Spray nozzle

A nozzle and body technology, applied in the field of electroplating, can solve problems such as the inability to update the chemical solution, insufficient copper in the hole, and affect the processing quality of the workpiece, so as to improve the quality of electroplating products and increase the amount of liquid outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

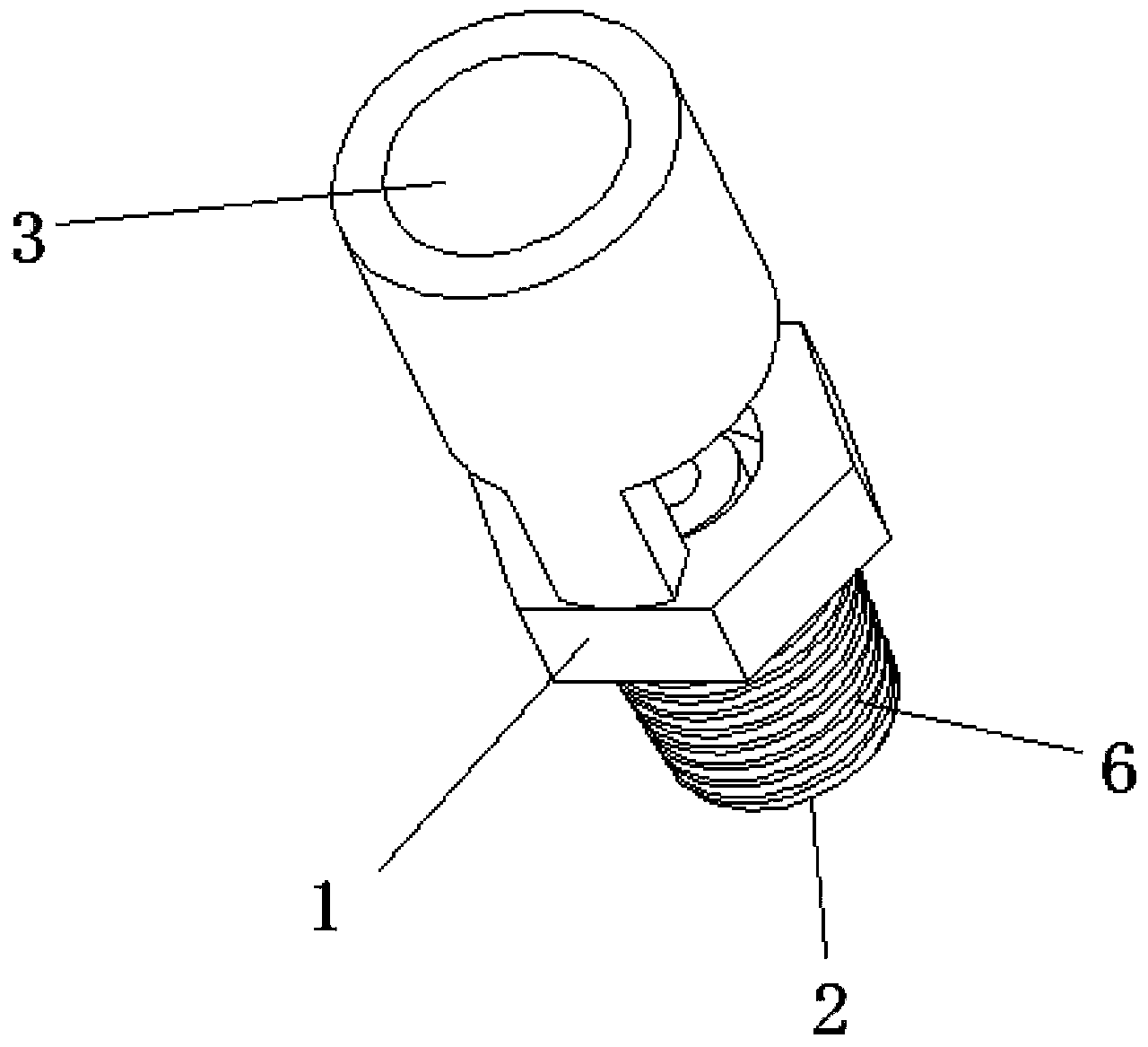

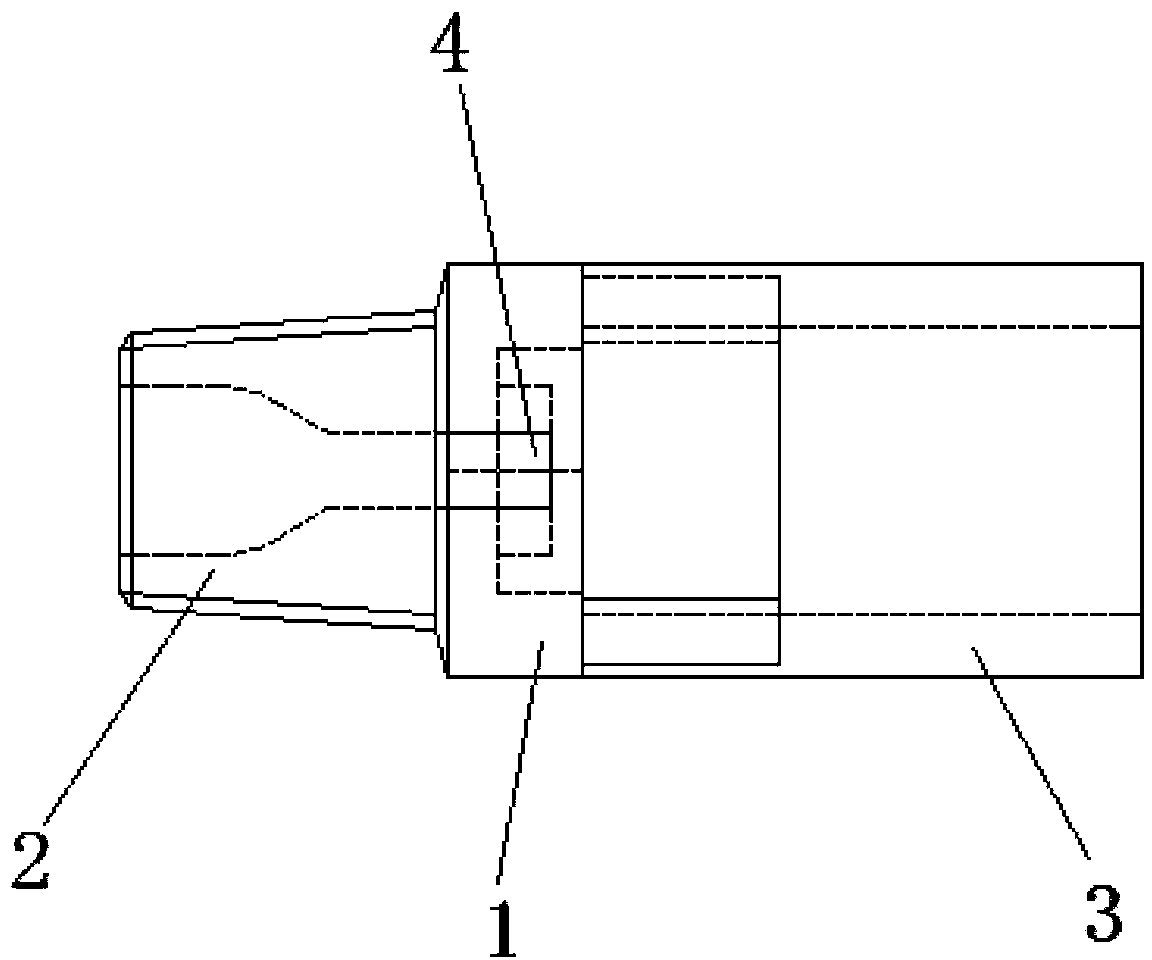

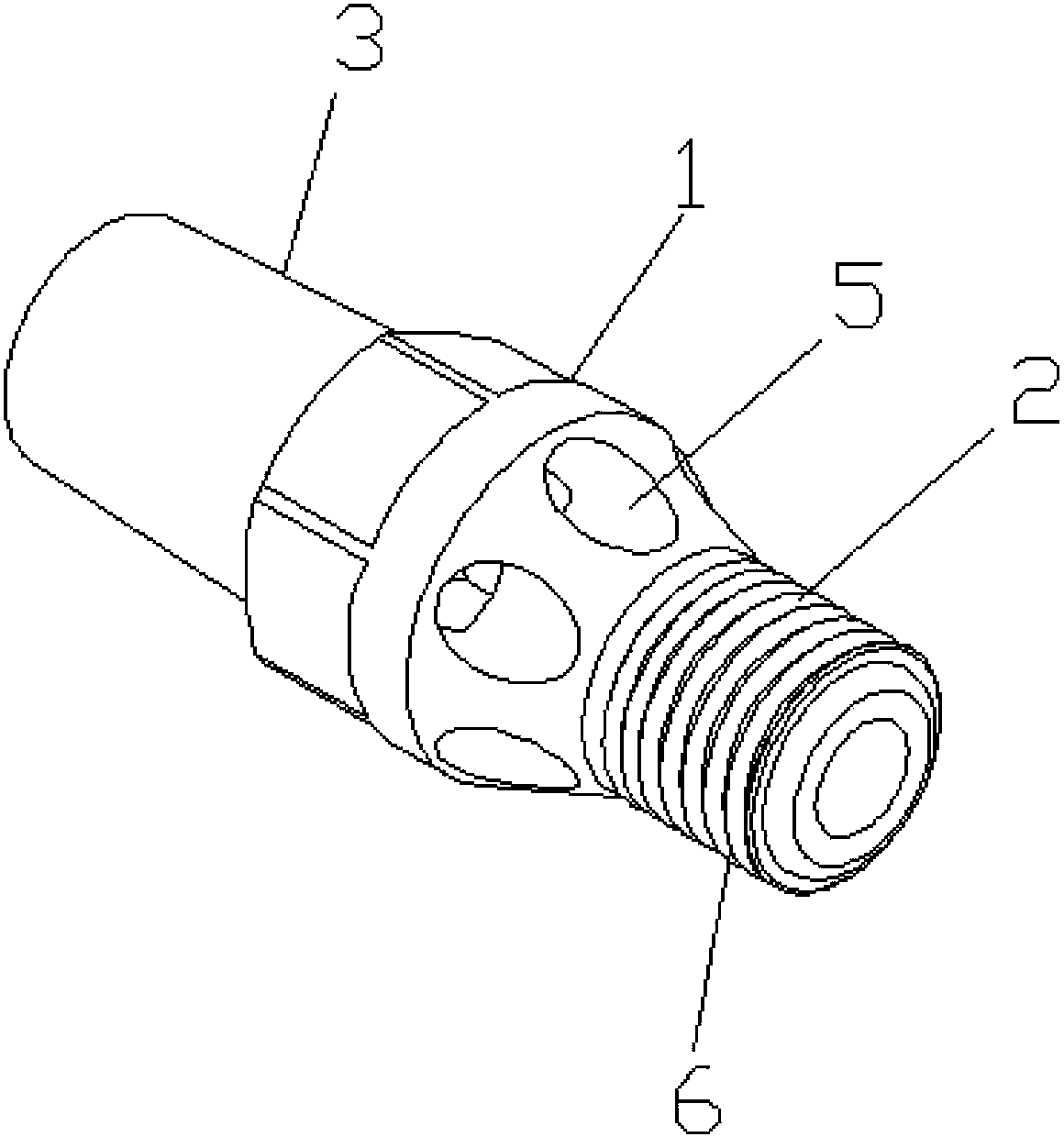

[0021] like image 3 , 4 As shown, a nozzle includes a nozzle body 1, one end of the nozzle body is provided with a liquid inlet port 2, the opposite end of the nozzle body is provided with a liquid outlet port 3, and the inside of the nozzle body is provided with cavities 4 respectively In communication with the liquid outlet port and the liquid inlet port, the outer surface of a part of the nozzle body close to the liquid inlet port is an inclined surface, and the angle between the inclined surface and the axis of the liquid inlet port is an acute angle, and the inclined surface Sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com