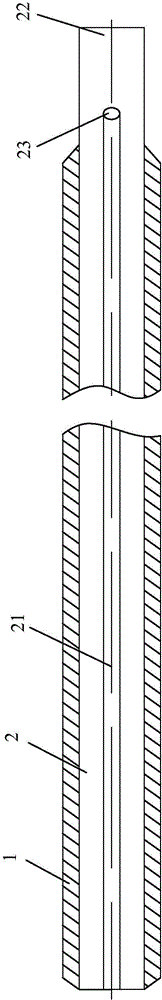

Spray tube electrospinning head

InactiveCN103422180AIncrease speedIncreased polarizationSpinnerette packsFilament/thread formingTaylor coneElectric field

The invention discloses a spray tube electrospinning head, and belongs to the field of electrospinning. The spray tube electrospinning head comprises an electrospinning head body, wherein a solution connecting portion is arranged on the tail portion of the electrospinning head body, a horn-shaped spinning nozzle, a polarization throat port and a solution chamber hole are formed in the electrospinning head body in sequence from top to bottom, and are communicated with one another, the inner wall face of the spinning nozzle is a circular-arc curved surface which gradually expands outwards, the port diameter of the polarization throat port is smaller than the hole diameter of the solution chamber hole, the outer wall of the head portion of the electrospinning head body is of a cone shape, and the diameter of the cone gradually decreases outwards. The spray tube electrospinning head can increase the forming speed of a Taylor cone, improve the velocity of a solution when the solution passes through the spray tube electrospinning head, and is better in electric field directivity.

Owner:常州市亚国新能源科技有限公司

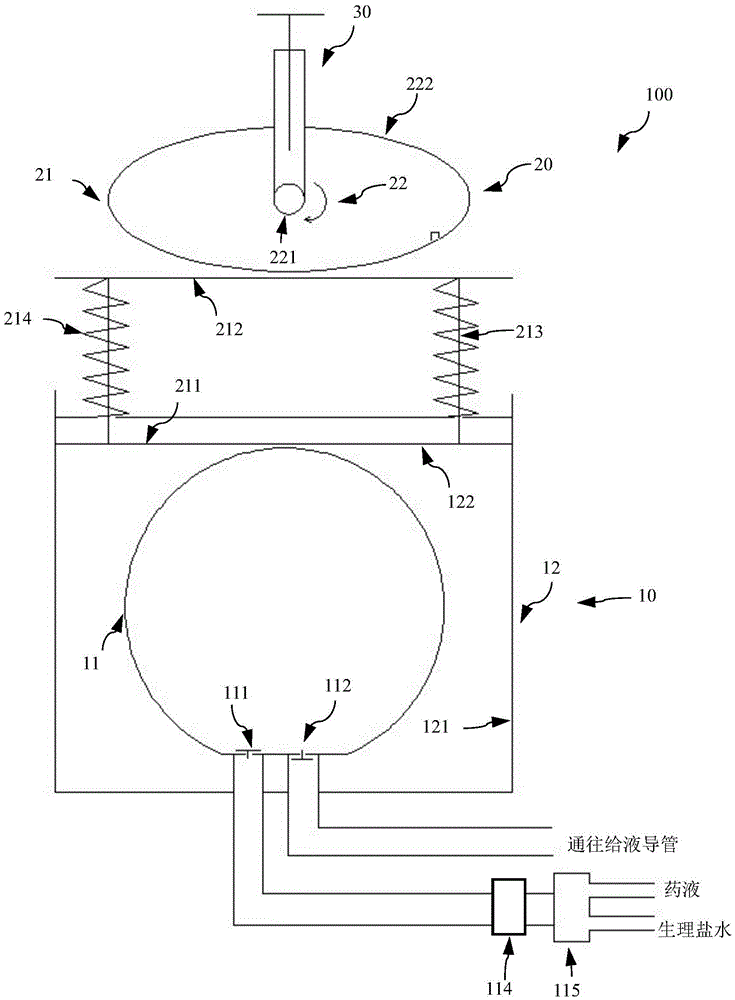

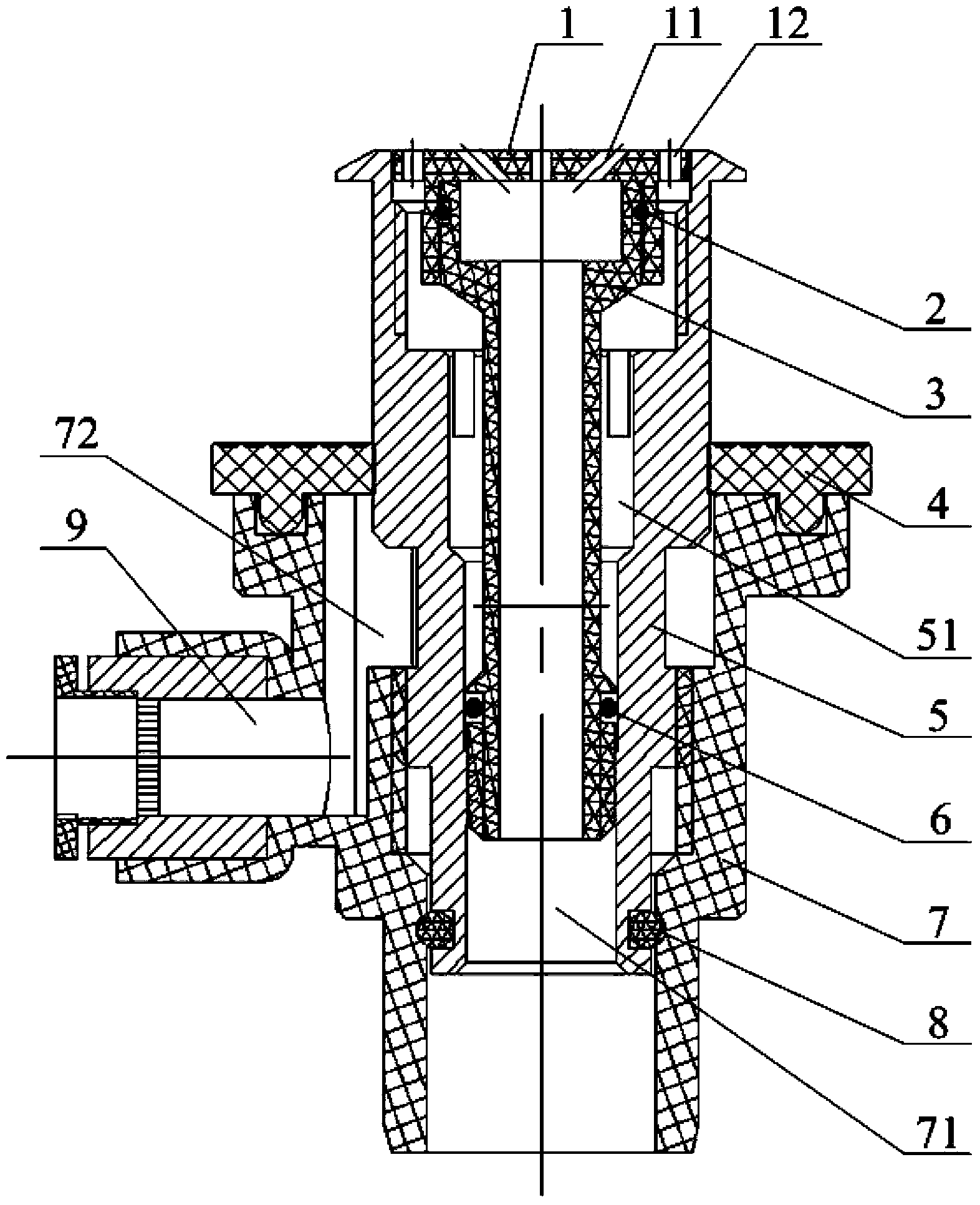

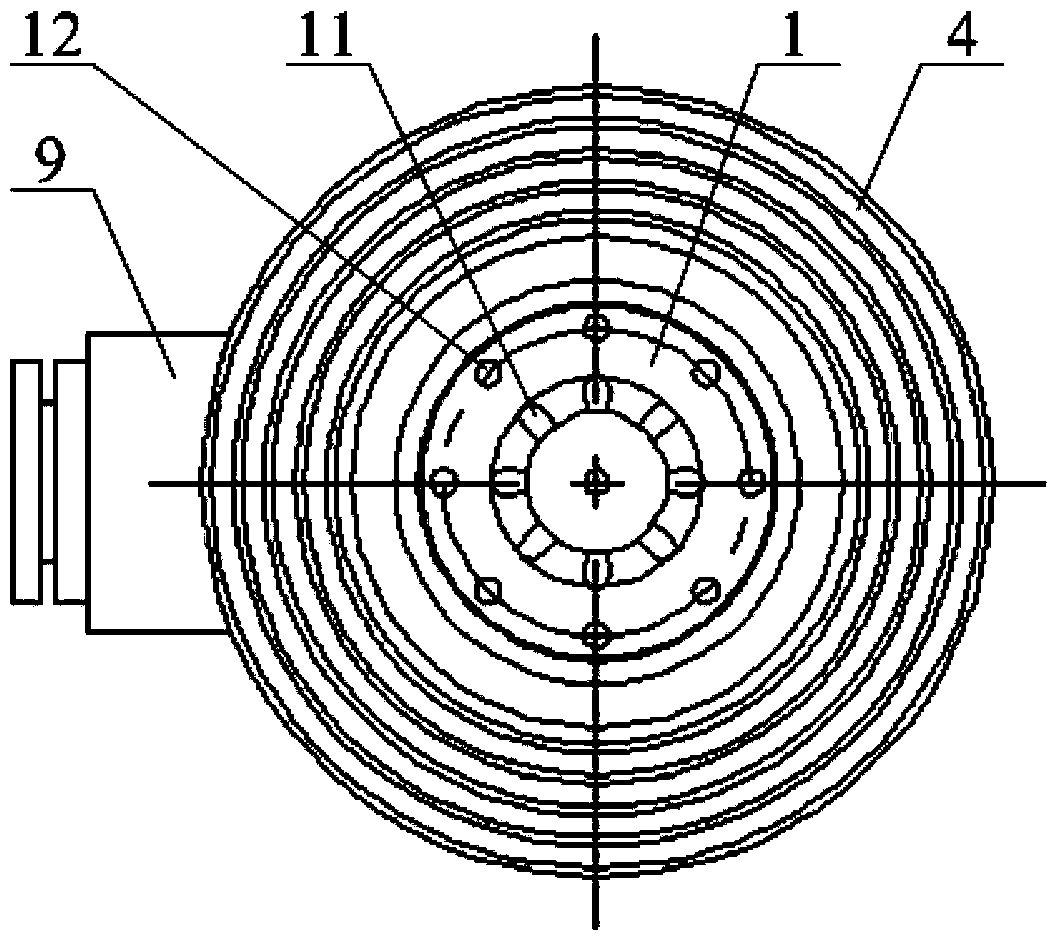

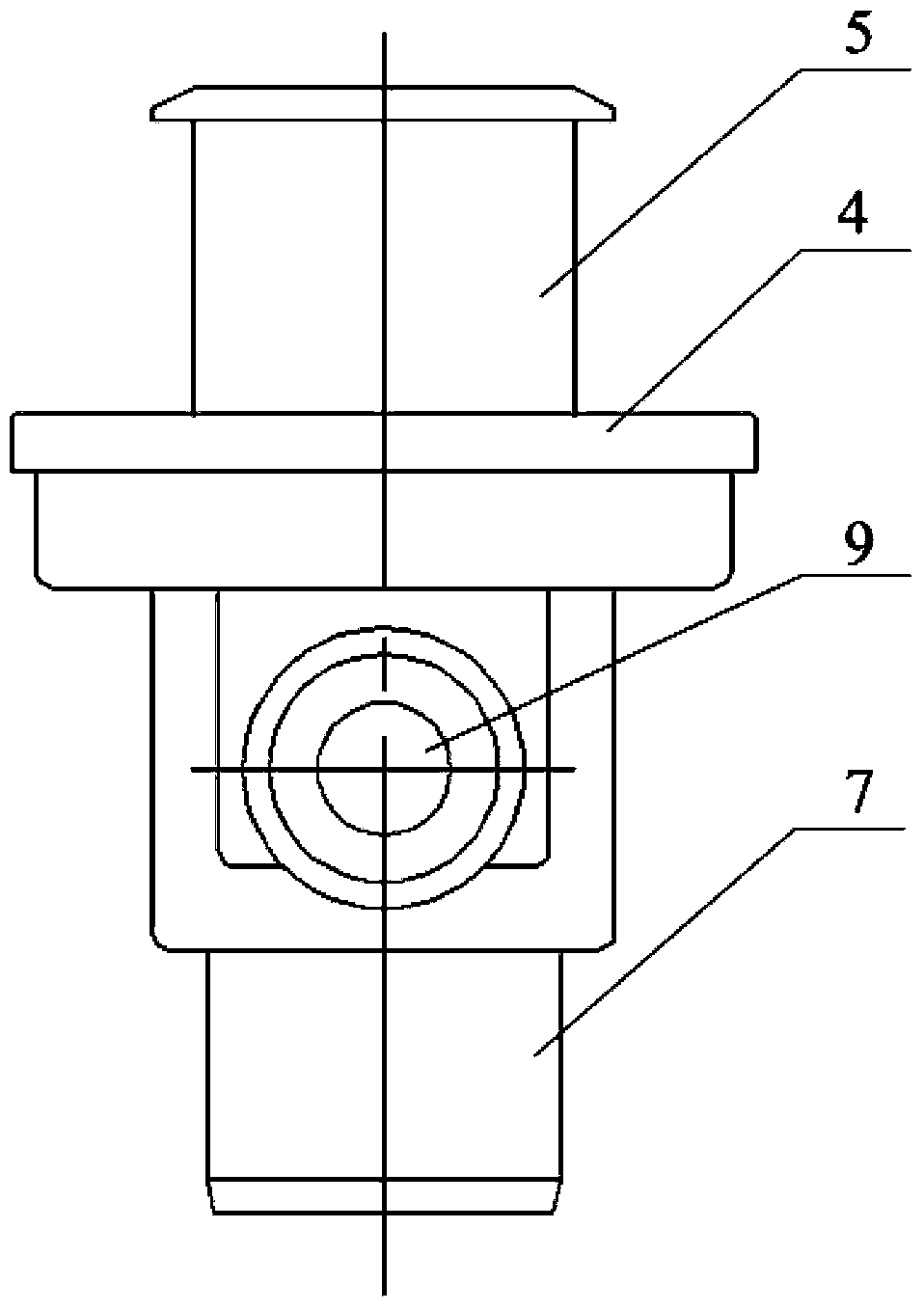

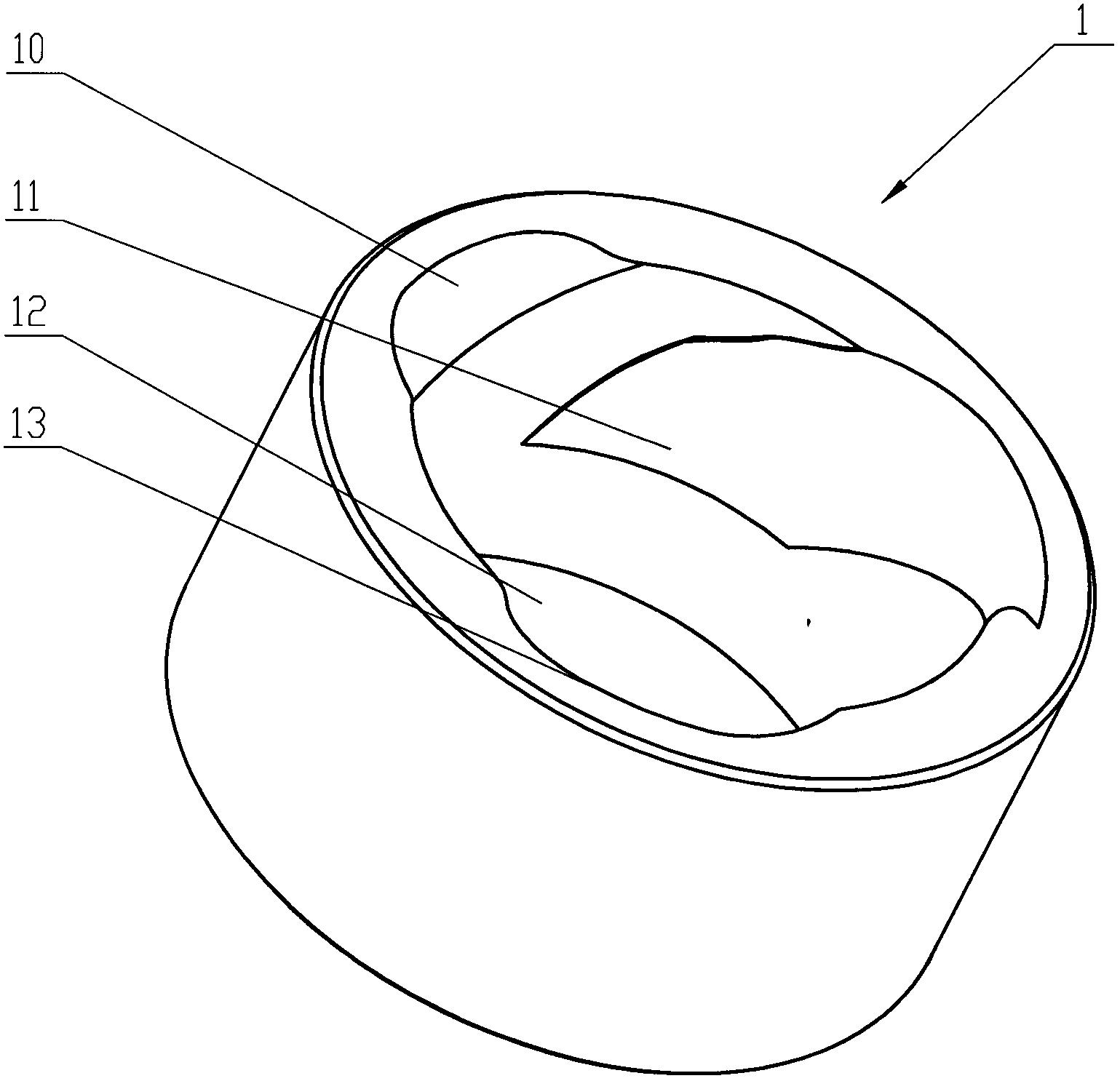

Pulse transfusion micropump

The invention provides a pulse transfusion micropump which is used for delivering medical solution or normal saline pulse to a solution catheter which is disposed in a vessel. The pulse transfusion micropump is characterized by including the following: a medicine solution cavity unit for accommodating medicine solution, the medicine solution cavity provided with a solution inlet and a solution outlet thereon, the solution inlet provided with a one-way valve thereon for defining one way entrance of the medicine solution, the solution outlet provided with a one-way valve thereon for defining one way exit of the medicine solution; a pulse excruciating unit which is communicated with the medicine solution cavity and is used for excruciating the medicine cavity and includes a reciprocating piece and a power source, the reciprocating piece being communicated with the medicine solution, the power source providing power to the reciprocating piece. The pulse transfusion micropump has a large injection force in terms of the medicine solution, can perform solution washing and solution discharging, which greatly facilitates medicine feeding of medical staff. The medicine solution cavity of the pulse transfusion micropump has no moving pieces, no wearing, and does not introduce material pollution.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

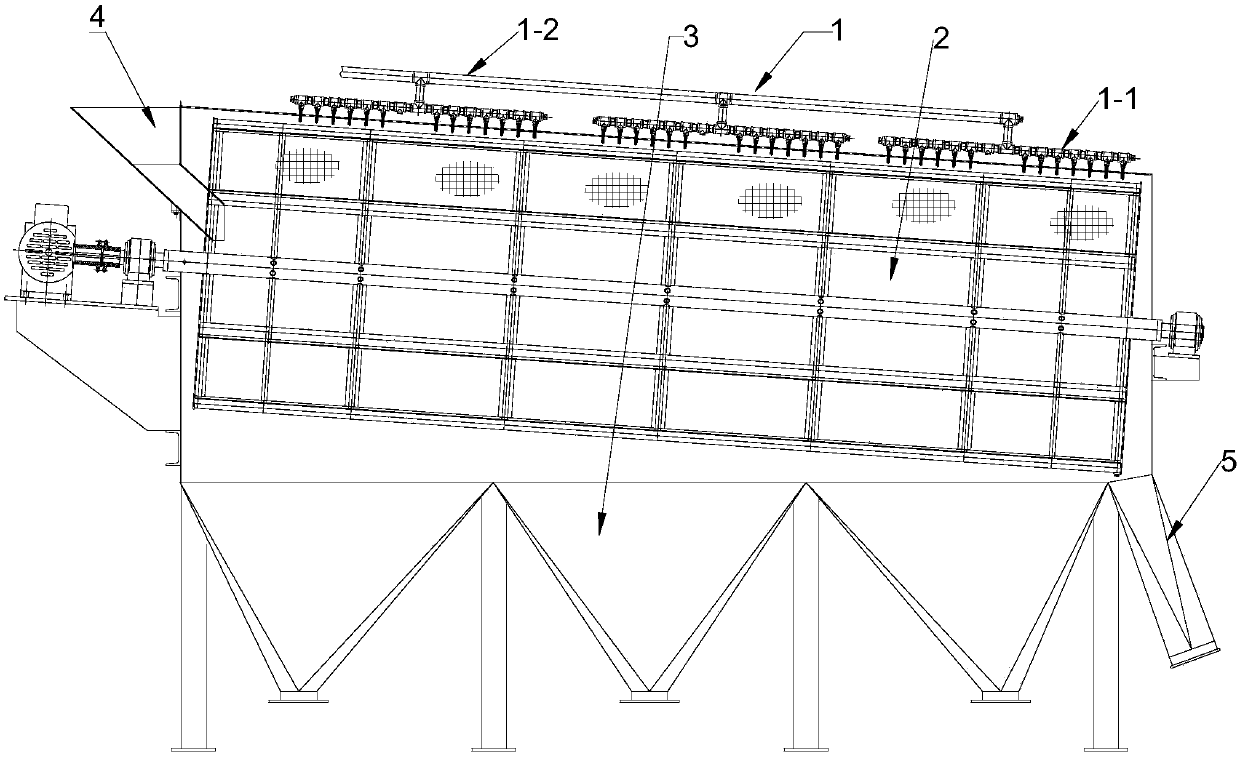

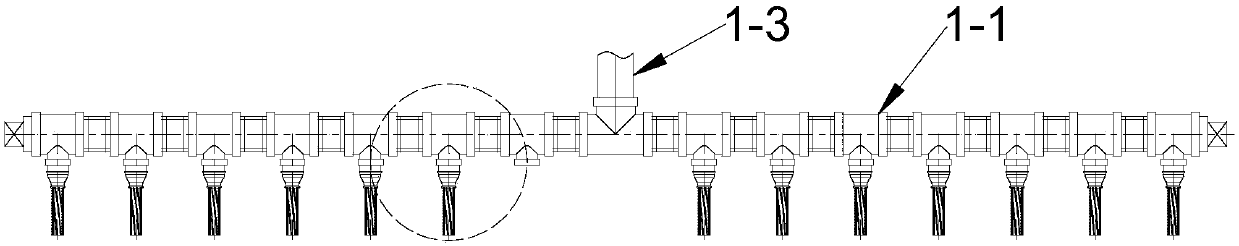

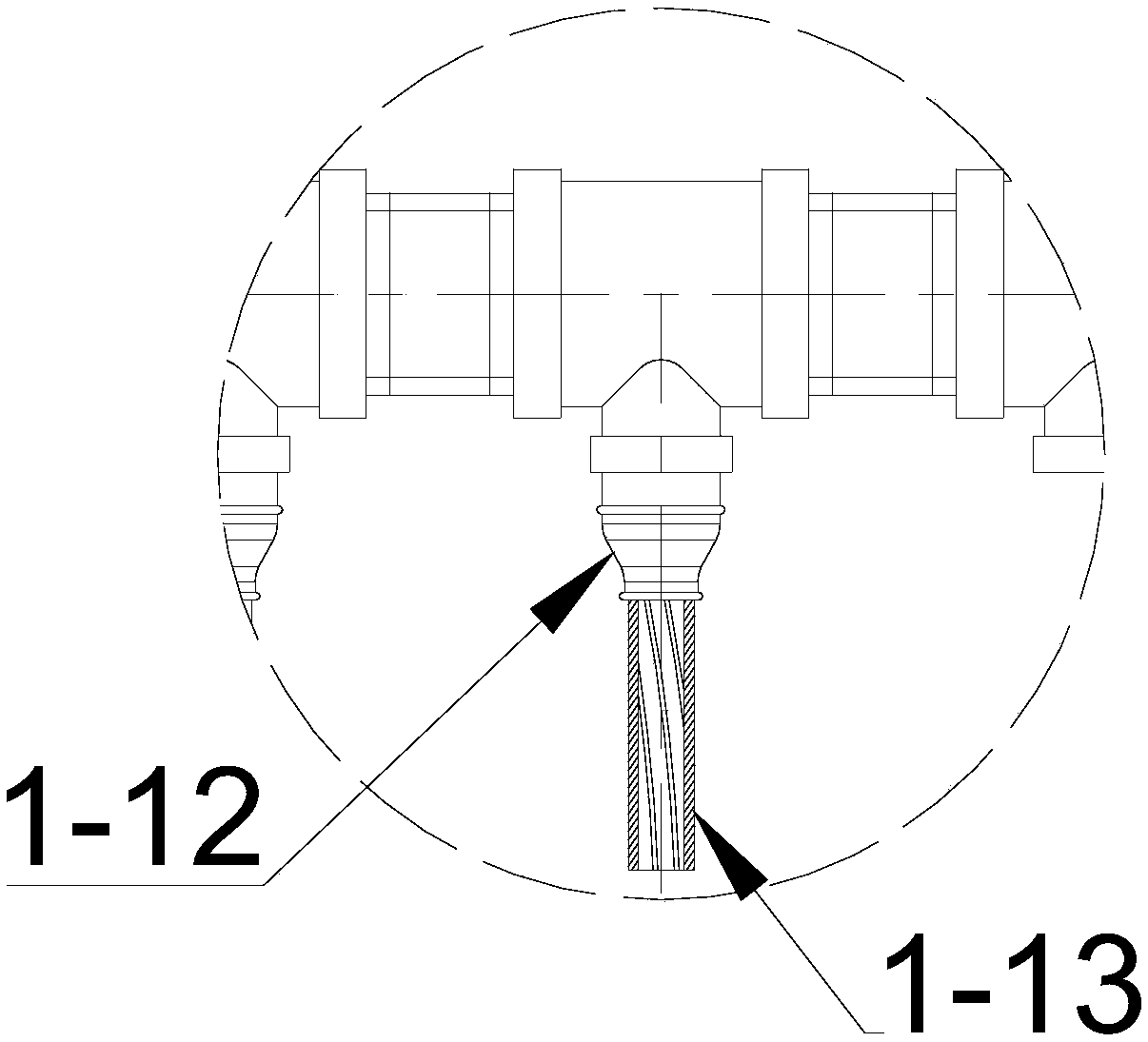

Non-clogging roller screen

The invention relates to the technical field of roller screens, in particular to a non-clogging roller screen. The non-clogging roller screen comprises a barrel, a feed port, a screen underflow discharge opening, and a coarse material discharge opening, and is characterized by further comprising a high pressure air spray device used for conveying high pressure air; the high pressure air spray device is arranged above the barrel in a suspending manner. Compared with the prior art, the non-clogging roller screen provided by the invention has the advantages that the high pressure air spray deviceis added above the barrel, so that direct spray force for the screen is increased, high speed airflow can produce certain vibration force on the screen, therefore, screen clogging can be further prevented, and the work efficiency is improved.

