Novel centrifugal rotor oil filtering machine

A centrifugal rotor and oil filter technology, which is applied in centrifuges and other directions, can solve problems such as difficulty in increasing the rotor speed, affecting the use effect, deformation of the rotor shell, etc., and achieve good dynamic balance, good oil filtering effect, and increased speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

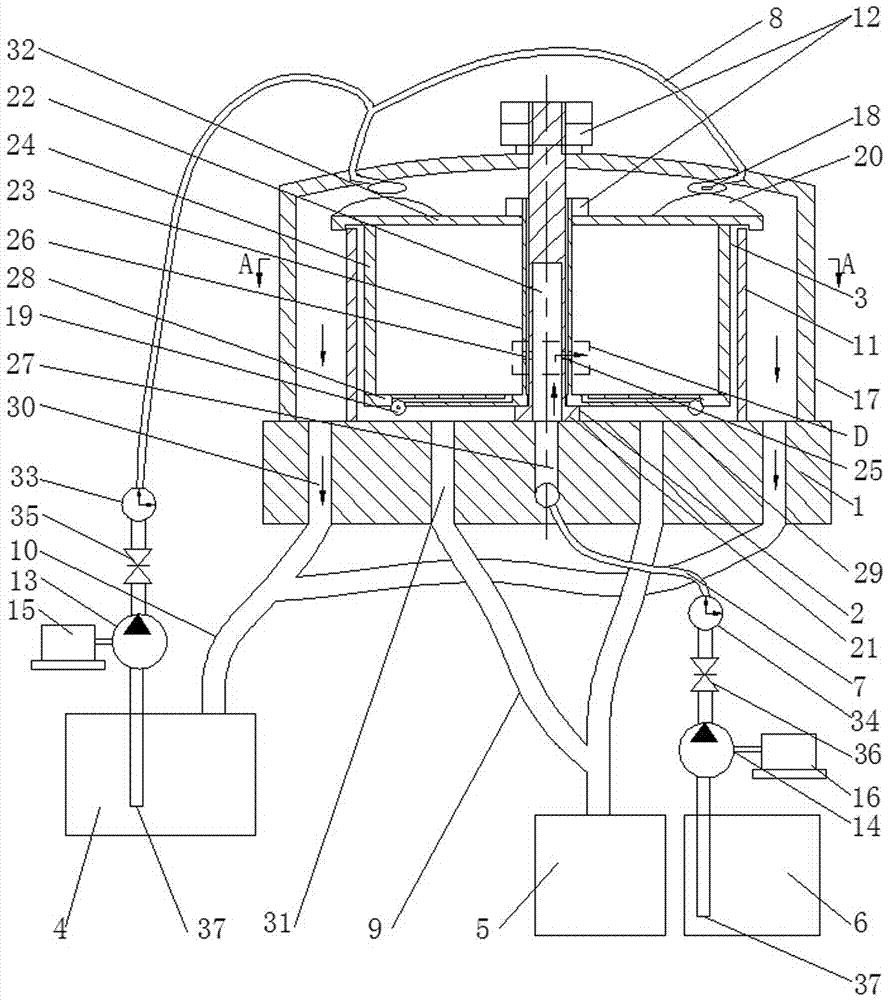

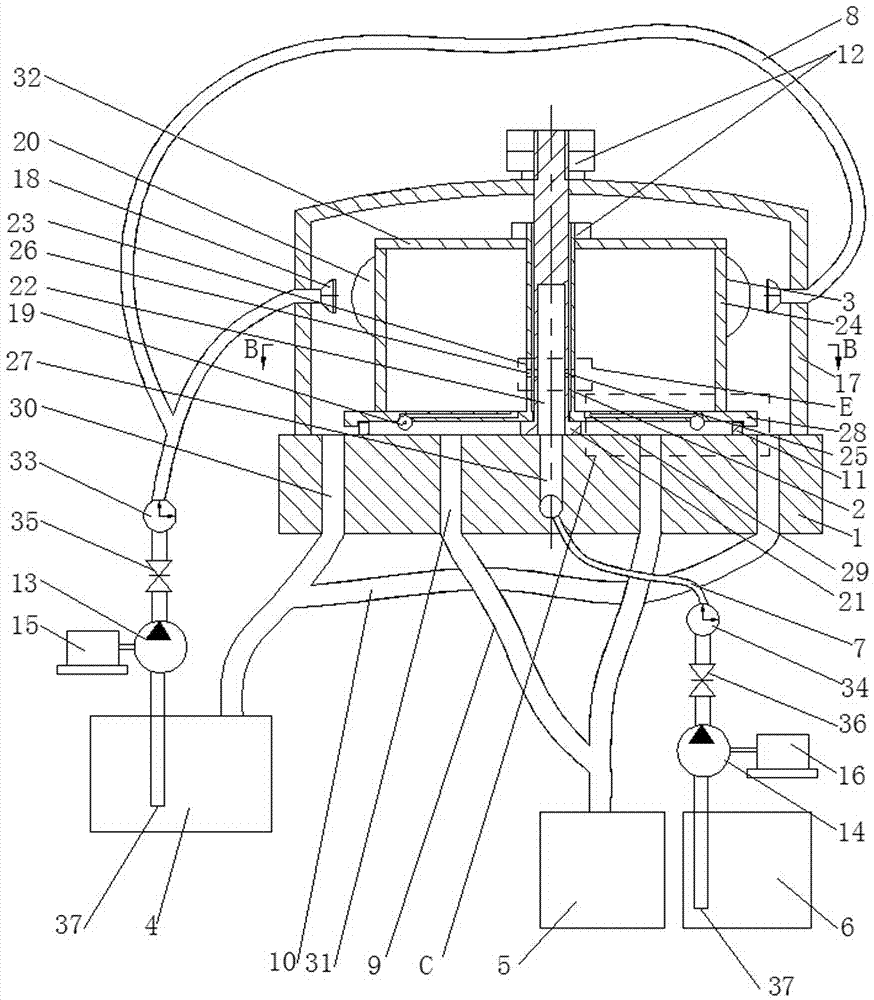

[0019] Specific implementation mode one: as figure 1 , figure 2 and Image 6 As shown, this embodiment discloses a new centrifugal rotor oil filter, which consists of a base 1, a central shaft 2, a rotor 3, a working hydraulic oil tank 4, a cleaned oil tank 5, and an uncleaned oil tank 6. Uncleaned pressure oil pipe 7, cleaned oil return pipe 9, outer cover 17, two rotor nozzles 19, two oil pumps, two motors and at least two lock nuts 12, the two oil pumps They are oil pump one 13 and oil pump two 14 respectively, and the two motors are motor one 15 and motor two 16 respectively; it is characterized in that: the novel centrifugal rotor oil purifier also includes an oil-separating sleeve 11, a high-pressure working hydraulic pressure Oil pipe 8, working hydraulic oil return pipe 10, multiple outer cover nozzles 18 and multiple blades 20;

