Handpiece assembly, air duct system and fan

A component and machine head technology, which is applied in the field of household appliances, can solve the problems of reducing the air volume of the bladeless fan outlet, reducing the wind feeling of the user, and reducing the noise, so as to enhance the wind feeling experience, reduce the noise problem, and reduce the processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

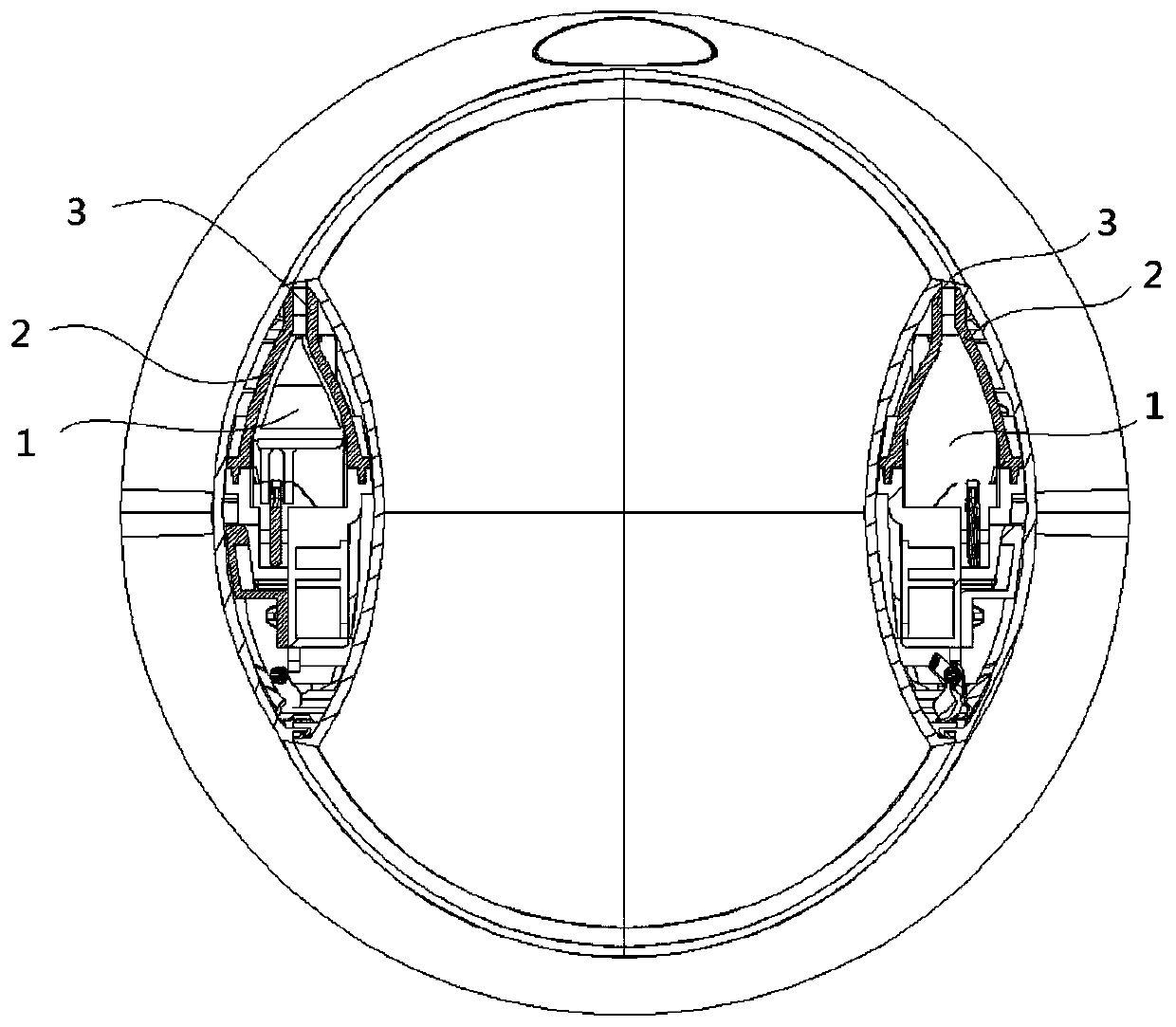

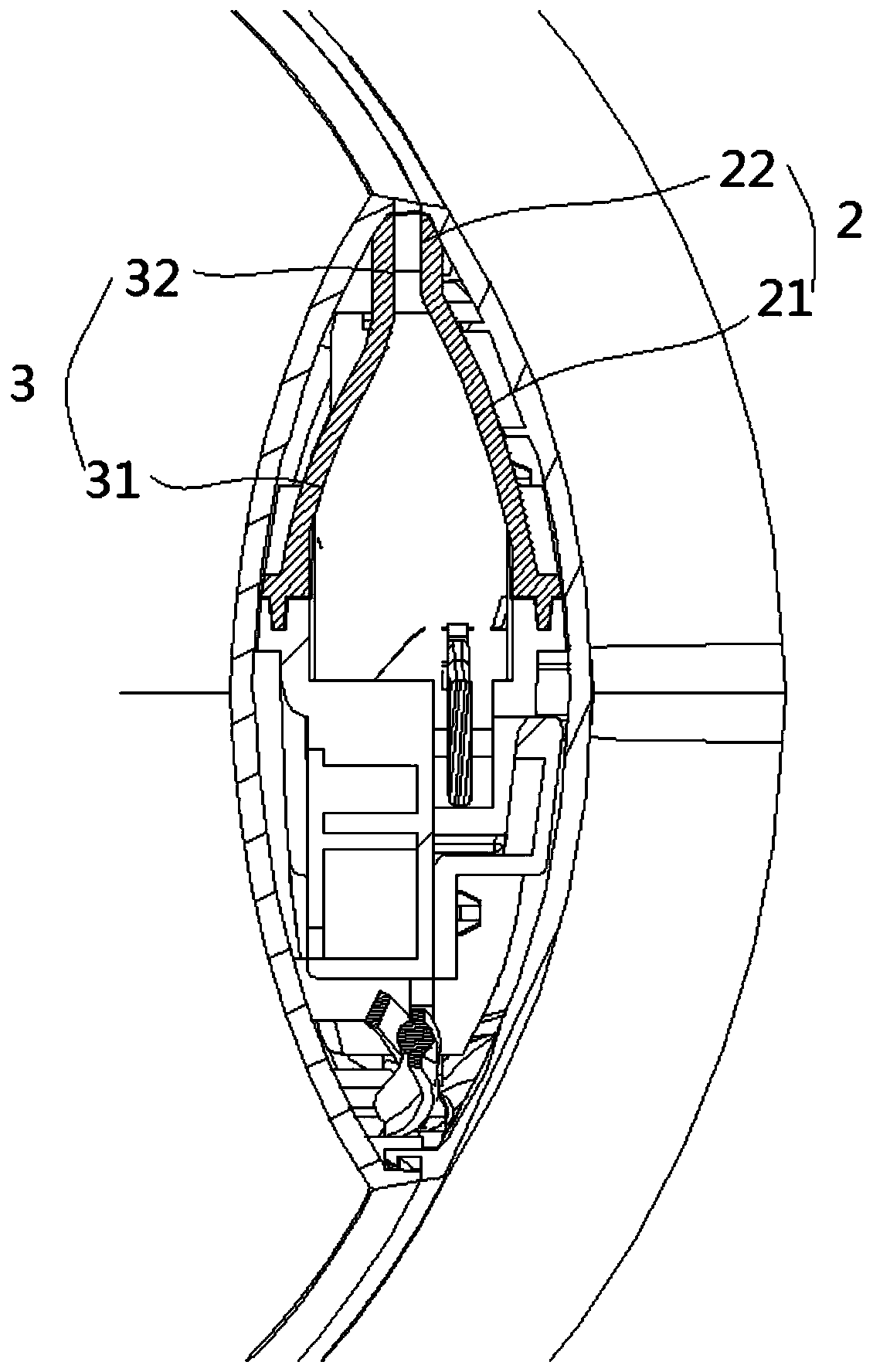

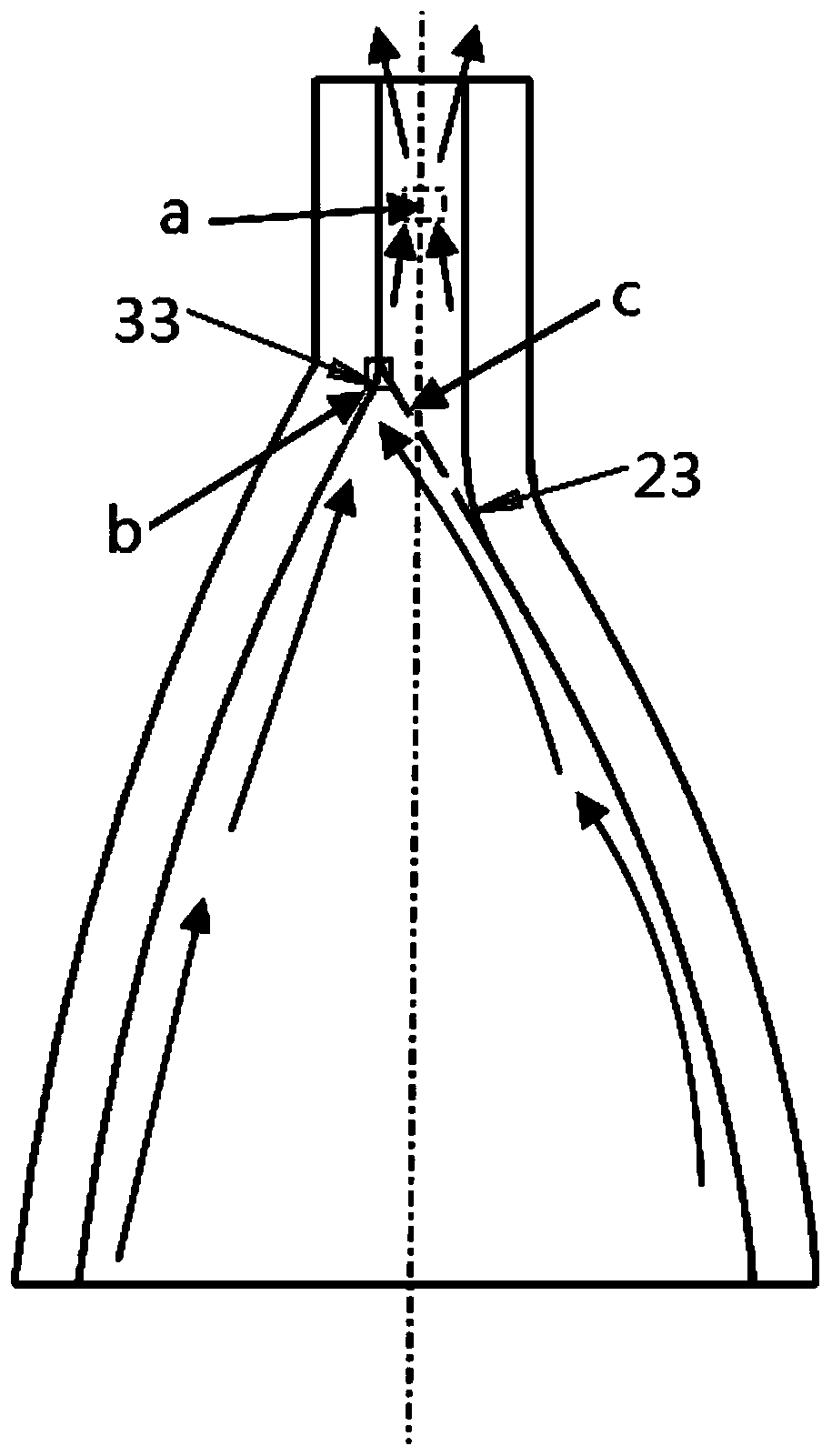

[0058] Figure 1 to Figure 5 As shown, a head assembly provided in this embodiment includes an air outlet duct 1 and an air guide plate, and several air guide plates form a plurality of air outlet parts at intervals between the air outlet duct, and the air outlet parts have mutually oppositely arranged The first wind wall 2 and the second wind wall 3, wherein: the first wind wall 2 includes a first arc-shaped guide surface 21 and