Owner:陈健康

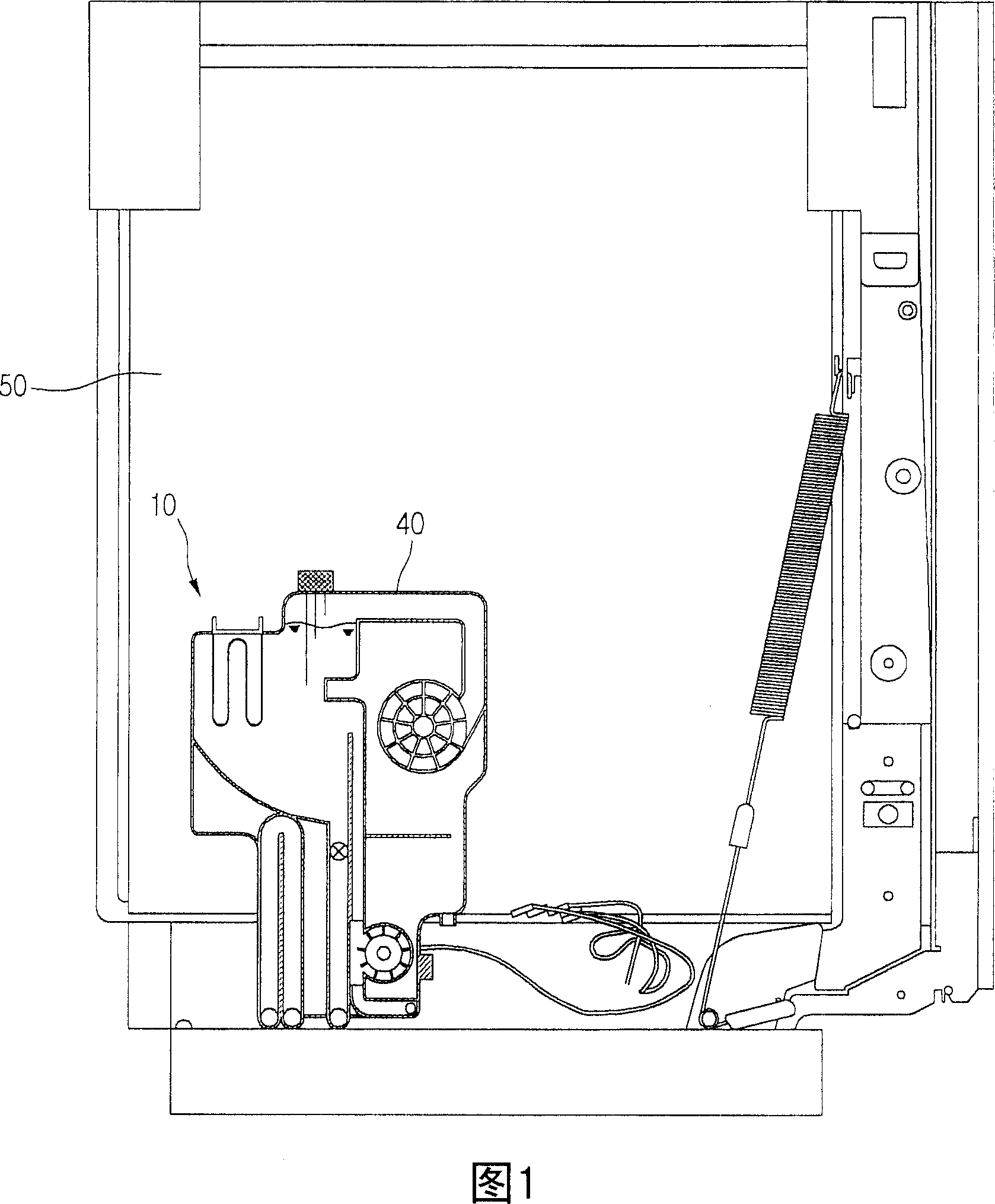

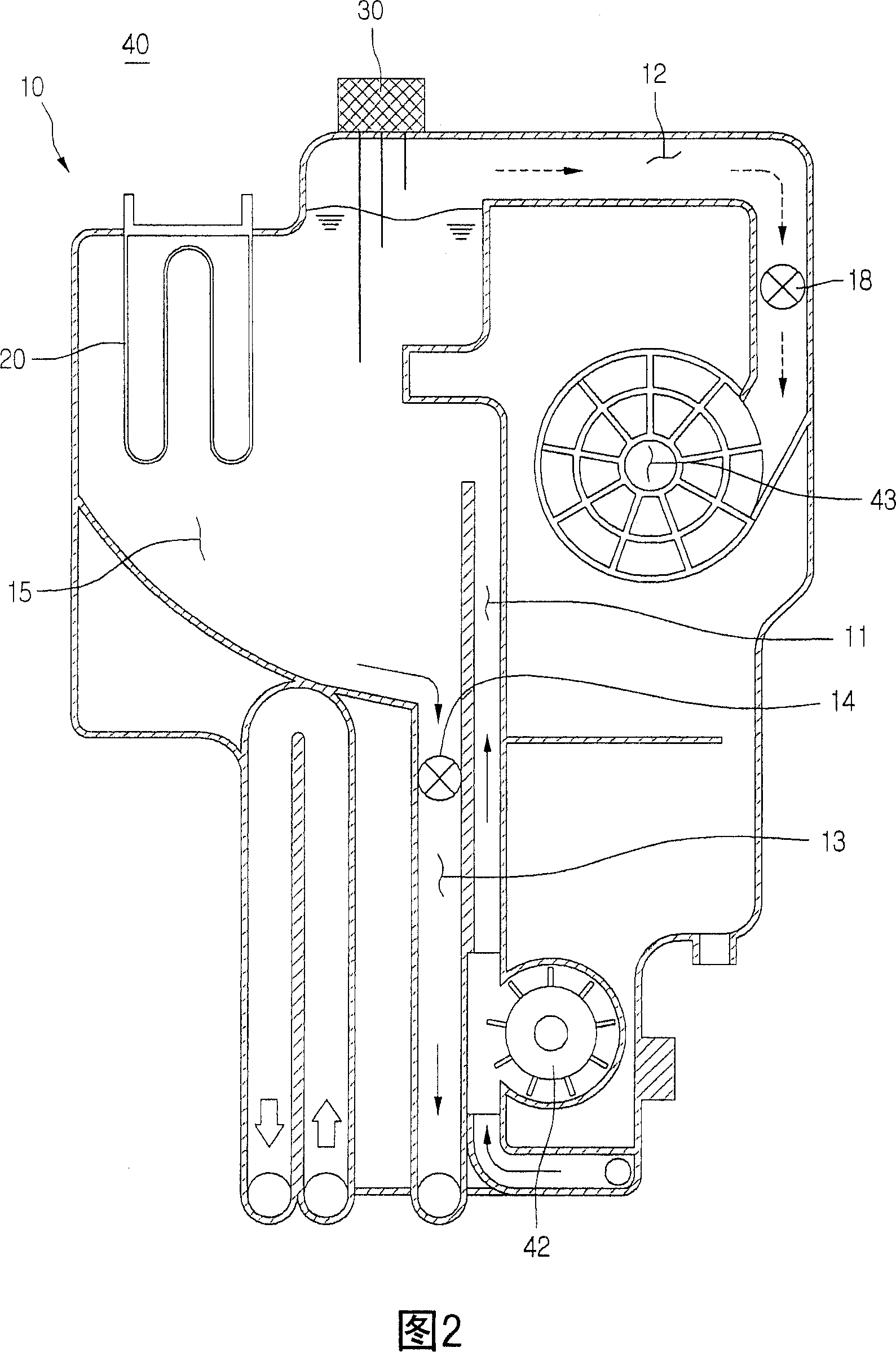

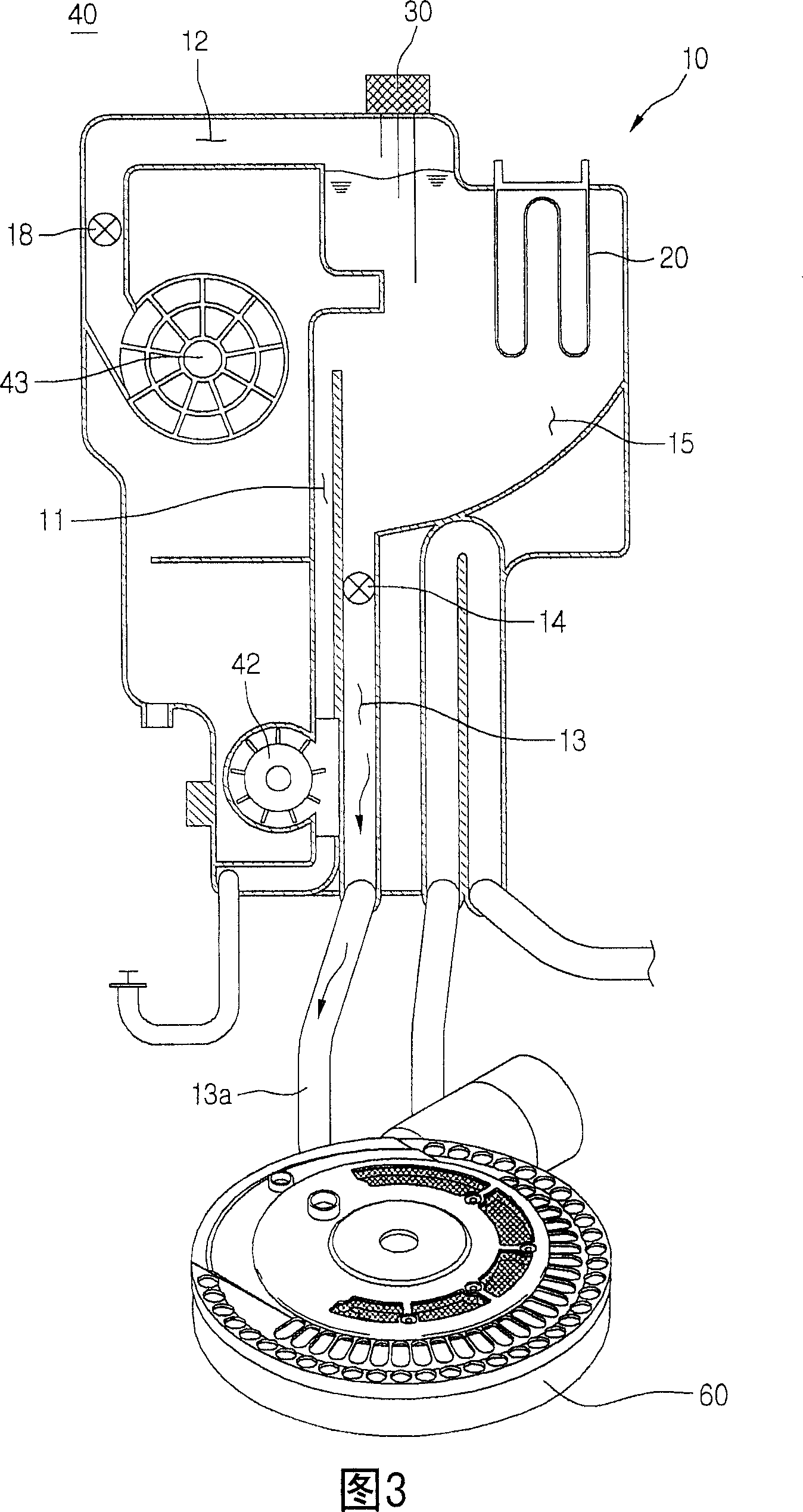

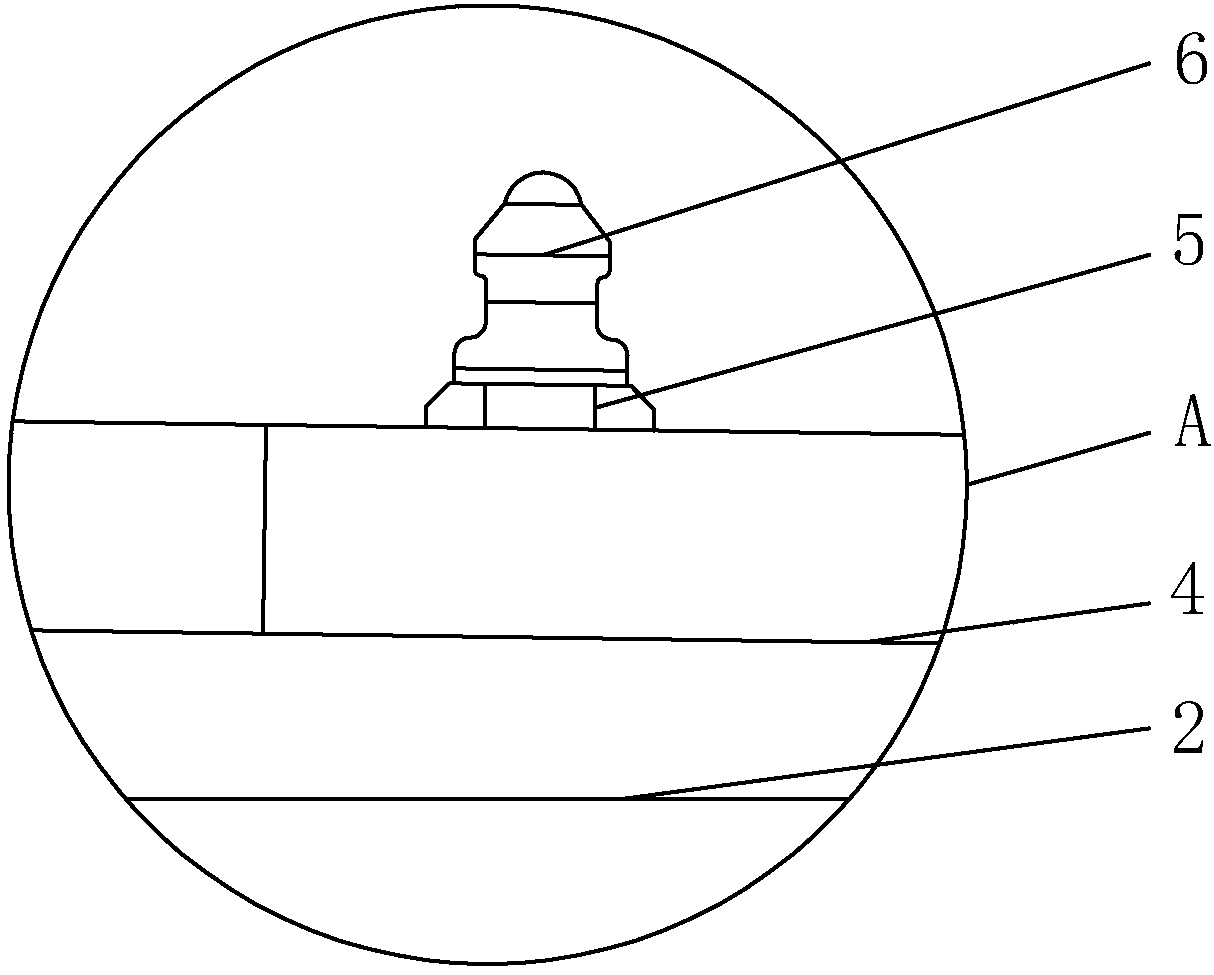

Dishwasher and method of supplying water of dishwasher

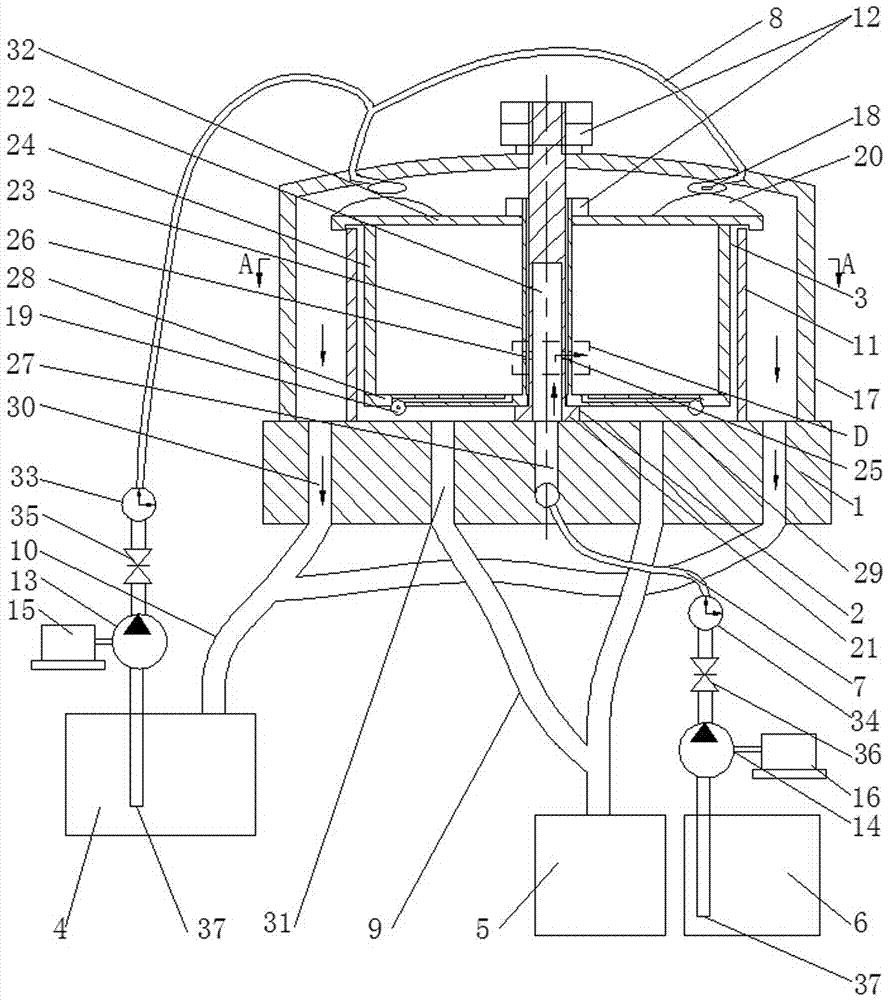

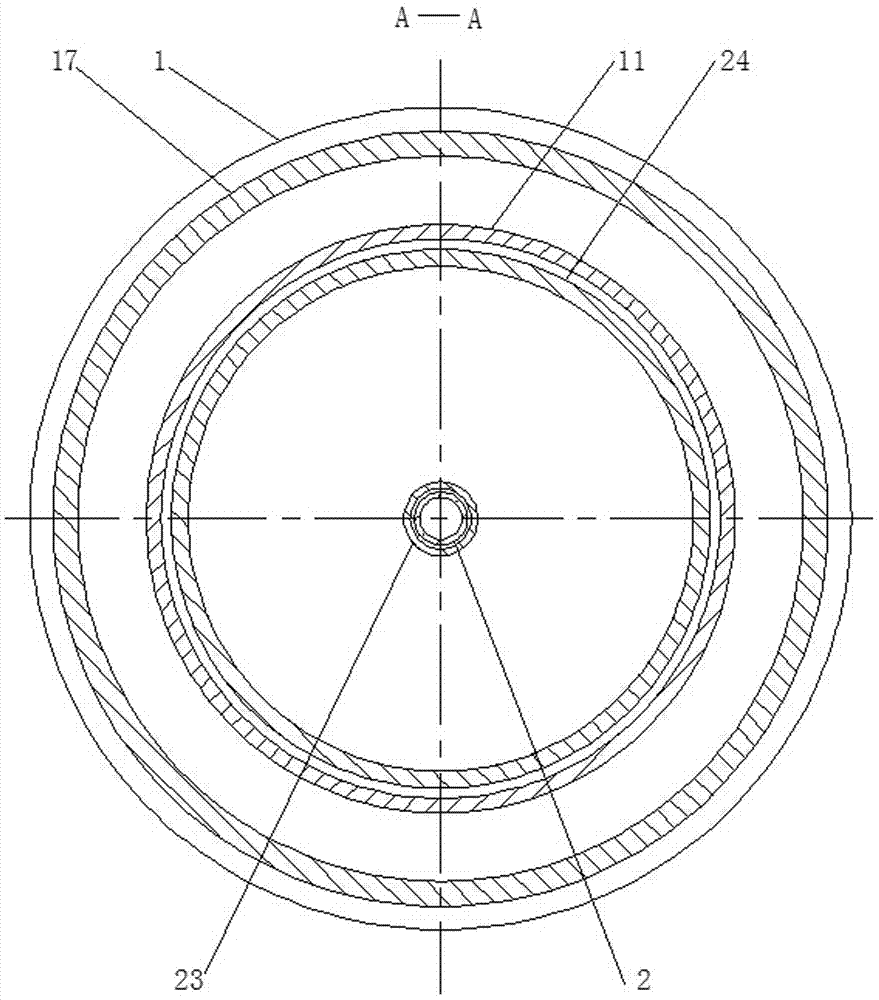

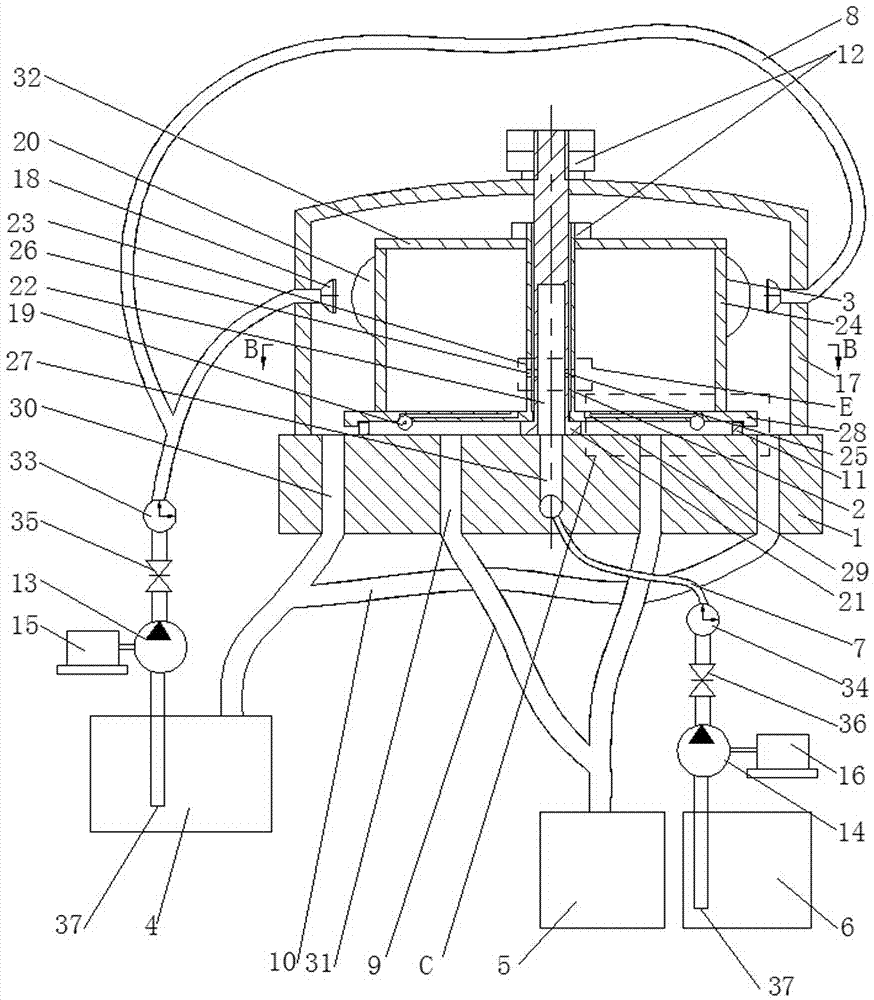

InactiveCN1973751AIncrease jet powerShorten the lengthCleaning equipmentTableware washing/rinsing machinesEnvironmental engineeringGenerating unit

Provided are a dishwasher and a method of supplying water in the dishwasher. The dishwasher includes a tub enclosing a washing chamber, a sump holding washing water to be supplied to the tub, and an air brake assembly having a steam generating unit that heats the washing water to be supplied to the tub.

Owner:LG ELECTRONICS INC

Simulation rainfall test device used for electric device

PendingCN105572497AImprove workabilityReduce wasteEnvironmental/reliability testsHigh pressureWater spray

The invention relates to a simulation rainfall test device used for an electric device. The test device comprises a water tank, a water transmission member and water spraying mechanisms, which are successively arranged. The water transmission member comprises a water pump and a buffering assembly. The water pump is connected with the water tank and parallel-connected water spraying branches. The buffering assembly is arranged between the water pump and the buffering assembly. Each of the water spraying members comprises a valve and a nozzle movably connected with a corresponding branch. According to the invention, it is ensured that a high-voltage electric device can get wet in the simulation rain satisfying requirements during an electric test in a rainfall state and reliability of the device in a natural rainfall condition is verified.

Owner:CHINA ELECTRIC POWER RES INST +1

Multifunctional water-powered scrubber

InactiveCN102273974AFew partsSimple structureMovable spraying apparatusBathroom accessoriesWater sprayBathing

The invention discloses a multifunctional water-driven rubdown device, and belongs to a bathing appliance for daily life. The rubdown device mainly consists of a handle and a rubdown head, wherein the rubdown head is provided with a rotor and a brush bundle or a sponge strip embedded into the front side of the rotor, the rotor is sleeved on a fixed column of the handle, a reversing sleeve which slides axially is arranged between the rotor and the fixed column, a reversing sheet is arranged at the inner end of the reversing sleeve, the outer end of the reversing sleeve is connected with a conversion button with a water spray hole, a drainage cover connected with a shell of the head of the handle is arranged at the edge of the rotor, and an oblique nozzle is arranged on a lug boss at the inner side of the drainage cover. The rubdown device has simple structure, and is easy to manufacture and low in cost; during bathing, the conversion button is pulled outwards, and water is sprayed in the center, so that the rubdown device plays a role in powerful flushing; the conversion button is pushed inwards, and the rotor rotates, so that the rubdown device achieves the effects of removing dirt and massaging while flushing and rubbing; and the rubdown device is convenient to use, is multifunctional, and is particularly suitable for the old and the handicapped.