[0020]One end of the central shaft 2 is provided with a boss 21, the boss 21 of the central shaft 2 is detachably connected to the upper...

specific Embodiment approach 2

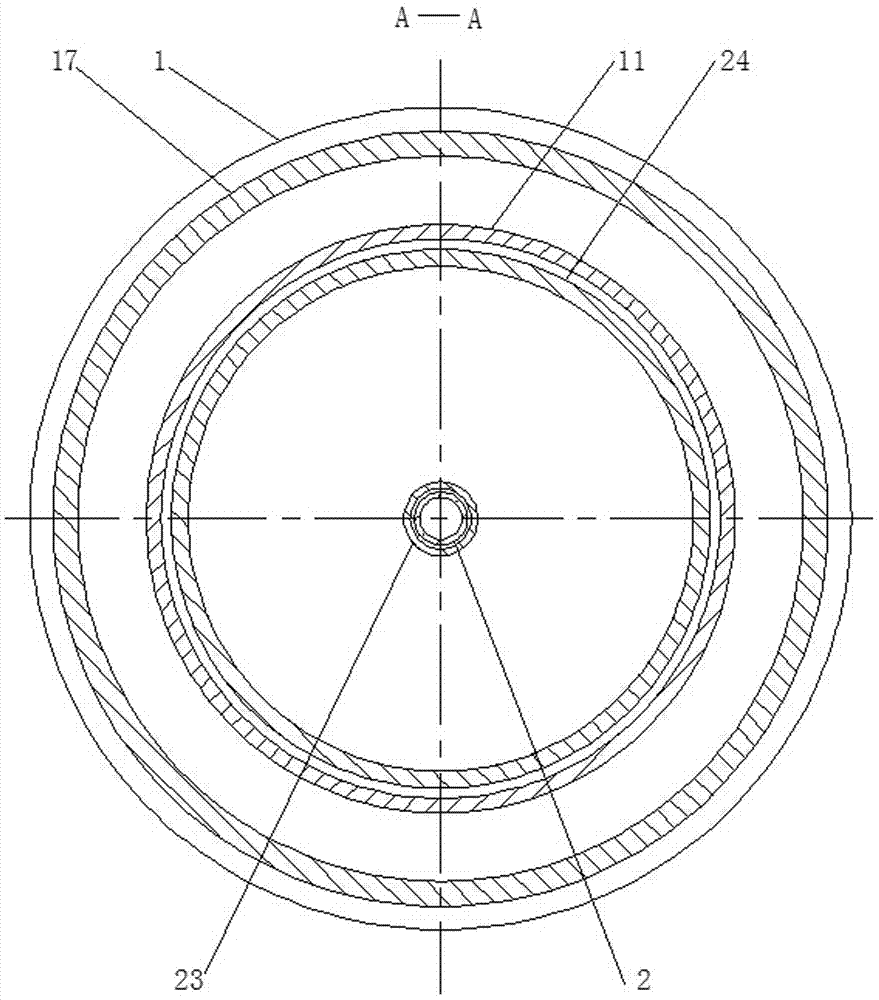

[0021] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of Embodiment 1. The rotor 3 includes a central sleeve 23, a housing 24, a bottom cover 28 and a top cover 32. The lower end of the central sleeve 23 is connected to the bottom The upper surface of the cover 28 is fixedly connected, the middle part of the bottom cover 28 is provided with a shaft hole, and the outer shell 24 is sleeved on the outside of the central sleeve 23, and the lower end of the shell 24 is fixedly connected with the upper surface of the bottom cover 28. 24. The center sleeve 23 and the shaft hole are set coaxially. The top cover 32 is fixed on the upper surface of the shell 24. The middle part of the top cover 32 is provided with a sleeve passing hole. The outer edge of the top cover 32 An outer edge is provided downward, and the upper end of the oil-separating sleeve 11 is arranged inside the outer edge of the top cover 32 .

specific Embodiment approach 3

[0022] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of Embodiment 1. The plurality of blades 20 are evenly arranged along the outer periphery of the top surface of the rotor 3 , and each blade 20 is arranged along the radial direction of the rotor 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com