A method for reducing corrosion of crystal plate in cuprum chemistry mechanical lapping technics

A chemical-mechanical and grinding technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of corroded chips, defects, scrapped wafers, etc., achieve comprehensive cleaning, increase spray force, and reduce corrosion of wafers. effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

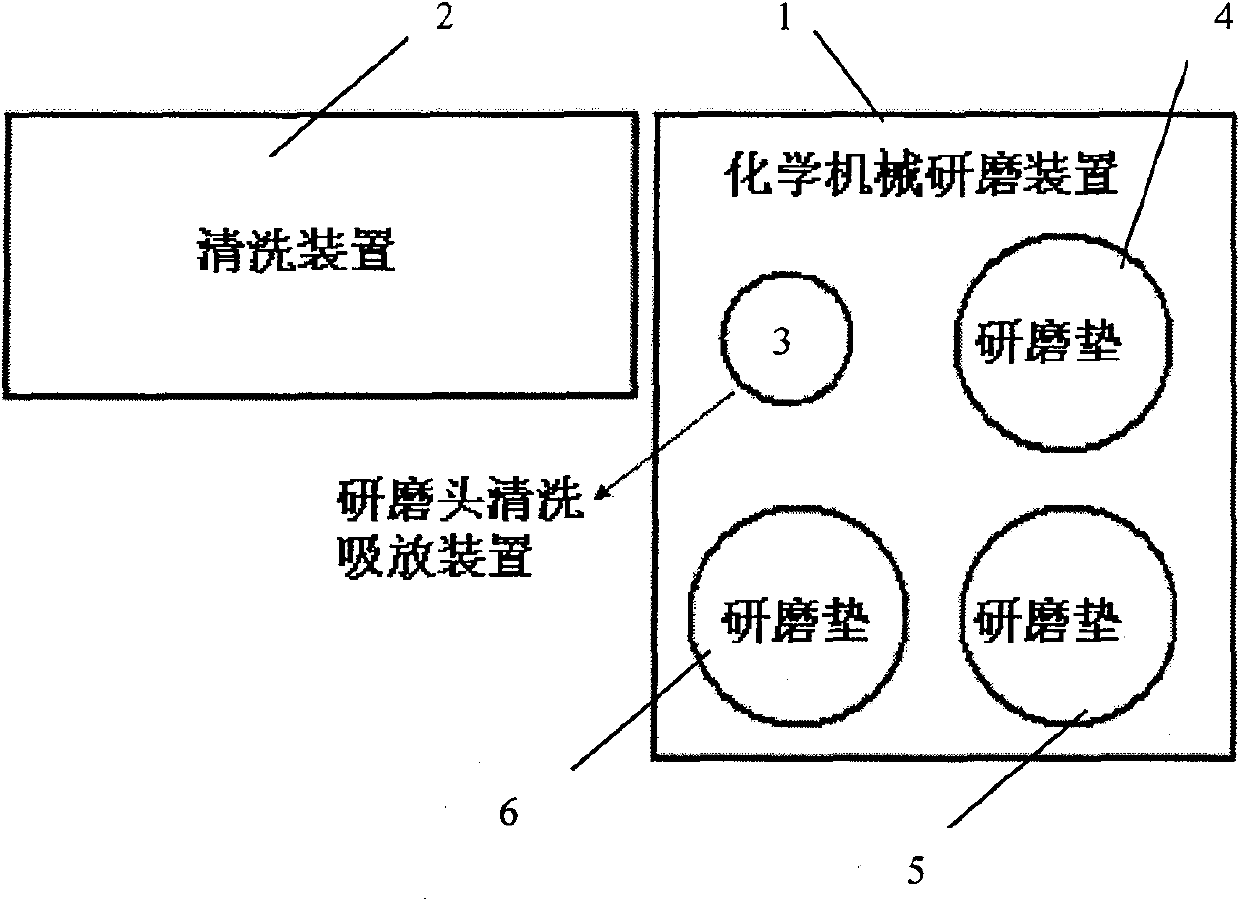

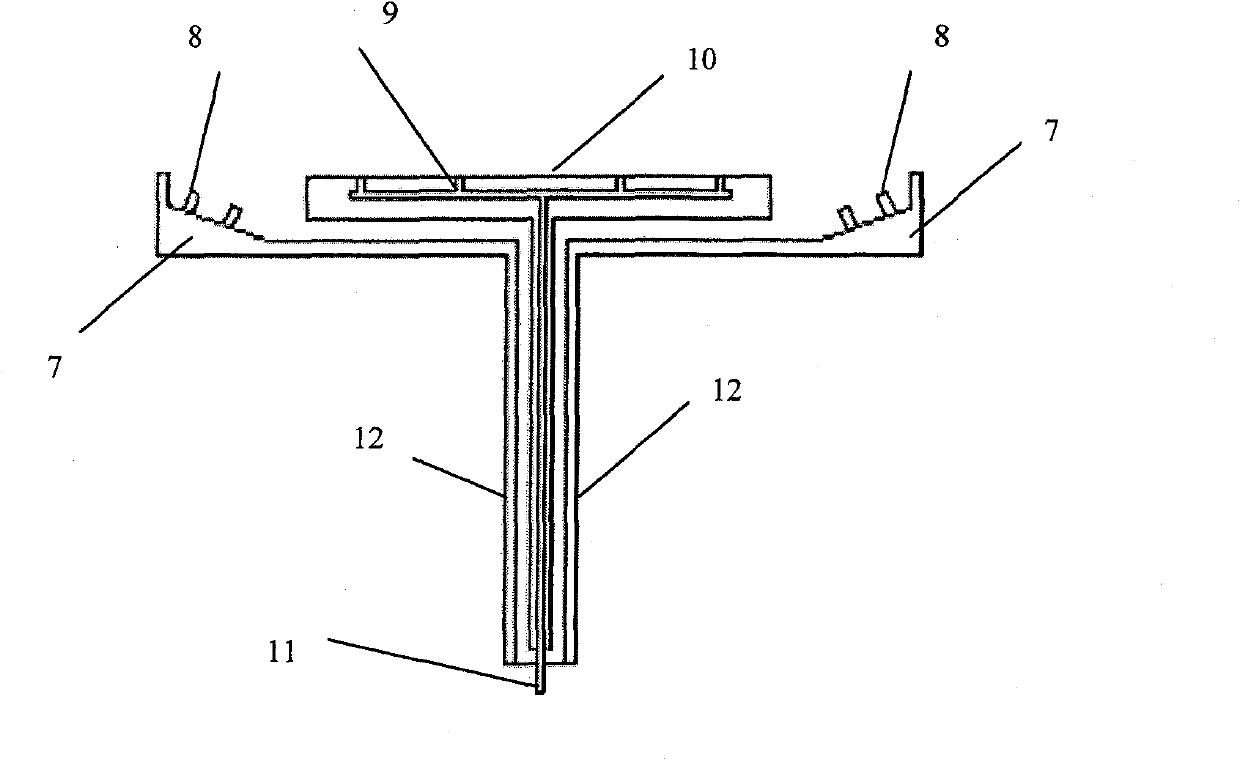

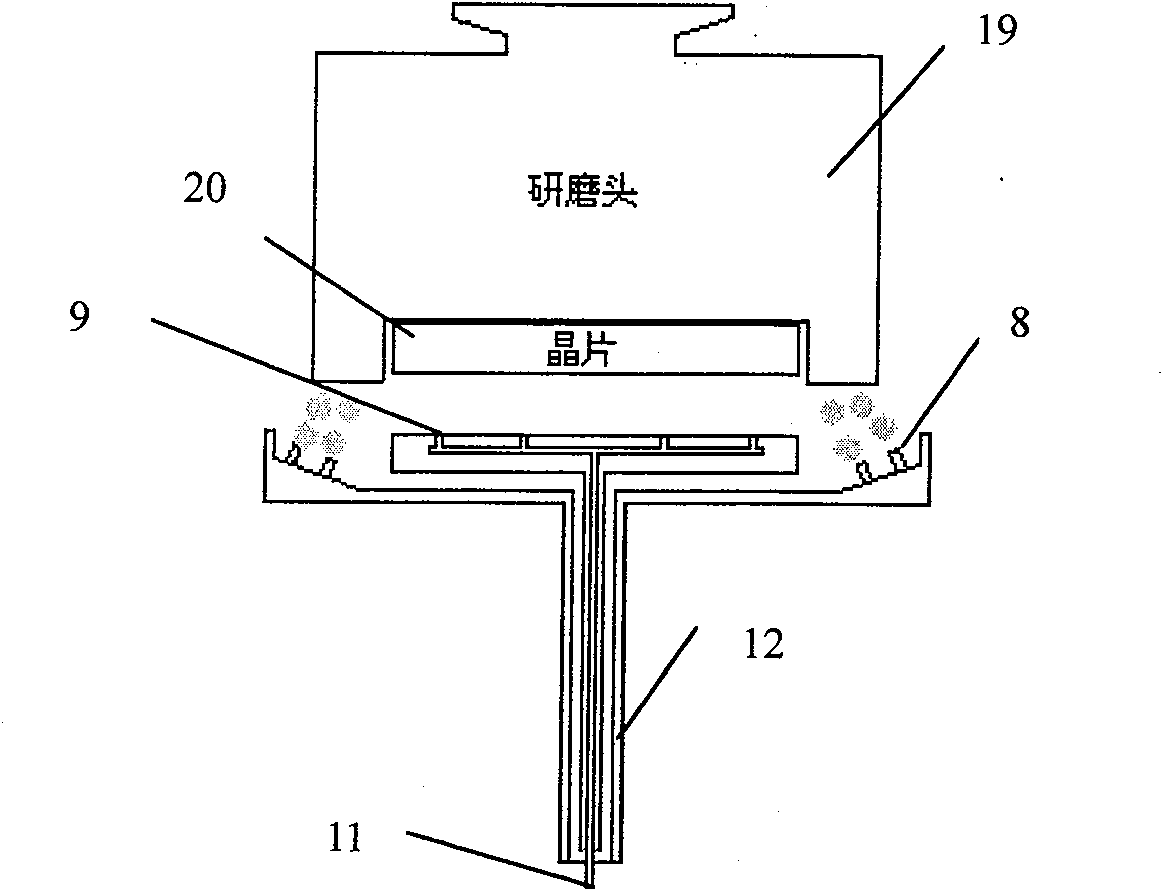

[0023] refer to figure 1 , 3 As shown, when the existing chemical mechanical grinding device is working, each grinding head 19 needs to go to the grinding head cleaning suction device 3 to suck a piece of wafer 20 respectively, and then go to the grinding pad 4, the grinding pad 5, and the grinding pad 6 for grinding. , Turn back to the grinding head cleaning suction device 3 to put down the wafer 20, and the manipulator passes the wafer 20 to the cleaning device 2 again. And the method of the present invention is exactly after grinding, before turning back to the grinding head to clean the suction and release device 3, open the water nozzle 9 of the suction and release platform 10, certainly also can open the water nozzle 8 of the cleaning cup 7 simultaneously, at this time working status as Figure 4 shown.

[0024] Such as Figure 5 As shown, it is a liquid circuit diagram of the grinding head cleaning suction device of the present invention. Control valves 13, 14 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com