Owner:沈兆棣

Intelligent spraying system and control method for same

InactiveCN109276736ALong spray strokeWide range of sprayingUsing liquid separation agentAtomized substancesElectricityMoisture sensor

The invention discloses an intelligent spraying system and a control method for the intelligent spraying system. The intelligent spraying system comprises a cloud server, an intelligent spraying device, a control module, a sensor module, a network module and an intelligent terminal, wherein the control module is electrically connected with the cloud server, the intelligent spraying device, the sensor module and the network module, the cloud server is connected with the intelligent spraying device and the network module, and the network module is in communication connection with the intelligentterminal; and the sensor module comprises a temperature sensor, a dust concentration sensor, a humidity sensor and a satellite positioning sensor. The control method comprises the following steps that S1, the geographical location information of a garbage disposal site, and the dust concentration, temperature and humidity information in the external environment of the geographic position are acquired, and the difference values of the dust concentration, temperature and humidity inside and outside the garbage disposal site are compared; and S2, the cloud server feeds back the different movements performed by the intelligent spraying system to the intelligent terminal.

Owner:ZHUHAI C R E S TECH CO LTD

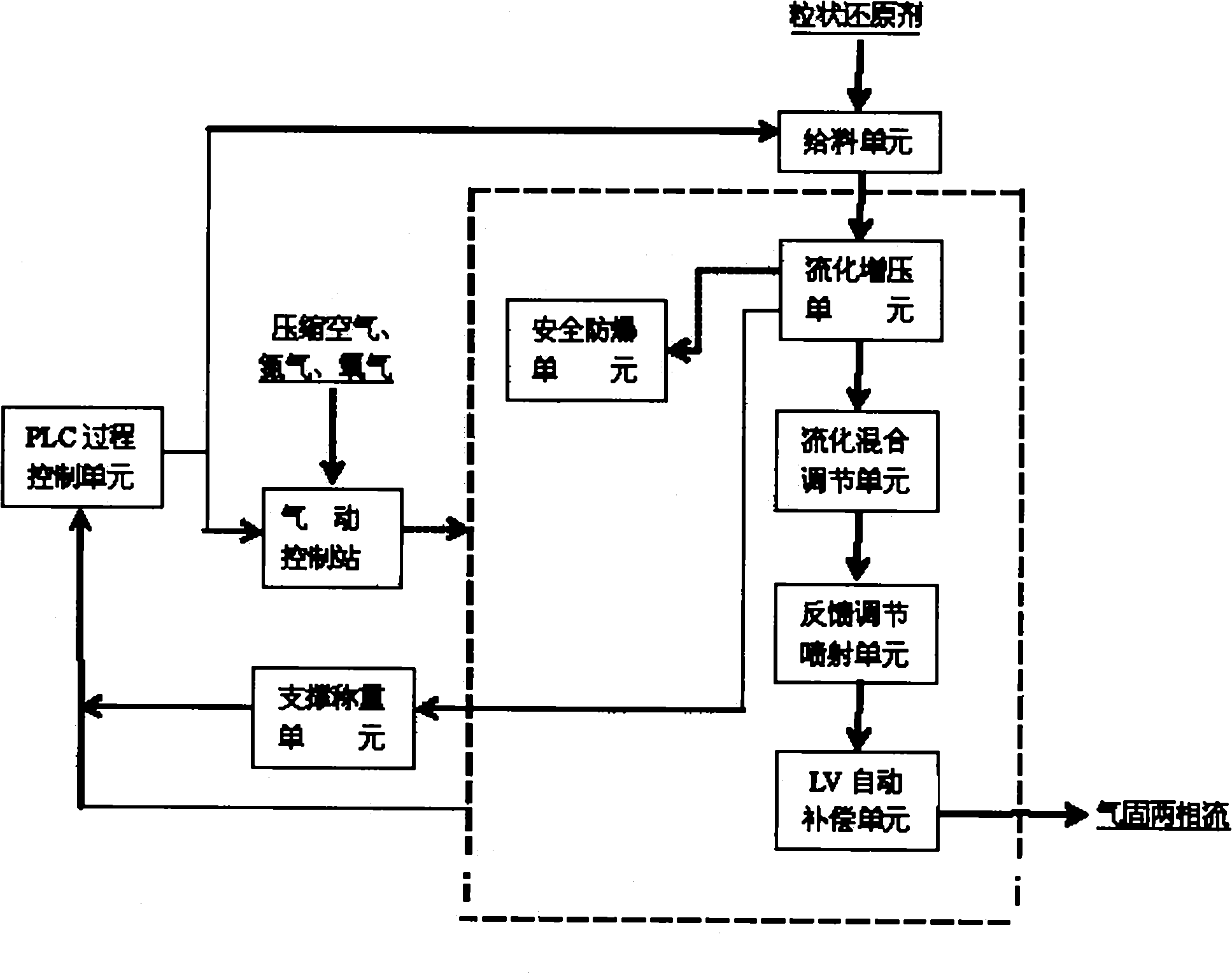

New automatic spraying system for solid reducing agent

The invention discloses a new automatic spraying system for a solid reducing agent. The system is provided with a feeding unit, a fluidized boosting unit, a fluidized hybrid adjusting unit, a feedback adjustment spraying unit, an LV automatic compensation unit, a supporting and weighing unit, a pneumatic control station and a PLC process control unit, wherein the reducing agent enters the fluidized boosting unit through the feeding unit by means of the dead weight and forms initial gas-solid two-phase flow in the fluidized hybrid adjusting unit after being boosted to flow out; the feedback adjustment spraying unit adjusts the proportion of the initial two-phase flow to meet the requirements of the reducing technology; the LV automatic compensation unit detects and rapidly responds to the gas-solid two-phase flow to ensure no recharging of liquid copper; the pneumatic control station distributes compressed air, nitrogen gas and oxygen required by the process and a meter gas source required for controlling each unit to each point; and the PLC process control unit programs, processes the switching value and the analog quantity, sends a control signal and gives an instruction to the feeding unit to ensure that the feeding unit is in a normal operating state. The automatic spraying system can realize automatic spraying of the solid reducing material and ensure uniform and controllable material supply.

Owner:昆明理工精诚科技有限责任公司 +1

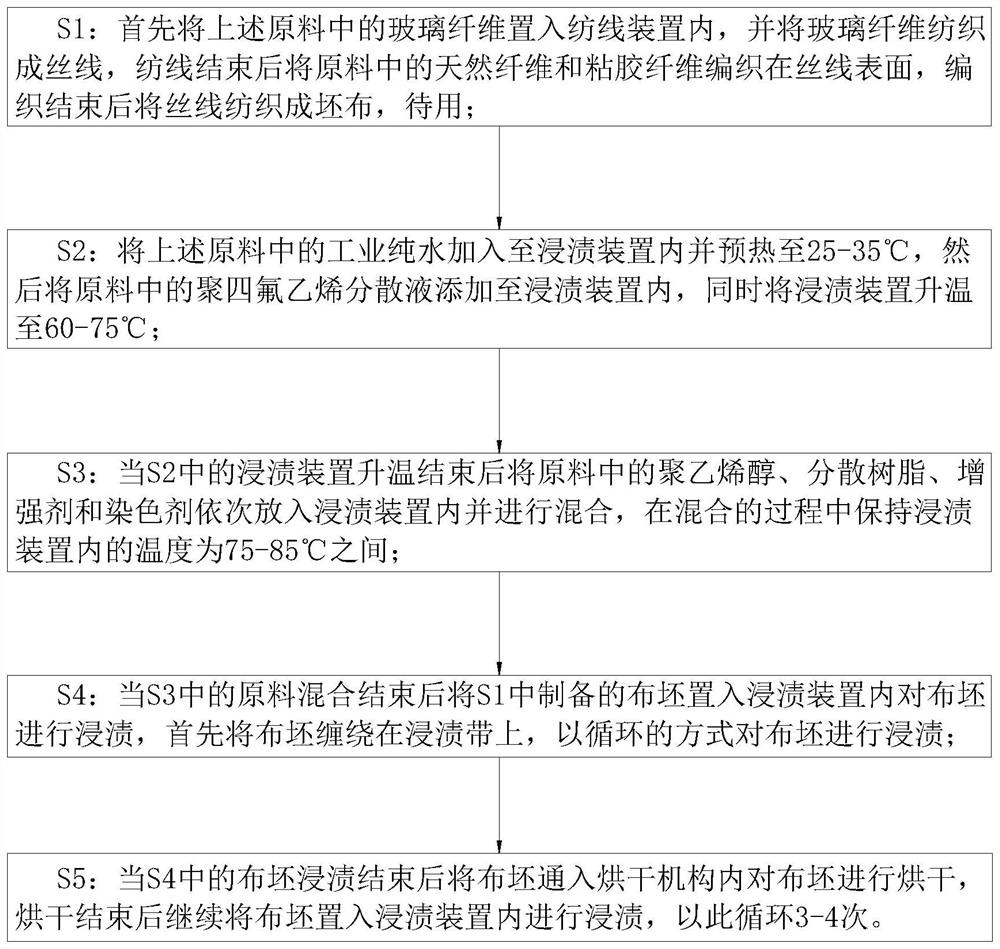

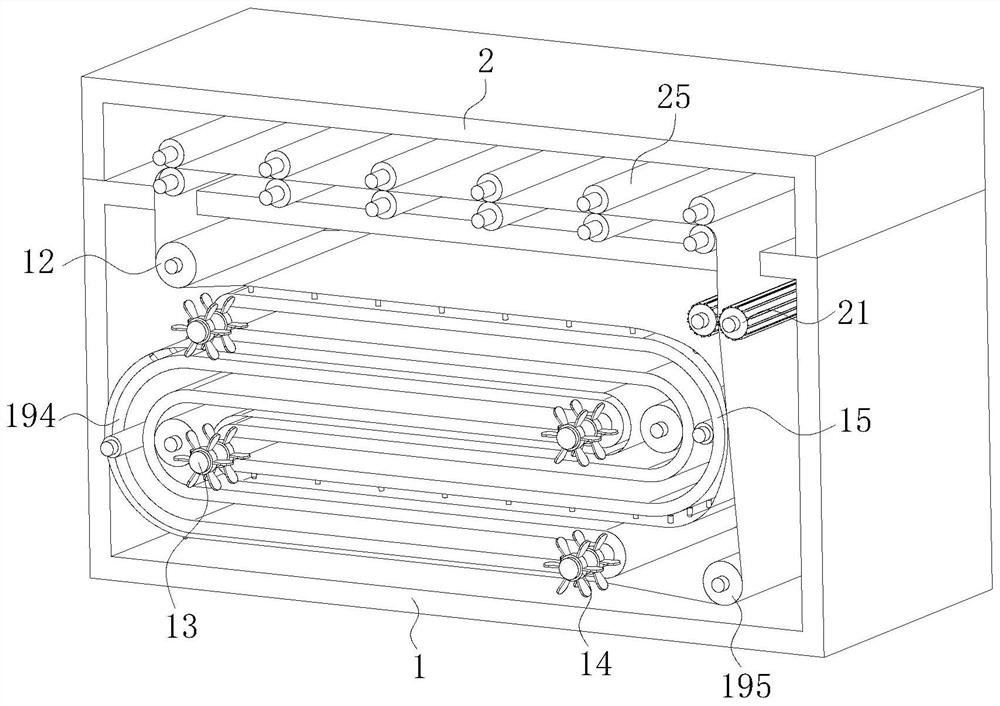

Production process of PTFE fiber cloth

PendingCN111607921AIncrease stickinessImprove wear resistanceLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsPolymer sciencePolymer chemistry

The invention belongs to the technical field of PTFE fiber cloth, and particularly relates to a production process of PTFE fiber cloth. An impregnation device comprises an impregnation box; a first rotating roller is rotationally connected into the inner wall of the impregnation box through a rotating shaft; the right side of the first rotating roller is rotationally connected with a first impregnation belt in the inner wall of the impregnation box through uniformly arranged rotating rods; the outer surface of one side, extending out of the first impregnation belt, of each rotating rod is fixedly connected with rotating blades which are uniformly arranged; the outer surface of the first impregnation belt is in sliding connection with uniformly-arranged spray heads. The impregnation deviceis mainly used for solving the problems that in the impregnation process of existing PTFE fiber cloth in the impregnation device, due to the fact that the concentration distribution of polytetrafluoroethylene dispersion liquid is not uniform, only the surface of the fiber cloth is usually impregnated with the polytetrafluoroethylene dispersion liquid, a coating of the polytetrafluoroethylene dispersion liquid is accumulated and thickened on the fiber cloth, and in the process, a certain impregnation effect can also be achieved, but the fiber cloth is cracked after being dried, so that the service life of the fiber cloth is shortened.

Owner:程明

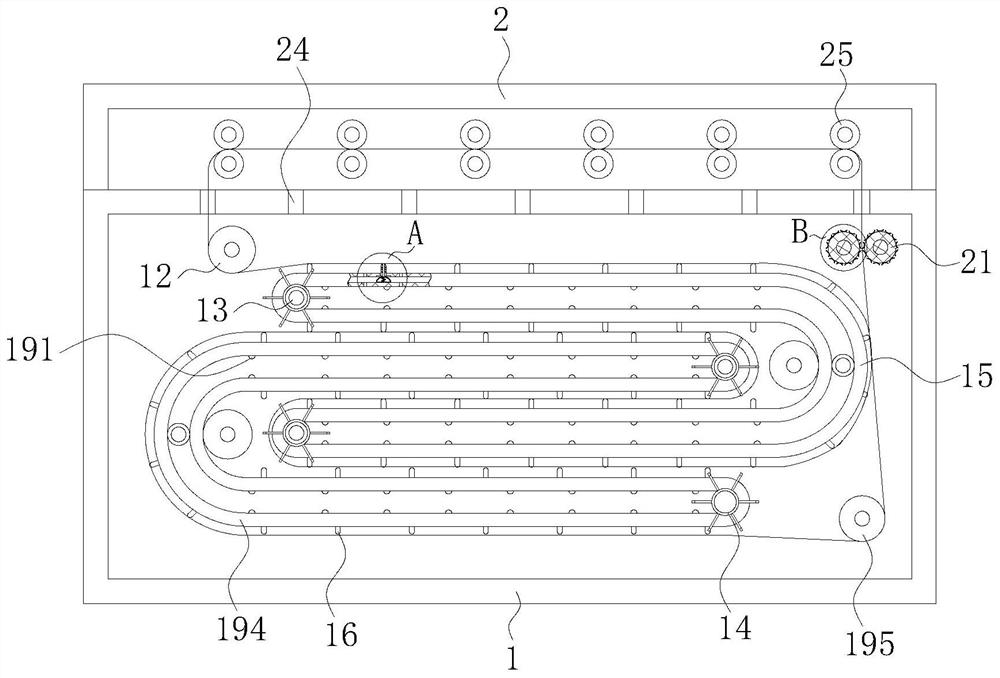

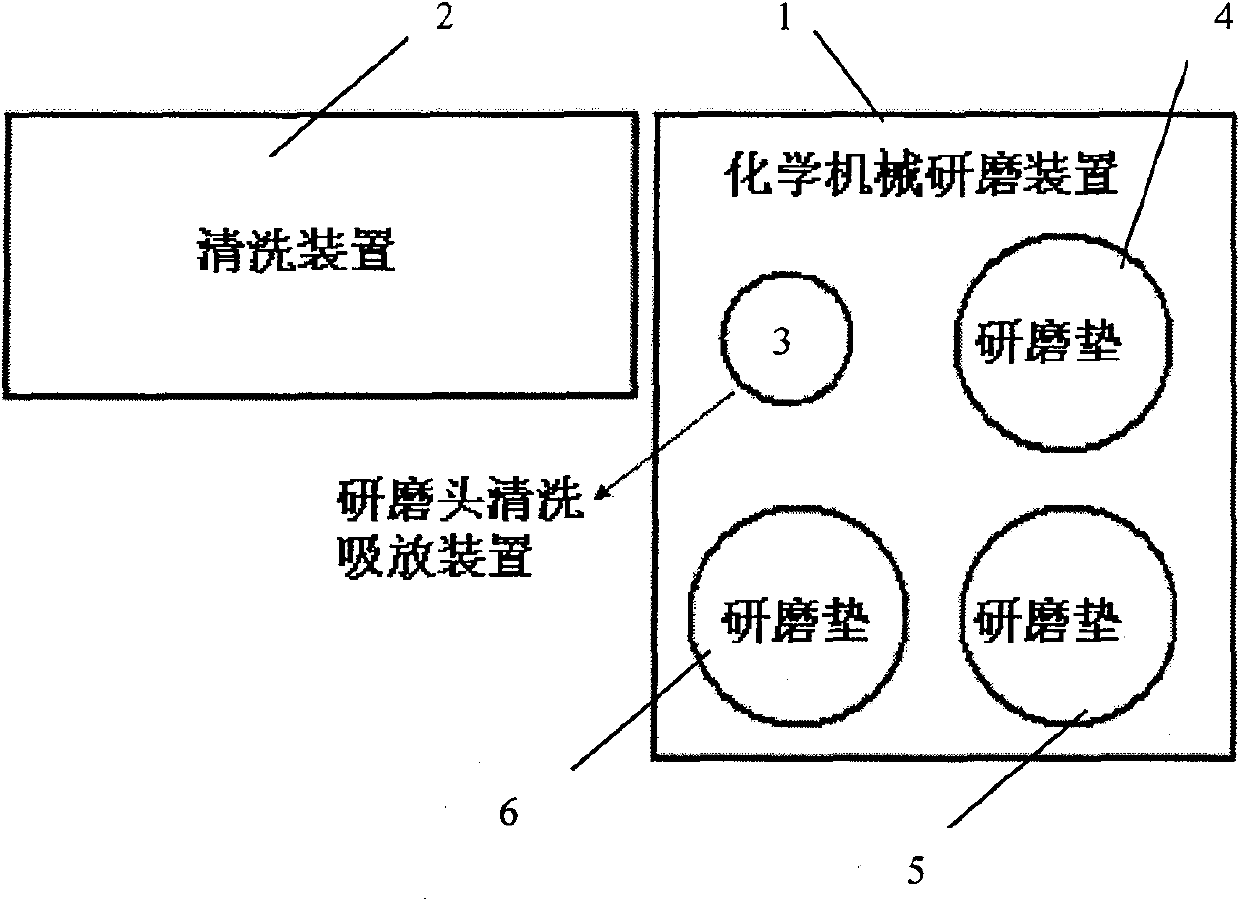

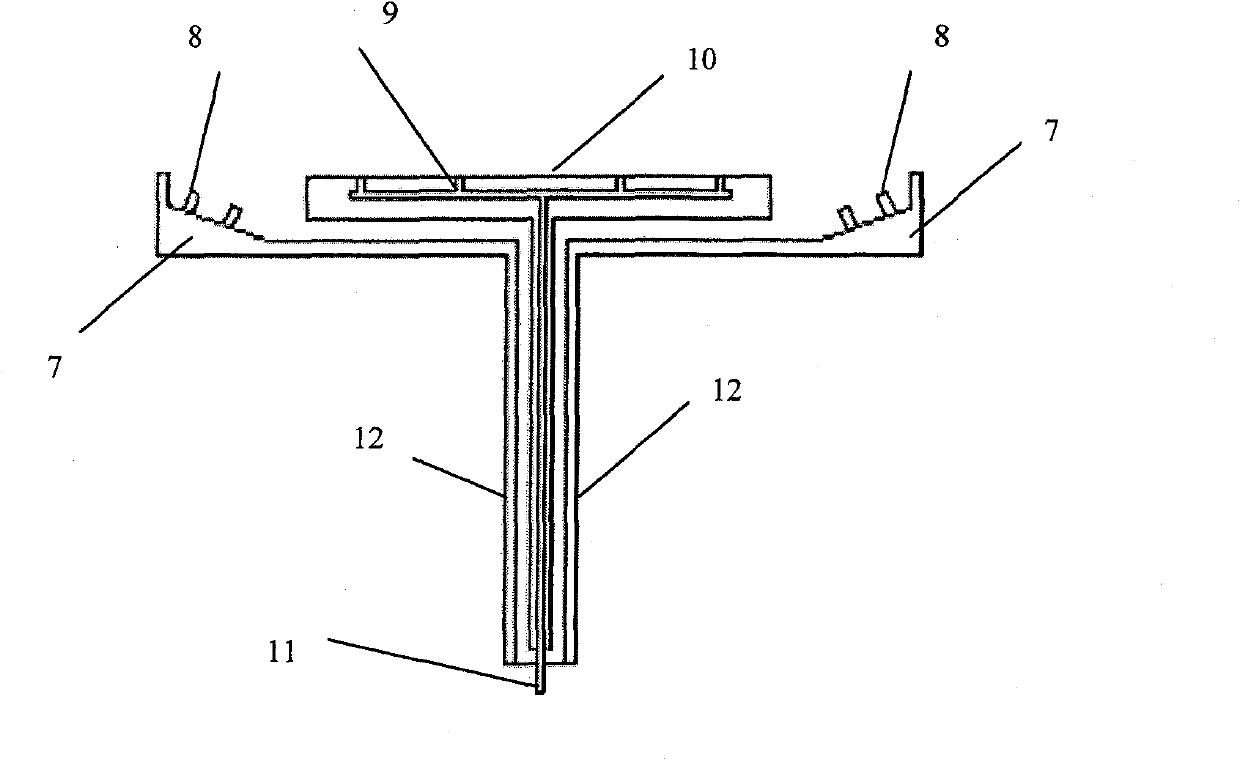

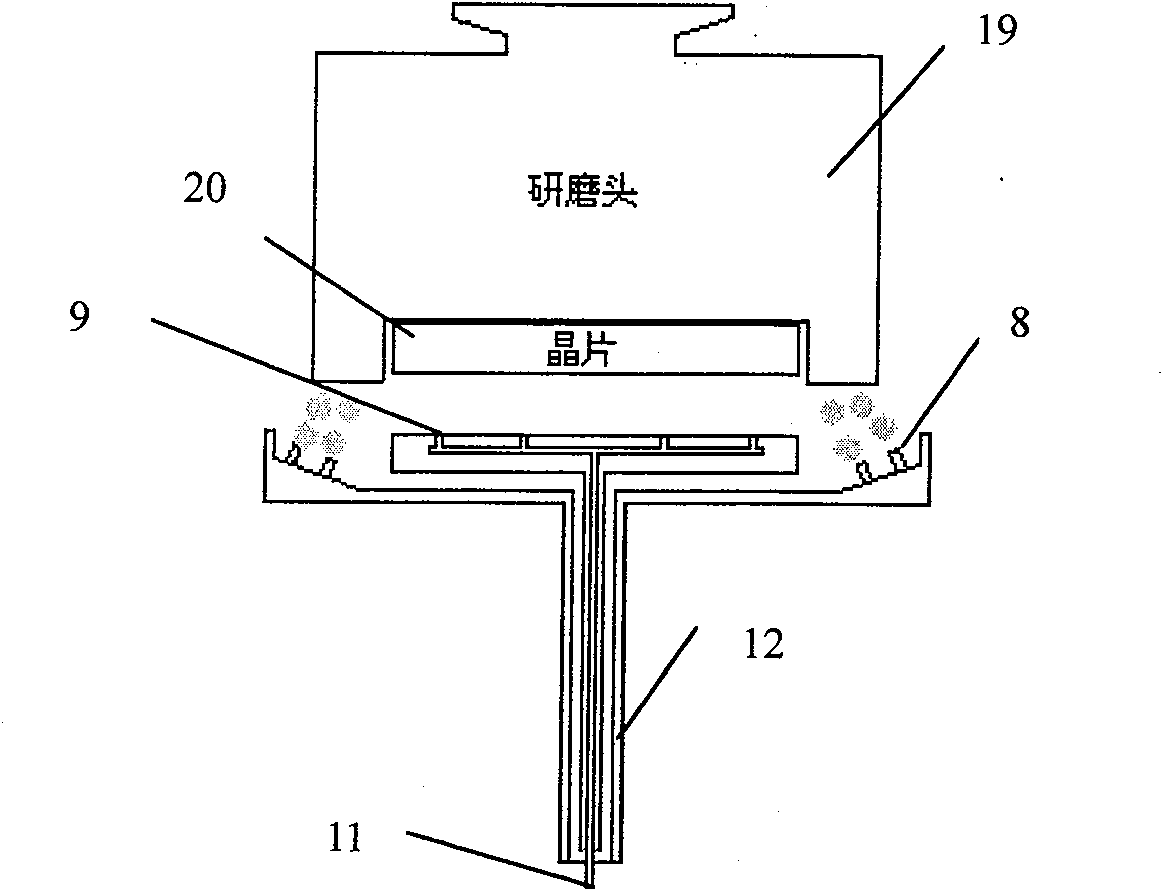

A method for reducing corrosion of crystal plate in cuprum chemistry mechanical lapping technics

ActiveCN100592960CWill not be harmedIncrease jet powerSemiconductor/solid-state device manufacturingDesorptionEngineering

