Plate-spring universal powerful peening machine

A shot peening machine, powerful technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve the problems of poor flexibility, increase the surface hardness of metal parts, large stress mechanism, etc., and reduce the number of nozzles in the whole machine. , Extended service life, continuous effect of stress wall panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

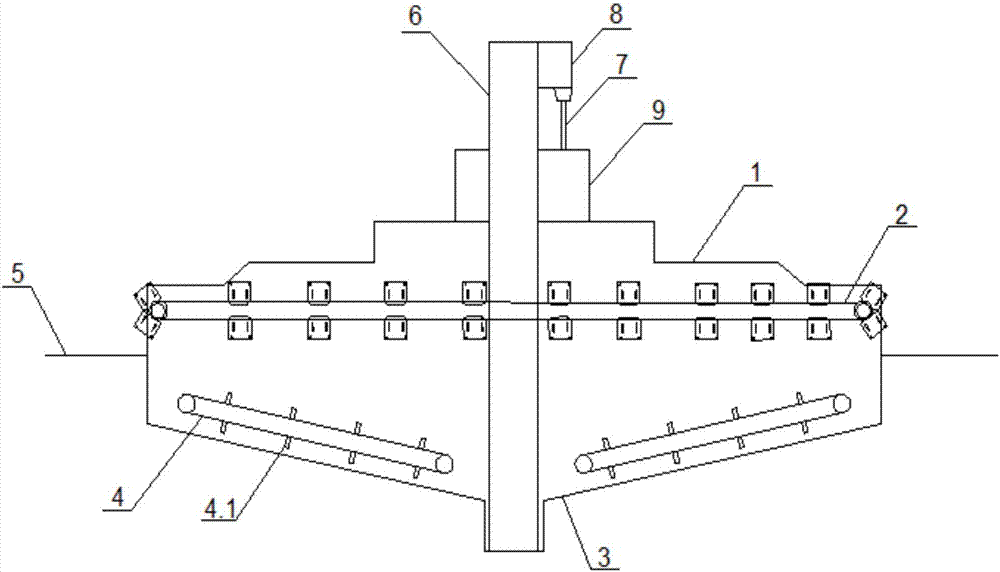

[0032] Such as figure 1 Shown, a kind of leaf spring universal powerful shot blasting machine comprises shot blasting chamber 1, comprises

[0033] The collision type nozzle mechanism 9 is located at the top of the shot blasting chamber, and is used for collision type shot blasting. The shell bolt of the collision type nozzle mechanism can be fixed on the top of the shot blasting chamber, and the entrance of the shot in the nozzle to enter the shot blasting chamber is opened;