a first outlet surface following the first arc-shaped guide surface 21 along the airflow direction 22; the second wind wall 3 includes a second arc-shaped guide surface 31 and a second outlet surface 32 connected to the second arc-shaped guide surface 31 along the airflow direction; the first outlet surface 22 and the second outlet surface A wind outlet gap is formed between the flow surfaces 32, and along the flow direction of the airflow, the extension surface of the first arc-shaped flow guide surface 21 meets the second flow surface 32, and the ex...

Embodiment 2

[0075] Such as Figure 6 to Figure 7 As shown, a kind of air duct system provided for this embodiment includes: the head assembly in the above-mentioned embodiment 1; the air inlet assembly 4 is installed under the power device 5, and the external air flows into the power device 5 through the air inlet assembly 4 Middle; the deflector assembly 6 is covered on the power unit 5, and its air outlet is connected to the air outlet duct 1.

[0076]Specifically, such as Figure 7 As shown in the figure, the air inlet assembly 4 includes: an air inlet wall 41, which is ring-shaped, and several air inlet structures are arranged on it. Enter the air duct system through the air inlet hole. Because the initial air intake direction is basically parallel to the axial direction of the air duct, several deflectors 42 are installed in the middle of the air inlet wall 41. The deflectors 42 are vertically arranged and have a certain air intake gap between them. Plate-shaped structure, the ext...

Embodiment 3

[0080] Such as Figure 8 As shown, it is a fan provided in this embodiment, specifically a bladeless fan, which includes the air duct system in Embodiment 2 above, which specifically includes the air outlet duct 1, the air inlet assembly 4, the power The device 5 and the corresponding flow guide assembly 6 have all the technical advantages thereof, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com