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

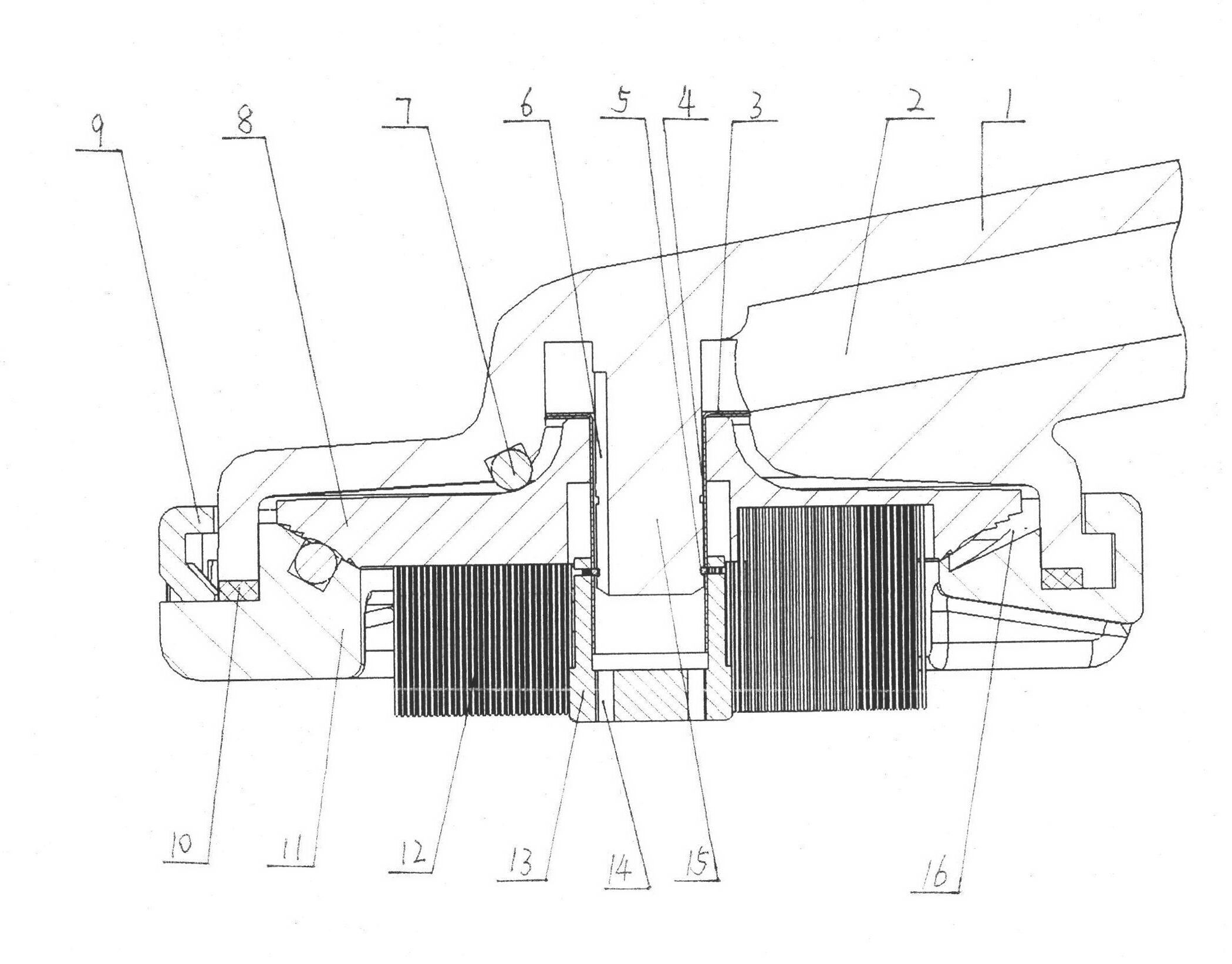

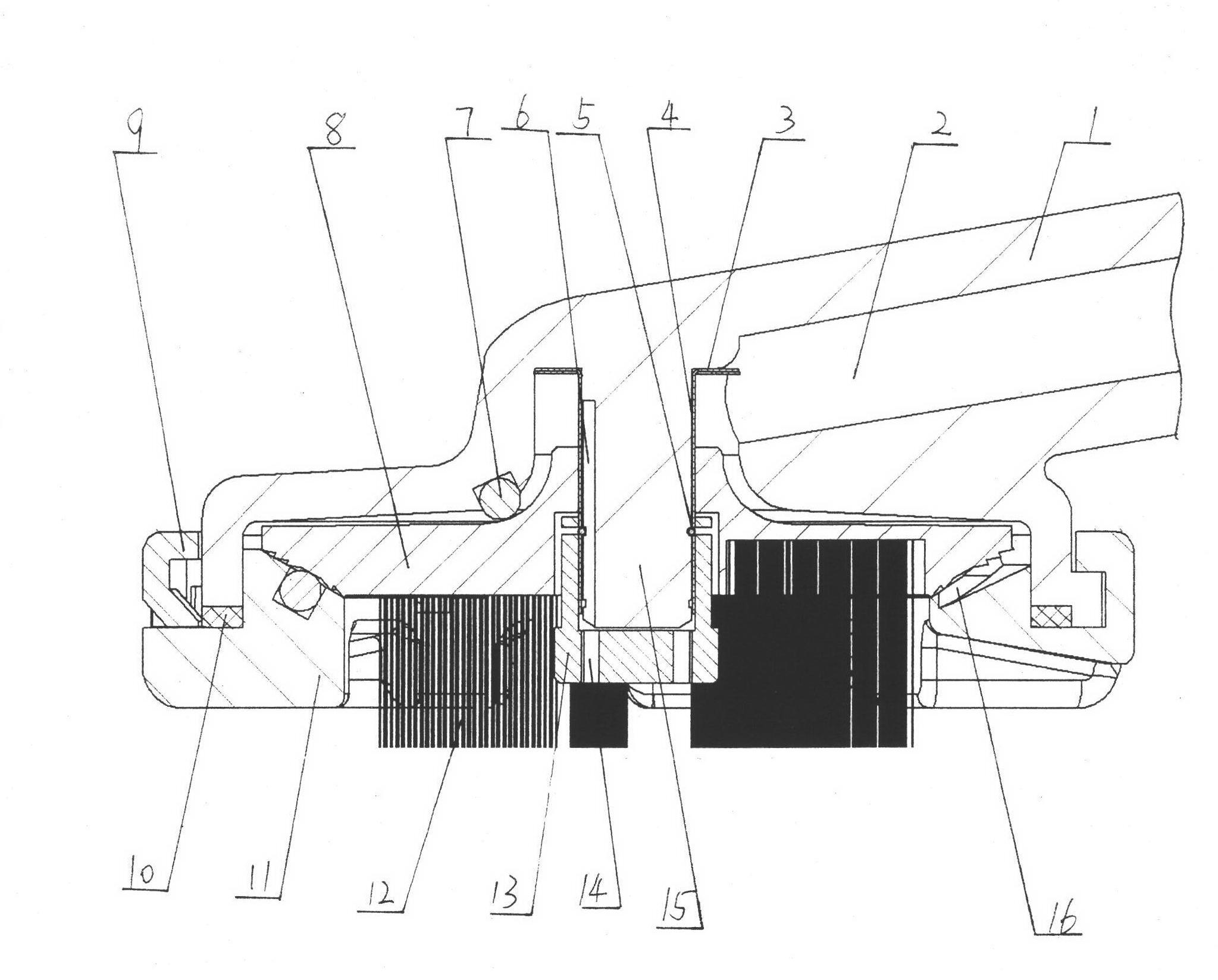

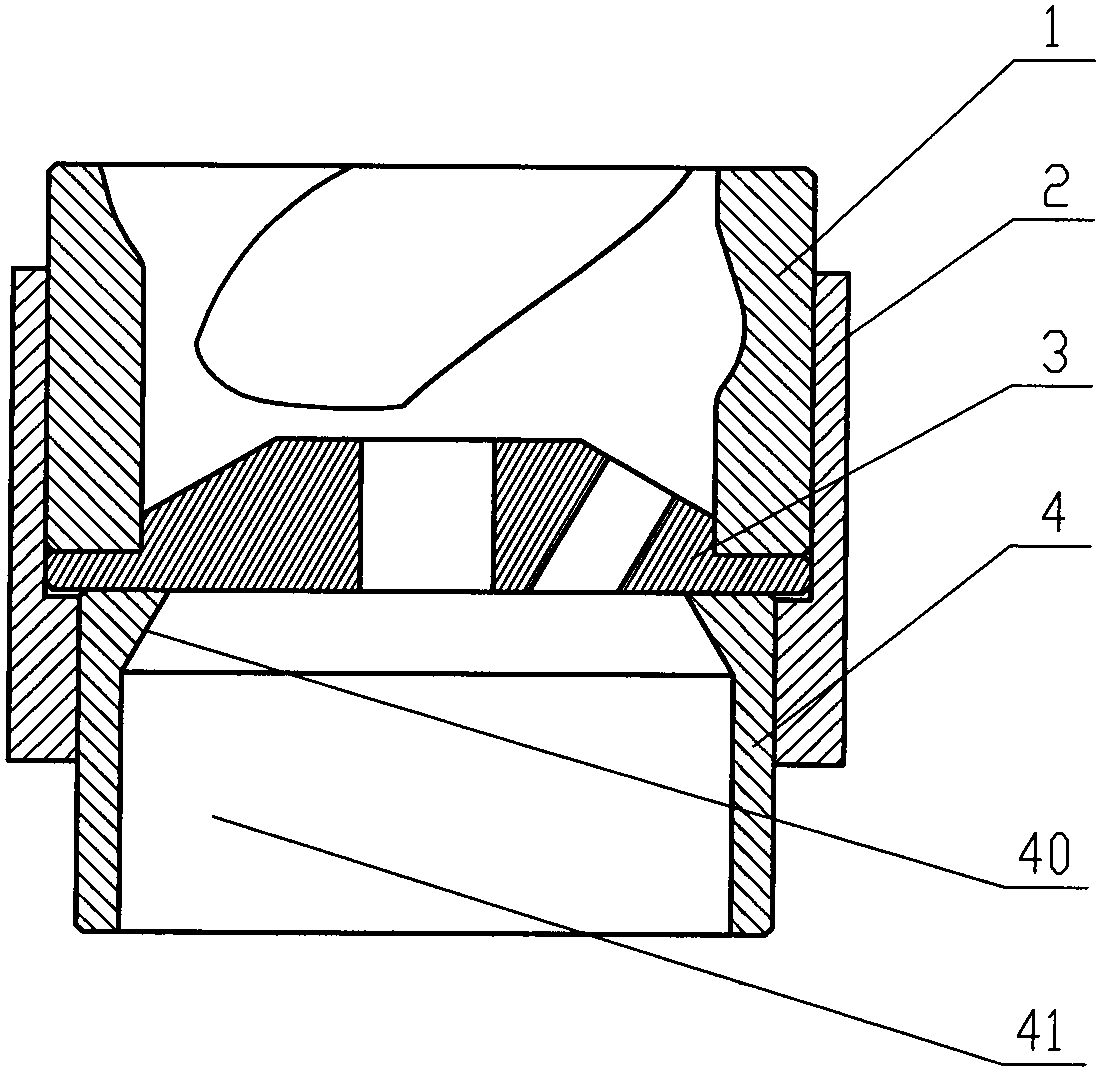

Massage bathtub and massage nozzle

ActiveCN104289337AEliminate discomfortIncrease oxygen contentSpray nozzlesLiquid spraying apparatusPositive pressureMassage

The invention discloses a massage nozzle. The massage nozzle comprises a nozzle body, a nozzle mandrel and a nozzle decorative cover, wherein the nozzle mandrel is connected to a first cavity in the nozzle body; a second cavity is formed between a water outlet nozzle in the nozzle mandrel and the nozzle mandrel; an air inlet is formed in the periphery of the nozzle body; an air pump is communicated with the first cavity through the air inlet; an air inlet hole is formed in the side wall of the nozzle mandrel; the first cavity is communicated with the second cavity through the air inlet hole; the nozzle decorative cover is provided with an air outlet hole communicated with the second cavity and a water outlet hole communicated with the water outlet nozzle; and the air outlet direction of the air outlet hole is intersected with the water outlet direction of the water outlet hole. As the nozzle is added with the air pump with power, a negative-pressure natural air absorption mode in the prior art is changed to positive-pressure air intake to largely enhance the massage force of a water column, and the water column contains rich bubbles through airflow to enable the massage effect to become richer. The invention further discloses a massage bathtub including the massage nozzle.

Owner:阿波罗(中国)有限公司

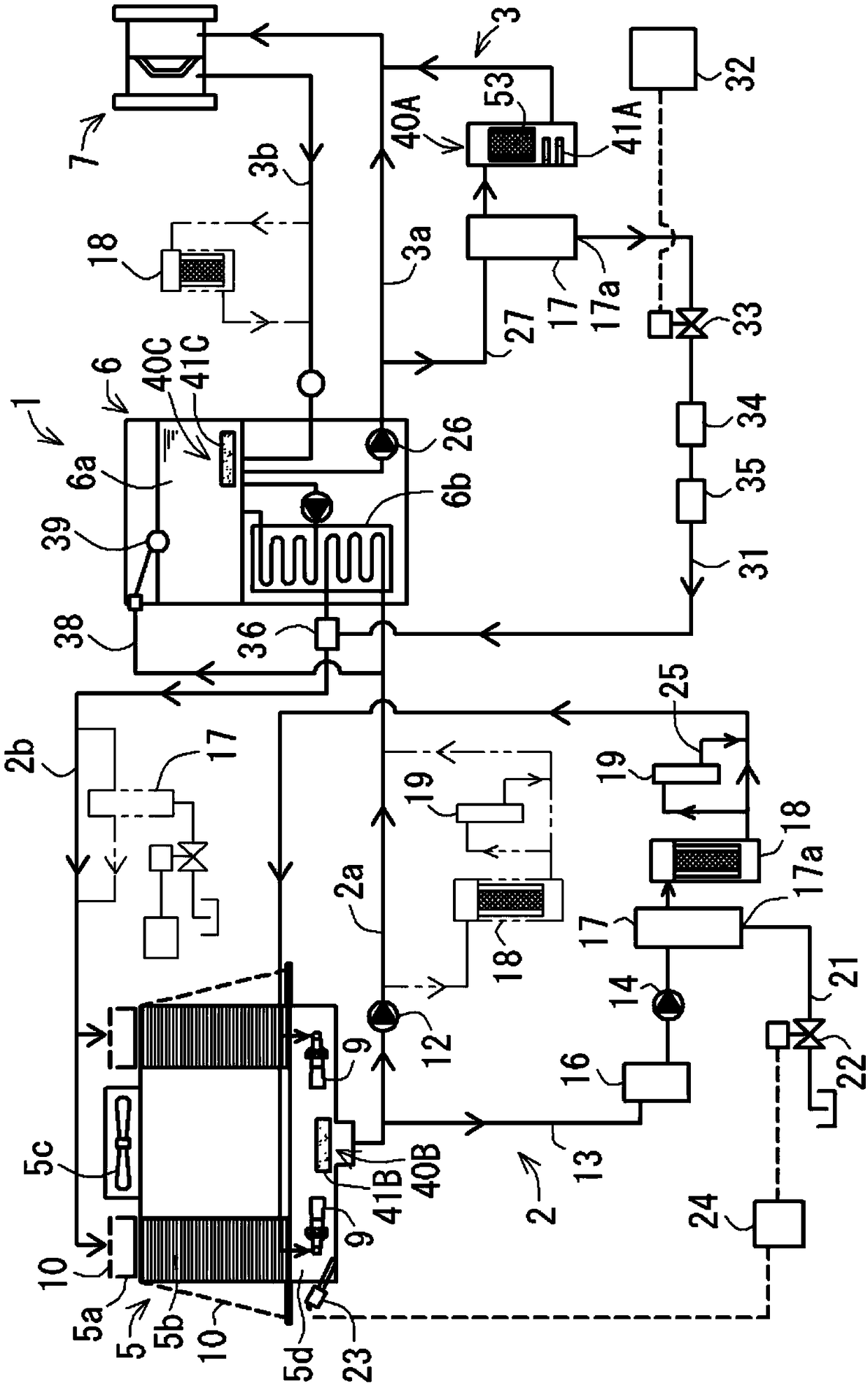

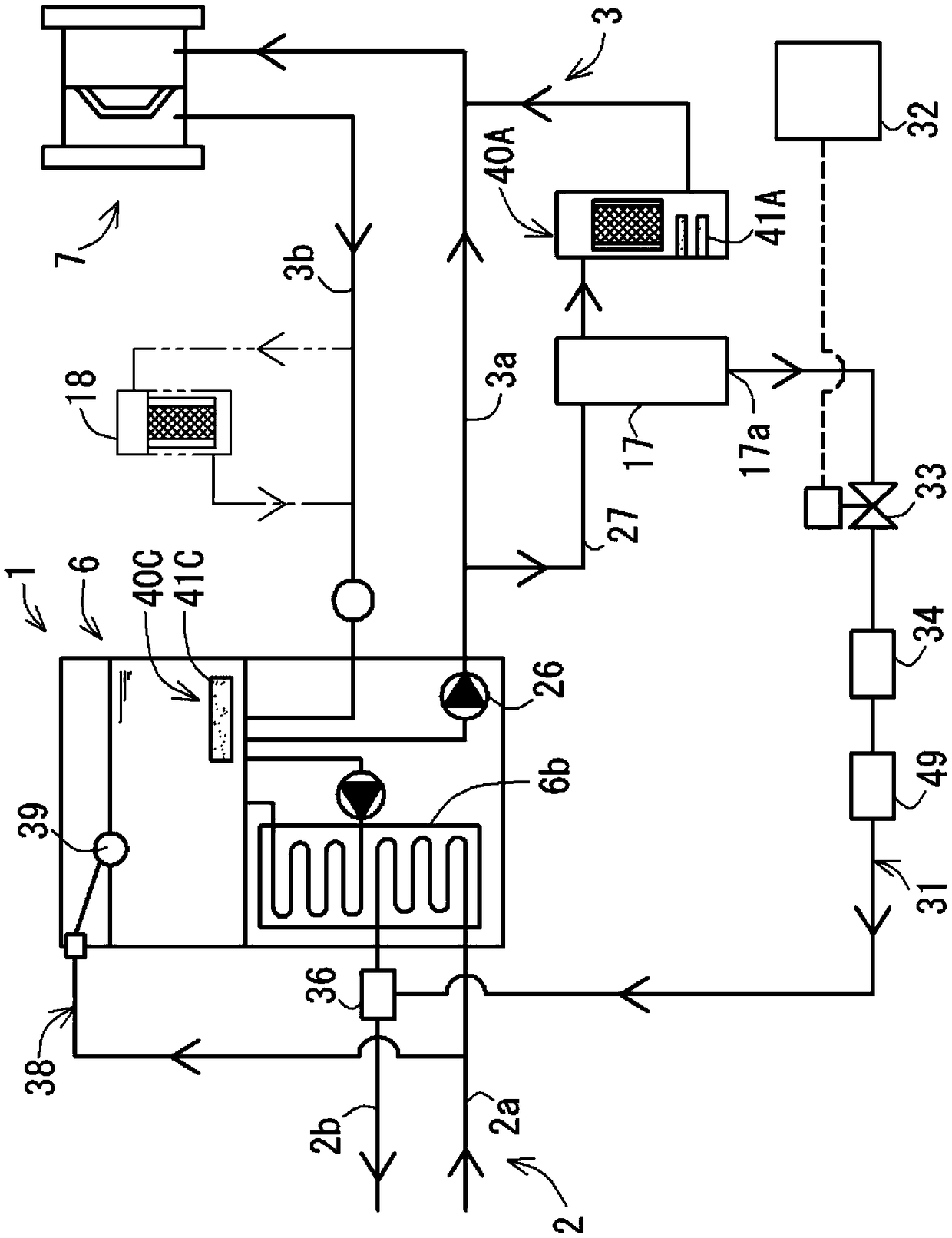

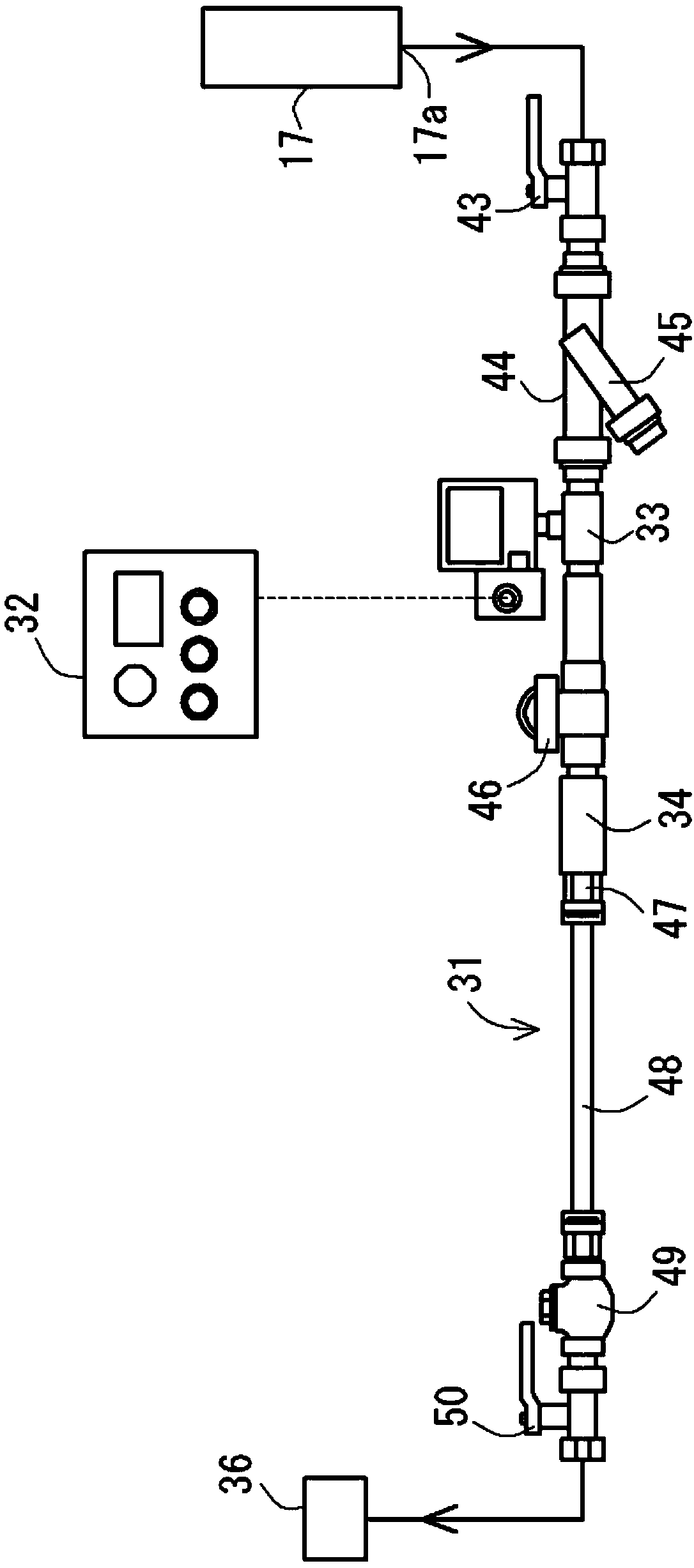

Cooling-water circulation system

InactiveCN109154483AImprove water qualitySimple structureCleaning heat-transfer devicesTreatment involving filtrationCooling towerEngineering

This cooling-water circulation system 1 is provided with: a cooling tower side circulation path 2 for circulating cooling water between a cooling tower 5 and a chiller 6; and a chiller side circulation path 3 for circulating cooling water between the chiller 6 and a to-be-cooled part 7. The cooling tower side circulation path 2 and the chiller side circulation path 3 are connected to each other bya first connection pipe 31 for introducing, into the cooling tower side circulation path, the cooling water circulating through the chiller side circulation path.