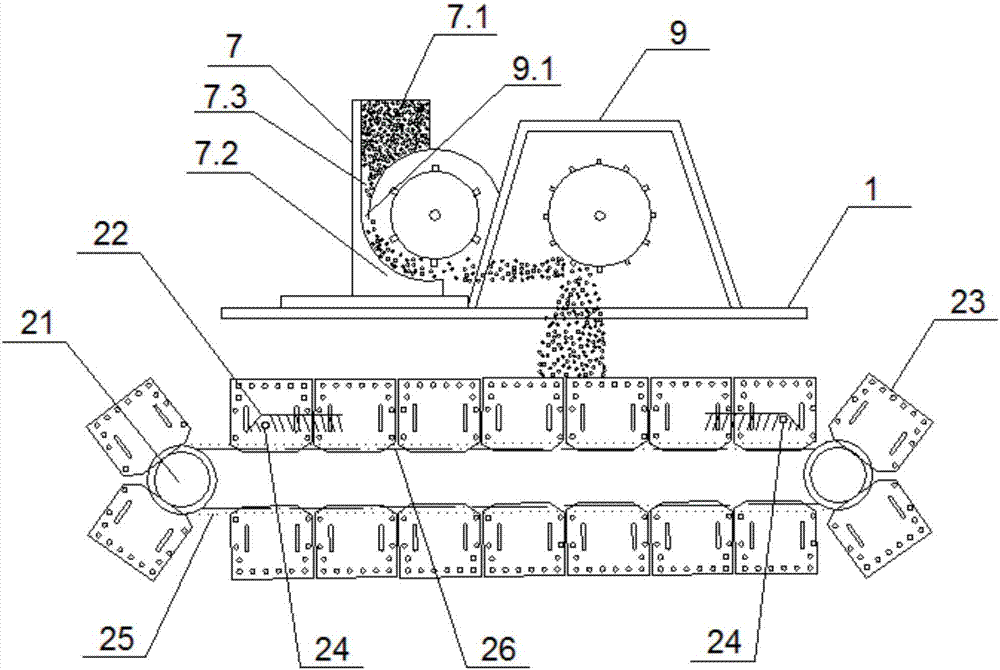

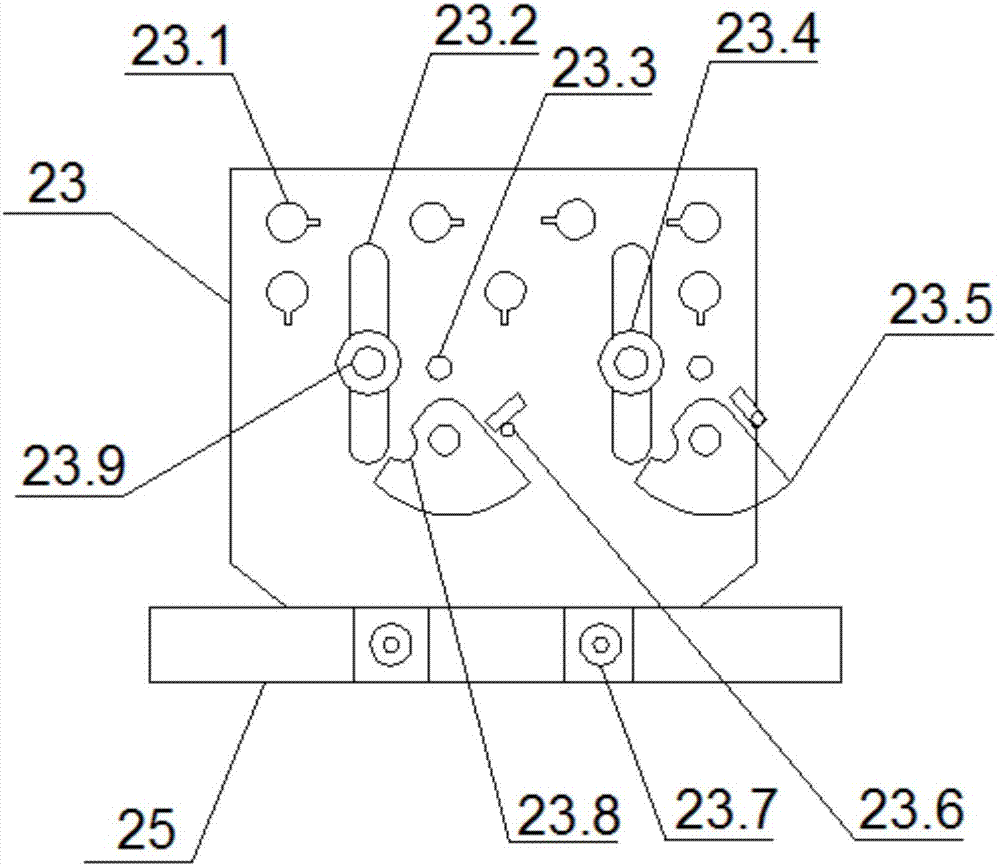

[0034] Such as figure 2 , image 3As shown, the stress fixture 2 is a chain rotary type, which runs through the shot blasting chamber 1 and is used to transport the workpiece, including the chain A25, the upper and lower rails 26 for the chain A25 to travel, located at the two ends of the chain A25 and walking on the upper and lower rails. The running wheel 21 in the middle of the lower track 26, the two sides of the chain A25 are provided with a number of stress wall panels 23, the stress wall panel...

Embodiment 2

[0041] In this embodiment, a dust removal pipeline is set above the shot blasting chamber 1 to absorb the dust generated during the shot blasting process. The stress fixture 2 adopts 350 chain shafts 23.7 with a diameter of 35 cm to form a chain, and every two chain shafts 23.7 fix a stress wallboard 23. In addition, a track 26 is set on the running route of the chain to change the soft walking state of the chain. Slopes 22 are arranged on both sides of the end track 26, and the bump tip 24 is fixed on the slope 22. A recovery pit 3 and a recovery pit 3 are set under the stress fixture 2 The inclined ends of both ends are equipped with a chain scraping mechanism, and the central depression of the recovery pit 3 is equipped with a hoist 6, and the two sides of the hoist 6 have projectile inlets. 8. The screen 8.2 with an aperture of 40 meshes is used, and the length of the shell 8.1 is 1200mm. The shaft seat is fixed on the shells at both ends with bearings, carrying the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com