Owner:TOYOTA BOSHOKU KK

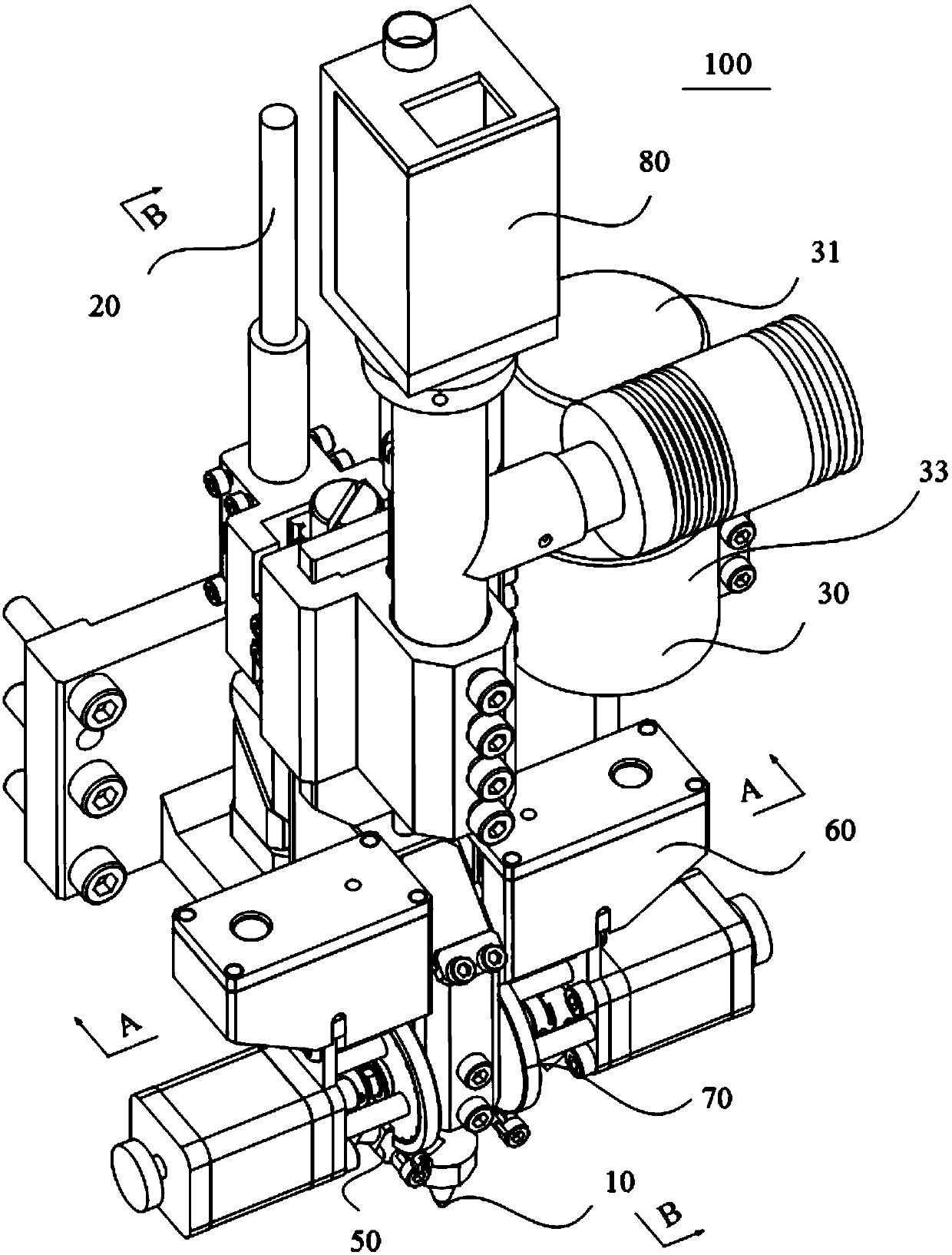

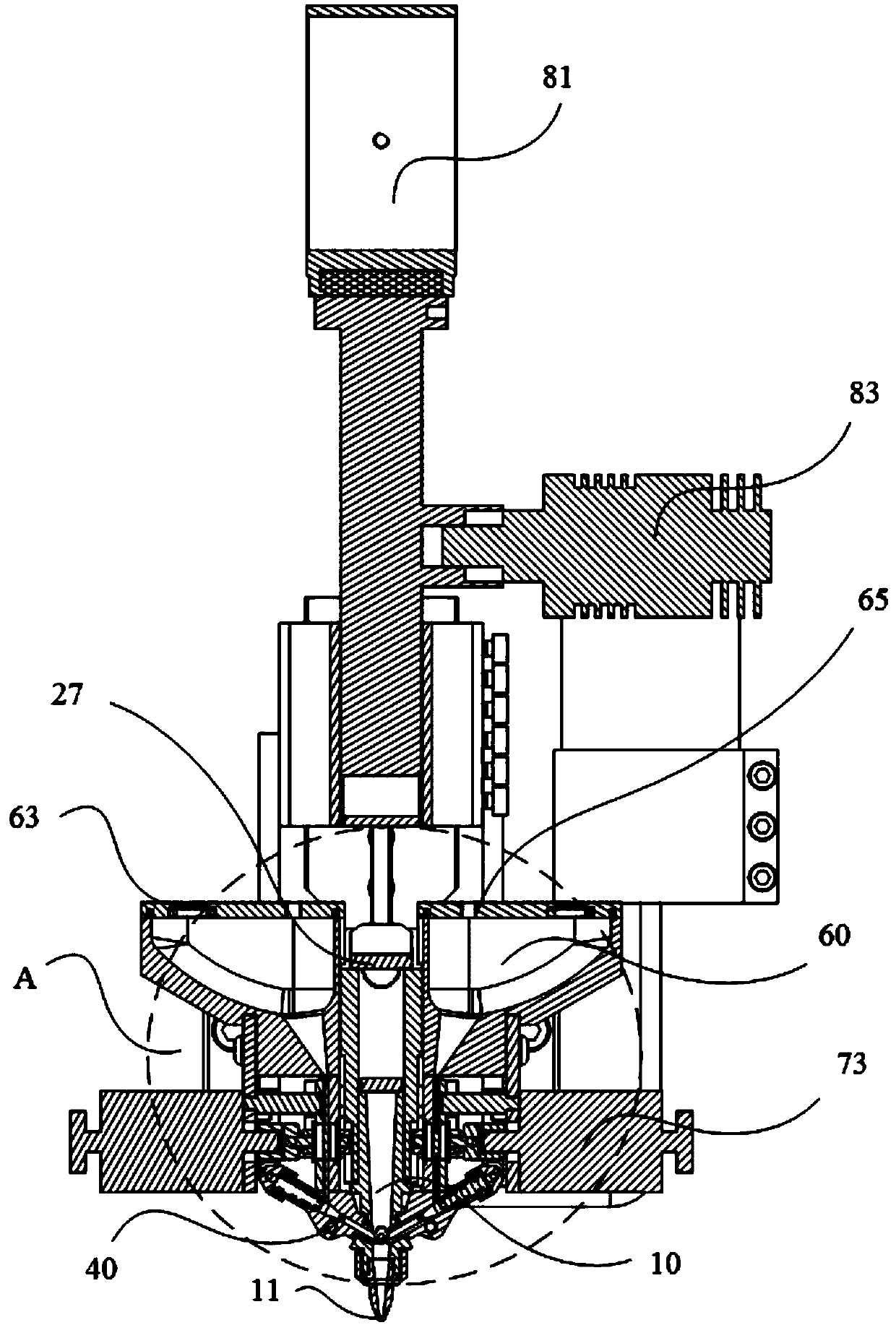

Welding equipment

PendingCN109590561AEasy to controlStable injection pressureMetal working apparatusSoldering auxillary devicesFixed positionTin

The invention discloses welding equipment for tin ball welding. The welding equipment comprises a spraying cavity, a laser module, a pneumatic module, a feeding module and a seal device. A tin ball fixing position is formed in the spraying cavity. A laser emitting port of the laser module is opposite to the tin ball fixing position and is used for heating a tin ball located at the tin ball fixingposition. An air outlet of the pneumatic module communicates with the spraying cavity and is used for spraying the machined tin ball. A conveying runner is formed in the feeding module and provided with a feeding port and a discharging port, and the discharging port communicates with the spraying cavity and is used for conveying the tin ball to the tin ball fixing position. The seal device is movably arranged on the feeding module so as to open or seal the feeding port. According to the purpose, the problems that in the laser tin welding process, spraying power control is poor, and the weldingprecision is influenced are solved.

Owner:SHENZHEN H TECH CO LTD

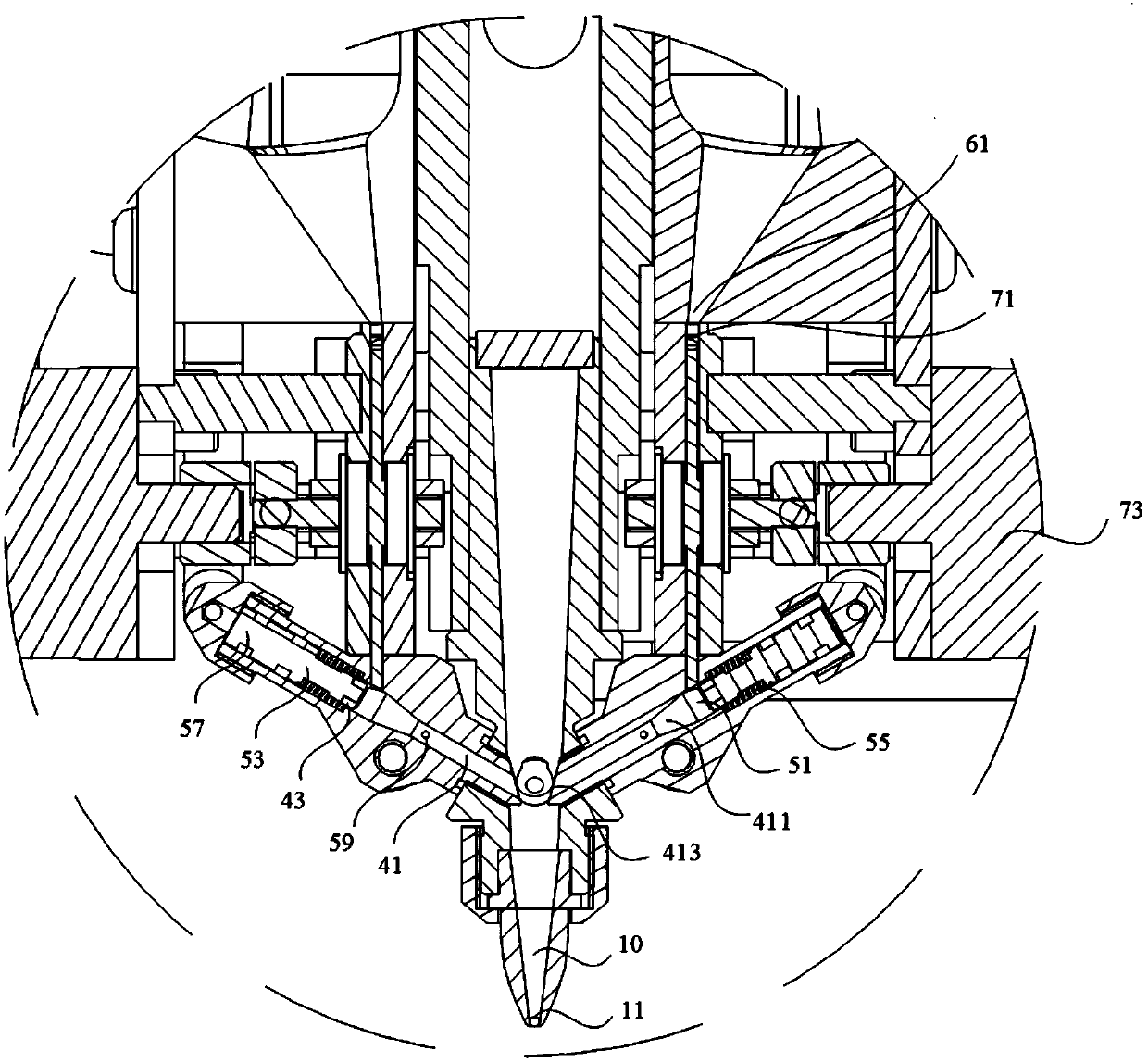

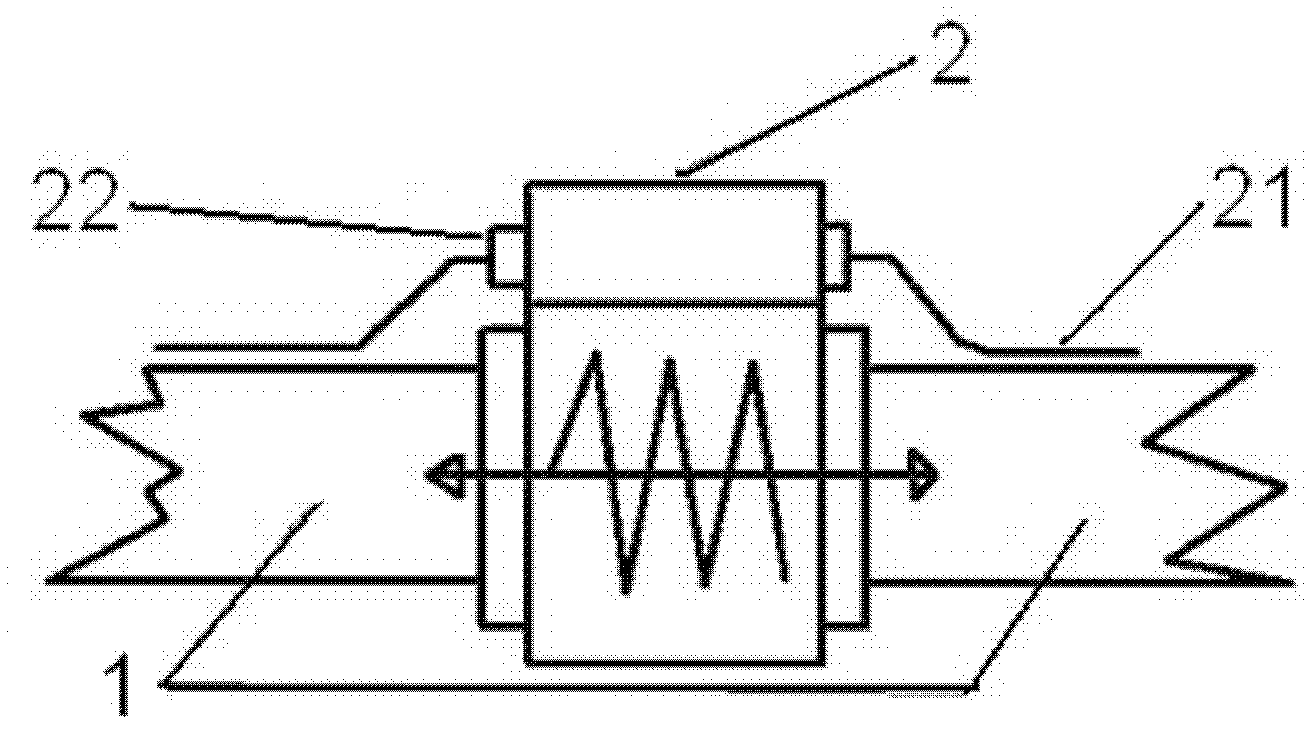

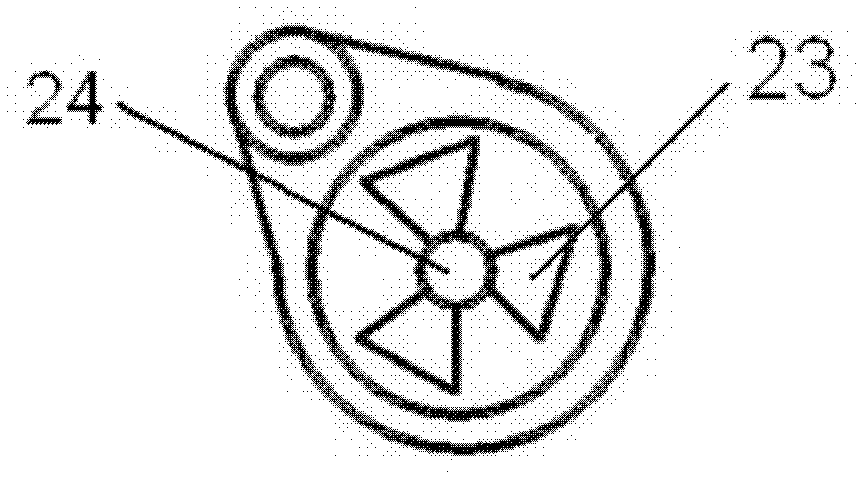

Water band pressurizing device and method and fire fighting apparatus

InactiveCN102430220ADoes not significantly increase spaceIncrease the striking powerFire rescuePipe-jointsWater flowEngineering

The invention provides a water band pressurizing device, a water band pressurizing method and a fire fighting apparatus. The water band pressurizing device comprises a water flow conveying belt consisting of a plurality of sections of water bands which are mutually communicated, wherein an axial-flow electric pump is arranged at a node between every two adjacent sections of water bands; the axial center of a blade of the axial-flow electric pump is parallel to the water flow direction in the water bands; and the axial-flow electric pump is used for pressurizing water flowing through the node along a water flow direction. After sequentially flowing through the node, the water flow is pressurized in a way of relay, so the problem that it is difficult to delivery water to a high floor during fire fighting is solved. The water band pressurizing device has the advantages of high fire-fighting efficiency, flexible operation, compact structure and the like.

Owner:SANY HEAVY IND CO LTD (CN)

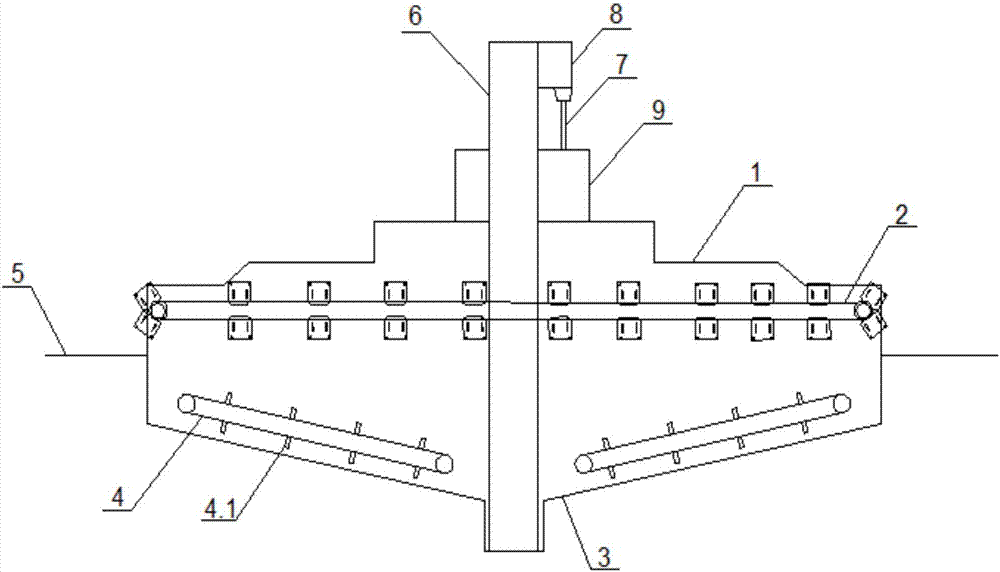

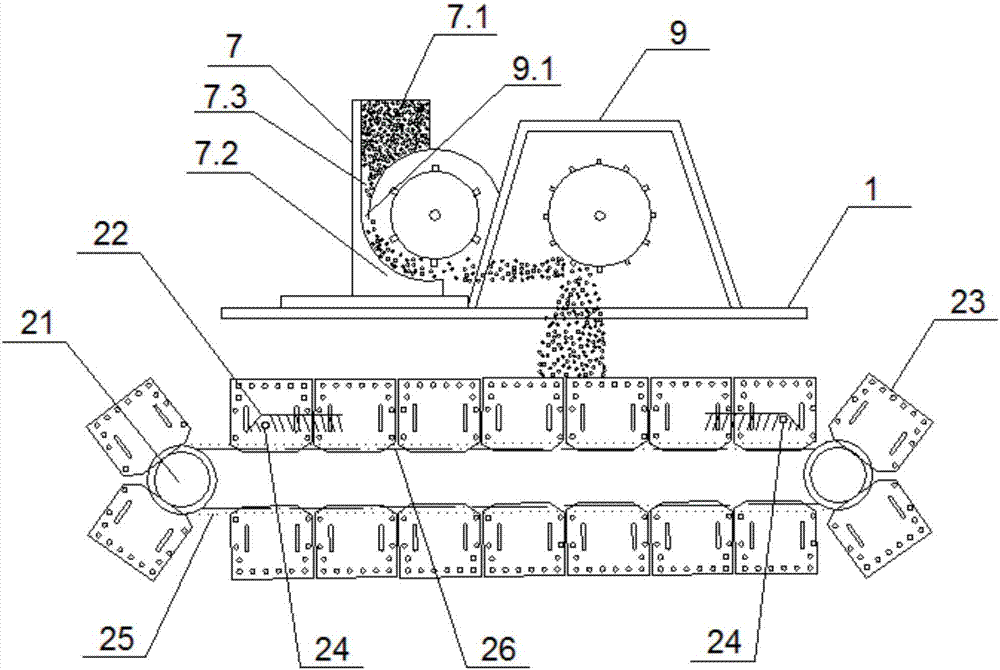

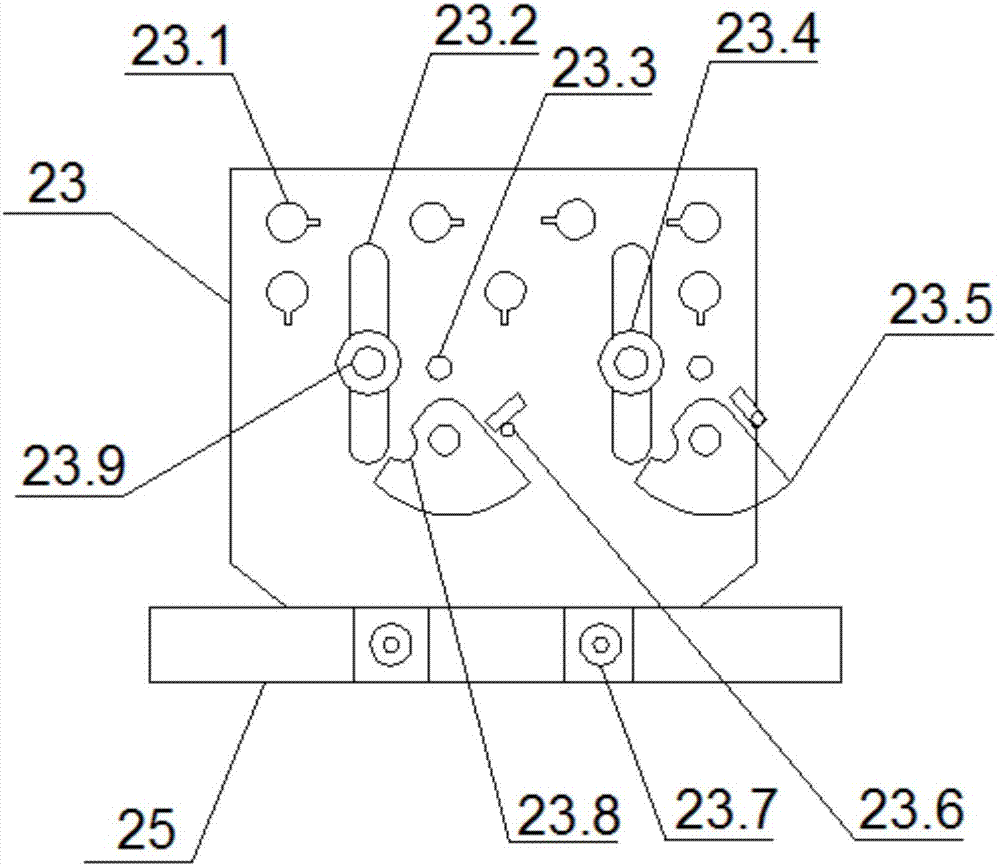

Plate-spring universal powerful peening machine

PendingCN107186627ALarge projectile flowGreatly increased projectile flowAbrasive machine appurtenancesAbrasive blasting machinesSpray nozzleDust control

The invention relates to the field of metal workpiece surface treatment, in particular to a plate-spring universal powerful peening machine. The plate-spring universal powerful peening machine comprises a peening room, a collision type spray nozzle, a stress jig, a pill collecting device and a dust-removing mechanism. According to the plate-spring universal powerful peening machine, an upper rail and a lower rail are arranged on the two sides of a machine body of the complete machine, small walking wheels at the two ends of a chain walk between the upper rail and the lower rail for changing the soft property of the chain, the two sides of the chain are additionally provided with stress wall-plate fixing workpieces, a chain scraper board is matched with a hoister to conduct pill collecting, stive, scrap iron pills and sundries are separated by using a separator, and collision pill spraying is conducted by the collision type spray nozzle. The plate-spring universal powerful peening machine has the advantages that the structure is simple and practical, the cost is low, the pill spraying intensity is high, the flow is large, the coverage rate is high, energy is saved, blocking is avoided in the pill conveying, the workpieces are convenient to clamp, dust removing is timely, and the scrap pills can be separated.

Owner:宁波市鄞州博恒易得机械设备有限公司

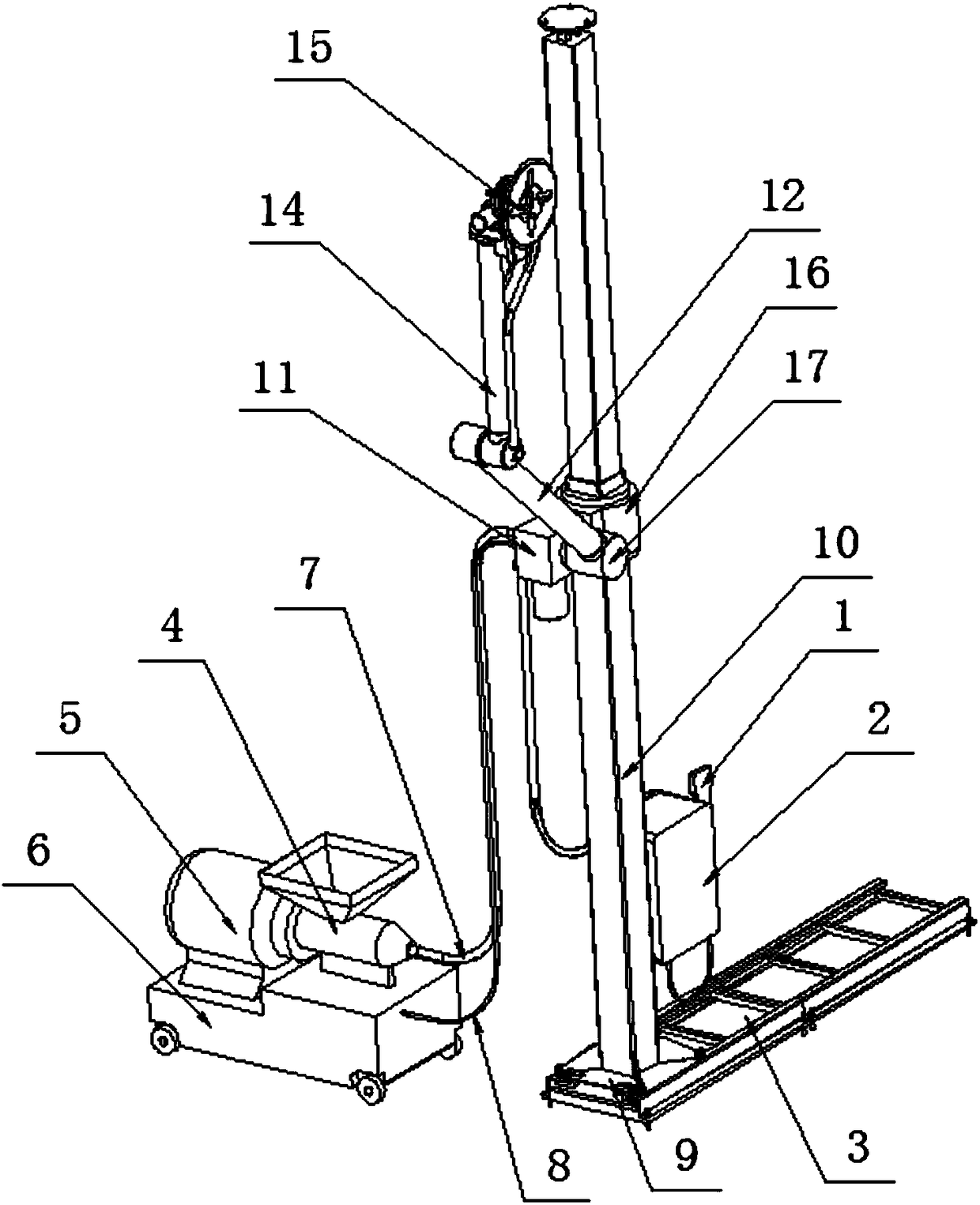

Automatic painting mechanical arm

PendingCN108301605AQuality assuranceIncrease jet powerBuilding constructionsEngineeringHigh pressure

The invention discloses an automatic painting mechanical arm, and relates to a decoration device and facility. The automatic painting mechanical arm comprises a sliding rail, the sliding rail is connected with a locating seat through a locking device, the locating seat is connected with a sliding column, the sliding column is provided with a moving block, and the sliding column and the moving block are connected in a sliding mode. The moving block is provided with a fixing device, the moving block is connected with a transfer box, the transfer box is connected with a smoothing device, the smoothing device is connected with one end of a delivery pipe, and the other end of the delivery pipe is connected with a feeding device through the transfer box. The smoothing device is connected with one end of a gas delivery pipe, and the other end of the gas delivery pipe is connected with a vacuum pump through the transfer box. When the automatic painting mechanical arm is used, materials needingto be painted are added into the feeding device, painting materials on the feeding device are conveyed to a smoothing disk under the control of a control device and ejected from the smoothing disk tobe applied on a wall surface, high pressure gas output by the vacuum pump is transmitted by the gas delivery pipe to the smoothing disk to increase spray force of the painting materials sprayed fromthe smoothing disk, and the purpose of painting is realized.

Owner:广州市明创自动化科技有限公司

Fountain system

ActiveCN108514983AImprove securityConvenience to workLiquid spraying apparatusEngineeringProtection layer

The invention relates to a fountain system. The fountain system comprises a main body and a left-auxiliary-connection fountain water pipe, wherein a fountain top is arranged at the upper end of the main body, and a side protection layer is connected to the outer side of the fountain top; an outer-disc fountain pipe is fixed to the upper end of the side protection layer, and a connection fasteningmechanism is arranged at the outer end of the outer-disc fountain pipe; a nozzle is formed in the upper end of the connection fastening mechanism, and a middle-disc fountain pipe is installed at the inner side of the connection fastening mechanism; a communication pipe is connected to the outer wall of the middle-disc fountain pipe, and an inner-disc fountain pipe is installed at the inner side ofthe middle-disc fountain pipe; and a connector is formed in the inner side of the inner-disc fountain pipe. The fountain system disclosed by the invention has the following beneficial effects: a right-side-connection water suction pipe and a filter suction head are arranged, and large impurities in water can be filtered through the filter suction head; and water is sucked in from the interior ofthe water suction pipe through the working of a first pressurized water pump and a second pressurized water pump to be conveyed, so that improvement for the injection power of water in a fountain is facilitated.

Owner:日照新睿招商发展有限公司

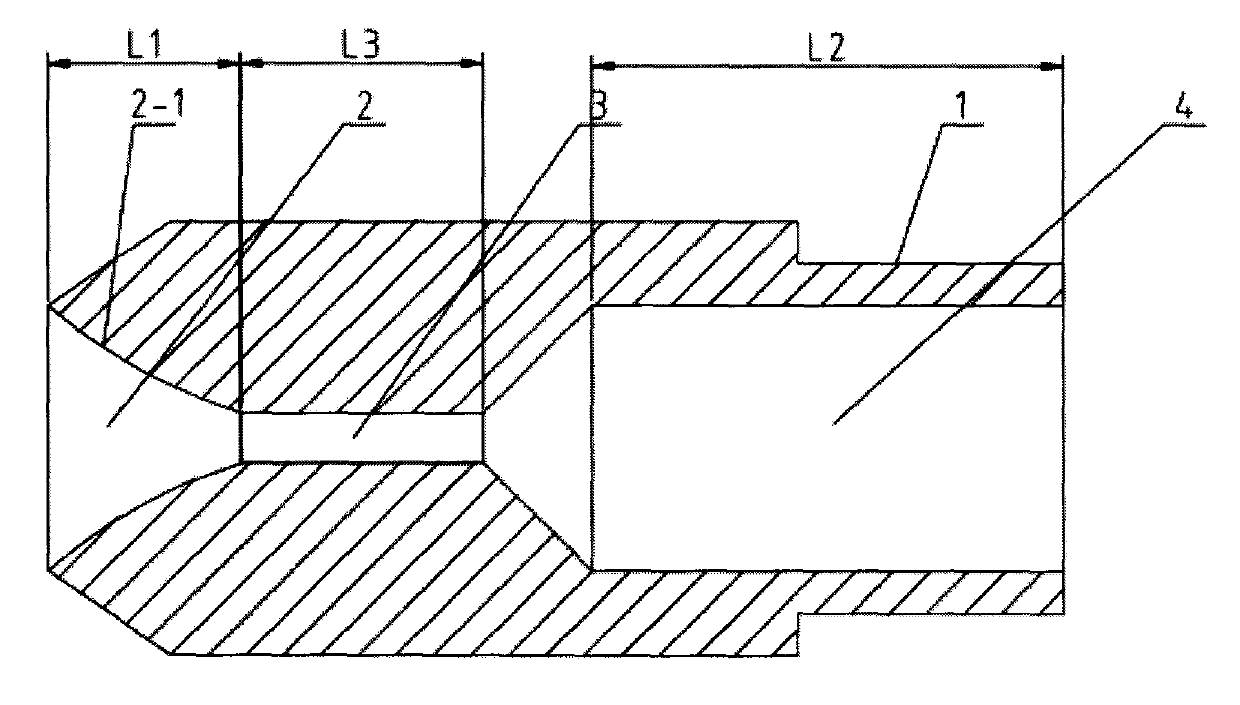

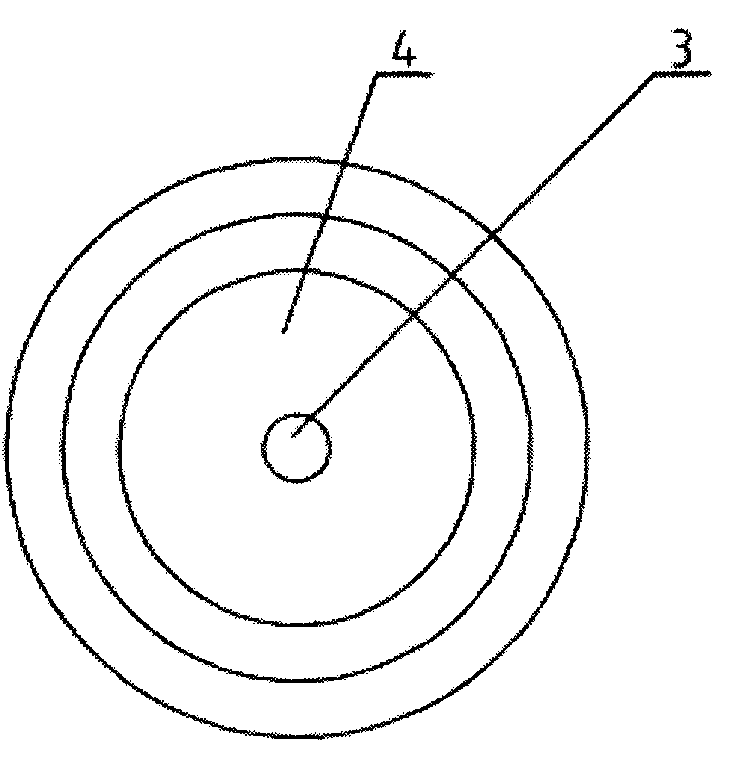

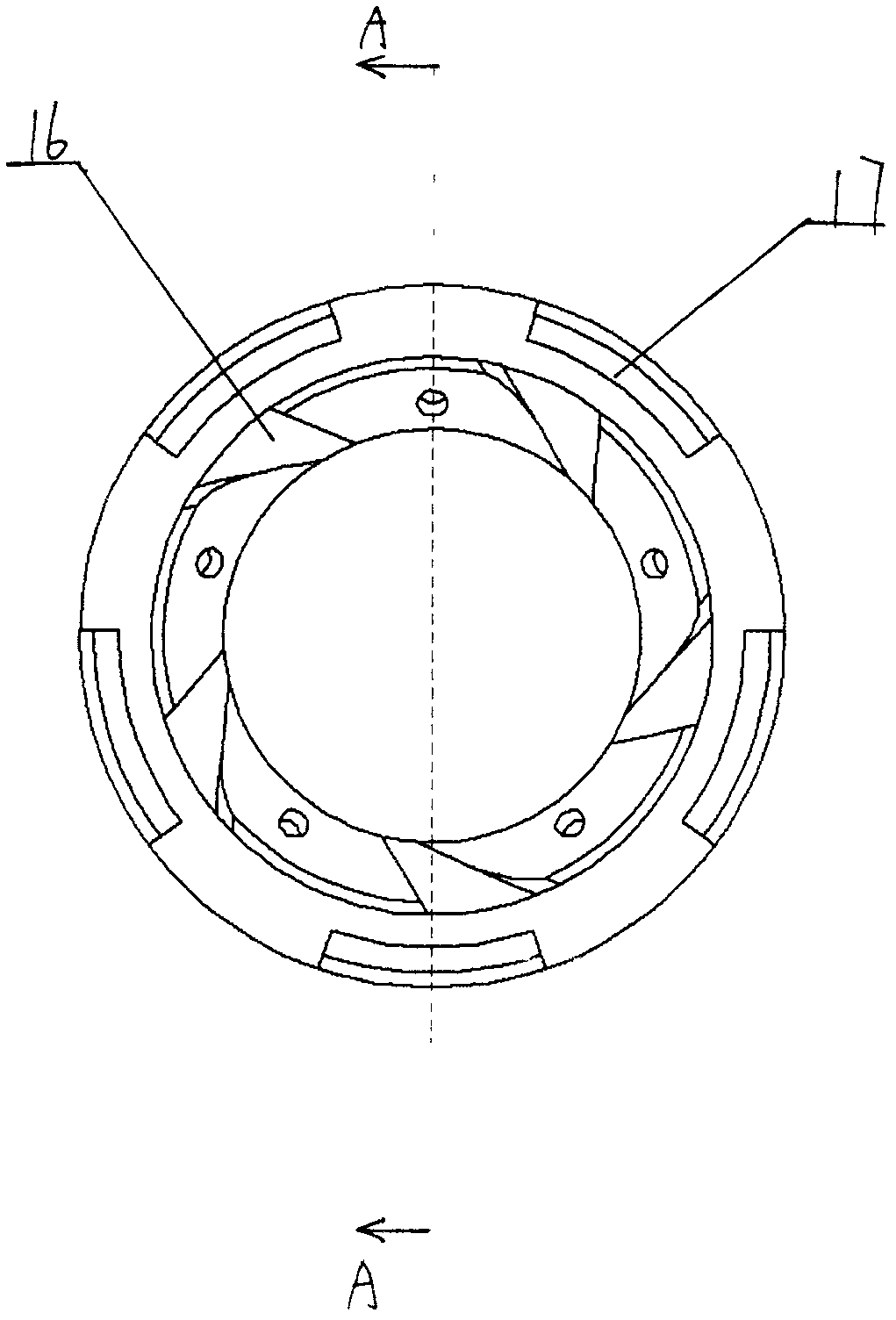

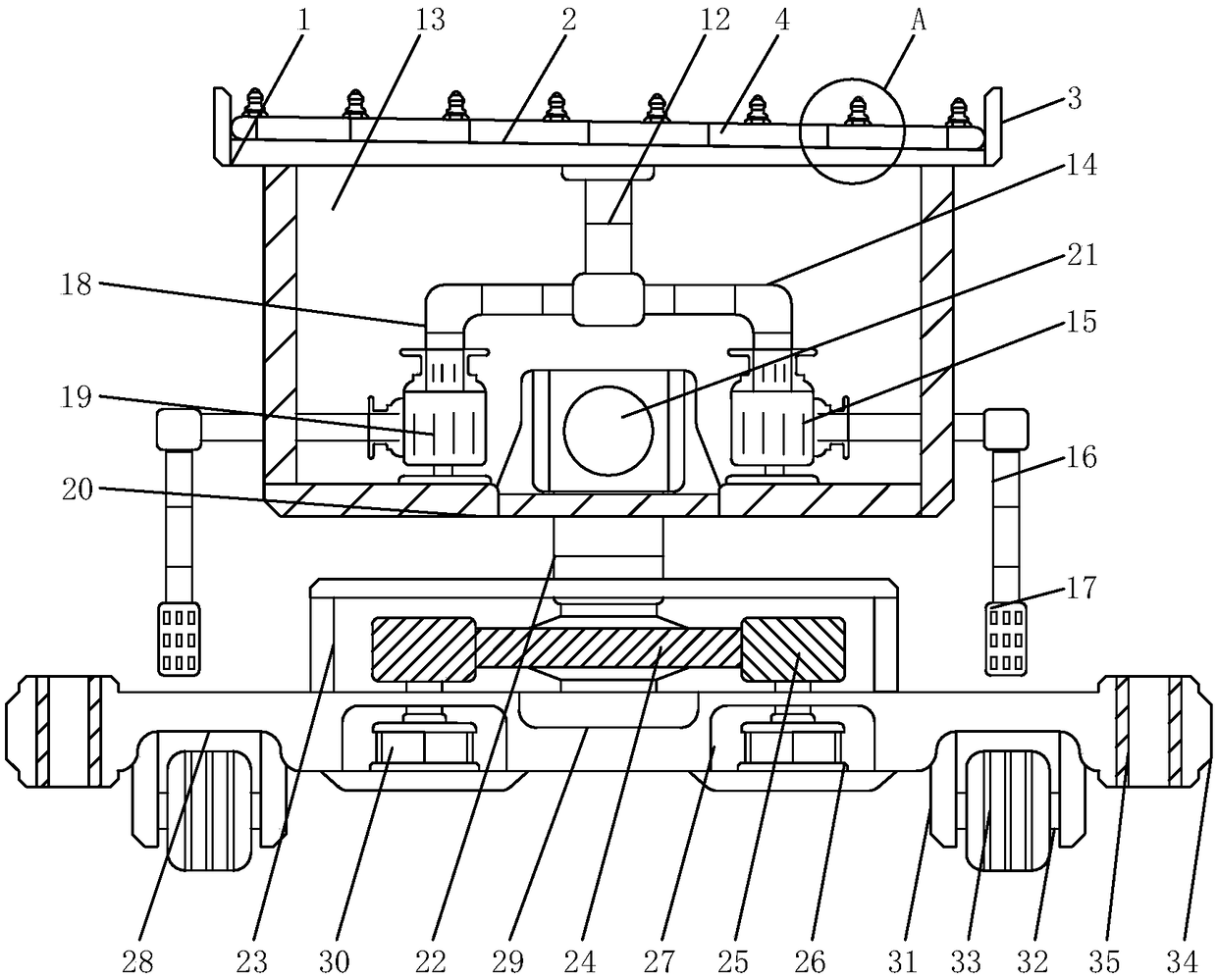

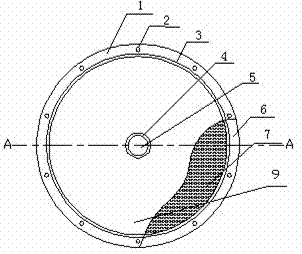

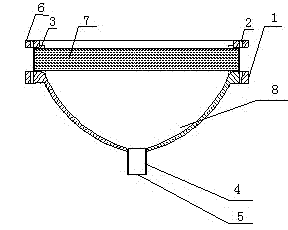

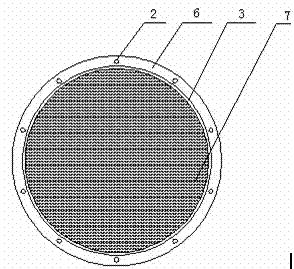

Titanium micro-pore aerator disc

InactiveCN102730856AAvoid easy cloggingLarge apertureWater aerationSustainable biological treatmentHigh resistanceTitanium alloy

The invention provides a titanium micro-pore aeration disc, belonging to a waste water treatment technology. The titanium micro-pore aeration disc consists of a bottom plate, titanium alloy porous panels, and an air guide tube; the bottom plate is round; fixing holes are arranged around the bottom plate; the bottom plate is divided into an upper plate cover and a lower plate cover; the titanium alloy porous panels are mounted between the two plate covers; a plurality of air vents are arranged on the titanium alloy porous panels; the air vents are 15-25 microns in diameter; and 5000-8000 micro-pores are arranged on the titanium micro-pore aeration disc in an area of 1 square meter. Sealing strips on the titanium alloy porous panels are sealed with the upper plate cover and the lower plate cover of the bottom plate. A semispherical cavity is formed between the titanium alloy porous panels and the lower plate cover. The bottom plate and the air guide tube are manufactured by machining a stainless steel material; and the titanium alloy porous panels are formed by machining titanium alloy powder. The titanium micro-pore aeration disc has the advantages of small aperture, large injection pressure, and simple structure, and the vents are not easy to be blocked. Furthermore, the titanium micro-pore aeration disc has the most outstanding advantages of high resistance of corrosion caused by ozone oxidation and organic chemical waste water, particularly aniline-contained waste water, and long service life.

Owner:JIANGSU FENGYUAN ENVIRONMENTAL TECH ENG

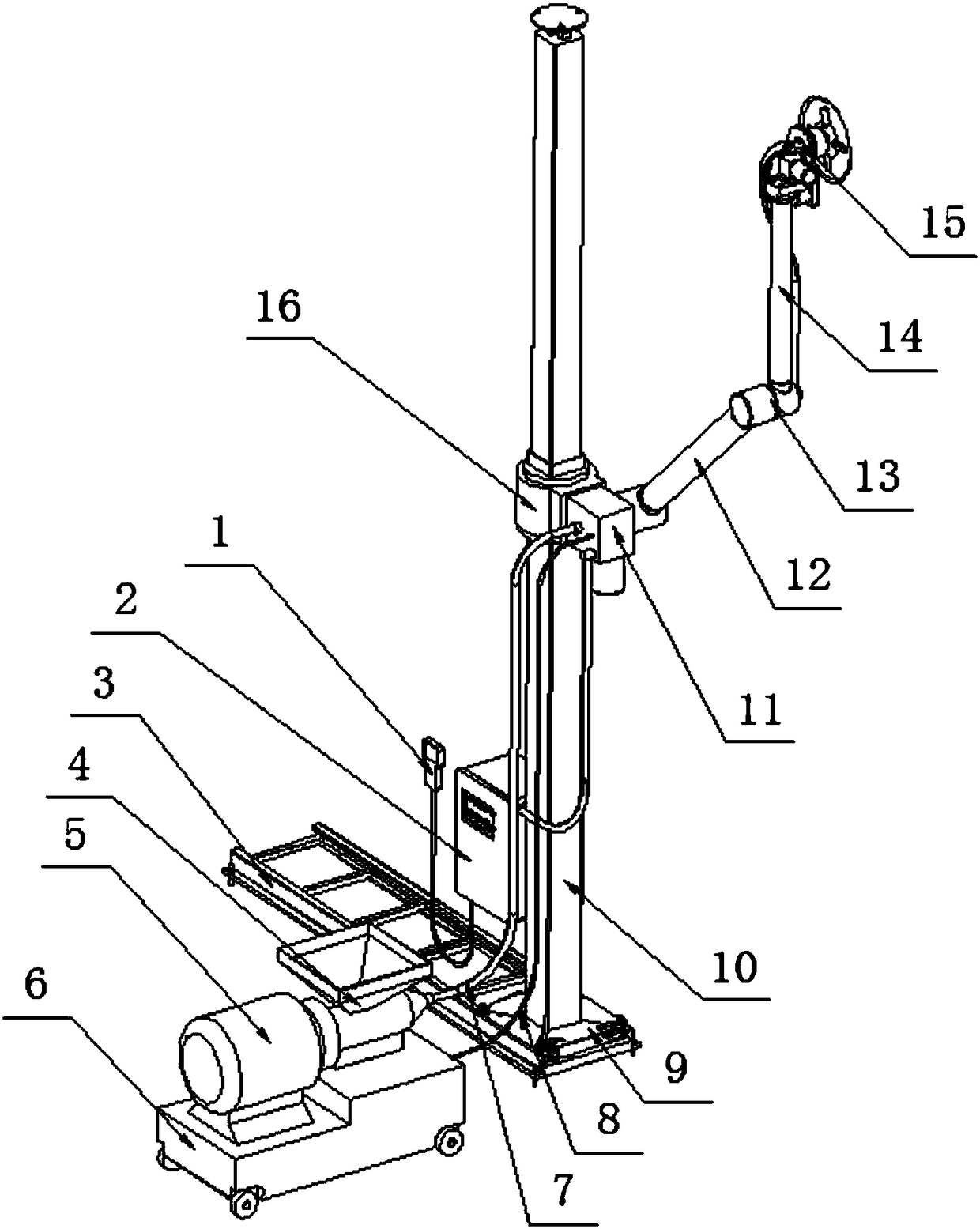

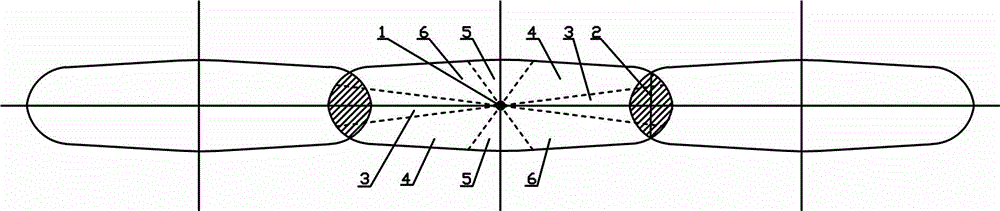

Uniform-thickness high pressure spraying grouting method used for diaphragm wall construction

InactiveCN105002911AImprove construction efficiencyImprove impermeabilityFoundation engineeringLow speedSlurry

The invention discloses a uniform-thickness high pressure spraying grouting method used for diaphragm wall construction. The uniform-thickness high pressure spraying grouting method comprises the following step of performing construction in a variable-speed rotary jet grouting and spray rod variable-speed lifting mode by utilizing a grouter. A nozzle is a single large-diameter nozzle. Through the construction mode of variable-speed rotary jet grouting and spray rod variable-speed lifting, low-speed grouting is performed in the wall forming direction; the grouting time in the wall forming direction is prolonged through low-speed lifting of a spray rod, and the wall forming length in the wall forming direction is increased, so that construction of high pressure spraying grouting holes is reduced, and accordingly the efficiency of the high pressure spraying grouting construction is improved; the wall forming range is larger, and the construction efficiency is higher. The situation that the wall forming thickness at the position of the spray rod is much thinner than that at the jetting far end because of the affection of a tilt angle is avoided. An original double-nozzle structure is replaced through adopting the single nozzle, so that jet power and penetrating power of the nozzle are enhanced; slurry and a soil mass are thoroughly mixed; and impermeability of a wall body is improved. And meanwhile, the situation, which occurs when the double-nozzle structure is adopted, that wall forming on two sides is not symmetrical or wall forming is finished only on one side caused by clogging of a nozzle on one side is avoided.

Owner:张松

Spray nozzle

InactiveCN104338631AEnough injection pressureIncrease injection pressureSpray nozzlesAcute angleSpray nozzle

The invention discloses a spray nozzle. The spray nozzle comprises a spray nozzle body, wherein a liquid inlet end is arranged at one end of the spray nozzle body; a liquid outlet end is arranged at the opposite end of the spray nozzle body; a cavity communicated with the liquid outlet end and the liquid inlet end respectively is formed inside the spray nozzle body; an inclined plane is arranged on the outer side surface, near the liquid inlet end thereof, of the spray nozzle body; the included angle between the inclined plane and the axis of the liquid inlet end is an acute angle; a plurality of drainage holes are formed in the inclined plane and are communicated with the cavity inside the spray nozzle body respectively. Through arrangement of the inclined spray nozzle body as well as the drainage holes, forming a radial shape, arranged on the spray nozzle body at intervals, the spray nozzle can provide a high enough spraying pressure; the flow of liquid entering the spray nozzle body is enlarged through the drainage holes to enlarge the outflowing amount of the liquid at the liquid outlet end of the spray nozzle, so that the spray nozzle has a very high spraying amount and a very high spraying force, and thus the quality of an electroplated product is improved; particularly, the spray nozzle can provide great help when a workpiece hole is relatively deep.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

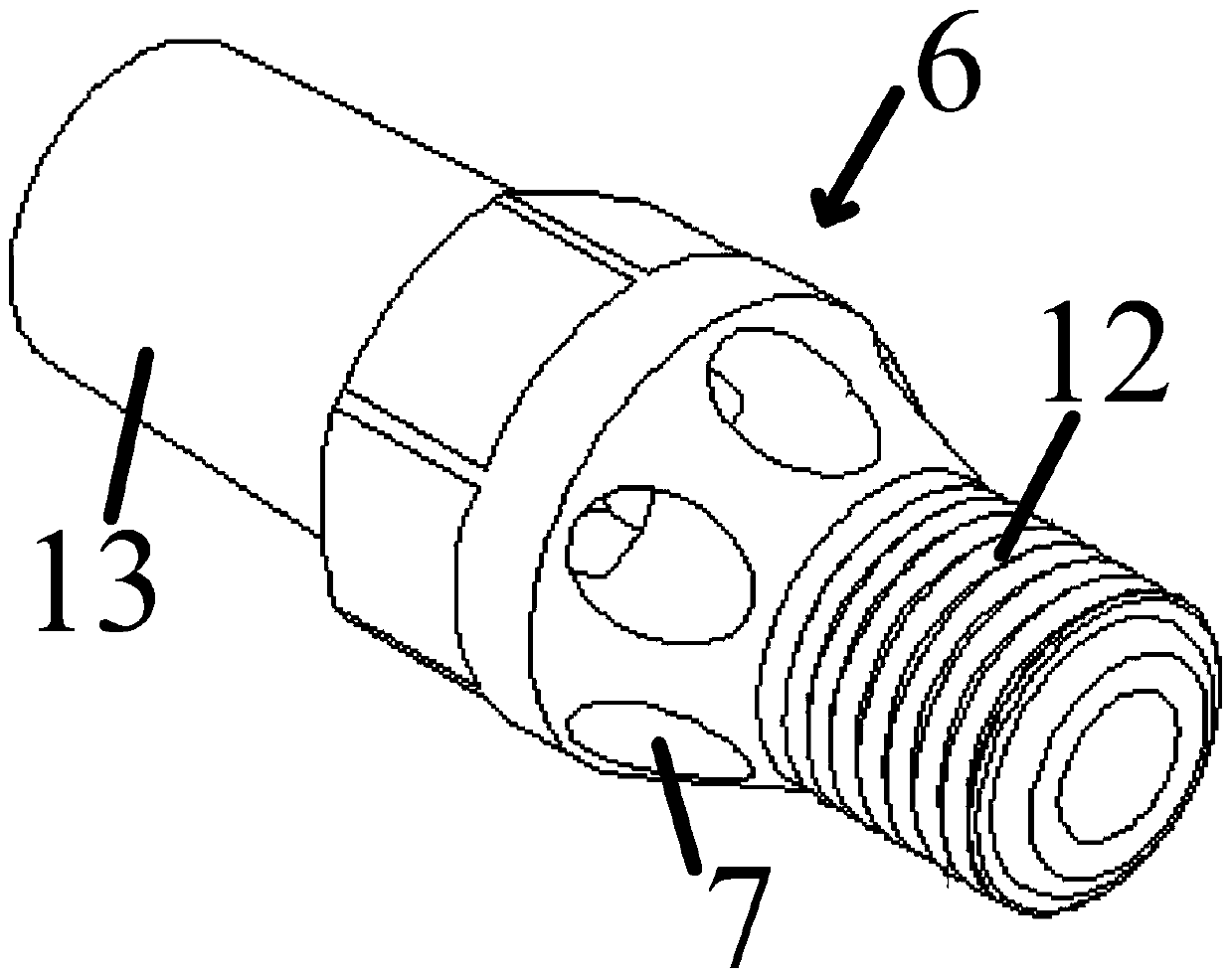

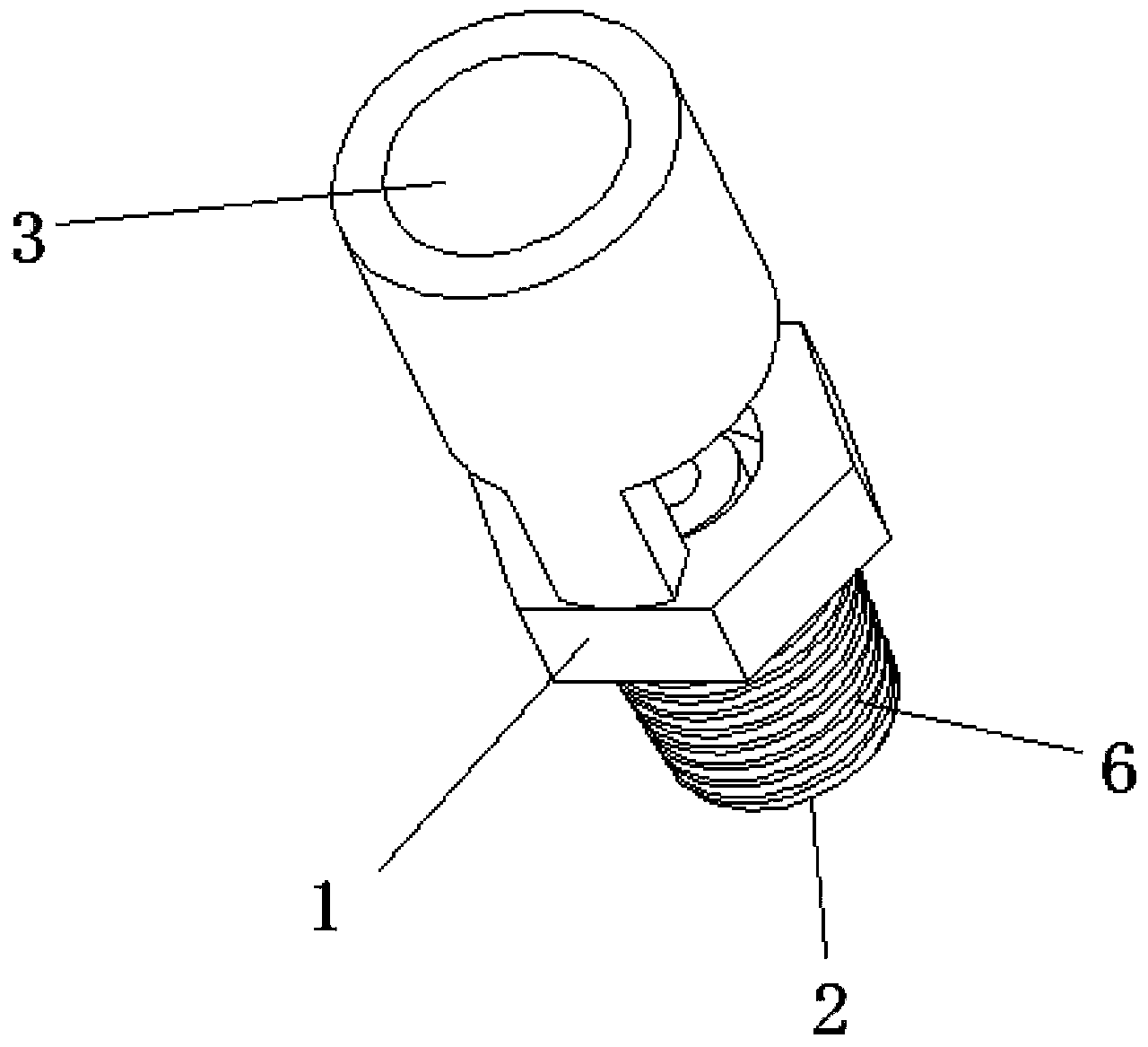

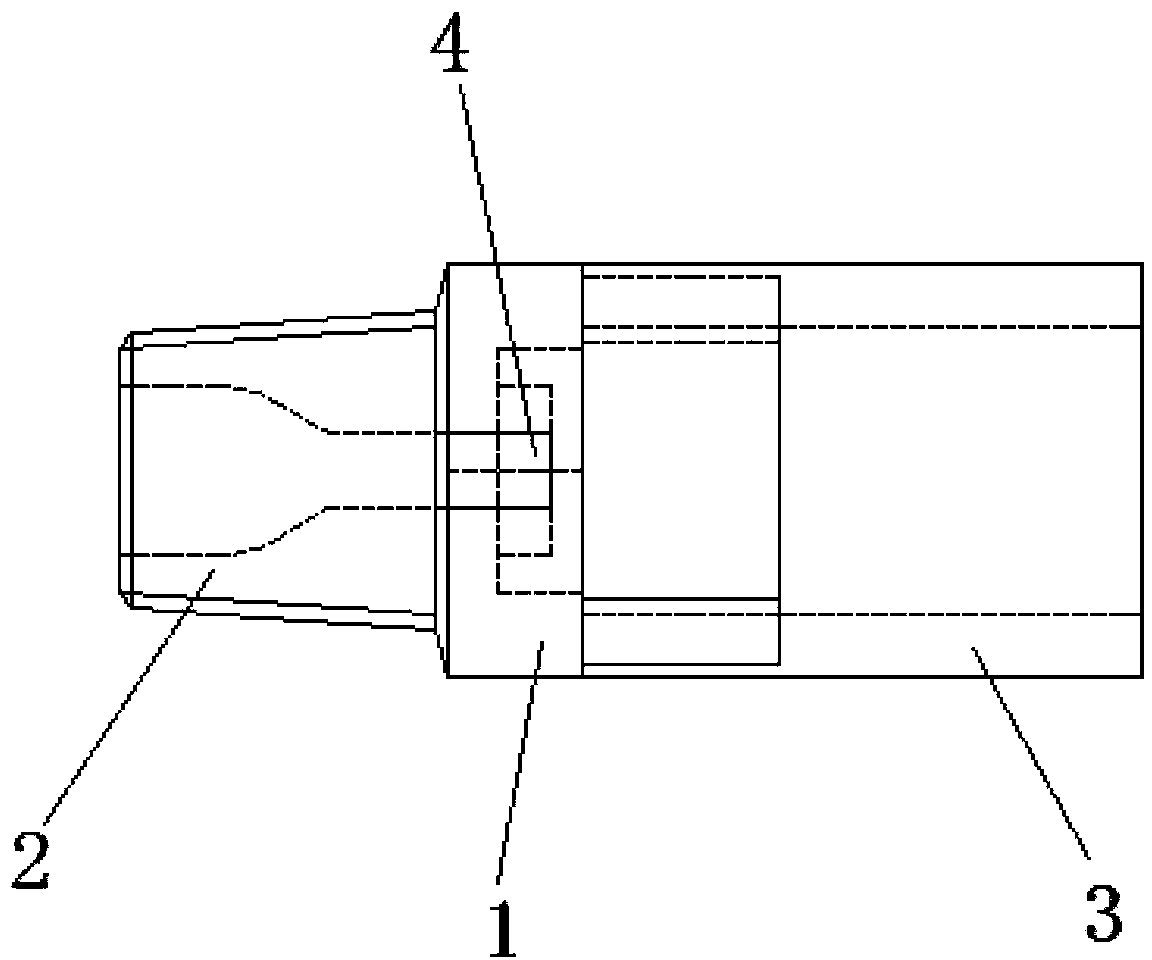

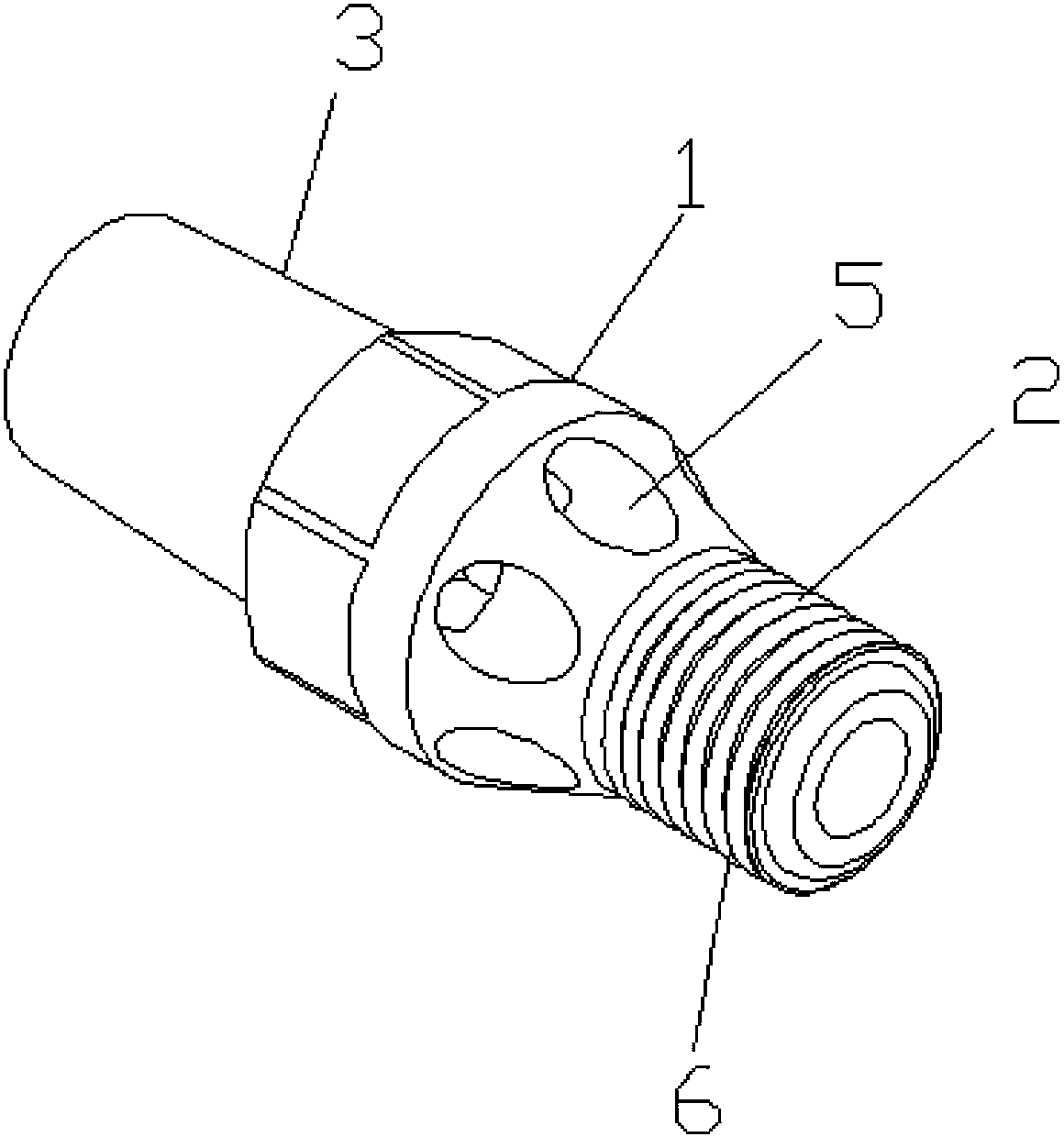

Marine high-pressure spraying nozzle

InactiveCN103507935AOvercome the shortcomings of insufficient injection power and low injection efficiencyIncrease jet powerPropulsive elementsHigh pressureNozzle

The invention relates to a marine high-pressure spraying nozzle which comprises a sleeve shell, a cavity, a conical body and a connector. The marine high-pressure spraying nozzle is characterized in that the conical body is fixed between the cavity and the connector through the sleeve shell, the sleeve shell, the cavity and the connector are connected through threads, the conical body is provided with a spraying hole, and the sleeve shell is provided with a reflection face corresponding to the spraying hole. The marine high-pressure spraying nozzle overcomes the defects that an existing high-pressure spraying nozzle is insufficient in spraying power, and low in spraying efficiency, an arc face reflection type spraying mode is used, the spraying power is enhanced, the spraying effect is improved, and stability of a ship is further improved.

Owner:WUXI TONGCHUANG FIBERGLASS BOAT FACTORY

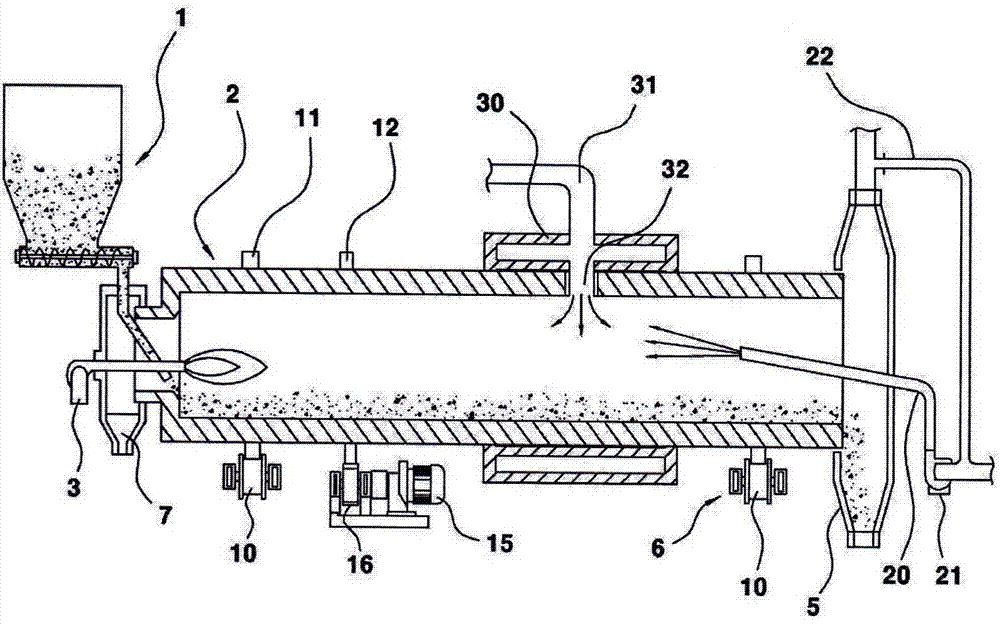

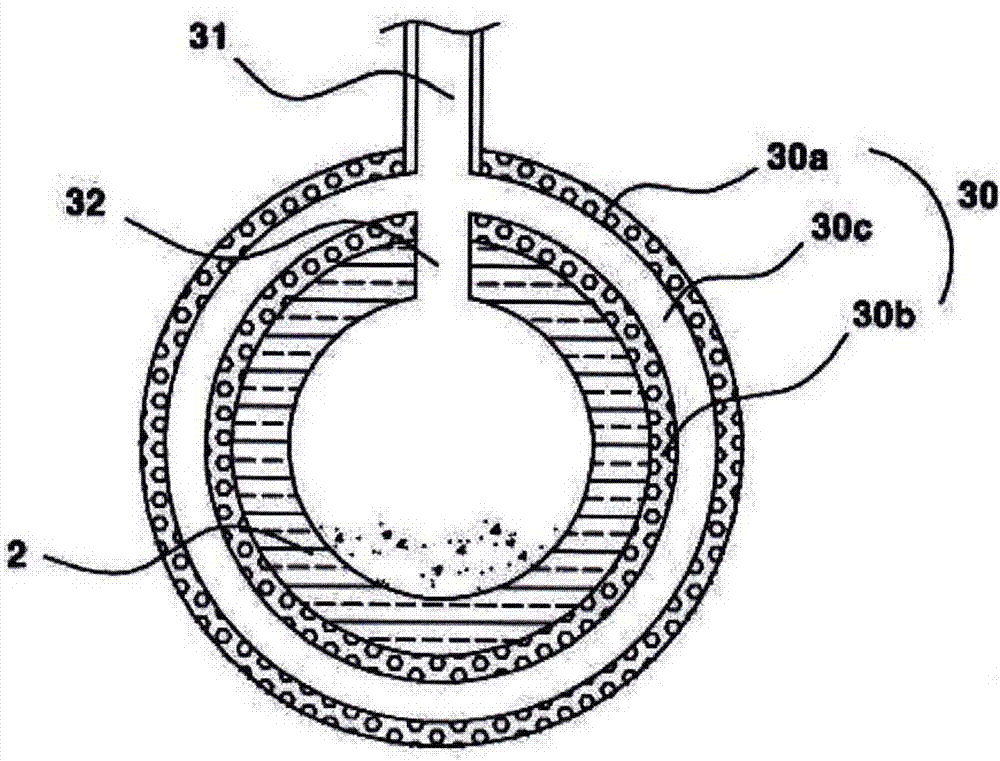

Apparatus for manufacturing bamboo activated carbon

ActiveCN103663447ASmall structural changesPromote formationCarbon compoundsBiofuelsActivated carbonEngineering

A manufacturing apparatus for activated bamboo carbon comprises a rotary kiln furnace; a burner; a reflux gas supply pipe; an outer container; a steam supply pipe; and a steam discharging hole. The reflux supply pipe is installed within the rotary kiln furnace so that the exhausted gas is collected by a blower in an outlet part of the rotary kiln furnace to supply the reflux gas including carbon monoxide to the rotary kiln furnace. The steam supply pipe is formed through the outer container toward the outer periphery of the rotary kiln furnace. The steam discharging hole is punched on one side of the outer periphery of the rotary kiln furnace, and open only when the steam discharging hole corresponds to the steam supply pipe by rotation of the rotary kiln furnace so that steam is supplied according to the rotation cycle of the rotary kiln furnace. The steam supply pipe and the steam discharging hole are formed to supply steam on an emission aperture of the reflux gas supply pipe within the rotary kiln furnace.The manufacturing apparatus for activated bamboo carbon enlarges micropore and surface area through improvement so as to obtain activated bamboo carbon with improved quality.

Owner:株式会社太江

Arc planing and cutting system and arc planing and cutting bar thereof

InactiveCN105983797AFull combustion reactionHigh ambient temperatureArc welding apparatusWelding/cutting media/materialsCutting forceBiomedical engineering

The invention aims to provide an arc planning and cutting system and an arc planning and cutting bar thereof. A planning and cutting force of the arc planning and cutting bar can be promoted. In order to achieve the purpose, the arc planning and cutting bar comprises a core wire and a coating, wherein the core wire has a holding end and a part coated with the coating. The arc planning and cutting bar is characterized in that the core wire is provided with a gas inlet and a gas path, wherein the gas inlet is located at the holding end and the gas path extends to the tail end of the core wire along the center of the core wire.

Owner:KUNSHAN BANKNOTE PAPER

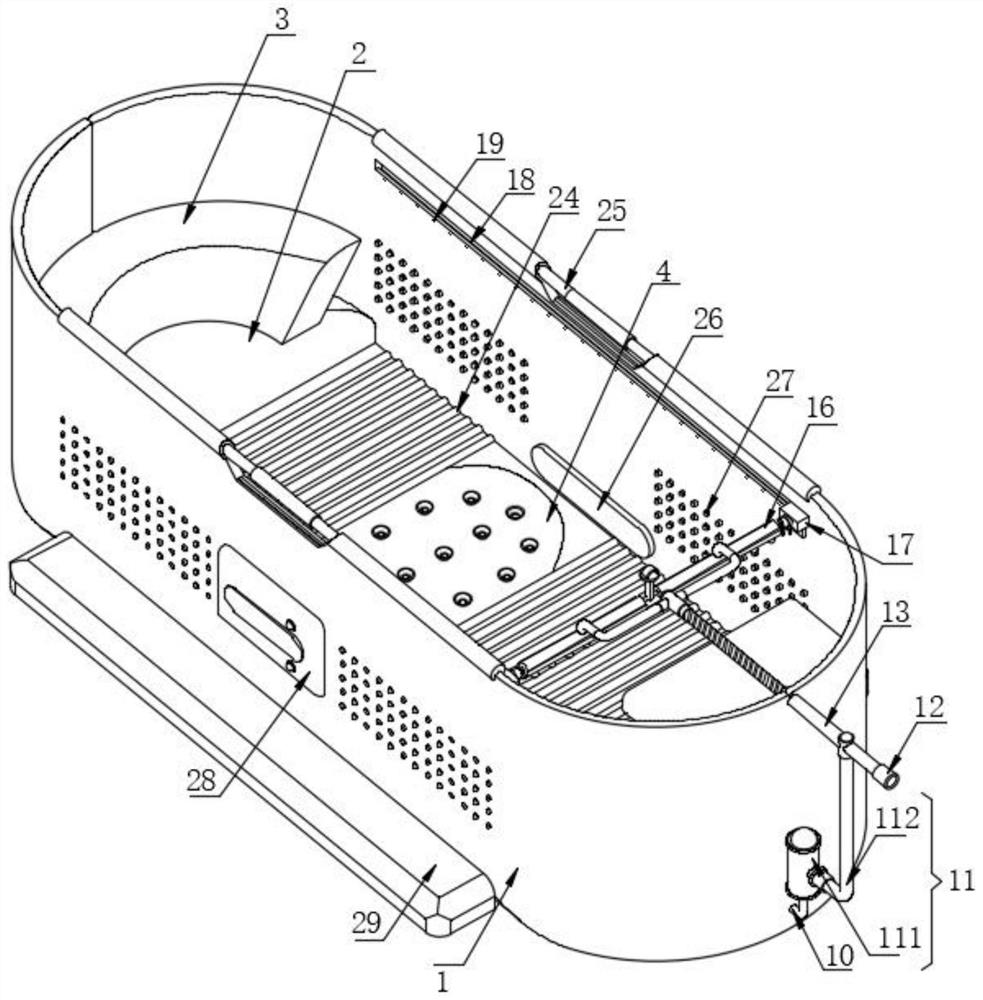

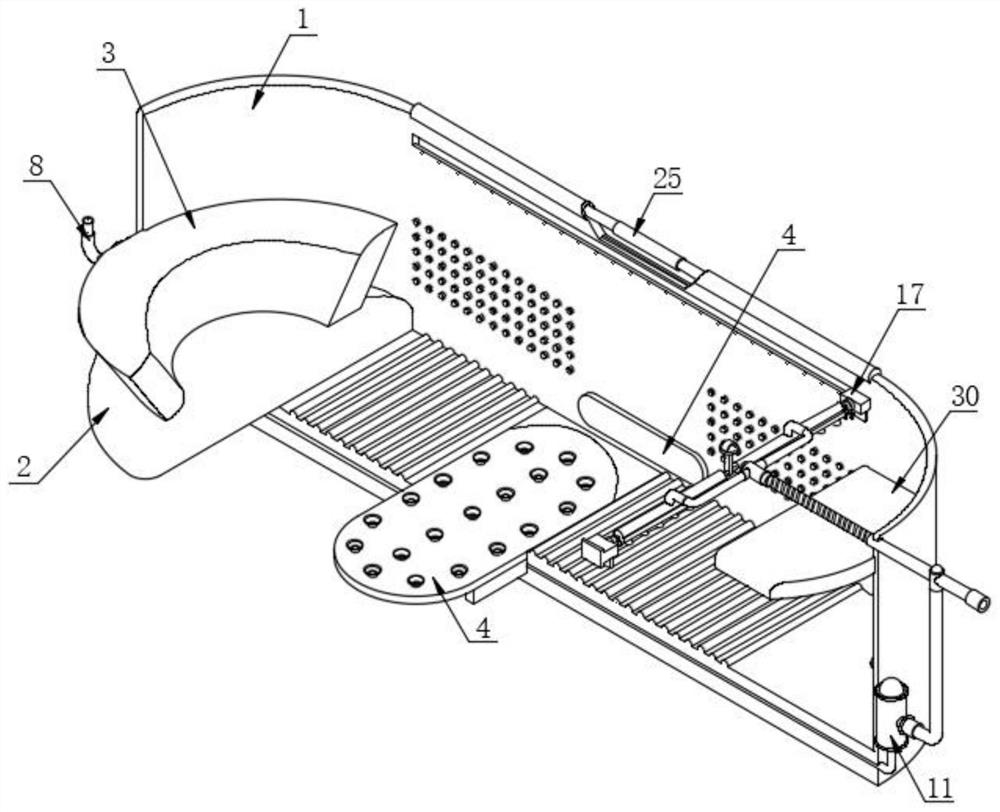

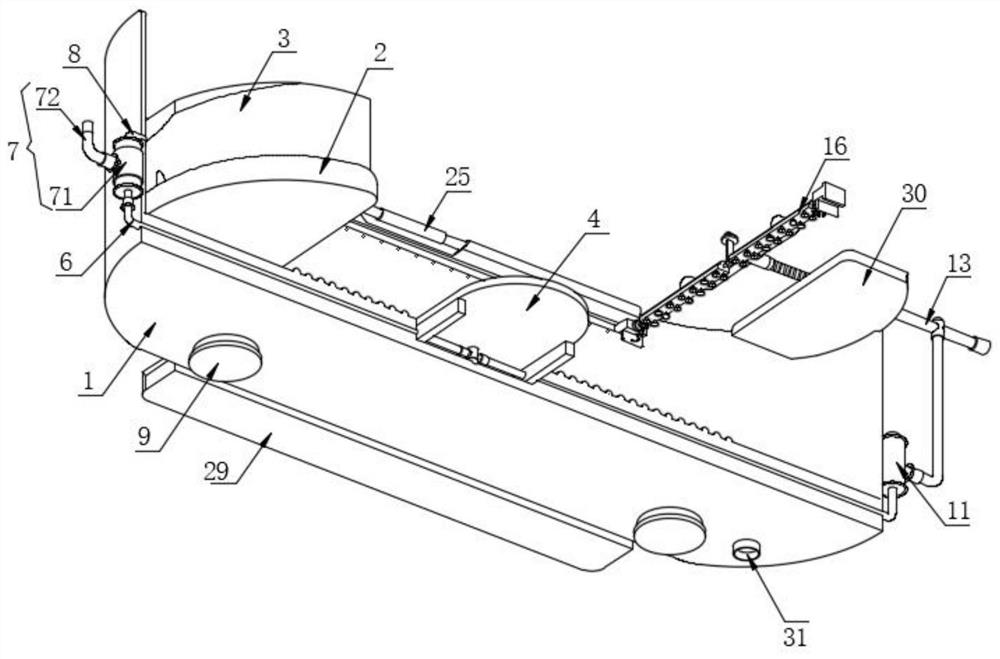

Intelligent bathtub with adjustable cleaning nozzle and adjusting method thereof

ActiveCN113768392AEffective flushingIncrease water pressure impactElectrotherapyBathsControl engineeringWater resources

The invention discloses an intelligent bathtub with an adjustable cleaning nozzle and an adjusting method thereof, and belongs to the technical field of intelligent bathtubs, the intelligent bathtub comprises a bathtub body, a permeable box is arranged on the left side of the lower surface of the inner wall of the bathtub body, and the upper surface of the permeable box is fixedly connected with the lower surface of a back cushion. The two spraying pipes are adjusted by holding the handle, the two spraying pipes can be driven to move leftwards by pulling the handle, water sprayed by the spraying heads can effectively wash the inner wall of the bathtub body, in the process of pressing the handle downwards, the handle drives the spraying pipes to turn downwards through the strong ribs, the position of the spraying heads is adjusted to be close to the inner side wall of the bathtub body, and water pressure impact force is increased; and secondly, when the spraying head continues to be adjusted, the handle can be held to turn over laterally, as a rotating shaft is sleeved with the bearing, the spraying pipe can turn over laterally to clean the bathtub body in multiple directions, and compared with a traditional mode, the scheme effectively achieves the purpose of cleaning the bathtub body in a multi-direction and synchronous spraying mode, saves water resources and improves the flushing effect at the same time.

Owner:江苏奥洁智能家居有限公司

Novel centrifugal rotor oil filtering machine

The invention relates to a novel centrifugal rotor oil filtering machine, and belongs to the field of impurity pollution oil centrifugal purification treatment. A rotor is installed on the outer side of a center shaft in a sleeving manner, an oil isolating sleeve is installed on the outer side of the rotor in a sleeving manner, an outer cover covers the exterior of the rotor, blades are arranged at the top end face of the rotor, outer cover spraying heads are arranged nearby the inner top face of the outer cover and are communicated with a high-pressure working hydraulic oil pipe, the spraying direction of the multiple outer cover spraying heads is coincident with the rotating direction of the rotor, and jetting is carried out in the tangential direction of the rotor; a center hole is communicated with an inner cavity of the rotor through a first transition oil hole and a second transition oil hole, the center hole of the center shaft is communicated with an oil inlet channel in a base, one end of a cleaned pressure oil way arranged inside a rotor bottom cover is communicated with the inner cavity of the rotor, and the other end of the pressure oil way is provided with a rotor spraying head; and the jetting direction of the rotor spraying head is opposite to the rotating direction of the rotor, and jetting is carried out in the tangential direction of the rotor. The novel centrifugal rotor oil filtering machine is used for centrifugal purification treatment of oil such as cutting oil, line drawing oil, circulatory system oil, anti-rusting oil, flushing oil and cold heading oil which are easily polluted by impurities.

Owner:孙亮熙

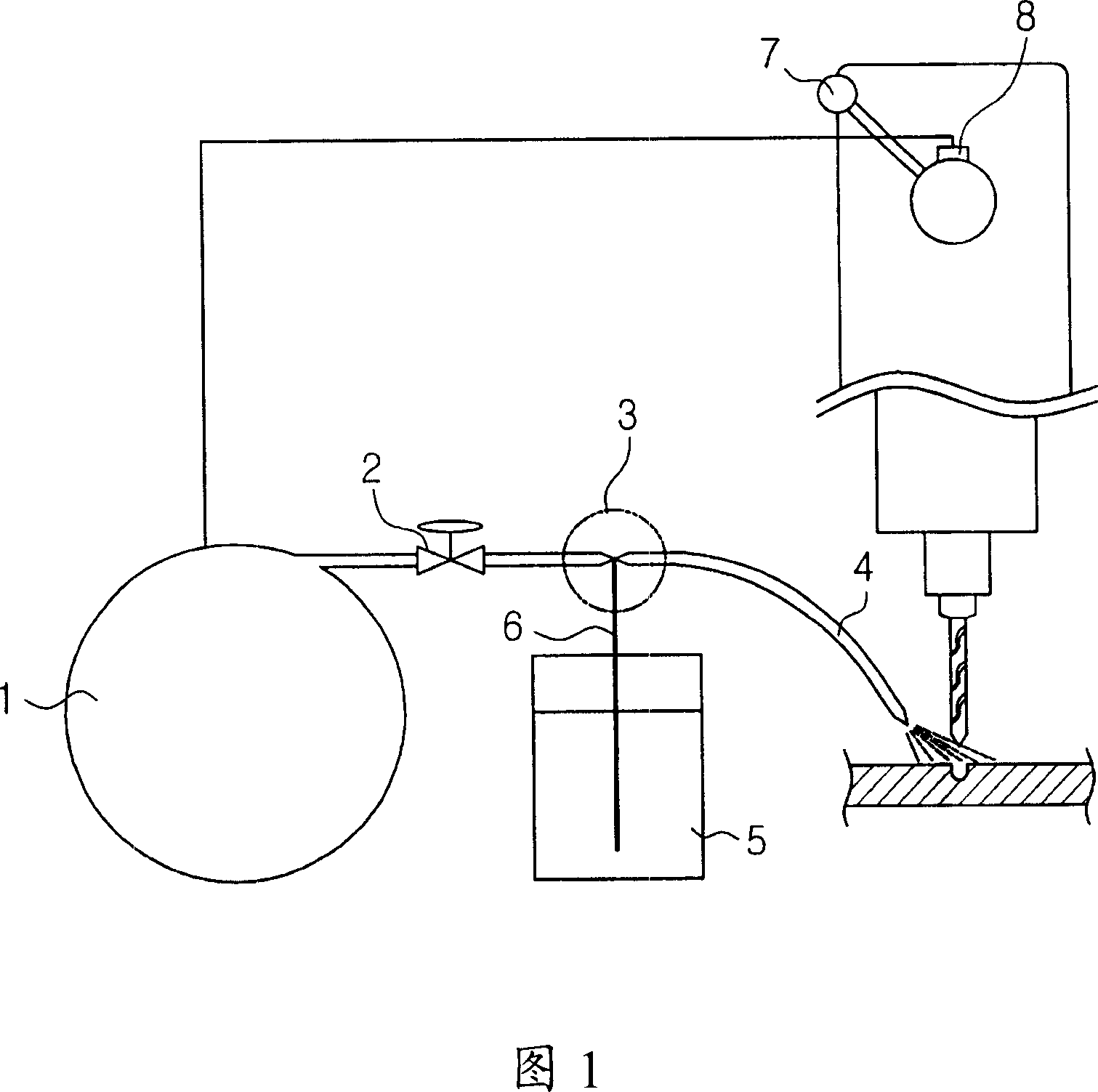

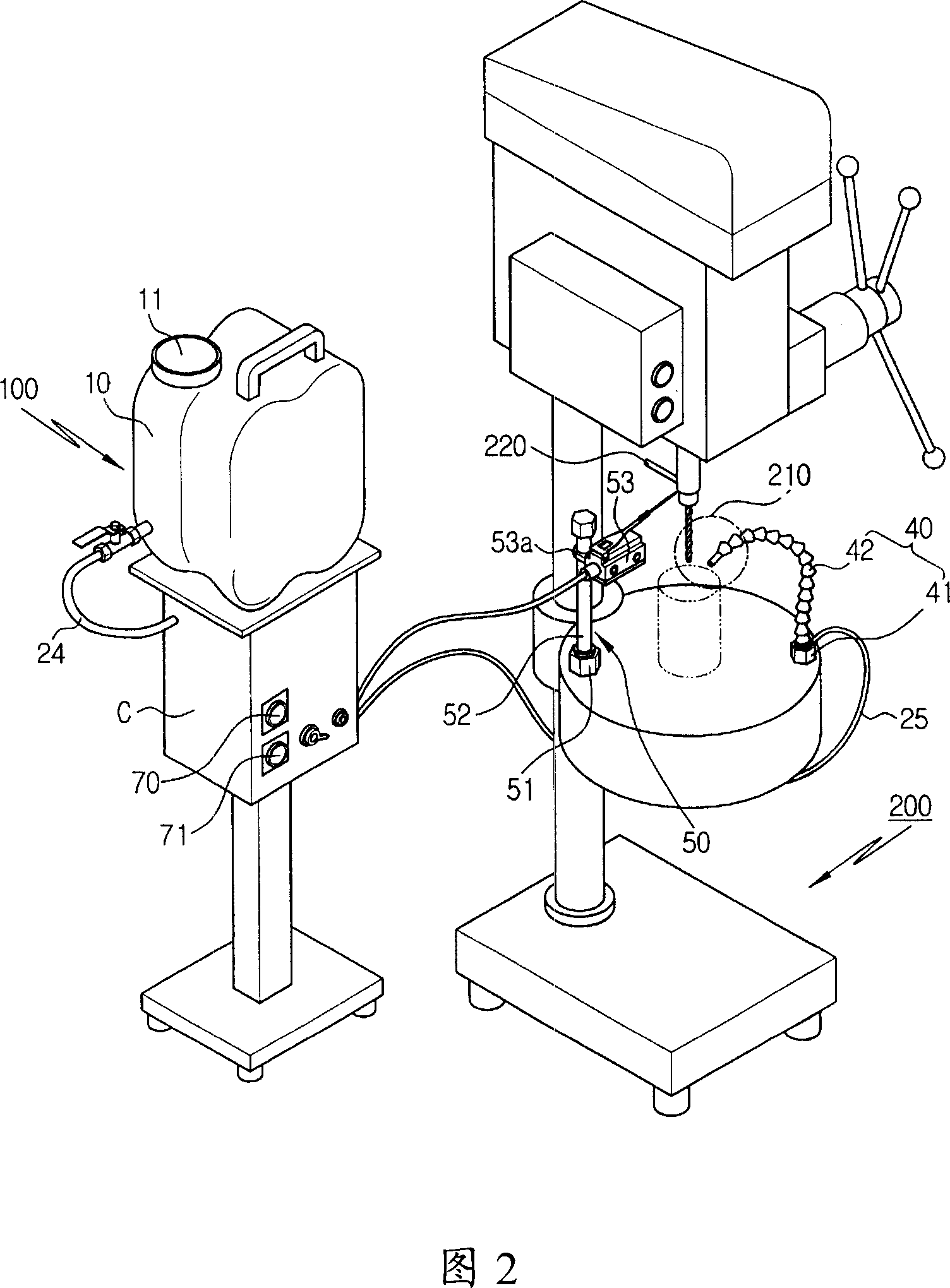

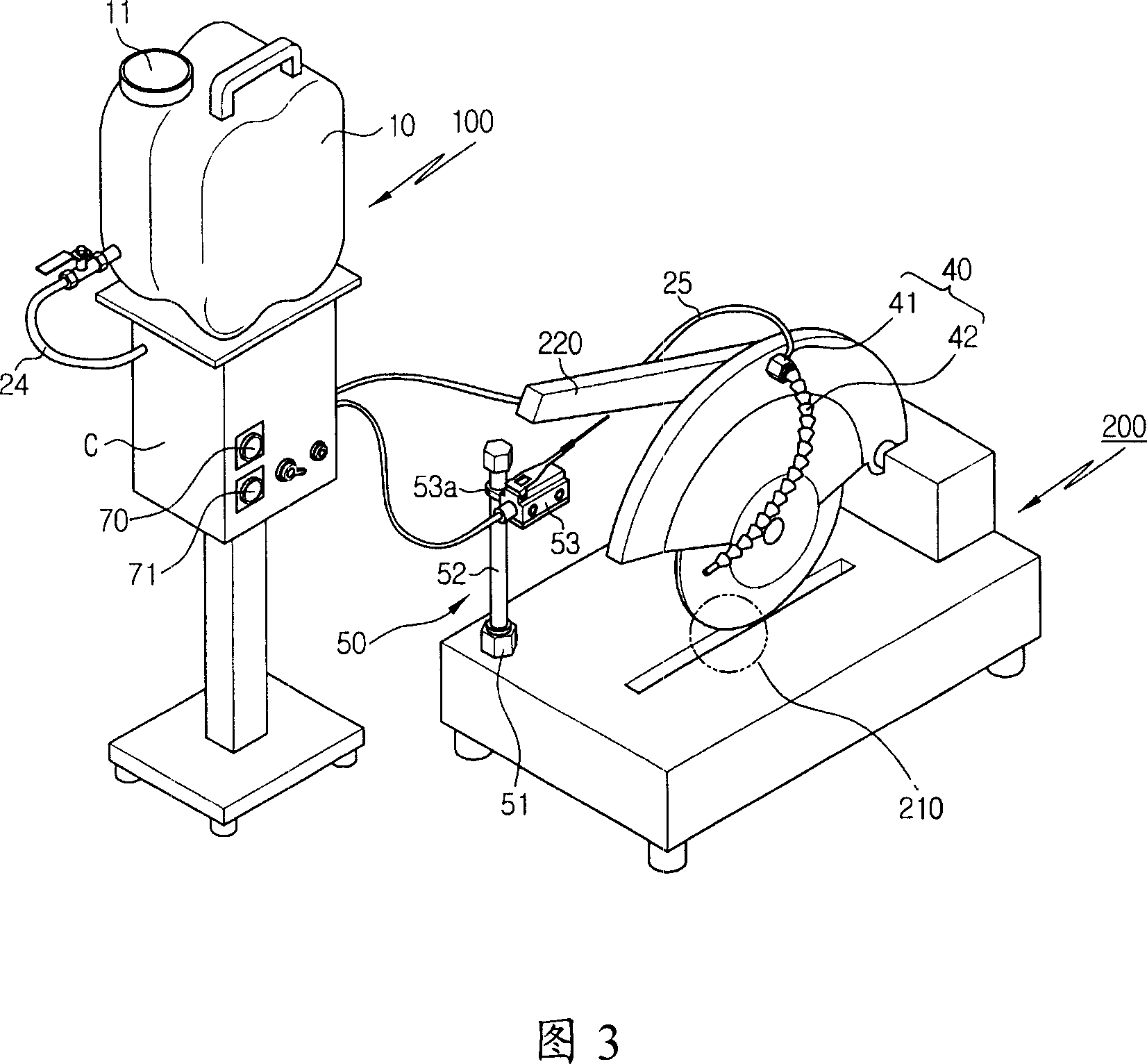

A portable apparatus for suppling cutting oil

InactiveCN101058154AIncrease jet powerBoard gamesMaintainance and safety accessoriesSpray nozzleFuel tank

The present invention relates to a portable apparatus for supplying cutting oil which is used for working instrument. The characteristics of the mentioned apparatus is that in order to improve the spraying force of the cutting oil through simple structure and to set muzzle part and switch part for the working instrument which needs cutting oil, to make the cutting oil in the oil box be inhaled by the supplying oil cylinder, at the same time, to spit the cutting oil and air to the muzzle part. The muzzle part and the switch part can be loaded and unloaded.

Owner:李美子

fountain system

Owner:日照新睿招商发展有限公司

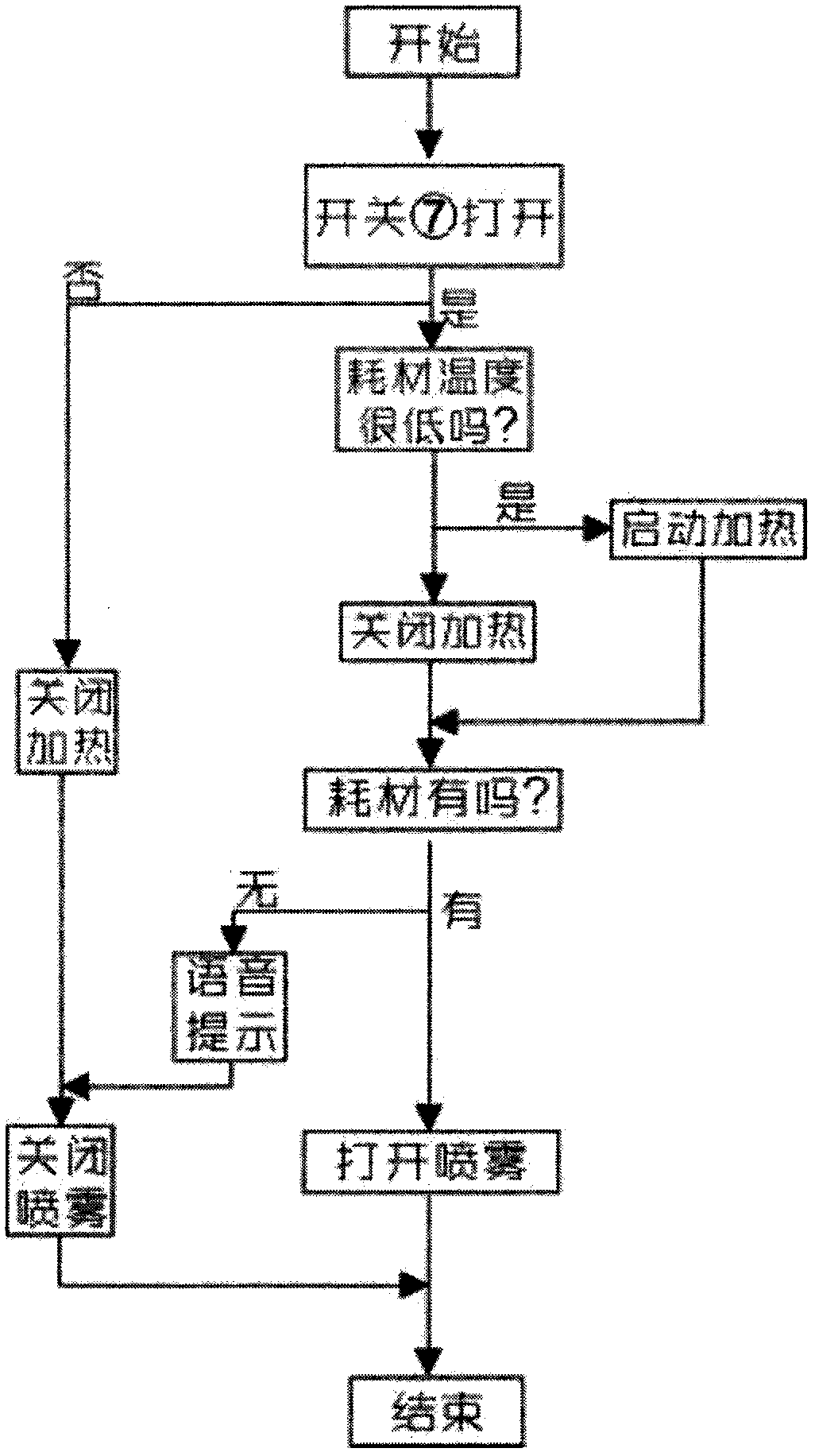

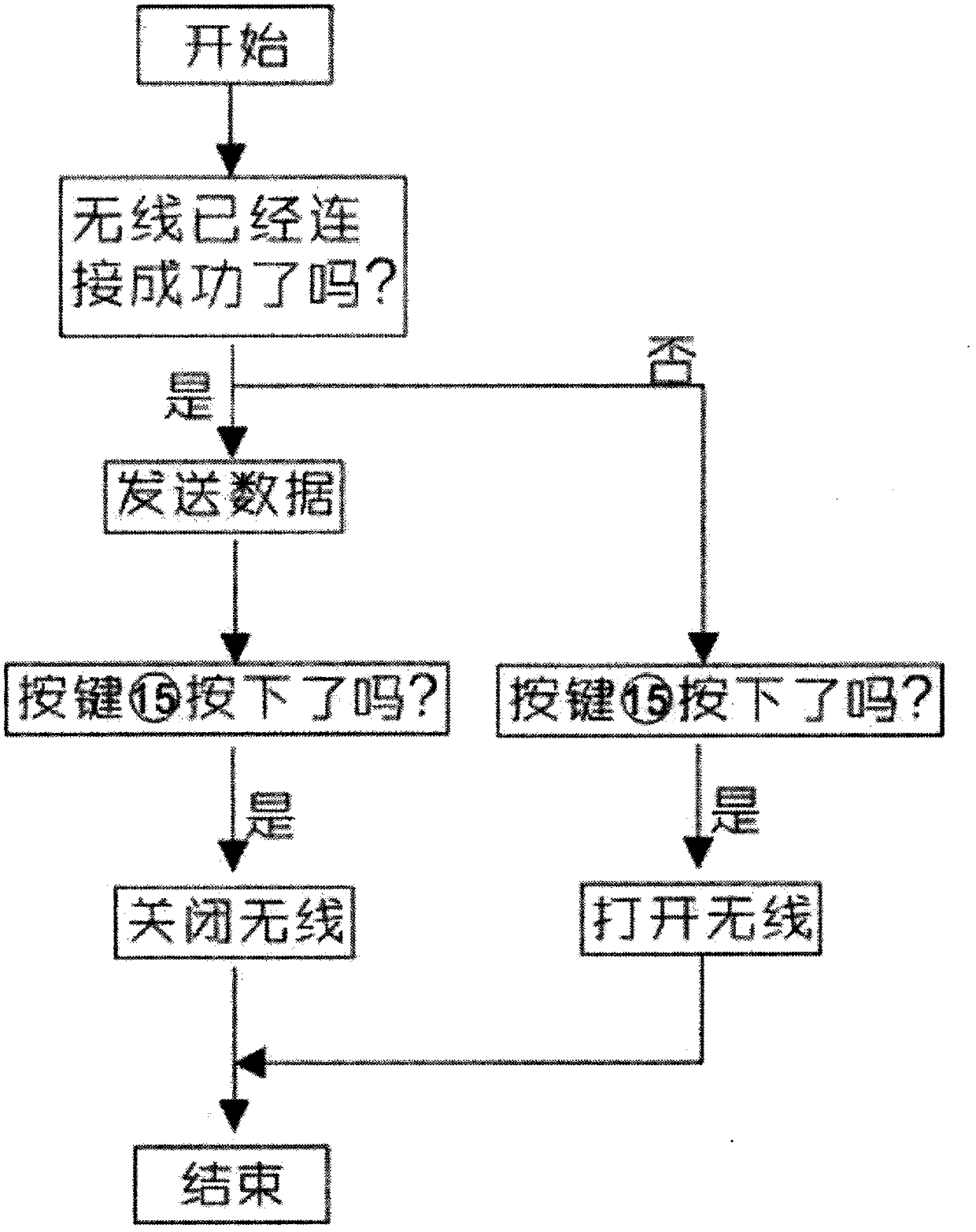

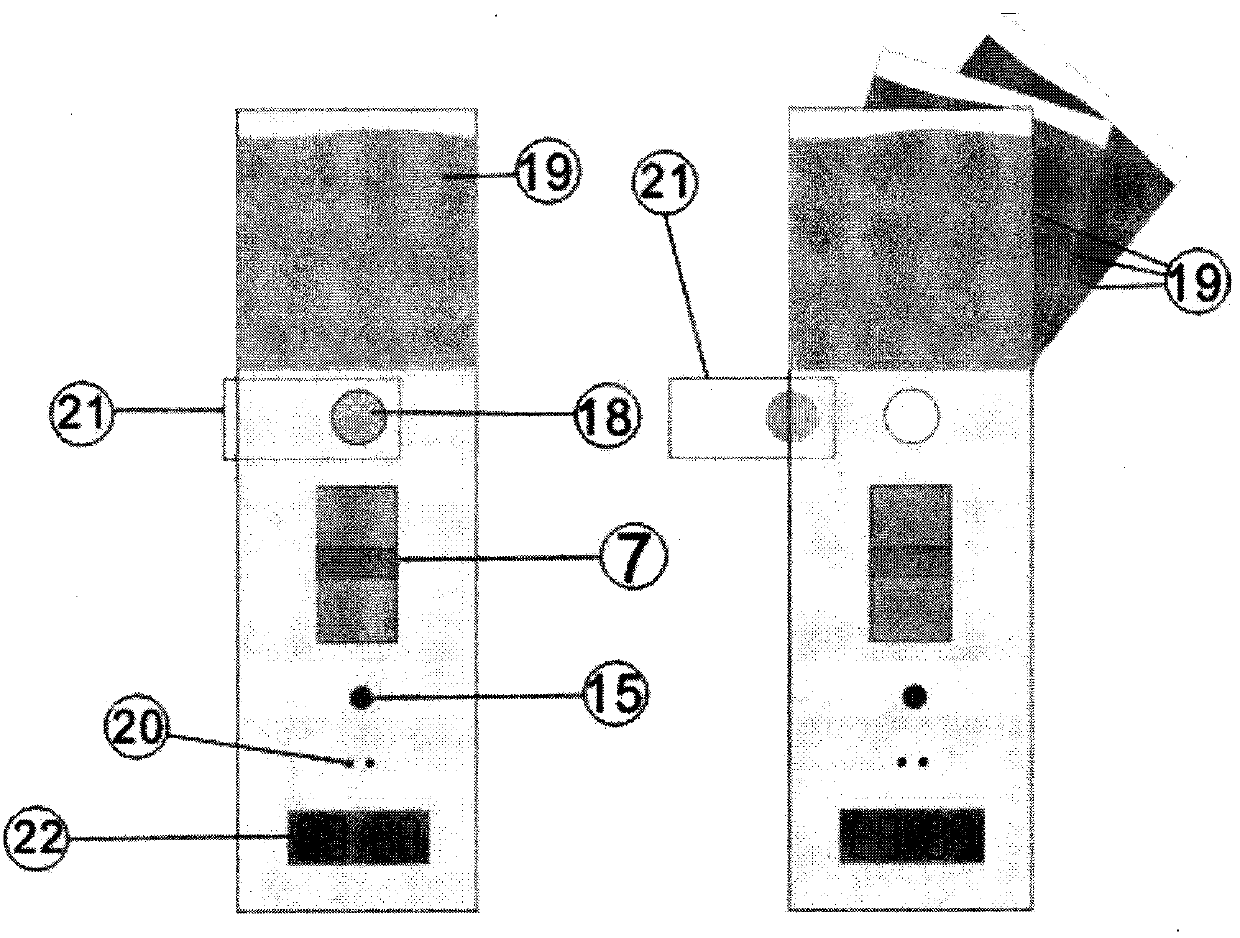

Multifunctional electronic mist spraying system using natural liquid consumable items

InactiveCN107693908AExtend your lifeIncrease jet powerMedical devicesMedical applicatorsSkin whiteningSide effect

The invention provides a multifunctional electronic mist spraying system using natural liquid consumption items. Through screening of natural substances and the novel structural design, program designand circuit design for prolonging service life, people's urgent demands for skin care and disease treatment can be met, skin care can be conducted anytime and anywhere, and treatment of trachea (bronchia) diseases and pulmonary diseases can be conducted anytime and anywhere. The system is great in convenience and effectiveness and wide in suitable customer range and has the advantages that 1, inthe skin care industry, the effects of moisture preservation, wrinkle resistance, skin whitening and the like can be better than those of normal chemical cosmetics, and skin quality can be improved anytime and anywhere by spraying mist once; 2, in the aspect of treating diseases, stimulation, sensitization, hormone dependence and other side effects caused by existing various chemical spraying agents can be reduced, and great medicine expense can be reduced for the people suffering from diseases for a long time.

Owner:万允志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com